Huge Commercial Heating System Retrofit! https://youtu.be/nLWTEj_qcAE?si=fAArm6-16X_O0bW5 The Hub is on the road in Missoula, Montana for five days to pipe up 1.2M Btu’s of hot water heating for a 45+n unit condo property. The Hub’s Eric Aune joins the Mickelson Plumbing crew for an intense but fun project in this episode of our ‘Hub On Read more

Featured Articles

Huge Commercial Heating System Retrofit!

The Hub is on the road in Missoula, Montana for five days to pipe up 1.2M Btu’s of hot water heating for a 45+n unit condo property.

The Hub’s Eric Aune joins the Mickelson Plumbing crew for an intense but fun project in this episode of our ‘Hub On The Road’ series.

In this video we showcase the reliable MegaPress IPS fitting system. We rely on the RIDGID propress tools and press booster for assembly of the piping connected to the Viessmann Vitocrossal 200 commercial hot water boilers.

Thanks to our partners for making this project possible. It’s with their support we were able to produce this educational video showcasing some world-class plumbing & hvac products and tools.

Please checkout our partners here:

Viega LLC Ridge Tool Company (RIDGID Tools) Viessmann Manufacturing

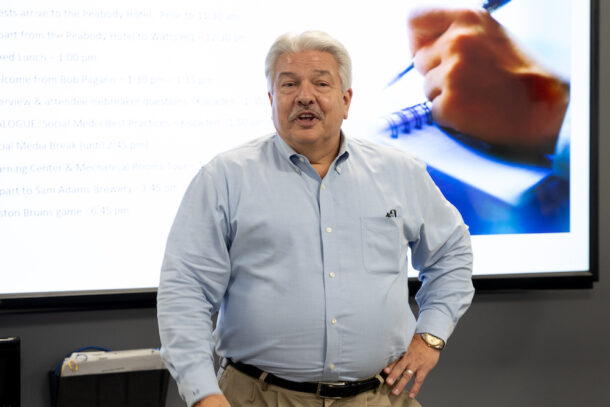

In today’s ever-changing business landscape, strengthening the contractor/wholesaler channel is critical to survival. A recent general session at PHCC CONNECT drilled deep into the conversation. “How does my supplier make me look like a rock star?” asked Dan Callies, President, Oak Creek Plumbing, Inc., Oak Creek, Wis., during the “Collaborative Connections: Strengthening Supplier-Contractor Relationships for Read more

In today’s ever-changing business landscape, strengthening the contractor/wholesaler channel is critical to survival. A recent general session at PHCC CONNECT drilled deep into the conversation.

“How does my supplier make me look like a rock star?” asked Dan Callies, President, Oak Creek Plumbing, Inc., Oak Creek, Wis., during the “Collaborative Connections: Strengthening Supplier-Contractor Relationships for Success” general session at the PHCC Connect show last month in Cleveland. Joining Dan on stage was an all-star cast featuring emcee Robert Grim, Senior Vice President, Global Sales, InSinkErator, Mount Pleasant, Wis.; Scott Robertson, President, Robertson Heating Supply Co., Alliance, Ohio; Kathryn Poehling-Seymour, President and CEO, First Supply LLC, Madison, Wis.; and Jason Pritchard, Co-Founder, PriCor Technologies, Seattle.

From l to r: Robert Grim, Senior Vice President, Global Sales, InSinkErator, Mount Pleasant, Wis.; Scott Robertson, President, Robertson Heating Supply Co., Alliance, Ohio; Kathryn Poehling-Seymour, President and CEO, First Supply LLC, Madison, Wis.; and Jason Pritchard, Co-Founder, PriCor Technologies, Seattle.

That’s the million-dollar question, right? How does the supplier/contractor relationship make each other better at his/her jobs, and contribute to the overall company mission? Throw in the manufacturer here too, for that matter. Some of the fundamental tenets for strengthening that relationship—that were discussed at the general session—included collaboration, value distribution services, availability, technology and training, and expectations.

Can’t We Just Get Along?

InSinkErator’s Grim asked about the value of working together, and Poehling-Seymour stressed that collaboration is critical in this relationship. “We must understand the pain points and what is working and what isn’t.”

And with that comes better communication. “We are in a relationship industry where communication is imperative,” said Pritchard. If that means paying a bit more for that stronger relationship, then so be it, intimated Pritchard.

Callies echoed this but stressed right communication over more communication. The common thought is “wide equals pricing and deep equals relationships,” said Callies.

So, let’s go deep as an industry. When asked what the landscape is going to look like in five-to-10 years for the contractor/wholesaler/manufacturer, people, processes and services matter. Through trust and preferences, “Relationships are going to matter more,” said Pritchard.

What about expectations? “We want to be around for another 10-20 years,” said Robertson. “We want to see contractor loyalty in the channel,” continued Robertson. “And that means a loyalty to the wholesaler in your particular market.”

Stock Market

Let’s not avoid the 800-lb. gorilla in the room. With contractor loyalty, comes availability and pricing. For Robertson, inventory presence is critical so much so that Robertson Supply holds inventory for approximately 100-125 days. “Listen, we don’t make or install anything so we better be damn good at inventory management,” said Robertson.

Value distribution services ties right in here, “It’s about right product, right time, right price,” said Poehling-Seymour. “Be that added value family.”

Tech Relevant

It’s imperative for these brick-and-mortar supply houses to stay on top of the latest trends and technology. “The key to survival is to stay progressive and current,” said Robertson. Upon further self-reflection, “how do we make it easier to find product?” asked Robertson. “This includes being totally integrated with our contractor partners and researching and developing a technology that contractors will use.”

Poehling-Seymour added that First Supply LLC institutes “customer councils” to continuously get a pulse of the customer. “We try to make sense of the noise,” said Poehling- Seymour. “Where is critical mass in that noise so we can make the right decisions?”

Poehling-Seymour added that First Supply LLC institutes “customer councils” to continuously get a pulse of the customer. “We try to make sense of the noise,” said Poehling- Seymour. “Where is critical mass in that noise so we can make the right decisions?”

Unless you’ve been riding under a technology rock, Artificial Intelligence (AI) has dominated the talk in most every corner of the tech universe, and it has crept into the PHVAC industry as well. While artificial intelligence, in and of itself, can sound scary and intimidating, according to Poehling-Seymour, “AI has real application in the industry purchasing and predictability.”

For suppliers, it’s imperative to keep all “moving-forward” options available, as Robertson suggests. This includes, and nothing new and earth shattering in our industry, maximizing e-commerce when necessary. “E-commerce presents the right tools at your fingertips,” said Poehling-Seymour. Robertson adds that for his company, online ordering represents 20% volume. Other tech advancements, which included the use of QR codes to streamline processes and online training, were mentioned.

Training Room

InSinkErator’s Grim offered that in today’s business landscape, there is more need for training.

In fact, says Grim, PHCC members ask for training and education now more than ever. “With evolution and advancement comes training and education,” said Callies. Doubling down on this, Poehling-Seymour stated that First Supply opened a training center and offers a variety of training through streaming content.

Callies suggests that people still are the cogs in the wheel that makes this industry run, “Digital when you can, verbal when you must.” Pritchard and Poehler-Seymour agree, saying that people and the process are key through direct communication, and that includes all members of the channel—contractors, manufacturers, all the way down to the inside and outside sales, drivers, dispatchers, etc. within each organization.

So, let’s go back to the original question: How do we all make each other look like rock stars? Consuming all of the above, and, quite simply, “look for successes and build on them,” said Callies.

This article originally ran in PHCC’s Solutions magazine. You can learn more about the Plumbing-Heating-Cooling-Contractors (PHCC) Association at www.phccweb.org.

When he is not performing wildcats on his snowboard or running ollies on his skateboard, Nick Parlet @plumbingsk8r keeps busy with his residential service plumbing company, Tidy Pipes Plumbing, Webster, N.Y. As a third-generation union plumber, Parlet’s dad and his grandfather encouraged him to join and learn the trade, so at the age of 22 Read more

When he is not performing wildcats on his snowboard or running ollies on his skateboard, Nick Parlet @plumbingsk8r keeps busy with his residential service plumbing company, Tidy Pipes Plumbing, Webster, N.Y.

As a third-generation union plumber, Parlet’s dad and his grandfather encouraged him to join and learn the trade, so at the age of 22, Nick joined the local plumbing union. Nick began doing two years of pre-apprentice work and then started his five-year apprenticeship. After five years of schooling, Nick became a journeyman and worked commercial new build construction. Parlet eventually ended up working in the commercial plumbing service, and after doing that for many years—as well as doing side jobs for family and friends—he decided to open his own residential plumbing company, Tidy Pipes Plumbing.

“To be honest, I didn’t know if there was ever a time that I was certain about going on my own; however, with growing on social media with Plumbingsk8r and meeting a ton of great people in the industry, it was clear that there was more money to be made owning your own. My wife and I—spur of the moment—bought a truck on a random Tuesday, and the rest was history,” says Parlet.

“To be honest, I didn’t know if there was ever a time that I was certain about going on my own; however, with growing on social media with Plumbingsk8r and meeting a ton of great people in the industry, it was clear that there was more money to be made owning your own. My wife and I—spur of the moment—bought a truck on a random Tuesday, and the rest was history,” says Parlet.

Being on his own with the new company came a new wave of excitement knowing that each call Parlet received would grow his business further. “Interacting with my own customers was really exciting; I felt a greater sense of accomplishment and purpose for each job that I went to,” says Parlet.

Joining the union proved beneficial for Parlet. “There are many benefits as a union member, especially for those going into the trades young. They offer coverage for health and dental insurance, as well as retirement options and pension plans. There is also the perk of having your education and schooling provided for you if you go through the full apprenticeship program. It’s just nice knowing there is a group of people keeping your best interest in mind when you are first coming into the trade,” says Parlet.

For those interested in getting started in the trades, “Go for it!” says Parlet. “Consider the benefits for your future and remember that the trades pay. It is knowledge that will never go out of style. Tradesmen will always be import in the future and AI can’t take your job.”

So how does this translate to how we as an industry getting more people interested in the trades? “If there was more focus on the money to be made, I think there would be a lot more interest. There are always jokes about plumbers, and they have this stigma surrounding them that they are low paying job, but in reality you can make the same amount and in many cases more than someone who is 3-5 years out of college,” says Parlet.

The Balance

Believing in the notion that stress is a killer, Parlet is trying to stay level headed about keeping the right work life balance. First and foremost, Nick loves spending time with his wife and kids, and he knows full well that he does not want to shave a few years off his short time on earth just to make a few extra bucks. “Starting my company has been very challenging for balancing everything because I want to please all of my customers, and that sometimes means working late and working weekends, but I am confident that this is just part of the start-up process,” says Parlet.

Social Connections

As time went on, the confidence grew. And, once Nick started growing on social media and was asked to be part of the Oatey ambassador program, he says he met so many great people, good friends to this day that all became mentors.

Nick (r) with Evan Berns at Oatey

“My buddy Thomas Young, aka TYCustoms, Nick from Cheddars Plumbing Co, Jake from MotherFlushers, and Roger Wakefield all instilled a lot of confidence in me and really made me realize that I was capable of owning my own company as well. I hope to be a role model in showing the younger generation that there are other options besides college and that the trades are always growing and need workers,” says Parlet.

“Huge shout out to everyone at Oatey, by the way! Amanda, Alyssa, Katherine, and Tyler, you guys are awesome! They have really helped to push me further into the spotlight of the plumbing social media community and for that I am very thankful. Because of Oatey I was able to meet some of my best friends today.”

Speaking on the importance of social media, “About a year and a half ago, my good friend Brian was constantly sending me TikTok plumbing videos through text messages,” recalls Parlet. “After a few times of clicking the links, I was locked out of watching the TikTok videos unless I downloaded the app. So, I downloaded the app and without putting any thought into the name so I created @plumbingsk8r.

The Hub’s Tim Ward (l) and John Mesenbrink (r) share a laugh at the RIDGID afterparty during PHCC Connect in Cleveland.

“At that time, I was really only posting on my personal Instagram page. One day I was bored, I posted what I did at work to my Instagram story. I was shocked at the response I got from my friends that were not in the trades. My friends were actually interested in what I did for a living and would often ask me for help with their own plumbing issues. I started putting a little more though into filming my plumbing videos and edits. One night, Brian told me I should post one of my videos to the TikTok and I was a little hesitant at first but I eventually did. The next morning, I woke up at my video had 75,000 views. I was shocked. I posted another one and it didn’t do so good. I posted one more and that one took off as well.

“Every day, I would post what I did at work and I started to gain a little following. I reached out to other plumbing content creators and ended up building some good friendships. We would talk a lot about content creating but also about being a business owner. A lot of them sparked the idea of opening my own company at that time. I enjoy everything about plumbing, including meeting other people who are more knowledgeable about the trade than me. Social media has become a tool I’ve been able to use to learn more than I ever thought I could about the plumbing and the business side of things.

“There have been so many times I’m on a job and think to myself. ‘I bet TY would know the answer to why this is doing that.’ So, I call up my buddy that lives on the other side of the country and sure enough he knows exactly what I’m talking about.

“As for the time I put into my videos today, I try to post at least once a day. I try to film jobs that at different such as pouring a lead joint because you do see that very often. The filming process does not take much extra time but the editing and cross posting process can take anywhere from 30 mins to five hours per video. If I don’t feel creatively motivated, I will not edit or post that day. In a sense, social media has become a 2nd job for me but it’s a job that I can do when I feel like it so there is no pressure. I’m just having fun with it and meeting as many people as I can,” says Parlet.

“As for the time I put into my videos today, I try to post at least once a day. I try to film jobs that at different such as pouring a lead joint because you do see that very often. The filming process does not take much extra time but the editing and cross posting process can take anywhere from 30 mins to five hours per video. If I don’t feel creatively motivated, I will not edit or post that day. In a sense, social media has become a 2nd job for me but it’s a job that I can do when I feel like it so there is no pressure. I’m just having fun with it and meeting as many people as I can,” says Parlet.

In conclusion, when Nick started his plumbing career in commercial new construction, he felt as if he was not challenged enough. “I learned a lot about installation but not as much about what I was actually installing. In order to be a good service plumber, you need to know how everything works in order to properly diagnose and fix the problem. “Every service call that I go on has its own challenges and when I find the solution to the problem, fix the issue and put a smile on my customers face, that is the rewarding part.”

Oh, and that name @plumbngsk8r? “I have been skateboarding since I was 10 years old and I still really enjoy skating and filming with my friends,” says Parlet.

You’ll see Nick if you attend the 2024 WWETT Show, KBIS in Vegas, “and I was recently picked to attend the RIDGID Experience, which I am extremely excited about, and I’m hoping to get to the ‘holy grail’ of power tools event, the Milwaukee Pipeline.

Trusted Tools

What I keep on me at all times

• Utility knife

• 6-in. 1 screw driver

• High quality pocket flashlight

• Milwaukee marks all marker

Always in the bag hand tools

•Channel Locks / Knipex Plier wrench

• Needle nose Cresent Wrench (Ferguson brand – Raptor)

• 16 ft. tape

Power tools I use almost daily

• Milwaukee auto cutter

• RIDGID Snake (preferably a K-50)

• RIDGID Press tool (RP-115)

This past October, a select group of social media influencers that represent small or mid-sized, light commercial plumbing contractors attended a Watts two-day “Social Media Summit” at the company’s North Andover, Mass. and Franklin, N.H. locations. Guests included Mechanical Hub’s very own Eric Aune @mechanicalhub; Paige Knowles @plumber_paige; Travis Abaire @t.a.p.plumbingandheating; Matt Fleming @allstarplumbinginc; Evan Read more

This past October, a select group of social media influencers that represent small or mid-sized, light commercial plumbing contractors attended a Watts two-day “Social Media Summit” at the company’s North Andover, Mass. and Franklin, N.H. locations. Guests included Mechanical Hub’s very own Eric Aune @mechanicalhub; Paige Knowles @plumber_paige; Travis Abaire @t.a.p.plumbingandheating; Matt Fleming @allstarplumbinginc; Evan Berns; and Chris Sbrocco @chris_sbrocco.

The Watts and social media crew

The purpose of the summit was to develop Watts’ own “rolodex” of online influencers who could help build Watts product excitement and awareness. Hosting a social media influencer summit provided the potential to deepen Watts’ social media influencer connections, assist in digital marketing, and gain contractor-level voice of customer. “Watts welcomed the group plumbers to discuss how social media can play a role in learning and collaborating within the plumbing and piping industry,” said Aune.

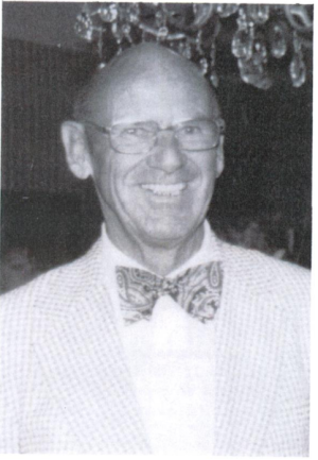

Guests were initially greeted to a hearty welcome from Watts CEO, President, and Chairperson of the Board, Bob Pagano. “We were greeted warmly by members of the Watts social media and marketing team, and heard a message from CEO Pagano about his vision for what’s coming next at Watts,” said Berns.

Watts CEO Bob Pagano

Following the opening remarks from Pagano, by an open dialogue on influencer benefits was held hosted by Ryan Kiscaden, Manager, Sales Enablement, with a quick breakdown of the Watts family of products from Shashwat Nath of the Watts Product Team. “After touring their state-of-the-art facility, we were able to ask questions and get our hands on products in their training room,” said Berns.

Abaire continued, “I’ve always liked the products that Watts put out, but to see firsthand the level of care, precision, and pride that actually goes into making their products gave me a whole new level of respect and trust in the Watts brand.”

Director of Training, Greg Gyorda, gives the group a tour of a working Watts mechanical room.

In the afternoon of that first day, the group toured the mechanical rooms and learning center and met with Greg Gyorda, Director of Training, and members of the Watts training team, including Kari Stocks, Training Campaign Manager. “Watts has built a world-class training facility at their headquarters where hands-on technical training is a main focus,” said Aune.

The gang at the Sam Adams brewery

Moreover, “I was impressed with the training facility, as I didn’t realize how many brands are under the Watts umbrella. They had a bit of everything at the training facility to check out and with which to get hands-on,” said Fleming.

Day one concluded with some authentic Boston flavor. “The Watts team showed us some of what Boston has to offer with a tour of Sam Adams brewery and a Boston Bruins game,” said Berns.

On the second day, the group took a one-hour trip to Watts’ Franklin Manufacturing Facility in Franklin, N.H. This facility is a center of excellence in manufacturing Watts’ specialty products that require some level of fabrication. This includes Watts-branded plumbing flow control products. The products that are manufactured at this state-of-the-art, lean facility are used worldwide in various residential and commercial applications. “We were able to tour their incredible manufacturing facilities, and got a look at the many steps that the Watts products go through before we see them on the shelf. It was great to see some of the smiling faces behind the products that we all know and love,” said Berns.

The Hub’s Eric Aune talks with Franklin Manufacturing Facility tour guide Pete Bertagna.

Tour guide Pete Bertagna captivated the group with some of the foundry’s processes, including how the world-renowned backflow preventers are made. “The Franklin factory tour gave us the opportunity to assemble our own backflow preventer from the parts manufactured on site; it was so cool to see the whole process from start to finish,” said Aune.

Fleming assembles his very own backflow preventer.

Fleming concurred, “The factory was also cool seeing all the backflow preventers that I’ve installed for years actually come to life.”

There is a need to continue to simplify plumbing systems and experiences over time. Online social media influencers are a “cog in the wheel” to positively influence the next generation and change perceptions. The Social Media Summit and those content creators that participated are cogs on the Watts messaging wheel. There is a growing need for training programs and education and Watts is taking training very seriously and believe it is key to its success.

The social media crew from l to r: Chris Sbrocco, Eric Aune, Matt Fleming, Travis Abaire, Paige Knowles, and Evan Berns

Overall impressions from the Social Media Summit:

- Eric Aune @mechanicalhub:

“Watts has been present in the industry for decades longer than my 25-year plumbing and heating career. Connecting with people who make, design and distribute the products was a special experience of which I’m thankful to have taken part.”

- Matt Fleming @ allstarplumbinginc:

“At the end of the day, it was great to get to hang out with all my plumbing peers from across the country. I definitely value the friendships I’ve made through social media, and I always look for to an opportunity to hang with everyone.”

- Evan Berns @re.plumb

“The trip was a great opportunity to connect with some of the plumbing and heating industries leading professionals. Overall, it was a great event for Watts to get more involved with the online community and develop their social media presence.”

- Travis Abaire @t.a.p.plumbingandheating

“It was really a great and educational experience, and I’m thrilled I was asked to be a part of it.”

- Paige Knowles @plumber_paige

“I learned a lot about their environment and training opportunities. Seeing how backflow preventers were made, and being able to make one, was awesome!”

Geothermal heating and cooling is a well-established technology; it’s been around in simplistic forms for more than half a century and has developed at an impressive rate to become a technology that is providing real solutions for decarbonization and grid management. In its years of growth and innovative development, geothermal has taken on many different Read more

Geothermal heating and cooling is a well-established technology; it’s been around in simplistic forms for more than half a century and has developed at an impressive rate to become a technology that is providing real solutions for decarbonization and grid management. In its years of growth and innovative development, geothermal has taken on many different forms and variations, all of which have their own unique benefits.

The Vanderbilt Breakers Mansion saves $36,000 a year with Direct Geothermal Exchange.

The first recorded closed-loop geothermal design installed was a water-free direct exchange geothermal system in 1945. Robert C. Webber (1911-1984) is acknowledged by most to be the inventor of the ground-coupled heat pump system. In fact, according to a September 1948 issue of “The Refrigeration Industry,” Webber was the first to heat his seven-room home in Indianapolis by reversing the cycle on his home freezer. The issue featured Webber as The Refrigeration Industry’s “Man of the Month.” Webber’s “freezer in reverse” was also featured in Ripley’s Believe it or Not in 1948.

Caption: Robert C. Webber (1911-1984)

Direct geothermal exchange (DGX) waterless geothermal systems, also known as direct exchange systems, offer an innovative and sustainable way to heat and cool your home without requiring water in the loop for heat exchange. Unlike many other types of systems, DX uses a closed-loop refrigerant circuit to release heat from under our feet, eliminating the need for water that other systems require. One of the most vital benefits of Direct Exchange Waterless Geothermal is how efficiently it produces year-round temperature control using safe, reliable refrigerants.

There are many pioneers within the sustainable and renewable energy field, one of which is Bill Buschur, President of Total Green Manufacturing. Bill is a recognizable figure within the geothermal industry, and within the niche of waterless geothermal, with a history in the development of the technology used today. For reference, back in 1980, EarthLinked Technologies (ETI) established itself as a research company in the geothermal industry, becoming the original direct exchange manufacturer. It continued to have great success over the years as it carved out a niche in the geothermal industry. ETI partnered with Total Green Mfg. for five years, and Total Green acquired the 38-year-old DGX Manufacturing company.

Total Green Crew installs a DGX system.

A little history

“At around 12 years old, I began to ride along with my father in the service truck and I would run back and forth from the truck to get him tools or the parts he needed to make the repairs,” Buschur shared with us, “As I got a little older, I began building geo ground loops. I remember we had two football practices a day, and I would come home and build loops for the rest of the day. Eventually, I began to go to the job site with other crew members and help with the installation process.”

Young Bill Buschur working on site.

One of the keys to innovation is passion, and Bill Buschur has no issue with showing his passion through actions and incredible results. Bill has grown his business from a hard-working crew of only four people to becoming the largest direct exchange geothermal contracting company in the U.S., installing over 100 DX systems on a yearly basis.

Establishing the Waterless® brand was no small feat for Bill, but after earning a degree in Business Management and a refrigeration certification, topped off by 30 years of experience in geothermal heat pump technology, he’s become the driving force behind the biggest name in Direct Geothermal Exchange nationwide.

Quality is vital in any field, but Bill has ensured that his geothermal direct exchange units are to the highest standard, stating, “Dad always taught us that ‘If you don’t do things right the first time, you’ll end up doing it again’”. So we made sure we didn’t cut any corners when it came to Designing and Installing a geothermal system.”. This has been a key factor in how effectively Total Green has kept up with the latest technology.

At the end of the day, the million-dollar question is, “Are direct exchange waterless geothermal systems as efficient as water-based geothermal systems?” The answer is yes. Past criticisms of DX systems have primarily revolved around the question of environmentally friendly refrigerants. Today modern DX systems use advanced refrigerants that are both environmentally friendly and efficient with heat transfer, which will enhance the performance of the system altogether.

Bill Buschur in his younger years learning the trade (right).

We’re fortunate to have so many diverse options when considering which geothermal system to choose from, accompanied by so many industry pioneers behind each system. As we continue to push for the world to embrace and prioritize sustainability and energy efficiency, minimizing negative environmental impact and using the natural resources given to us, we should make a conscious effort to do so as one piece of that ever-forming puzzle. Any and every geothermal system contributes to a brighter, greener, world-changing future for us and generations to come.

We are on the same team, we are in the same boat, and we are a part of the geothermal heat pump revolution, changing the world for the better.

Mimi (Hannah) Egg is a Social Media Marketing Consultant with a passion for writing and researching. She has overseen the social media accounts for multiple private and corporate organizations and is constantly learning new ways to understand and optimize demographic outreach and form beneficial business connections through social networking for her clients. She can be reached at Mimieggshell@gmail.com

Mimi (Hannah) Egg is a Social Media Marketing Consultant with a passion for writing and researching. She has overseen the social media accounts for multiple private and corporate organizations and is constantly learning new ways to understand and optimize demographic outreach and form beneficial business connections through social networking for her clients. She can be reached at Mimieggshell@gmail.com