By Dave Dunbar, Retired – National Sales Manager at General Pipe Cleaners Recently, we have posted a series of blogs with the title ‘How Not to Break Your Stuff, where we shared best practices from contractors who excel at keeping their drain cleaning machines operational and profitable. After looking at some of the feedback that Read more

General Pipe Cleaners

By Dave Dunbar, Retired – National Sales Manager at General Pipe Cleaners

Recently, we have posted a series of blogs with the title ‘How Not to Break Your Stuff, where we shared best practices from contractors who excel at keeping their drain cleaning machines operational and profitable. After looking at some of the feedback that we got from that series, we decided to write this ‘tongue in cheek’ guide to breaking your equipment as fast as possible. This article is designed for plumbers and drain cleaners who want to destroy as many machines, cables, push rods and accessories as possible, and will be invaluable to contractors who need to show a huge annual loss for tax purposes, or who have more money than they know what to do with. All others are advised to do the exact opposite of these top five suggestions!

- Simply toss your drain cleaning machines and snakes into the back of your truck as soon as the job is over with no cleaning or lubrication, and don’t give them a second thought until the next drain cleaning job. Ride them hard and put them away wet! And whatever else you do, never put Snake Oil or any other lubricant on the cables! I’m sure that cable will look as good as new the next time you go to use it!

- Pretend that your drain cleaning cable is a battering ram and force it down the drain as hard as you can! Or, better yet, if you have a power feed on your machine, just shove the feed control lever into forward, step on the foot pedal, and then check your social media for a few minutes. No problems!

- Never use a starting tool…just put your biggest, baddest cutter on the end of your cable, ram the snake down the drain and hope for the best. After all, size matters in this line of work, and it’s important to show the clog who’s boss!

- Never use anti-freeze in your pump during the winter months. It takes way too much time, and after all, time is money! If you drive really-really fast to and from the job site and only do the bare minimum when cleaning the line, you can have that high pressure water jetter back in your heated garage before the pump head has a chance to freeze. Absolutely probably!

- Why use a thirty-dollar cutting tool to clear an obstruction in a pipe when you could use a three-thousand-dollar camera head? After all, the camera head is right there in the pipe, and that hunk of concrete that you’re looking at probably only needs a little nudge to push it out of the way. Besides, it’s just a video camera that you’re shoving down a clogged sewer, what could possibly go wrong?

Based on nearly a century of experience, we’re pretty sure that all these suggestions will have the intended effect of destroying your stuff as quickly as possible. Try doing the exact opposite and see what happens! For more information, call the Drain Brains at 800-245-6200, or visit drainbrain.com.

Prevent basement flooding and messy floors with the Flood-Guard™ from General Pipe Cleaners. Heavy rains, snow melt, and ice jams from rough winters and warm springs can cause seasonal structure flooding. So can year-round precipitation and runoff in urban districts, coastal regions, flood plains, shorelines, and areas adjacent to rivers, lakes, and lagoons. Flood-Guard helps Read more

Prevent basement flooding and messy floors with the Flood-Guard™ from General Pipe Cleaners.

Heavy rains, snow melt, and ice jams from rough winters and warm springs can cause seasonal structure flooding. So can year-round precipitation and runoff in urban districts, coastal regions, flood plains, shorelines, and areas adjacent to rivers, lakes, and lagoons.

Flood-Guard helps protect property in all those flood-prone locations.

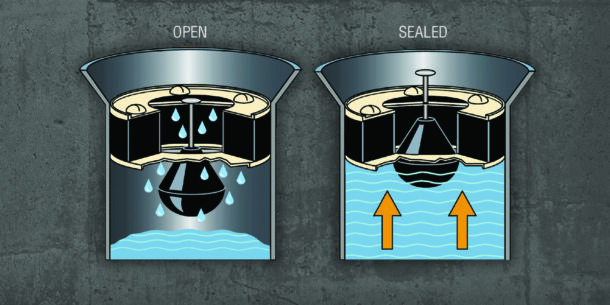

Available for 2”, 3”, and 4” floor drains, Flood-Guard operates like a check valve to seal off water back-up caused by overloaded sewers. Water flows normally through the drain until the sewer begins to back up. The Flood-Guard float then rises to seal off the drain opening until water recedes.

A screwdriver and a couple minutes are all you need to install Flood-Guard. Once in place, it can prevent property damage – and ugly clean up jobs! Flood-Guard is also available in a stand pipe model for handling extreme, extended pressure.

For details, contact the Drain Brains® at General Pipe Cleaners at 800-245-6200 or 412-771-6300, or visit https://drainbrain.com/Flood-Guard.

Year-after-year, top plumbing and drain cleaning pros make the Super-Vee® from General Pipe Cleaners their “go-to” machine for small line stoppages! The Super-Vee easily unclogs sink and small lines up to 3” in diameter. It’s so rugged that many last for 10, 20, or even 30 years. It’s that reliable! FEATURES: For sinks, tubs and Read more

Year-after-year, top plumbing and drain cleaning pros make the Super-Vee® from General Pipe Cleaners their “go-to” machine for small line stoppages! The Super-Vee easily unclogs sink and small lines up to 3” in diameter. It’s so rugged that many last for 10, 20, or even 30 years. It’s that reliable!

FEATURES:

- For sinks, tubs and laundry drains

- Slide-Action™ chuck built into grip shield

- Automatically adjusts to different cable diameters

- Quick-change cartridge makes switching cables clean and easy

- Unique Dyna-Thrust™ bearing system for longer tool life.

- Band-It™ splashguard minimizes excess water spray from the spinning drum.

- Holds 50 ft. of 1/4″ or 5/16″, or 35 ft. of 3/8″ Flexicore® cable.

- Flexicore wire rope center cables have unequalled strength yet the right amount of flexibility.

- Made in U.S.A.

The Super-Vee is built to clear clogged drains for a decade or more. And our Dyna-Thrust™ bearing system is one reason why. It helps carry the weight of the drum, significantly reducing wear on the motor shaft bearing and extending the life of the tool. Of course, the drain cables are Flexicore® – with an integral wire rope center. Nobody makes cables like General.

By Dave Dunbar, Retired – National Sales Manager at General Pipe Cleaners Roots are your sewer pipes’ worst nightmare! Tree roots are constantly in a state of hunger and thirst, searching relentlessly for water and nutrients. Both are abundantly available inside the drainpipes that lead from our homes to the septic systems or municipal sewage Read more

By Dave Dunbar, Retired – National Sales Manager at General Pipe Cleaners

Roots are your sewer pipes’ worst nightmare! Tree roots are constantly in a state of hunger and thirst, searching relentlessly for water and nutrients. Both are abundantly available inside the drainpipes that lead from our homes to the septic systems or municipal sewage treatment plants that process our waste.

Root hairs are tiny, sometimes only a few cells wide, but they grow quickly and can sense the vibration of running water. When they squeeze through a small crack or crevasse in a drainpipe and find what they are looking for, they begin to grow and expand. Over a period of months and years, this unrelenting pressure on the pipe expands the initial crack and begins to cause severe damage. Before you know it, you have a tree root blocking your drain and the pipe is leaking like a sieve. When a plumber or drain cleaner encounters a pipe in this condition, ignoring the problem is not an option. Depending on conditions and circumstances, there are several strategies that a professional can use to solve the problem.

Here are the top five ways of dealing with root incursions:

Replace or Reline the Infested Pipe

If a drainpipe has lost its structural integrity, obviously, the best solution would be to replace it. Modern plastic pipe, when properly installed, will be far more waterproof and durable than what is in the ground at the present moment. Or, if digging a trench through the customer’s property is not the most convenient solution, there are a multitude of pipe relining products and strategies that are almost as good. Because replacing or relining is a foolproof solution to the problem, a growing number of municipalities across North America mandate replacing leaking pipes whenever the property changes hands. If this is the case, the contractor and customer have no choice.

However, despite replacement/relining being the best engineering solution to the customer’s problem, it will certainly be the most expensive. So, if the contractor’s plans are not mandated by municipal statutes, there may be a number of factors to consider before recommending this course of action. For example, how old is the customer, and what is their financial situation? How long do they intend to keep the property? Are there geographic considerations that make other options more attractive? If none of these other considerations prevent it, then pipe replacement remains the best solution.

Cable Drain Cleaning Machine

Although replacing or relining the pipes is a foolproof solution, the most commonly used method of removing and cutting roots is a cable style drain cleaning machine like General Pipe Cleaners’ Speedrooter 92. Much of this has to do with cost and expediency. For a few hundred dollars and two hours’ time, the customer is usually rewarded with a functioning drainpipe. Contrast this with enduring several messy construction days and perhaps tens of thousands of dollars for a pipe replacement job. It is a small wonder that, after doing the math, customers continue to pick the drain cleaning option despite the fact that it does not fix the underlying problems that allowed the root incursion in the first place. Any cracks, crevices, or separations that existed in the pipe before using the snake are certainly still there. These openings act as inducements for more root incursion, as well as allowing inflow of rainwater, which contributes to sewage overflows into our rivers, lakes, and oceans. At best, snaking a drain to remove root incursions is a temporary solution. However, as we will see, there are things a contractor can do to increase the effectiveness of this option.

High-Pressure Water Jetters

Another tool that can perform many of the same functions as the drain snake already mentioned is a high-pressure water jetter, which has become the go-to tool for a lot of professionals for issues in any large drain. Like a cable-style drain cleaning machine, jetters have ways to mechanically remove roots from the inside of a pipe.

First, there are Chain Saw Nozzles that convert the kinetic energy of the high-pressure water generated by the pump to spin a chain saw nozzle at the end of the hose. These chain saws can rotate at speeds up to 30,000 RPM, more than enough to buzz through the toughest root incursions. If the pipe isn’t completely filled with wood, then a high-performance nozzle can often do the trick. These jetter nozzles are designed with the same technology used to make nuclear submarine propellers and convert almost 100% of the water’s energy to high-pressure streams that cut like razors.

Although high-pressure water jetters are also a temporary solution to the problem of root incursion, they have the advantage of preparing the pipe for more thorough inspections or pipe relining. When a professional gets done jetting a drain line, it will look like a new pipe again!

Flexible-Shaft Technology

Flexible-Shaft machines utilize a swiftly rotating wire coil inside a flexible hollow tube or hose that is connected to a cutting device on the front end. Because these cutters rotate at approximately 2,000 RPM, Flex-Shaft machines are adept at milling, pipe prep and root removal. For this reason, they are used extensively in the pipe relining industry, and have also become popular with plumbers and drain cleaners whose only goal is to cut and remove root incursions.

Flexible-Shaft machines tend to be used in tandem with pipe inspection systems, giving the contractor pinpoint control over the root cutting process. Like the snake style machines and high-pressure water jetters previously described, using a Flexible-Shaft machine to cut roots is a temporary solution to the customer’s problem. However, as already mentioned, they are often used for milling and pipe prep in the relining process. When utilizing the proper cutting tool, they leave the pipe in perfect condition to adhere to the material used in the pipe relining procedure. Testing has shown that pipe relining is often just as effective as pipe replacement at repairing the damage done to sewer pipes by root incursions.

Root Killing Solutions

Root Killing Solutions are chemical or biological products that the contractor introduces into the affected pipe to kill existing roots and inhibit further growth. While there are quite a few products available to the professional, most recommend that they be used either within one hour after cutting the roots with one of the methods already described, or after 8 weeks. Many contractors will recommend a thorough drain cleaning session with their snakes, jetters or Flexible-Shaft machines coupled with a root killing product. They will then attempt to lock the customer into a bi-yearly or annual preventative maintenance contract to reintroduce root killer to keep the problem at bay. This strategy can be a highly effective alternative for customers who do not wish to spend the money for a pipe replacement or pipe relining job, or do not plan to own the property indefinitely.

Most contractors do not lock themselves into using just one of these strategies when dealing with root incursions. More and more professional drain cleaners seem to have snakes, high-pressure water jetters, Flexible-Shaft devices, root killing products and sewer inspection cameras on every truck. As technology progresses in the field of plumbing and drain cleaning, contractors have more and more options available to them.

Remember, staying abreast of all the developments in our industry will give you the flexibility to successfully address the unique features of every job and every customer!

Sporting the highest flow rate of any water jet without a holding tank, the JM-3055 from General Pipe Cleaners packs plenty of punch to clear grease, sludge, sand, ice, and other stubborn stoppages from long, outside 4” to 8” lines. The muscular machine’s 3000 psi, 5.5 gpm pump unleashes high-pressure water streams that pulverize clogs Read more

Sporting the highest flow rate of any water jet without a holding tank, the JM-3055 from General Pipe Cleaners packs plenty of punch to clear grease, sludge, sand, ice, and other stubborn stoppages from long, outside 4” to 8” lines.

The muscular machine’s 3000 psi, 5.5 gpm pump unleashes high-pressure water streams that pulverize clogs – and flush them away. On demand Vibra-pulse® technology helps the hose slide easily down long runs – and around tight bends.

Part of General’s popular, powerful Jet-Set® range of electric, gas, and trailer water jets, the rugged, reliable JM-3055 is excellent for use in restaurants, hotels, hospitals, factories, schools, sports arenas, care facilities, shopping centers, and more.

Easily maneuvered into position, the superbly balanced JM-3055 sports a removable 300 ft. capacity hose reel mounted on a robust, tubular chassis with four, flat-free foam core tires and a wheel brake.

Standard safety features include a thermal relief valve to protect the pump from heat damage, a backflow check valve, and inlet filter. The JM-3055 also comes complete with toolbox and spray wand with trigger.

For details, visit www.drainbrain.com/jets. Or contact General’s Drain Brains® at 800-245-6200 or 412-771-6300.