Seasoned leaders to accelerate the adoption of QuickFitting’s rapidly growing press and push‑to‑connect product lines QuickFitting®, a leading innovator in plumbing and HVAC connection technology, announces the addition of two veteran sales professionals who will deepen regional coverage as the company introduces a wave of new solutions to market. Mike Foster, West Regional Sales Manager Read more

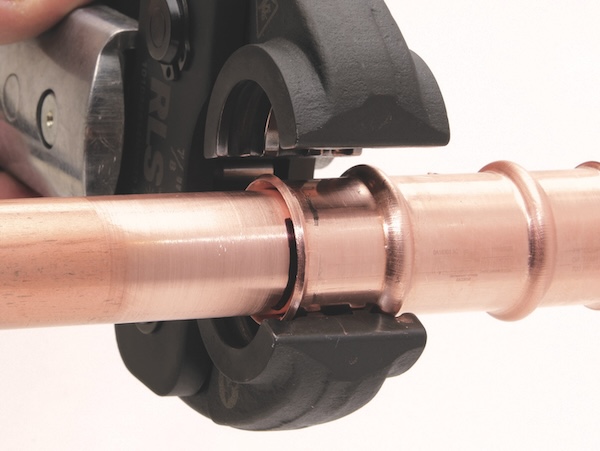

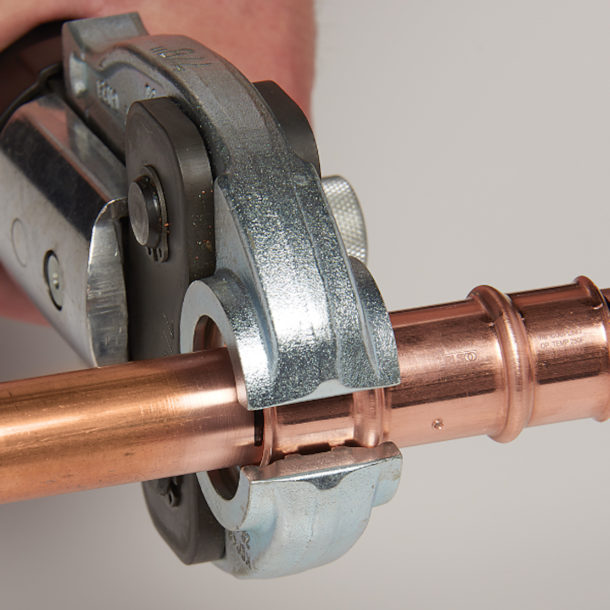

press fittings

Seasoned leaders to accelerate the adoption of QuickFitting’s rapidly growing press and push‑to‑connect product lines

QuickFitting®, a leading innovator in plumbing and HVAC connection technology, announces the addition of two veteran sales professionals who will deepen regional coverage as the company introduces a wave of new solutions to market.

Mike Foster joins QuickFitting as West Regional Sales Manager. Foster brings more than 25 years of outside‑sales success with major HVAC manufacturers, recognized for building distributor relationships and mentoring teams across the western United States.

QuickFitting has named Bill Braisted Regional Sales Manager for the Southeast. Braisted has spent nearly two decades in building‑products sales and specification, guiding multifamily and commercial projects throughout the Southeast and establishing strong ties with architects, engineers and distribution partners.

As Regional Sales Managers, Foster and Braisted will concentrate on cultivating lasting relationships with manufacturer representatives, distributors, contractors and the design community. Their priority is to champion QuickFitting’s SurePress® and push-to-connect technologies in the field, broadening market awareness, securing new distribution agreements and ensuring partners have the training and support they need to specify and install QuickFitting products with confidence. Working closely with their representative agencies, they will host product demonstrations, share best practices and relay customer insights that help QuickFitting stay ahead of evolving job‑site needs.

“Mike and Bill understand what contractors need on the jobsite and how distributors measure success,” says Bill Hunsberger, the company’s Director of Wholesale Sales. “Their experience and energy will help QuickFitting reach additional customers, secure new project specifications and support our partners throughout an ambitious product‑launch schedule.”

The appointments coincide with the rollout of next‑generation SurePress® fittings, an expanded push‑to‑connect refrigerant line for HVAC/R technicians, and upcoming brass push-to-connect product line extension later this year. Together, these launches reinforce QuickFitting’s one‑system approach to simplifying installs and driving contractor productivity.

St. Louis — Rapid Locking System (RLS), a leading provider of press-to-connect fittings for the HVAC/R market is proud to announce that its couplings, elbows, reducers, tees, caps, bushings and SAE flares are officially certified A2L-compliant. Attaining A2L compliance required RLS to participate in a thorough testing and screening process, across multiple 3rd party testing Read more

The publication of ASTM B1029 marks another milestone for the growing press industry Viega is proud to announce the publication of the ASTM B1029: Standard Practice for Press-Connect Joints with Seamless Copper and Copper Alloy Tube and Press Fittings. ASTM is a global organization that develops and provides standards for various industries and applications. Viega Read more

The publication of ASTM B1029 marks another milestone for the growing press industry

Viega is proud to announce the publication of the ASTM B1029: Standard Practice for Press-Connect Joints with Seamless Copper and Copper Alloy Tube and Press Fittings. ASTM is a global organization that develops and provides standards for various industries and applications. Viega took part in a rigorous consensus process to document best practices for creating press-connect joints. The new ASTM B1029 standard aims to enhance the reliability, efficiency, and adoption of press-connect technology in its approved applications by providing a standardized practice to be used industry-wide.

As a leader in the industry, Viega’s history, expertise, and innovative approach was instrumental in shaping this standard. Their commitment to innovation and quality is reflected in ASTM B1029, which aligns with the company’s mission to provide solutions that meet the highest industry standards. By collaborating with ASTM, Viega aims to support the widespread adoption of press-connect technology, offering engineers and installers a reliable, predictable, and efficient alternative to traditional joining methods.

Call to Action for Engineers and Specifiers

Viega encourages engineers, specifiers, and installers to incorporate ASTM B1029 language and practices into their projects to take advantage of the benefits offered by press-connect technology. The standard provides a clear framework for achieving optimal joint integrity and system performance.

Benefits of Press-Connect Technology:

- Fast: Press-connect fittings significantly reduce installation time compared to traditional methods.

- Safe: Eliminates the need for open flames or chemicals, reducing the risk of fire and exposure to harmful substances.

- Versatility: Suitable for a wide range of applications, from residential plumbing to complex industrial systems.

- Consistent: Simple connections create less variability between installers and more reliable systems.

One of the nation’s largest aerospace firms planned to expand and modernize existing capabilities at an occupied research and development facility in southern California. Xcel Mechanical Systems, based in Gardena, CA, was hired to design and build the mechanical, plumbing and process piping elements of the new project. To minimize risk and maximize labor efficiency Read more

One of the nation’s largest aerospace firms planned to expand and modernize existing capabilities at an occupied research and development facility in southern California. Xcel Mechanical Systems, based in Gardena, CA, was hired to design and build the mechanical, plumbing and process piping elements of the new project. To minimize risk and maximize labor efficiency, the Xcel team selected NIBCO® Press fittings and valves as a smart solution for the multi-phase project.

“Leveraging press technology mitigates the inherent risks of working with open flame within an occupied space,” said Jason Gordon, Xcel Mechanical’s vice president of operations. “We chose NIBCO Press for this job for multiple reasons, including safety, time and labor savings, and aesthetics,” said Gordon, whose firm has been a preferred design-build mechanical contractor on the sprawling campus for more than two decades. “NIBCO is a proven brand name in our industry. That’s important to us because the products we select are a reflection on our company.”

After four carefully planned construction phases, three and a half years of steady and precise work, the $8 million HVAC, plumbing and piping elements of the estimated $50 million laboratory modernization project are nearing completion.

The total renovation project included remodeling existing labs located on the ground floor of a three-story, 1960s-era research and manufacturing facility; labs which must be constantly redesigned and reconfigured to meet the specific requirements of each new contract award. The owner’s primary goal was to convert the subdivided lab space into a large open floor plan, creating the opportunity to build-out a modern, flexible and scalable “factory of the future” that would maximize the total available 160,000-square feet of lab and manufacturing space and 57,000-square feet of office space.

The building was stripped down to concrete on all four sides, exposing what was left: columns, high ceilings, and slabs. The original building design included old stanchion supports with piping and electrical systems running up from the floor. To free up valuable floor space, the new design features steel overhead utility racks that now run 500-600’ feet across the exposed ceiling for a nice clean application. Major mechanical and plumbing systems were removed and redesigned to align with the new design.

Project team members, from left: Wes Whittle (Piping and Plumbing Superintendent); Foreman Shawn Gibson (Pipefitter, Welder); Jason Gordon (VP of Operations); Foreman Ray Adams (Plumber, Pipefitter); Tim Brown (Service Technician); Steve Prisk, CSHO, ASH (Safety Director).

The Safety Factor

In this facility, the mains on the overhead utility distribution racks are sized 2” down to ¾”. Separately, the HVAC system has chilled water and heating hot water lines measuring up to 4” in diameter. Some of those lines drop down from a chilled water system located on the roof that serves a newly installed air handler.

“Typically, we would use steel for those 4” lines,” Gordon said. “But since the piping ran down an existing shaft, there were safety concerns around welding or grooving the 4” steel. And then there was the weight factor and what would be required to run steel pipe down that shaft versus copper,” he said.

“For these reasons, my foremen advocated for the additional material spend on copper. Obviously, the material cost is considerably more but we felt the safety benefits and labor savings would offset it,” Gordon said. “We are a strong believer in getting perspective from our foremen. If they support the plan, believe in the products they are installing, and it makes sense financially, then it’s a win-win.”

Gordon said using NIBCO Press on the project also meant not having to go through the facility’s Hot Work permitting process which typically adds time to any project. “The customer liked that the NIBCO product removed a certain level of risk, and also the smell of soldering and flux from an operational lab environment,” he said. “So, in the end, our customer was happy. Our safety team was happy. And our field personnel were happy.”

Labor Savings is Big

NIBCO Press is easy to install which helps reduce labor costs while keeping projects on schedule. “Material is material, but labor is what makes or breaks a job,” Gordon said. The project’s process piping system consists of three copper lines, one each for compressed air, nitrogen, and industrial vacuum systems. Each run is 400-500’ long and includes multiple connection points. Gordon said the press product made working in smaller areas and also making multiple connections overhead much easier from both a safety and labor efficiency perspective. “We fabricated a fair amount of material used in this job, but with a multitude of small overhead connection points located 6-12’ apart along these lengthy runs, the copper press solution was key. We saved a minimum of 30-40% on labor on some parts of this job, and significantly more on other parts,” he said.

Minimizing System Downtime

Through the life of the project, the ongoing challenge was to build safely around the 100-200 employees who were working in the lab areas. The project’s four-phase approach called for temporarily relocating employee teams into other parts of the facility while completing construction one section at a time. “Using NIBCO Press not only reduced labor time, but it shortened shutdown periods, allowing us to get the building back online sooner.”

Looking Good

Although functionality and flexibility played an important role in modernizing this facility, creating a visually appealing space was also a consideration, Gordon said. “Aesthetically the NIBCO Press product is a good-looking product and a clean application overall,” he said. “For nitrogen systems, we would typically purge and braze, and afterward the copper is oxidized. When we install press, the copper looks brand new. It’s a good look.”

Smart Solution

As the project nears completion, Xcel Mechanical will continue to use NIBCO Press systems to ensure their reputation for high quality and good workmanship is maintained. Press is easy to install and the labor cost savings generated cannot be understated. The proven performance of Press makes it a smart solution for every job.

For more information, visit www.NIBCO.com or contact Sally Boyer, manager of marketing communications, at boyers@nibco.com.

There seems to be some confusion in the HVAC/R industry right now about press fittings. So RLS – manufacturer of the original RLS (Rapid Locking System) press fittings that were first sold under the ZoomLock brand name – wants to set the record straight. While you can’t always trust what you hear, you can always Read more

There seems to be some confusion in the HVAC/R industry right now about press fittings. So RLS – manufacturer of the original RLS (Rapid Locking System) press fittings that were first sold under the ZoomLock brand name – wants to set the record straight.

While you can’t always trust what you hear, you can always trust the facts. And here are some undisputed facts about HVAC/R press fittings:

FACT: RLS is the inventor, patent holder and manufacturer of the original HVAC/R press fittings, which were introduced under the ZoomLock brand in 2015, through an exclusive agreement with Parker Hannifin Corporation’s Sporlan division. The fittings were designed and engineered – and continue to be made – in America.

FACT: The exclusive agreement ended in late 2019, and RLS stopped supplying fittings for ZoomLock in August of 2020. (See the official announcement here)

FACT: In August of 2020, Parker began selling press fittings manufactured in Europe by Conex Banninger (the Conex B MaxiPro line) under the “ZoomLock Max” name.

FACT: RLS now sells the exact same fittings, tools and jaws that were originally sold as ZoomLock under their own RLS brand name. That is why the original ZoomLock tools and jaws still work perfectly with RLS fittings – and always will.

FACT: Any rumors being circulated about RLS/ZoomLock jaws needing to be “traded in” or replaced are simply not true.

FACT: RLS fittings and jaws use a patented double circular press, with 360˚ metal-to-metal connections. ZoomLock Max/Conex B MaxiPro fittings and jaws use a hexagonal press similar to what is used in plumbing.

FACT: RLS fittings have a 6+ year proven track record of success worldwide. Conex Banninger introduced the new B MaxiPro design sometime after June of 2019.

FACT: The only difference between the original ZoomLock fittings and the current RLS fittings is the name. The product is identical – and made in the same American factory.

Want more facts? You can get them from the source by visiting rapidlockingsystem.com or emailing sales@rapidlockingsystem.com.