Organizations will work together to emphasize career opportunities in the trades Reliance Worldwide Corporation (RWC), a leading manufacturer of premium branded push-to-connect plumbing products, valves, secondary pipe supports, firestopping solutions and fluid control technologies, is partnering with Home Builders Institute (HBI), a national leader in career training for the building and construction industry, as the exclusive Trade Read more

Sharkbite

Organizations will work together to emphasize career opportunities in the trades

Reliance Worldwide Corporation (RWC), a leading manufacturer of premium branded push-to-connect plumbing products, valves, secondary pipe supports, firestopping solutions and fluid control technologies, is partnering with Home Builders Institute (HBI), a national leader in career training for the building and construction industry, as the exclusive Trade Sponsor for its 22 plumbing programs across the U.S., primarily serving Job Corps students and justice-involved individuals.

These HBI programs provide students with the skills, experience and placement services they need to have a successful career while helping the trade address labor shortages.

“We are thrilled to engage with HBI and believe this is the beginning of an important, long-lasting partnership,” said Chris Carrier, Marketing Director, Americas at RWC. “HBI’s ability to connect, train and place potential new talent into the trade makes them an ideal partner. Not only do we see this as an opportunity to help our trade, but also an opportunity to help the local communities that these programs are in.”

This partnership was a natural opportunity for RWC to double down on its commitment to promote and further the plumbing trade after its Careers in Construction Month efforts, through its SharkBite® and HoldRite® brands, in October.

“Our diverse product portfolio enables us to produce solutions that are designed to help plumbing contractors work more efficiently in the field,” Carrier continued. “In our conversations with them, we’ve recognized the need to help the trade address its labor challenge.”

HBI’s programs help approximately 10,000 students each year receive real life, hands-on training and find meaningful careers in the trades. HBI also provides them with job placement and transition assistance, and qualified graduates are able to enter advanced training programs to expand their education and experience.

“Home Builders Institute is proud to welcome our new partner, Reliance Worldwide Corporation,” said HBI President and CEO Ed Brady. “Together, we are training the next generation of skilled labor for the building industry. As HBI’s exclusive Trade Sponsor of our plumbing programs, RWC will provide its excellent products to help train our students in 22 locations nationwide. In the process, they will develop customers for life as our graduates enter the industry. I look forward to working with RWC and to seeing how the many resources they bring to the table will help enhance our training programs and ensure the future success of our students.”

To further discuss this partnership during IBSx – the 2021 International Builders Show – please visit RWC or HBI’s exhibits. Learn more about RWC and its family of brands.

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect Read more

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect slip and transition fittings.

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect slip and transition fittings.

“SharkBite gives you a wide range of slip fittings and valves to repair burst copper or CPVC pipes quickly,” said Michael Kornegay, SharkBite Product Manager. “Up to two inches of damaged pipe can be removed using a single fitting, even in wet lines, and a drain valve can be easily added to prevent future freezing.”

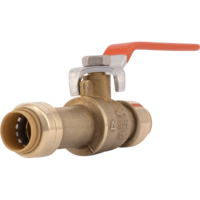

Ideal for working with multiple pipe types and in tight spaces, SharkBite’s Brass Push transition fittings can be installed in wet lines and can transition between pipe types, including PEX, copper, CPVC, PVC, polybutylene, HDPE and PE-RT pipes, making them one of the most versatile solutions.

“SharkBite’s push-to-connect transition fittings come with color-coordinated collars for each specific pipe material,” Kornegay continued. “The tool-free transition fittings allow for quick and easy repair of copper pinhole leaks and replacement of brittle polybutylene pipe or broken CPVC.”

Since pipes are at a higher risk of freezing and bursting in the winter, it pays to have a solution like SharkBite’s push-to-connect slip and transition fittings handy for a quick fix. Follow these steps to get the job done fast:

- Cut the pipe cleanly – Be sure the pipe is clean of scratches or debris. If working with copper pipe, use a deburr tool or sandpaper to remove any sharp edges or burrs.

- Measure and mark the insertion depth – Use SharkBite’s Deburr & Gauge Tool to mark the insertion depth on the damaged pipe.

- Make the connection – Push the fitting to the insertion marks. Then, turn on the water and check the connection.

When it comes to repairing a burst, frozen pipe, SharkBite push-to-connect slip and transition fittings save time. Pipe transitions make working with PEX, copper, CPVC, PVC, polybutylene, HDPE and PE-RT pipes hassle free, and SharkBite offers the flexibility of repairing the damaged pipe in wet lines under full flow.

“Just cut, push and done,” Kornegay said. “These SharkBite products allow you to quickly repair those frozen, burst pipes in a short amount of time, so you can finish a job with ease and move on to the next.”

Learn more about SharkBite’s repair options at SharkBite.com.

Some brands become so popular people begin to refer to all products in the category by that name, such as Kleenex or Band-Aid. Similarly, push-to-connect fittings weren’t quite as popular as they are today until Reliance Worldwide Corporation (RWC) introduced them to the U.S. market nearly 20 years ago. It revolutionized the category and made Read more

Some brands become so popular people begin to refer to all products in the category by that name, such as Kleenex or Band-Aid.

Similarly, push-to-connect fittings weren’t quite as popular as they are today until Reliance Worldwide Corporation (RWC) introduced them to the U.S. market nearly 20 years ago. It revolutionized the category and made the work of contractors and plumbers quicker, more efficient and more reliable. Now, SharkBite brass push fittings are the industry standard for push-to-connect plumbing— so much so that some people refer to fittings from other brands as SharkBite.

SharkBite’s Journey to the U.S.

After seeing the success of its push-to-connect fittings in Australia, water control and plumbing solutions manufacturer RWC introduced the fittings in the U.S. market as the SharkBite push-to-connect plumbing system in 2004. Today, SharkBite has become so popular that it is estimated a fitting connection is made every 2.5 seconds, according to the manufacturer’s data.

Fittings That Pushed the Boundaries of Plumbing Tech

Before push-to-connect technology, plumbers could only rely on soldering, gluing or using a specialized tool to connect pipes. These methods are sufficient in some cases but can be challenging when transitioning between different pipe types or installing in tight spaces.

To address these issues, SharkBite designed its push-to-connect fittings to connect different pipe types such as PEX, copper, CPVC, PE-RT and HDPE in tight spaces without special tools, crimps, glue or soldering.

Further Advancing Push-to-connect Technology

With SharkBite’s success, especially as a solution for emergency repairs and pipe transitions, RWC continued to build upon its innovations in push-to-connect technology:

- SharkBite introduced its own brand of durable yet flexible PEX pipe into North America. The pipe enables quicker leak repairs compared to rigid copper pipe and is often quicker to install in tight spaces.

- The company launched 1-1/4 in., 1-1/2 in. and 2 in. SharkBite fittings, which gives contractors who work on commercial projects the ability to work quicker using push-to-connect technology.

- SharkBite launched EvoPEX fittings. The groundbreaking PEX-only fitting system for meter-to-fixture installation allows for faster and more reliable installations on new construction jobsites.

A Connection You Can Trust

Plumbers can trust the secure fit of a push-to-connect fitting thanks to its tight-sealing o-ring, pipe-locking stainless steel grab ring and corrosion-resistant brass body. All of its parts work together to make a 3-second connection long-lasting, and the fittings require no tools, can be connected in wet lines and are compatible with multiple types of pipe.

SharkBite’s Legacy

Every new product SharkBite introduces is created to empower contractors to work smarter, not harder. By reducing installation times, SharkBite gives contractors time back that they can spend on parts of their job that require more resources, like growing their business and investing in their workforce.

Michael Kornegay is the SharkBite product manager at RWC — a market leader and manufacturer of water control systems and plumbing solutions for residential, commercial and industrial applications.

Michael Kornegay is the SharkBite product manager at RWC — a market leader and manufacturer of water control systems and plumbing solutions for residential, commercial and industrial applications.

Complete Suite Includes SharkBite and HoldRite Products Designed for Efficiency Reliance Worldwide Corporation (RWC) is a market leader and manufacturer of water control systems and plumbing solutions for residential and commercial applications. For plumbing business owners, the importance of building a strong team that works together seamlessly and efficiently is paramount. The same holds true Read more

Complete Suite Includes SharkBite and HoldRite Products Designed for Efficiency

Reliance Worldwide Corporation (RWC) is a market leader and manufacturer of water control systems and plumbing solutions for residential and commercial applications.

For plumbing business owners, the importance of building a strong team that works together seamlessly and efficiently is paramount. The same holds true for RWC’s engineers when developing water heater solutions. All products must work in concert to perform and last.

That’s why RWC offers a complete water heater installation system designed to increase productivity and durability on the job. The products, ranging from fittings and valves to tank supports, work together so users can purchase the bulk of water heater installation materials from a single source. This ensures compatibility, efficiency and quality assurance.

RWC’s water heater products, which work together as a complete solution, include:

- SharkBite Flexible Water Heater Connectors – Created with SharkBite push-to-connect ends, the water heater connectors enable quick installation. Perfect for pipes in tight spaces that don’t line up when replacing a water heater, the connectors are available in corrugated and braided hoses.

- SharkBite Thermal Expansion Relief Valve – SharkBite Thermal Expansion Relief Valve eliminate the need for an expansion tank, shut-off valve and fitting. Compatible with PEX, copper, CPVC, PE-RT, and HDPE pipe, the valve protects hot water supply systems where high-pressure conditions are likely to occur as a result of thermal expansion.

- HoldRite Water Heater Quick Stand and Platform Accessories – HoldRite water heater accessories and equipment platforms are lab-tested and some of most recognized water heater bracing and support systems in the market. The platforms safely elevate water heaters above the floor, supporting up to 100 gallons while still meeting code requirements.

Want to see these water heater products and accessories in action? Check out this interactive video.

RWC intentionally creates solutions that integrate seamlessly while also meeting the needs and regulations of modern residential and commercial applications. Developed, assembled and tested by RWC’s team of engineers, users can be assured each water heater product and accessory is built with superior design and functionality. RWC uses strict quality control processes and sophisticated technology in each assembly unit, so by the time products hit shelves, they’re exceeding industry standards.

Water heaters are often installed in tight, confined spaces that can be difficult to access, including closets and basements. It’s important to have a complete range of solutions from one family of brands that provides the flexibility and continuity to complete almost any type of job, regardless of space.

Products can be found at plumbing wholesalers across the U.S. and Canada. For up-to-date product availability, users are encouraged to contact their local supplier.

Learn more about RWC and its family of brands.

When looking for a new plumbing product, what’s most important? For many, the decision comes down to whether the product works and is affordable – and rightly so. But to maximize your investment and ensure the job’s success long after you leave the jobsite, it’s important to dig deeper into the products you use and Read more

When looking for a new plumbing product, what’s most important? For many, the decision comes down to whether the product works and is affordable – and rightly so. But to maximize your investment and ensure the job’s success long after you leave the jobsite, it’s important to dig deeper into the products you use and the manufacturer that creates them.

And once you find plumbing manufacturers you trust, you’ll have more confidence in your installs and worry less about customer callbacks. It may sound tedious to research manufacturers, but the payoff — knowing they’re reliable — is worth the extra time.

So, how do you find trustworthy manufacturers? Start by asking the right questions:

Does the manufacturer have a proven track record of reliability?

Having a new product fail after installation isn’t a gamble any contractor wants to take. It should be a given that it was built to last.

When you install a product, you need to know it won’t fail. A reliable manufacturer ensures quality throughout production and creates products to comply with industry codes and standards.

This happens by:

- Choosing quality materials over cheaper materials.Instead of using lower-quality raw materials to save money, the manufacturer should use robust materials that last long after installation. And its product specs should be easy to find online to maintain transparency about the product.

- Performing rigorous independent testing.Each product should undergo months of repetitive and extreme testing to make sure it can be pushed to its limits without failing. Try to find what a manufacturer has to say about their testing process — and if it exceeds minimum testing requirements.

- Helping lead compliance initiatives.Manufacturers shouldn’t just produce products that comply with industry standards. Company leaders should participate in initiatives promoting safer products that are better for the environment, such as the IAPMO WE Stand Committee.

- Owning the manufacturing process. Manufacturers who own the production of their products from raw material to final product have more control over the product quality and when things need to be adjusted.

Does the manufacturer create products that work seamlessly with existing solutions?

As a contractor, it’s a must that new products can work well with the ones you already use. It’s the manufacturer’s responsibility to make sure their solutions complement not only those in the same product line but also ones from different brands and materials.

Does the manufacturer’s leadership spend time on the jobsite?

Manufacturers should constantly seek ways to improve plumbers’ jobs, and the only way to truly do that is to walk alongside them on the jobsite. The manufacturers you partner with should be asking about your biggest pain points and presenting real solutions.

And even if you’re not yet one of their customers, the manufacturer should make it clear how they support and communicate with contractors like yourself. Look for evidence of strong customer relationships by reading online reviews, testimonials, case studies and support pages.

Partnering with the Right Manufacturers

The next time you search for a new plumbing product, take time to consider the reputation and business practices of the manufacturers. You’ll end up with more reliable products that will, in turn, help boost your own reputation with your customers.

Chris Carrier is the Marketing Director, Americas at RWC – a market leader and manufacturer of water control systems and plumbing solutions for residential and commercial applications.

Chris Carrier is the Marketing Director, Americas at RWC – a market leader and manufacturer of water control systems and plumbing solutions for residential and commercial applications.