RLS hosted its first pressing competition at the 2023 AHR Expo in Atlanta in February. It was a fun and exciting event, with teams of three competing to be the fastest at forming the letters “RLS” out of copper tube and RLS press fittings. A total of six teams competed, three on Monday and three Read more

Rapid Locking System

RLS hosted its first pressing competition at the 2023 AHR Expo in Atlanta in February. It was a fun and exciting event, with teams of three competing to be the fastest at forming the letters “RLS” out of copper tube and RLS press fittings.

A total of six teams competed, three on Monday and three on Tuesday. RLS named six team captains, who were then able to choose any two additional competitors to complete their teams. The two winning teams that completed the project the fastest are listed below.

Team 1 (Monday): Jeff DeMassari (@jeffjdemhvac), Michael Flynn (@flynnstone1) and Ben Thomson (@hvac_strong)

Team 2 (Tuesday): Jamie Christensen (@northwest_hvac), Justin Angelo (@truebluemechanical) and Michael Flynn (yes, he was on both winning teams!)

A big shout out and thank you to all of our six team captains, and to our referee, Robert Villagomez (@p.e.hvac):

Jeff DeMassari – @jeffjdemhvac

Jamie Christensen – @northwest_hvac

Shav Jumaev – @hvaclyfe101

Gabriel Gonzalez – @Hvac_sg

Pat Finley – @commercial_kitchen_chronicles

Lance Robinson – @solderweldhvac

RLS LLC, manufacturer of the Rapid Locking System line of flame-free press-to-connect fittings for HVAC and refrigeration systems, announces that Milwaukee® Tool, in partnership with RLS, has introduced RLS-compatible jaws for use with its popular M18™ FORCE LOGIC™ Press Tools. Available in sizes from 1/4″ – 1-3/8″, these new RLS ACR Press Jaws will allow Read more

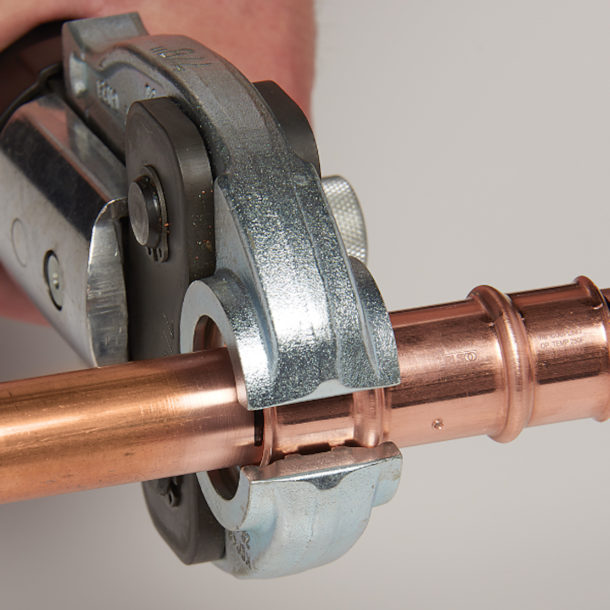

RLS LLC, manufacturer of the Rapid Locking System line of flame-free press-to-connect fittings for HVAC and refrigeration systems, announces that Milwaukee® Tool, in partnership with RLS, has introduced RLS-compatible jaws for use with its popular M18™ FORCE LOGIC™ Press Tools.

Available in sizes from 1/4″ – 1-3/8″, these new RLS ACR Press Jaws will allow M18 tool users to take advantage of the time-saving and safety benefits of flame-free RLS press connections for HVAC/R, without needing to invest in a new press tool. These are the industry’s first jaws approved to press RLS fittings using 32 kN (kilonewton) tools.

In addition, the new Milwaukee jaws are also compatible with a wide range of other 32 kN tools on the market, including those from manufacturers such as RIDGID, Klauke, Viega, Dewalt, NovoPress and Rothenberger. Contractors who already own any of these tools will only need to purchase the Milwaukee jaws to begin installing RLS fittings.

Milwaukee’s RLS-compatible jaws will be sold exclusively through Milwaukee distributors. Contact Milwaukee or visit milwaukeetool.com for details. For more information on RLS press fittings, and a complete RLS Tool & Jaw Compatibility Matrix, visit rapidlockingsystem.com.

About RLS Fittings

RLS press fittings connect in 10 seconds using a battery-powered tool and jaws, replacing the time-consuming process of manually brazing HVAC/R joints. The fittings result in faster, more consistent connections that reduce total installed costs, while also increasing jobsite safety by eliminating the use of an open flame. More than 10 million RLS fittings have been successfully installed since their introduction in 2015

Manufacturing Plant and Training Center in St. Louis, Missouri RLS LLC, manufacturer of the Rapid Locking System line of flame-free press-to-connect fittings for HVAC and refrigeration systems, has announced it will be moving into a new 80,000 square foot multipurpose facility in St. Louis, Missouri, which will serve as its corporate headquarters and will include Read more

Manufacturing Plant and Training Center in St. Louis, Missouri

RLS LLC, manufacturer of the Rapid Locking System line of flame-free press-to-connect fittings for HVAC and refrigeration systems, has announced it will be moving into a new 80,000 square foot multipurpose facility in St. Louis, Missouri, which will serve as its corporate headquarters and will include a state-of-the-art manufacturing plant, training center and showroom.

RLS will be relocating manufacturing from Shelbina, Missouri, where it has been sharing a plant with its sister company, Cerro Flow Products. Both are part of the Plumbing and Refrigeration sector of Marmon Holdings, a Berkshire Hathaway company. All RLS operations are planned to be consolidated into the new building by the end of 2021.

“We’re very excited to have manufacturing, office staff and training all under one roof,” said Paul Schubert, president of RLS. “The larger, upgraded facility will significantly increase our production capacity to meet the growing demand for our products. And the new training center will allow us to regularly educate HVAC/R contractors and distributors on our patented press technology, which is easily identified by our unique double circular press and flares.”

After originally introducing its press fittings in 2015 under the ZoomLock brand through a private-label agreement with Parker Hannifin, RLS has experienced tremendous growth since relaunching under its own brand name at the end of 2019. To support this continued growth, RLS has recently added more than 10 new positions in sales, marketing and engineering across the U.S., and is currently hiring.

“As more and more contractors discover the many benefits of using press fittings over the traditional brazing process, they continue to choose the time-tested and field-proven technology provided by RLS,” said Schubert. “As a result, we are continuing to invest in the facilities, equipment and people needed to meet demand.”

RLS press fittings connect in 10 seconds using a battery-powered tool and jaws, replacing the time-consuming process of manually brazing HVAC/R joints. The fittings result in faster, more consistent connections that reduces total installed costs, while also increasing jobsite safety by eliminating the use of an open flame.

For more information on RLS, visit rapidlockingsystem.com.

There seems to be some confusion in the HVAC/R industry right now about press fittings. So RLS – manufacturer of the original RLS (Rapid Locking System) press fittings that were first sold under the ZoomLock brand name – wants to set the record straight. While you can’t always trust what you hear, you can always Read more

There seems to be some confusion in the HVAC/R industry right now about press fittings. So RLS – manufacturer of the original RLS (Rapid Locking System) press fittings that were first sold under the ZoomLock brand name – wants to set the record straight.

While you can’t always trust what you hear, you can always trust the facts. And here are some undisputed facts about HVAC/R press fittings:

FACT: RLS is the inventor, patent holder and manufacturer of the original HVAC/R press fittings, which were introduced under the ZoomLock brand in 2015, through an exclusive agreement with Parker Hannifin Corporation’s Sporlan division. The fittings were designed and engineered – and continue to be made – in America.

FACT: The exclusive agreement ended in late 2019, and RLS stopped supplying fittings for ZoomLock in August of 2020. (See the official announcement here)

FACT: In August of 2020, Parker began selling press fittings manufactured in Europe by Conex Banninger (the Conex B MaxiPro line) under the “ZoomLock Max” name.

FACT: RLS now sells the exact same fittings, tools and jaws that were originally sold as ZoomLock under their own RLS brand name. That is why the original ZoomLock tools and jaws still work perfectly with RLS fittings – and always will.

FACT: Any rumors being circulated about RLS/ZoomLock jaws needing to be “traded in” or replaced are simply not true.

FACT: RLS fittings and jaws use a patented double circular press, with 360˚ metal-to-metal connections. ZoomLock Max/Conex B MaxiPro fittings and jaws use a hexagonal press similar to what is used in plumbing.

FACT: RLS fittings have a 6+ year proven track record of success worldwide. Conex Banninger introduced the new B MaxiPro design sometime after June of 2019.

FACT: The only difference between the original ZoomLock fittings and the current RLS fittings is the name. The product is identical – and made in the same American factory.

Want more facts? You can get them from the source by visiting rapidlockingsystem.com or emailing sales@rapidlockingsystem.com.

RLS® LLC (“RLS”), manufacturer of the first press-to-connect fittings for the HVAC and refrigeration industries, announces the launch of their new RLS Certified Installer online training program at training.rapidlockingsystem.com. The new training portal walks HVAC/R contractors through the step-by-step process of making reliable, permanent copper tube connections using RLS press technology. “We’re very excited to Read more

RLS® LLC (“RLS”), manufacturer of the first press-to-connect fittings for the HVAC and refrigeration industries, announces the launch of their new RLS Certified Installer online training program at training.rapidlockingsystem.com. The new training portal walks HVAC/R contractors through the step-by-step process of making reliable, permanent copper tube connections using RLS press technology.

RLS® LLC (“RLS”), manufacturer of the first press-to-connect fittings for the HVAC and refrigeration industries, announces the launch of their new RLS Certified Installer online training program at training.rapidlockingsystem.com. The new training portal walks HVAC/R contractors through the step-by-step process of making reliable, permanent copper tube connections using RLS press technology.

“We’re very excited to offer this comprehensive new training program for users of RLS press fittings,” said Paul Schubert, President of RLS. “The new portal explains our patented press technology, how and why it works so well, and the steps required for proper installation. Both audio descriptions and video demonstrations are used to reinforce the material and facilitate learning.”

Users must pass a series of quizzes as they work through each section of the training program, as well as a final test after completing the entire course. After passing the final test, a customized certificate of completion can be downloaded.

In conjunction with the new training program launch, RLS has also introduced a new company logo. The new design comes as the company celebrates the sixth anniversary of the introduction of its revolutionary technology to the HVAC/R market. Originally introduced in 2015 under the ZoomLock® brand through a partnership with Parker Hannifin Corporation, RLS fittings are now sold exclusively under the RLS brand.

“Now that RLS press fittings have taken on their own identity in the marketplace, we felt it was time to give our logo a new look that represents our leadership position in the industry,” said Schubert. “The logo emphasizes our patented fitting design, including the unique flared ends which make it instantly recognizable as an HVAC/R fitting, setting it apart from those used for plumbing.”

RLS designs, develops, and proudly manufactures its fittings in America, at its centrally located Missouri factory. The press fittings replace the time-consuming and demanding conventional practice of manually brazing HVAC/R copper joints. RLS fittings allow for faster, more consistent connections that reduce total installed cost while also enhancing safety, since they do not require an open flame.

RLS is a subsidiary of Marmon Holdings, Inc., a Berkshire Hathaway company. For more information, visit rapidlockingsystem.com or training.rapidlockingsystem.com for the new online training program.