The latest stud finder design virtually eliminates false positives with multiple sensors and high-tech signal processing Plumbers are responsible for many tasks such as installing, repairing, and maintaining pipes, valves, fixtures, fittings, and drainage systems. To work safely and productively, plumbing contractors need as accurate a picture as possible of everything in the wall. Expediting Read more

pipes

The latest stud finder design virtually eliminates false positives with multiple sensors and high-tech signal processing

Plumbers are responsible for many tasks such as installing, repairing, and maintaining pipes, valves, fixtures, fittings, and drainage systems. To work safely and productively, plumbing contractors need as accurate a picture as possible of everything in the wall. Expediting plumbing work while minimizing costly mistakes, the stud finder is deemed an essential tool.

Plumbing contractors have long utilized stud finders with a design based on unrefined capacitive technology. While this technology can indicate the location of wood stud framing, it also discovers metal, plastic, wiring, and other objects in walls just as easily. Furthermore, constantly active, hypersensitive “deep scanning” models further increase the potential for “false positives” – objects mistakenly identified as studs. The result is that traditional stud finders frequently chirp or flash LED lights to indicate something was sensed, but it is not clear what that is.

Today, the challenge of quickly and accurately assessing what is within walls is only increasing. There is more behind the drywall than ever, including network cabling, plastic pipes, and tubing. Complicating matters, not all construction follows standard stud spacing practices of 16 inches or 24 inches on-center, and there are often additional support beams, fire blocks, and other framing features that can further muddy the picture.

In addition, piping may change directions to avoid studs, wiring, and other obstructions. Plumbing location also varies depending on the home’s style and layout.

Now, newer, and more refined technology is being introduced to the popular stud finder category, and it promises to redefine the standards for stud finder performance. The next generation “intelligent” models incorporate multiple sensors and sophisticated signal processing technology to alert the presence of false positives. Using a sophisticated, selectable deeper scan mode, the technology can also be used to quickly identify metal pipes and even plastic pipes or PEX tubing behind the walls when this is desired.

For professional plumbing contractors, this innovative technology will provide a more accurate representation of what is behind the drywall.

Increasing Plumbers’ Productivity and Profitability

For plumbers, maximizing their work efficiency and profitability involves knowing as clearly as possible what is inside a wall before cutting into it. They do not want to create damage. They want to reduce the risk of costly mistakes that need to be repaired.

To work safely and productively, plumbers typically rely on stud finders to accurately find the studs within a wall. This can be important to support long pipe runs and heavy fixtures. Plumbers also need to avoid wood studs, since most of the work involves remodeling rather than new construction.

Finding the voids between studs is necessary to quickly assess how much room there is within the wall space to reroute pipe or mount a new fixture. When remodeling a kitchen or bathroom, it can be particularly important to understand if the studs are plumb, or whether fire blocking runs horizontally.

To better address these needs, plumbers now can use advanced, second-generation stud finders like a new unit by Zircon Corporation that utilizes multiple sensors and sophisticated signal processing to filter out false positives.

Zircon, a wholly owned subsidiary of ZRCN Inc., has been in the stud finder game for more than 40 years. In 1980, the company manufactured the original StudSensor™ stud finder and invented the category. The Silicon Valley-based company produces more than just stud finders. They design and manufacture an extended range of sensor technologies in electronic hand tools including wall scanners, metal detectors, circuit breaker finders, drill guides, water detectors, and leveling tools.

The company’s latest innovation is the Wood Stud SuperScan® advanced stud finder with Target Control® Technology and FILTERz™ cancellation. By analyzing the complex data streams from multiple sensors and controlling the result using sophisticated intelligence, the stud finder can find wood studs and filter out metallic objects such as plumbing, conduit, straps, brackets, screws, protector plates, or ductwork in the wall.

DeepScan® mode locates the center of wood studs and metal up to 1½ inches (38 mm) deep within walls. A MetalliWarning® indicator will display when metal is detected.

Additionally, the technology can alert the user to the presence of other low density, non-metallic targets, like plastic pipe and PEX tubing. To prevent cutting into dangerous electrical wires, the device also provides WireWarning® Detection, which indicates the presence of live, unshielded AC electricity.

The stud finder has a new and improved user interface that provides an intuitive “go/no go” indication in response to what is being sensed. A new haptic vibration and a patented SpotLite® Pointer that shines an arrow-shaped beam on the wall.

For plumbers, the ability to quickly identify what is inside the wall before cutting into it will substantially increase their productivity and safety.

Given the opportunity to see a much clearer picture of what is in the wall, plumbers would do well to upgrade their existing stud finder with an affordable, next-generation model that is sure to become the new standard in scanning.

For more information, call Zircon Corporation at (408) 963-4550, e-mail: info@zircon.com, or visit www.zircon.com

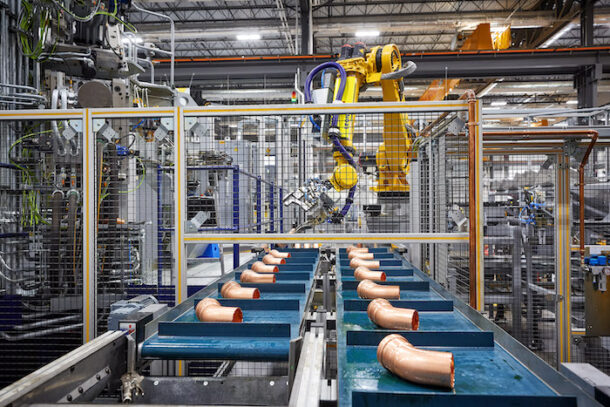

Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers. Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million Read more

Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers.

Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million and will increase the U.S. production of its industry-leading ProPress® products.

“As we continue to grow the business, we are bringing more production to the United States,” said Markus Brettschneider, CEO and President of Viega LLC. “These investments in our U.S. footprint will further support demand and leverage the talented U.S. manufacturing workforce, starting with the expansion of production capacity in Kansas.”

The McPherson manufacturing and distribution center is currently around 1 million sq. ft, with the facility more than doubling its footprint and workforce since opening in 2008. The new ProPress equipment is expected to be in production by the end of Q3 2023, with additional investments to come.

“We are proud to produce our fittings right here in Kansas. As we increase our U.S.-made products, we remain committed to creating highly skilled jobs in America, building out more sustainable manufacturing processes, and developing tomorrow’s workforce,” said Marki Huston, Head of Manufacturing for Viega LLC.

In addition to its McPherson, Kansas facility, Viega supports its customers and partners through distribution centers in Reno, Nev. and Carlisle, Penn., with further North American expansion planned for 2024 and 2025.

Imagine threading or welding 4″ carbon steel pipes, 40 feet in the air. Sounds difficult, time-consuming and potentially dangerous. All those pitfalls were avoided when a crew in Michigan used Viega MegaPressG fittings to pipe a new bean-roasting facility. The result was clean, attractive piping, a quick turnaround on project time, plus happy workers and Read more

Imagine threading or welding 4″ carbon steel pipes, 40 feet in the air. Sounds difficult, time-consuming and potentially dangerous.

All those pitfalls were avoided when a crew in Michigan used Viega MegaPressG fittings to pipe a new bean-roasting facility. The result was clean, attractive piping, a quick turnaround on project time, plus happy workers and owners.

Viega recently added MegaPressG fittings in sizes 2½” to 4″ to its lineup, and Schreiner Mechanical out of Frankenmuth, Michigan, was the first to install them, putting a couple dozen of the larger-diameter fittings into a new build in Gilford.

The project that Steve Schreiner, owner of Schreiner Mechanical, and his crew went to work on was a soybean-processing facility. The soybeans are roasted and crushed, then the oil is removed and used for biodiesel fuel and other applications. The remaining product is used to feed dairy cattle, leaving zero waste.

“What the plant does is unbelievable,” Schreiner said. “It’s favorable to the economy, and the oil can be used for several different products. There’s no waste.”

At first, Schreiner Mechanical was asked to do some plumbing in the office of the plant. Then the project, and need for Viega fittings, started to grow. The contractor was tasked with creating a gas main and system

At first, Schreiner Mechanical was asked to do some plumbing in the office of the plant. Then the project, and need for Viega fittings, started to grow. The contractor was tasked with creating a gas main and system

to supply the gas for the burners that roast the soybeans, plus they needed to plan for the plant’s future growth.

“The burners that are used are about 12 million BTU each, so they needed a high-pressure gas system in the plant feeding these machines,” Schreiner said. “That’s quite a large capacity, and in the future they’ll potentially have three more of these burners, so this gas system had to be designed to feed a tremendously large system.”

To do that, Schreiner Mechanical created a manifold with 4″ gas lines. Those lines work their way down to 2″ in size throughout the plant. It was the perfect place to put MegaPressG in larger-diameter sizes to work.

“Lines run throughout the plant for gas feeding the furnaces and rooftop units feeding other areas of the building,” Schreiner said. “There is probably about 500 feet of gas line with Viega fittings in this building.”

Schreiner will tell you he is “a Viega guy,” and when he began working on this project he was excited to hear that MegaPressG fittings in the larger sizes were on their way to market.

“If we’d had to thread this, it would have changed the whole philosophy on how to do things,” Schreiner said. “It would have made things 10 times more difficult, being 40 feet in the air, so we would have had to change the installation, plus it would have tripled or quadrupled the labor intensity. We’re talking about lift rentals and all things that come into play, plus the costs incurred for that, if we’d done it a different way than pressing. Threaded pipe would have been absurd.

“I’m excited that by using MegaPressG on this project, it was a time saver, a labor saver and safer than welding. The injury factor that can come up with different products is much bigger than with pressing. We would have had guys on the ground cutting and pre-fabbing pieces and then going up and down, but pressing in the air is much easier.”

In addition to providing the gas to the burners for the roasting in the plant, 2″ carbon steel lines with MegaPress fittings were also used for the oil line, moving the extracted crude oil from the beans into tanks.

Schreiner’s team is set up with Ridgid tools, and he said he feels that Ridgid and Viega together are the perfect combination.

“The Ridgid tool was a huge part of this successful application,” he said. “I’m passionate about the products I use, and when I find a good one, I stick with it.”

Viega District Manager Mike Norgan brought out the MegaPress XL PressBooster tool for Schreiner’s crew to use on the larger-diameter MegaPressG fittings, and Schreiner said it was simple to use.

“There was nothing more than smiles after using the tool,” he said. “Along with the large-diameter rings, it was easy and not cumbersome to use. Being able to press 12 or 14 large fittings in less than an hour is unbelievable.

“I tell people, ‘Look at what can be done [using Viega products]. This can be you and it’s this easy,’” he added. “Everybody’s hands are clean, there are no contaminants in the system, and there’s a lot to be said about that, having a contaminant-free system. When you have solder or threading oils or shavings, you have a high chance of contaminants, but with Viega, that chance is zero. I just cannot say enough about Viega. What we accomplished on this project with it is amazing.”

Broomfield, Colo. — Viega LLC is launching a new rewards program that will allow contractors to earn free Viega products and tools. Viega Rewards launched in early April. It’s open to small- to medium-sized contractors who use Viega products. Qualified participants will be awarded points according to annual spending tiers: Bronze (up to $10,000), Silver Read more

Broomfield, Colo. — Viega LLC is launching a new rewards program that will allow contractors to earn free Viega products and tools.

Viega Rewards launched in early April. It’s open to small- to medium-sized contractors who use Viega products. Qualified participants will be awarded points according to annual spending tiers: Bronze (up to $10,000), Silver ($10,000 to $20,000) and Gold ($20,000 and up). Rewards include free fittings, tubing, press tools, swag and training at Viega’s seminar centers.

https://youtu.be/ArZ-3u6TeL0

“Viega customers are passionate about the products and extremely loyal,” said Molly Morrow, Channel Marketing Manager. “We want to reward them for the loyalty that has made Viega the industry leader in pipe fitting installation technology and we thought giving them the products they already use and enjoy would be the best way to do it.”

The program is simple. Contractors enroll at ViegaRewards.us. When they make qualified purchases of Viega products, they upload the invoices on the claims page of the rewards website or the Viega Rewards app. Invoices are reviewed and points are paid out weekly.

The program is simple. Contractors enroll at ViegaRewards.us. When they make qualified purchases of Viega products, they upload the invoices on the claims page of the rewards website or the Viega Rewards app. Invoices are reviewed and points are paid out weekly.

When they’ve earned enough points to qualify for anything from sweatshirts to press tools, they can search the online catalog on the same site and choose their reward, which will be shipped to them. Points do not expire. Members also will receive special promotions. Enroll by Dec. 31, 2020, to earn 1,000 bonus points.

Wholesalers and distributors are not eligible for Viega Rewards. To learn more about the program, visit the About page on ViegaRewards.us. The site is administered by Incentive Solutions, an Atlanta firm.

Classes to be held in Colorado and New Hampshire Broomfield, Colo. — Viega, LLC has announced its Winter 2019-20 lineup of courses at its seminar centers in Broomfield, Colo., and Nashua, N.H. The offerings include topics from commercial piping solution to radiant design and LoopCAD. With two fully equipped state- of-the-art seminar centers, Viega is Read more

Classes to be held in Colorado and New Hampshire

Broomfield, Colo. — Viega, LLC has announced its Winter 2019-20 lineup of courses at its seminar centers in Broomfield, Colo., and Nashua, N.H.

The offerings include topics from commercial piping solution to radiant design and LoopCAD. With two fully equipped state- of-the-art seminar centers, Viega is an industry leader in supporting the trades and helping contractors become more versatile, skilled and efficient. To date, more than 40,000 people, from self-employed contractors to employees of large firms, have taken courses at the centers.

The classes are taught by experts with years of experience in the field and offer ample hands-on experience. Attendees leave with skills and knowledge that will show immediate benefits on the job.

Training seminars are listed below:

Radiant Design, Piping and Controls

Jan. 27-29, Nashua, N.H.; March 3-5, Broomfield, Colo.

Covers design theory and practice, piping arrangements and control strategies. Includes hybrid systems, multiple temperature piping arrangements and system component placement.

LoopCAD

Feb. 11-12, Nashua; Jan. 22-23, Broomfield

How to use LoopCAD software for radiant design and layouts. Covers heat loss, drawing layout, material selection and snow melt.

Commercial Piping Solutions

Dec. 3-4 and March 18-19, Nashua; March 3-4, Broomfield

Covers Viega systems and products and their appropriate uses. Includes PureFlow, ProPress and MegaPress; hybrid systems; installation techniques; project savings; hands-on installation and competitive information.

Hydronics 101 & Radiant Systems

March 3-4, Nashua; Jan. 16-17, Broomfield

Provides a basic understanding of how hydronic systems work. Topics include methods of heat transfer, piping materials and components, control strategies and installation methods.

Carbon Steel Press Technology

Jan. 13, Nashua

Covers the use of carbon steel press systems for residential, commercial and industrial piping applications.

Stainless Steel Press Technology

Feb. 20, Nashua

Covers the use of stainless steel press systems for commercial and industrial plumbing, heating and piping applications. Properties and chemical compatibility of 304 and 316 stainless steel will be covered.

Press Technology for Fuel Gas Piping

Feb. 3, Broomfield

Covers the use of carbon steel press systems for fuel gas piping in residential, commercial and industrial applications. Fuel types such as natural gas, LP gas, diesel, fuel oil and kerosene and their implications in NFPA 54 will be covered.

NFPA 13D Fire Sprinkler

Covers NFPA 13D requirements, system design, installation concerns and energy code compliance.

For more information and to register, click here.