Huge Commercial Heating System Retrofit! https://youtu.be/nLWTEj_qcAE?si=fAArm6-16X_O0bW5 The Hub is on the road in Missoula, Montana for five days to pipe up 1.2M Btu’s of hot water heating for a 45+n unit condo property. The Hub’s Eric Aune joins the Mickelson Plumbing crew for an intense but fun project in this episode of our ‘Hub On Read more

Viega

Huge Commercial Heating System Retrofit!

The Hub is on the road in Missoula, Montana for five days to pipe up 1.2M Btu’s of hot water heating for a 45+n unit condo property.

The Hub’s Eric Aune joins the Mickelson Plumbing crew for an intense but fun project in this episode of our ‘Hub On The Road’ series.

In this video we showcase the reliable MegaPress IPS fitting system. We rely on the RIDGID propress tools and press booster for assembly of the piping connected to the Viessmann Vitocrossal 200 commercial hot water boilers.

Thanks to our partners for making this project possible. It’s with their support we were able to produce this educational video showcasing some world-class plumbing & hvac products and tools.

Please checkout our partners here:

Viega LLC Ridge Tool Company (RIDGID Tools) Viessmann Manufacturing

The Plastics Pipe Institute, Inc. (PPI) today announced the appointment of Jason McKinnon, director of engineering services, Viega, LLC (Broomfield, CO), as the chair of its Education Committee. PPI is the major North American trade association representing the plastics pipe industry. “Our Education Committee,” stated David M. Fink, PPI president, “is counted on by the Read more

The Plastics Pipe Institute, Inc. (PPI) today announced the appointment of Jason McKinnon, director of engineering services, Viega, LLC (Broomfield, CO), as the chair of its Education Committee. PPI is the major North American trade association representing the plastics pipe industry.

“Our Education Committee,” stated David M. Fink, PPI president, “is counted on by the various industries we serve to provide viable, validated instruction on all aspects of plastic pipe. This includes courses and curriculum in each of our five divisions plus the Hydrostatic Stress Board. In his new role, Jason will assist in delivering courses at conferences with other organizations and use delivery platforms such as Red Vector and PPI’s own eLearn™ educational channel. His input on the new courses PPI will develop will be highly beneficial and valuable.”

McKinnon has more than twenty years of engineering and training experience developing new curriculum and training modules. He holds a Bachelor of Science – Mechanical Engineering Technology plus Master of Business Administration degrees from the University of Massachusetts. He has been a participating member of PPI for more than 10 years, mainly with the association’s Building & Construction Division, and was a founding member of the PPI Education Committee in 2013.

Founded in 1950, PPI’s five major divisions are Building & Construction, Drainage, Energy Piping Systems, Municipal & Industrial and Power & Communications. Its member companies share a common interest in broadening market opportunities that make effective use of plastics piping for building and construction projects, water and gas distribution, sewer and wastewater conveyance, oil and gas production, industrial and mining uses, plus power and communications systems. Additional information can be found at www.plasticpipe.org

The Plumbing-Heating-Cooling Contractors—National Association (PHCC) Educational Foundation is proud to announce the winners of our 2023 scholarships program. Fifty-seven students were selected to receive scholarship awards totaling $139,000. Applicants must be plumbing or HVAC apprentices or trade school students, or college students pursuing studies directly related to the plumbing-heating-cooling industry. The Foundation extends our congratulations Read more

The Plumbing-Heating-Cooling Contractors—National Association (PHCC) Educational Foundation is proud to announce the winners of our 2023 scholarships program. Fifty-seven students were selected to receive scholarship awards totaling $139,000. Applicants must be plumbing or HVAC apprentices or trade school students, or college students pursuing studies directly related to the plumbing-heating-cooling industry.

The Foundation extends our congratulations to all our winners and our thanks to the contractor donors and corporate sponsors who make these awards possible. Sponsorships are provided by A.O. Smith, Bradford White Corporation, Delta Faucet Company, InSinkErator, RIDGID, Scorpion Home Services Marketing, State Water Heaters, Sterling (a Kohler brand), SupplyHouse.com, Viega, the Texas and Massachusetts PHCC Auxiliaries, the PHCC Past National Officers, Bill Jones, and Gerry Kennedy, with additional funding from the generous donations made by PHCC contractors.

The 2024 PHCC Educational Foundation scholarship program will open for applications in January, with all submission materials due by May 1st. Information on the scholarship program can be found at https://phccfoundation.org/scholarships.

2023 PHCC Educational Foundation Scholarship Winners

- Thomas Langer of McKean, Pa. is studying Business Management at Indiana University of Pennsylvania and was awarded a $3,000 scholarship sponsored by A.O. Smith.

- Ryan Welte of Roscoe, Ill. is studying HVACR Installation, Service and Repair at Blackhawk Technical College and was awarded a $3,000 scholarship sponsored by A.O. Smith.

- Noah Gonzales of Beaumont, Calif. is studying Plumbing Installation, Service & Repair in the PHCC-ORSB Plumbing Apprenticeship Program and was awarded a $3,000 scholarship sponsored by Bradford White.

- Justin Hendrix of Reno, Nev. is studying Plumbing Installation, Service & Repair at PHCC of Nevada and was awarded a $3,000 scholarship sponsored by Bradford White.

- Nathaniel Sanchez of Allentown, Pa. is studying Plumbing Installation, Service & Repair at PHCC of Lehigh Valley LCTI and was awarded a $3,000 scholarship sponsored by Bradford White.

- Matthew Toohey of San Diego, Calif. is studying Plumbing Installation, Service & Repair at the PHCC of San Diego Academy and was awarded a $3,000 scholarship sponsored by Bradford White.

- Sarosh Ahmed of Sylvania, OH is studying Mechanical Engineering at The University of Toledo and was awarded a $3,000 scholarship sponsored by Delta Faucet Company.

- Cameron Barton of Amarillo, Texas is studying Construction Engineering at Texas Tech University and was awarded a $3,000 scholarship sponsored by Delta Faucet Company.

- Todd Daskalov of Costa Mesa, Calif. is studying Plumbing Installation, Service & Repair in the PHCC-ORSB Plumbing Apprenticeship Program and was awarded a $1,500 scholarship sponsored by Delta Faucet Company.

- Kyle Girard of Westford, Mass. is studying Plumbing Installation, Service & Repair at The Peterson School and was awarded a $1,500 scholarship sponsored by Delta Faucet Company.

- Lane Prindle of Navarre, Fla. is studying HVACR Installation, Service and Repair at Locklin Technical College and was awarded a $1,500 scholarship sponsored by Delta Faucet Company.

- Andrew Shields of Bryan, Texas is studying Mechanical Engineering at Rose-Hulman Institute of Technology and was awarded a $3,000 scholarship sponsored by Delta Faucet Company.

- Grant Styers of Gastonia, N.C. is studying Business Management at NC State and was awarded a $3,000 scholarship sponsored by InSinkErator.

- Matthew Dineen of Glendale, Wis. is studying Plumbing Installation, Service & Repair at Waukesha County Technical School and was awarded a $1,500 scholarship plus $1,500 in tools sponsored by RIDGID.

- Andrew Jacobs of Cypress, Calif. is studying Plumbing Installation, Service & Repair in the PHCC-ORSB Plumbing Apprenticeship Program and was awarded a $1,500 scholarship plus $1,500 in tools sponsored by RIDGID.

- Eliuth Perez Gonzalez of San Jose, Calif. is studying Plumbing Installation, Service & Repair at the PHCC-GSA Plumbers UAC Apprenticeship Program and was awarded a $1,500 scholarship plus $1,500 in tools sponsored by RIDGID.

- Cameron White of Trabuco Canyon, Calif. is studying Plumbing Installation, Service & Repair in the PHCC-ORSB Plumbing Apprenticeship Program and was awarded a $1,500 scholarship plus $1,500 in tools sponsored by RIDGID.

- Ricardo Amezquita of Lynwood, Calif. is studying Plumbing Installation, Service & Repair in the PHCC-ORSB Plumbing Apprenticeship Program and was awarded a $1,500 scholarship sponsored by Scorpion Home Services Marketing.

- Chase Fenner of Granger, Ind. is studying Plumbing Installation, Service & Repair at JATC Local 172 Apprentice Program and was awarded a $1,500 scholarship sponsored by Scorpion Home Services Marketing.

- Ashley Trester of New Orleans, La. is studying Business Management at Tulane University and was awarded a $1,500 scholarship sponsored by Scorpion Home Services Marketing.

- Sadiq Evans of Atlanta, Ga. is studying Mechanical Engineering at Alabama A&M and was awarded a $3,000 scholarship sponsored by State Water Heaters.

- Garrett Crabb of Cameron Park, Calif. is studying Plumbing Installation, Service & Repair at the PHCC-GSA Plumbers UAC Apprenticeship Program and was awarded a $1,500 scholarship sponsored by Sterling, a Kohler Brand.

- Matthew Emig of Springville, Iowa is studying HVACR Installation, Service and Repair in the PHCC of Iowa Online Program and was awarded a $1,500 scholarship sponsored by Sterling, a Kohler Brand.

- Jacob Mellen of Leeds, Maine is studying Plumbing Installation, Service & Repair at Central Maine Community College and was awarded a $1,500 scholarship sponsored by Sterling, a Kohler Brand.

- Tatiana Sicard of Mansfield, Mass. is studying Construction Management at Wentworth Institute of Technology and was awarded a $1,500 scholarship sponsored by Sterling, a Kohler Brand.

- Mario Alvarado Jr. of Moreno Valley, Calif. is studying Plumbing Installation, Service & Repair in the PHCC-ORSB Plumbing Apprenticeship Program and was awarded a $1,500 scholarship sponsored by SupplyHouse.com.

- Joseph Brehm of El Dorado, Calif. is studying Plumbing Installation, Service & Repair in the PHCC-GSA Plumbers UAC Apprenticeship Program and was awarded a $1,500 scholarship sponsored by SupplyHouse.com.

- Hannah Keller of St. Petersburg, Fla. is studying Plumbing Installation, Service & Repair with PHCC of Florida and was awarded a $1,500 scholarship sponsored by SupplyHouse.com.

- Anna Kurtz of Bethlehem, Pa. is studying Plumbing Installation, Service & Repair at PHCC Academy and was awarded a $1,500 scholarship sponsored by SupplyHouse.com.

- James Mantsch of Sacramento, Calif. is studying HVACR Installation, Service and Repair in the Sacramento City College Mechanical Electrical Technology Program and was awarded a $1,500 scholarship sponsored by SupplyHouse.com.

- Lamonte Wright of Murrieta, Calif. is studying Plumbing Installation, Service & Repair at PHCC Academy of San Diego and was awarded a $1,500 scholarship sponsored by SupplyHouse.com.

- William Broas of Oxford, Conn. is studying HVACR Installation, Service and Repair at Lincoln Technical Institute and was awarded a $3,000 scholarship sponsored by Viega, LLC.

- Aubree Carr of Stanwood, Wash. is studying Business Management at George Fox University and was awarded a $3,000 scholarship sponsored by Viega, LLC.

- Chase Carrico of Lakeville, Ind. is studying Plumbing Installation, Service & Repair at JATC Local 172 Apprentice Program and was awarded a $3,000 scholarship sponsored by Viega, LLC.

- Joseph Christensen of Lathrop, Calif. is studying Plumbing Installation, Service & Repair at PHCC-GSA Plumbers UAC Apprenticeship Program and was awarded a $3,000 scholarship sponsored by Viega, LLC.

- Samuel Gutierrez of Fullerton, Calif. is studying Plumbing Installation, Service & Repair in the PHCC-ORSB Plumbing Apprenticeship Program and was awarded a $1,500 scholarship sponsored by Viega, LLC.

- Erik Licona Perez of San Bernardino, Calif. is studying HVACR Installation, Service and Repair at San Joaquin Valley College and was awarded a $1,500 scholarship sponsored by Viega, LLC.

- Elijah Patterson of Coxs Creek, Ky. is studying HVACR Installation, Service and Repair at Bluegrass Community and Technical College and was awarded a $1,500 scholarship sponsored by Viega, LLC.

- Erin Perez of Richmond, Calif. is studying Plumbing Installation, Service & Repair with PHCC of Alameda & Contra Costa Counties and was awarded a $1,500 scholarship sponsored by Viega, LLC.

- Helen Tallulah King of Tallahassee, Fla. is studying Business Management at University of Alabama and was awarded a $10,000 Charles Hiley Memorial Scholarship sponsored by PHCC Educational Foundation.

- Anthony Cacciotti of Millstone Township, N.J. is studying Plumbing Installation, Service & Repair in the PHCC of New Jersey Academy and was awarded a $1,500 scholarship sponsored by PHCC Educational Foundation.

- Kadyn Campeau of New Richmond, Wis. is studying HVACR Installation, Service and Repair at Chippewa Valley Technical College and was awarded a $3,000 scholarship sponsored by PHCC Educational Foundation.

- Luke Ciaffaglione of Plantsville, Conn. is studying Construction Management at Central Connecticut State University and was awarded a $3,000 scholarship sponsored by PHCC Educational Foundation.

- Marley Colville of Coats, N.C. is studying Business Management at University of North Carolina at Chapel Hill and was awarded a $3,000 scholarship sponsored by PHCC Educational Foundation.

- Peter Diaz of Pomona, Calif. is studying Plumbing Installation, Service & Repair in the PHCC-ORSB Plumbing Apprenticeship Program and was awarded a $1,500 scholarship sponsored by PHCC Educational Foundation.

- Aiden Divelbiss of Youngstown, Ohio is studying HVACR Installation, Service and Repair at University of Northwestern Ohio and was awarded a $3,000 scholarship sponsored by PHCC Educational Foundation.

- Jake Dunlap of San Antonio, Texas is studying Plumbing Installation, Service & Repair at PHCC of San Antonio Apprentice Program and was awarded a $1,500 scholarship sponsored by PHCC Educational Foundation.

- Zachary Hulin of Huntington Beach, Calif. is studying Plumbing Installation, Service & Repair in the PHCC-ORSB Plumbing Apprenticeship Program and was awarded a $1,500 scholarship sponsored by PHCC Educational Foundation.

- Nathan Telander of San Antonio, Texas is studying Plumbing Installation, Service & Repair at PHCC of San Antonio Apprentice Program and was awarded a $1,500 scholarship sponsored by PHCC Educational Foundation.

- Cole Trautman of San Luis Obispo, Calif. is studying Mechanical Engineering at Cal Poly-San Luis Obispo and was awarded a $3,000 scholarship sponsored by PHCC Educational Foundation.

- Cody McManus of Dedham, Mass. is studying Business Management at Williams College and was awarded a $3,000 scholarship sponsored by PHCC of Massachusetts Auxiliary.

- Nicholas Graves of San Antonio, Texas is studying Plumbing Installation, Service & Repair at PHCC of San Antonio Apprentice Program and was awarded a $1,500 scholarship sponsored by PHCC of Texas Auxiliary.

- Joshua Fletcher of Knox, Ind. is studying HVACR Installation, Service and Repair at JATC Local 172 Apprentice Program and was awarded a $3,000 Need-Based scholarship sponsored by PHCC Past National Officers.

- Jason Fornito of Springfield, Pa. is studying Plumbing Installation, Service & Repair in the PHCC of Philadelphia Suburban Apprentice Program and was awarded a $3,000 Need-Based scholarship sponsored by PHCC Past National Officers.

- Victor Pacheco of Whittier, Calif. is studying Plumbing Installation, Service & Repair in the PHCC-ORSB Plumbing Apprenticeship Program and was awarded a $3,000 Need-Based scholarship sponsored by PHCC Past National Officers.

- Timothy Portnoy of Vista, Calif. is studying Plumbing Installation, Service & Repair at PHCC of San Diego Academy and was awarded a $3,000 Patty Jones Memorial Scholarship sponsored by William Jones.

- Hunter Styers of Gastonia, N.C. is studying Construction Management at University of Alabama and was awarded a $3,000 Gerry Kennedy Memorial Scholarship sponsored by Gerry Kennedy.

2023 PHCC Educational Foundation Scholarships Corporate Sponsors

About PHCC Educational Foundation

The PHCC Educational Foundation, a partnership of contractors, manufacturers, and wholesalers, was founded in 1987 to serve the plumbing-heating-cooling industry by preparing contractors and their employees to meet the challenges of a constantly changing marketplace. Students interested in pursuing a career in the plumbing or HVACR professions are invited to visit phccfoundation.org/scholarships for information on 2024 scholarships.

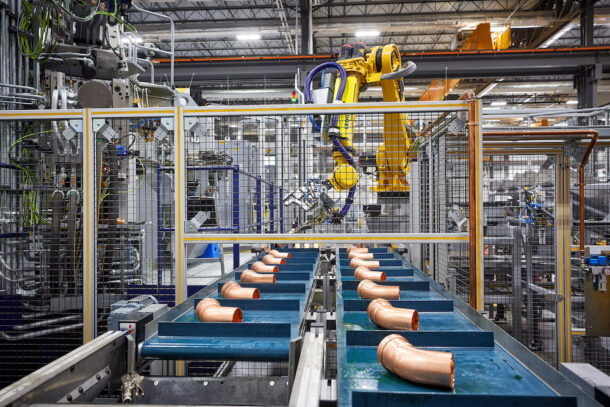

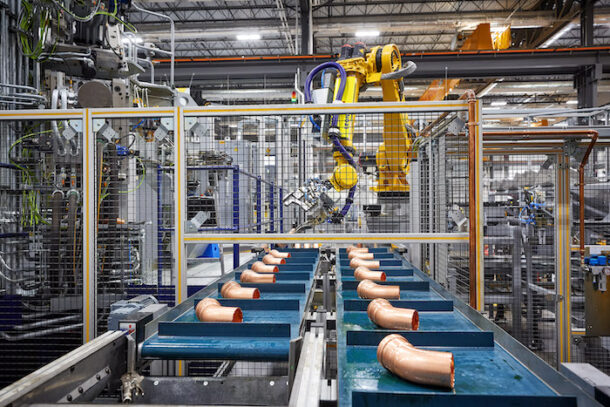

The 180,000-sq.-ft. plant in Shalersville, Ohio, will break ground in November 2023 and is expected to be operational in early 2025. Broomfield, Colo. — Viega recently announced that it will build a new manufacturing facility for its ProPress® and MegaPress® products in Shalersville, Ohio, about 40 miles southeast of Cleveland. Viega LLC President and CEO Read more

The 180,000-sq.-ft. plant in Shalersville, Ohio, will break ground in November 2023 and is expected to be operational in early 2025.

Broomfield, Colo. — Viega recently announced that it will build a new manufacturing facility for its ProPress® and MegaPress® products in Shalersville, Ohio, about 40 miles southeast of Cleveland. Viega LLC President and CEO Markus Brettschneider made the announcement.

“This is an exciting time at Viega, as our growth continues to prompt the expansion of our North American footprint,” said Markus Brettschneider, CEO and President of Viega LLC. “This new facility in Ohio, along with recent investments in our existing Kansas facility, further supports our growing demand and is part of Viega’s plan to increase North American production. We look forward to expanding our presence in this part of the country to further support our customers.”

The 80-acre parcel in Shalersville and the construction of the new plant represent an investment of approximately $200 million in Ohio. Viega’s business continues to grow in the U.S., and the additional plant will help support the increased demand for Viega products. It also aligns with the company’s sustainability goals, which include reducing the carbon emissions associated with importing products by manufacturing more items in the U.S. The new facility will be completely carbon neutral from the start, supporting the company’s long-term goal of achieving net-zero carbon emissions for all their plants by 2035.

“The expansion of our operations into Ohio shows our commitment to creating highly skilled jobs in the U.S.,” said Marki Huston, Head of Manufacturing for Viega LLC. “Our goal is to build more sustainable manufacturing processes and continue developing tomorrow’s workforce. With production scheduled to begin in early 2025, we expect to start hiring for positions as soon as January 2024, bringing more than 68 new jobs to the area over the next few years.”

Viega recently announced investments in new equipment for its McPherson, Kansas, manufacturing and distribution facility. In addition, Viega supports its customers and partners through distribution centers in Reno, Nev. and Carlisle, Penn., with more North American expansion planned for 2024 and 2025.

Viega worked with local, regional, and state organizations, including Team NEO, JobsOhio, Portage Development Board and the Shalersville-Streetsboro Joint Economic Development District on tax credit assistance and to select the 80-acre site. “We have a great manufacturing legacy, dedicated talent pool, and future-oriented industry resources to support Viega’s new operations,” said Team NEO Chief Executive Bill Koehler. “Along with JobsOhio and our local partners, we welcome Viega to the Northeast Ohio Region. We are confident they will thrive here.”

Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers. Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million Read more

Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers.

Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million and will increase the U.S. production of its industry-leading ProPress® products.

“As we continue to grow the business, we are bringing more production to the United States,” said Markus Brettschneider, CEO and President of Viega LLC. “These investments in our U.S. footprint will further support demand and leverage the talented U.S. manufacturing workforce, starting with the expansion of production capacity in Kansas.”

The McPherson manufacturing and distribution center is currently around 1 million sq. ft, with the facility more than doubling its footprint and workforce since opening in 2008. The new ProPress equipment is expected to be in production by the end of Q3 2023, with additional investments to come.

“We are proud to produce our fittings right here in Kansas. As we increase our U.S.-made products, we remain committed to creating highly skilled jobs in America, building out more sustainable manufacturing processes, and developing tomorrow’s workforce,” said Marki Huston, Head of Manufacturing for Viega LLC.

In addition to its McPherson, Kansas facility, Viega supports its customers and partners through distribution centers in Reno, Nev. and Carlisle, Penn., with further North American expansion planned for 2024 and 2025.