D.C. DebriefNIST CutsTekmar Invita 564 WiFi ThermostatNew Podcasts https://vimeo.com/1091685591 D.C. Debrief John offers valuable insight from his recent lobbying trip to Washington, D.C., where he joined the Plumbing Industry Leadership Coalition (PILC) to advocate for key industry issues. The agenda was wide-ranging, covering critical topics such as WaterSense, research and development funding, tariffs, and workforce Read more

Featured

Table of Contents

D.C. Debrief

John offers valuable insight from his recent lobbying trip to Washington, D.C., where he joined the Plumbing Industry Leadership Coalition (PILC) to advocate for key industry issues. The agenda was wide-ranging, covering critical topics such as WaterSense, research and development funding, tariffs, and workforce development challenges. While navigating the complexities of Capitol Hill, John observed firsthand that not all meetings carry the same weight—and that post-meeting debriefs with policymakers are inconsistent at best, highlighting the nuanced and often unpredictable nature of political engagement.

NIST Cuts

While in Washington, D.C., John participated in meetings at the National Institute of Standards and Technology (NIST), where he learned of looming workforce reductions and budget cuts. These potential setbacks could significantly affect key programs and raise serious concerns about the future of American manufacturing innovation and the country’s ability to remain competitive in global markets.

Tekmar Invita 564 WiFi Thermostat

Check out Eric’s recent video of the Tekmar Invita® 564 WiFi Thermostat. Designed to simplify smart thermostat upgrades and furnace-to-heat pump conversions, the Invita 564 makes installation easier than ever. Using the existing two wires from any living space, it connects to an HVAC Interface Module located in the mechanical room—delivering advanced control without the need for new wiring.

New Podcasts

Appetite For Construction: This week the guys travel to Bishopville, Md., to talk with Lauren and Josh Martin, owners of Seaside Plumbing about being active in the community, whether it’s through creative marketing, philanthropy work or visiting with schools to talk up the trades or hosting plumbing camps. Listen Here.

Make Trades Great Again: Have we become too complacent when it comes to ordering online? It’s 2025, and yet, for whatever reason, this online supplier is asking for four forms of order verification and signatures upon delivery for regular, everyday plumbing and hvac material orders. Listen Here.

Sign up for our newsletter: https://mechanical-hub.com/enewsletter/

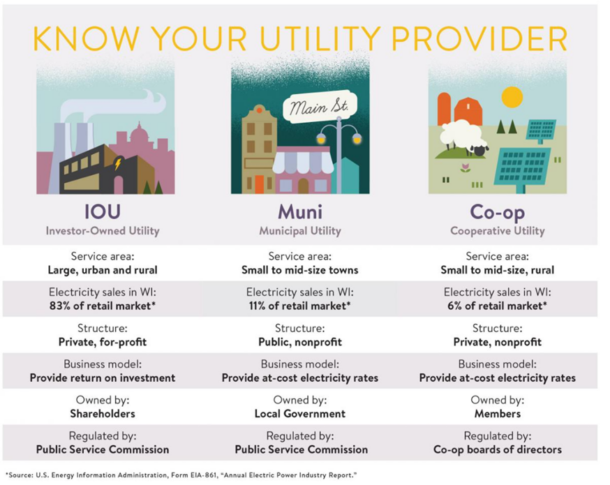

In the United States, there are three general types of electrical suppliers. They are: Investor-Owned Utilities (IOU) Municipally Owned Utilities (MUNI) Customer Owned Rural Cooperatives (Co-op) Investor-Owned Utilities include big names in Electrical & Natural Gas distribution such as Con Ed, Florida Power and Light, and Pacific Gas & Electric. These are investor-owned utilities. There Read more

In the United States, there are three general types of electrical suppliers. They are:

- Investor-Owned Utilities (IOU)

- Municipally Owned Utilities (MUNI)

- Customer Owned Rural Cooperatives (Co-op)

Investor-Owned Utilities include big names in Electrical & Natural Gas distribution such as Con Ed, Florida Power and Light, and Pacific Gas & Electric. These are investor-owned utilities. There are 168 IOUs in the US that serve about 110 million customers. They are regulated by their respective Public Service Commissions (PSCs) and must conform as a regulated monopoly.

Municipally Owned Utilities (there are 958 of them) include names like Rochester Public Utilities, Tampa Electric Company, and Philadelphia Gas Works. Since these utilities are owned by a municipality or another government agency, they are regulated by their owners, meaning the city or community.

Customer Owned Rural Cooperatives (there are 832 of them) include names like Texas-based Pedernales Electric Cooperative, The Nebraska Rural Electric Association, and New Jersey’s Sussex Rural Electric Cooperative. These utilities exist to bring the best services possible to their consumers, and they are run by the folks that pay also pay for the energy.

Investor-owned electric utilities are typically regulated and operate as vertically integrated monopolies with oversight from public utility commissions. They may operate in deregulated markets in which electric energy prices are set by the market and are subject to federal oversight of their wholesale market.

Before 1990, most investor-owned electric utilities were regulated and vertically integrated. That means that the utilities own electricity generators and power lines (both distribution and transmission lines). Presently about 30% of US electricity demand is serviced by these fully integrated utility markets. In much of the US, states have abandoned this system in favor of deregulation.

In traditionally regulated regions, utilities operate as a monopoly in their territories. That means that customers only have the option to buy power from them. To keep electricity rates reasonable, state regulators oversee these electric utilities and set electricity prices. Retail electricity prices are set based on the utility’s operating and investment costs alongside a fair rate of return, which is called a “revenue requirement”. This revenue is approved by the state’s public utilities commission and prevents utilities from overcharging customers for energy.

Smaller rural electric cooperatives power 56% of the American landscape, serving 42,000,000 residents, including 92% of impoverished counties.

There has been tremendous publicity for geothermal technologies. Direct use and enhanced geothermal systems are providing incredible baseload electricity and thermal energy for infrastructure. Geothermal technologies are strategically vital toward management of peak demand on the grid. The wide-spread power outages in Texas (2021) are an example of a runaway peak demand in the heating season.

“Ground Source Heat Pumps (GSHPs) are the key to managing demand on the electrical grid.”

With the high demand for air conditioning in the summertime, why would a wintertime freeze cause the electrical grid to “spike” as we saw in Texas in 2021? Most people know that air conditioning loads in the middle of August usually drive the greatest demand on the grid. However, electric heaters & air source heat pumps (ASHPs) are often used to handle peak heating loads, and they can double or triple that peak demand in the wintertime, when compared with summertime demand. Here’s a primer on how and why that is:

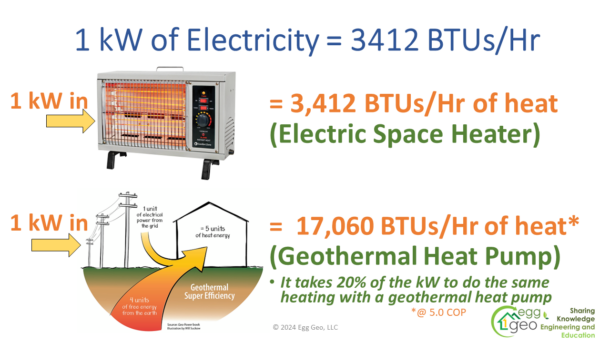

Energy Facts:

- 1 watt of electricity = 3.412 BTUs

- I kW of heat consumed by an electric heater = 3,412 BTUs of heat output

- I kW of heat consumed by an electric Geothermal Heat Pump (GHP) = 17,060 BTUs of heat*

- It takes 20% the kW to do the same heating with a GHP *(@5.0COP)

As it gets colder outside, Air Source Heat Pumps (ASHPs) must work harder to extract heat from the air. Geothermal Heat Pumps (GHPs) continue to have high efficiency operation regardless of outdoor temperature (because underground temps are reasonably stable).

Cold temperatures can reduce the efficiency of heat pumps, simply because it’s hard to extract heat from outside air as it gets colder. The efficiency of ASHPs drops as it gets colder outside, just as the gas mileage efficiency of a car drops when it’s climbing a hill. Geothermal heat pumps are not normally subject to drastic temperature fluctuations, because they’re coupled with the temperature in the shallow earth, which ranges between about 45 and 75 degrees in the US.

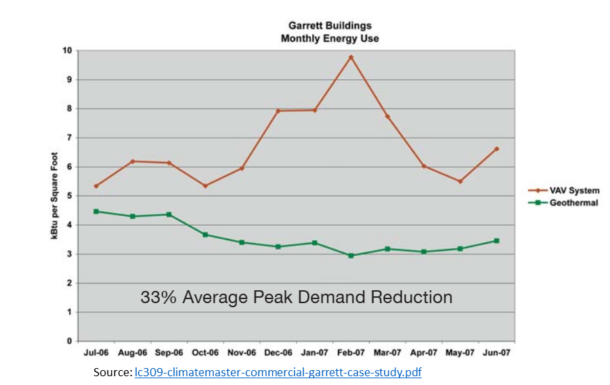

There have been a few Customer-Owned Rural Cooperatives (Co-ops) in recent decades that have been able to capitalize on reduced demand in summer, and increased revenue from electric GHPs in the winter. Look at the demand of two identical office buildings in Oklahoma. One has air-source heat pumps (ASHPs), the other, geothermal heat pumps (GHPs):

It’s obvious that there is a demand reduction in the summer, but the winter savings & peak demand reduction are remarkable. Here are some figures from Boyd Lee, an employee of CKenergy in Oklahoma:

- 2000 new GHPs replaced (both new construction and replacing gas furnaces)

- 4800kW Demand Reduction = $835,000/year.

- New sales totaled an additional 2,600,000 kWh, or about $260,000.

- Net annual increased revenue = $1,095,200.

What this means is that the electrical cooperative has more than $500 per year per home in additional income by going with a geothermal solution when compared to air sourced heat pumps. Electrical utilities typically look for payback in 60 years or less for infrastructure improvements such as power plants or distribution lines. Using that same logic, the utility has $30,000 per home to pay for the upgrades. That will more than cover the cost of the geothermal solution. And while ASHPs last 10 to 15 years, the GHP will last closer to 30 years because it can be installed all-indoors, and has a more stable heat exchange source, meaning it has much better working conditions.

Geothermal Exchangers Extract Energy from the Earth

The geothermal heat pump solution in the CKenergy case totaled 5142 Tons of capacity, and reduced demand by 0.65 kW per ton. That represents a 3.4 MW peak energy generation by the geothermal exchangers in the CKenergy case. Note that they see the geothermal exchangers as a source of energy, producing 3.4 MWs, removing that electrical load from the grid.

Energy Poverty

Energy Poverty

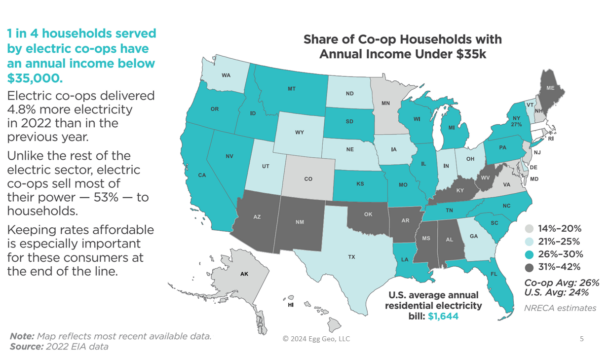

1 in 4 households served by electric co-ops have an annual income below $35,000. Electric co-ops delivered 4.8% more electricity in 2022 than in the previous year.

Unlike the rest of the electric sector, electric co-ops sell most of their power — 53% — to households. Keeping rates affordable is especially important for these consumers at the end of the line. -NRECA analysis U.S. average annual residential electricity bill: $1,644

Electrical co-ops are perfectly poised to create demand side management (DSM) program setting include deep subsidies for geothermal heat pump (GHP) installations. The numbers seem to bear out a model that could allow the Co-op to pay for the entire ground loop exchanger and offer “on bill financing” for the GHP, electrical, and distribution upgrades needed. With 92% of persistently impoverished communities paying energy bills to electrical cooperatives, these are the folks that could truly benefit with some relief from high energy costs. The cure to energy poverty can be partially met through this demand side management since their energy bills will be drastically reduced with GHPs.

What’s next? We will see electrical co-ops begin to take advantage of this remarkable opportunity, and millions of geothermal heat pumps will be installed over the next 20 years in cooperative communities. As these cooperatives begin to understand the demand side value of GHP’s, they will embrace the opportunity to utilize the energy source that is the earth for heating and cooling within their service areas.

Jay Egg is a geothermal consultant, speaker, writer, and the owner of Egg Geo. He has co-authored two textbooks on geothermal HVAC systems published by McGraw-Hill Professional. He can be reached at jaye@egggeo.com.

Jay Egg is a geothermal consultant, speaker, writer, and the owner of Egg Geo. He has co-authored two textbooks on geothermal HVAC systems published by McGraw-Hill Professional. He can be reached at jaye@egggeo.com.

Mimi Egg is a social media marketing professional, writer and media technical consultant for Egg Geo, focused on building online connections and educating on social media platforms. Her desire to educate the rising generation about green, sustainable living is a major focus in her career. Egg may be reached at mimieggshell@gmail.com

Mimi Egg is a social media marketing professional, writer and media technical consultant for Egg Geo, focused on building online connections and educating on social media platforms. Her desire to educate the rising generation about green, sustainable living is a major focus in her career. Egg may be reached at mimieggshell@gmail.com

The staff at Spark by Hilton™ in Redlands, California, turned to A. O. Smith for a water heater capable of providing ample hot water to their hotel. It’s no simple task to supply hot water all day, every day, to a hotel with 85 rooms, a kitchen and multiple commercial laundry facilities. But for A Read more

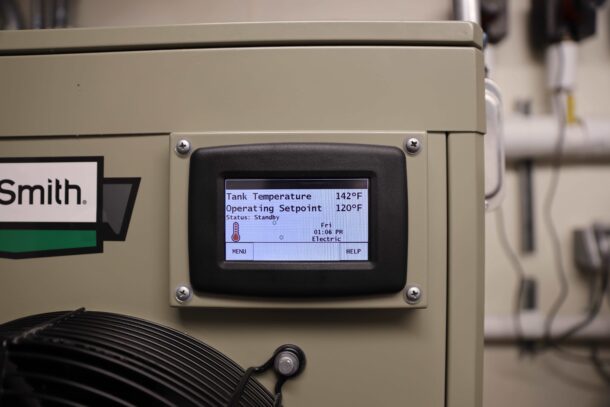

The staff at Spark by Hilton™ in Redlands, California, turned to A. O. Smith for a water heater capable of providing ample hot water to their hotel. It’s no simple task to supply hot water all day, every day, to a hotel with 85 rooms, a kitchen and multiple commercial laundry facilities. But for A. O. Smith, it was the perfect opportunity to showcase the power of the CHP-120 Fully Integrated Commercial Heat Pump Water Heater (HPWH).

The hotel chose to install four CHP-120 HPWH units—all of which function as part of a single fully integrated water heating system. It was critically important to the specifying engineer that the system be integrated as it makes installation significantly easier and is more cost-effective for the hotel.

“I prefer the CHP-120 model’s integrated system because it makes installation and piping easier than other competitive technologies,” said Peter Yoon, lead specifying engineer and owner of American Power Solutions. “The CHP-120 unit is more compact, which means our team does not have to worry about the typical mechanical room space constraints associated with an average commercial unit. We also do not have to worry about additional space for insulation or the need for a large pipe for the system, which makes my job very simple and easy.”

“It takes two days to install the units, with only 10 hours of water shutoff required. After those ten hours of work, your machine will be set to run,” noted Yoon. “There is not much maintenance needed except a filter replacement every year or every other year, so I love it.”

Features & Benefits:

- Industry-leading 4.3 Co-efficient of Performance (COP)

- ENERGY STAR®-certified

- Heat pump technology provides a more energy-efficient way to heat water with electricity

- Integrated 119-gallon tank enables heat pump to operate more frequently, saving money

- Three operating modes (Efficiency, Hybrid, and Electric) maximize efficiency while meeting specific hot water demands

- First-hour delivery exceeds 194 GPH

- Dual 6 kW heating elements provide additional heating capability for periods of high demand

- Maximum water temperature of 150° F in Efficiency and Hybrid modes, and 180° F in Electric mode

- Large touchscreen LCD display allows for mode selection, provides run information, and includes troubleshooting alerts and detail

Beyond improving the installation process, the CHP-120 HPWH provides the hotel with incredible cost savings on energy. The CHP-120 unit is four times more efficient than a standard electric water heater, saving the hotel up to $3,000 per unit on their annual electric bills. The CHP-120 does this by moving heat from the surrounding air rather than creating heat, allowing it to run at an industry-leading 4.3 Coefficient of Performance (CoP).

The CHP-120 HPWH comes with three different operating modes for maximum efficiency. The three operating modes (Efficiency, Hybrid, and Electric) allow facility managers to adjust as needed to meet the hotel’s varying hot water demands. Facility managers can easily switch between modes due to the CHP-120 unit’s large touchscreen LCD display, which allows for mode selection, and displays run information, including troubleshooting alerts and details. Dual 6 kW heating elements integrated into the unit provide additional heating capability for periods of high demand. This feature ensures that even when the hotel reaches maximum capacity, it can still supply ample hot water to customers, even those staying on the highest floors.

“We used to get customer complaints about not getting hot water on the higher floors of the hotel, but since installing A. O. Smith’s CHP-120 units there have been no customer complaints,” said the hotel manager. “The hot water on the first floor is the same temperature hot water that guests experience on the third floor of the hotel.”

In addition to improving the guest experience, the CHP-120 unit also qualifies for significant utility rebates in the state of California. Payback time on the investment of installing a unit is expected to be just under two years.

“With the current rebate program, it’s almost cost-free to the customer,” said Yoon. “When replacing an old boiler, the investment in new technology is typically the biggest barrier, but with the CHP-120 HPWH we received a big rebate upfront. California has aggressive energy savings goals, so they provide generous rebates on high-efficiency technology like the CHP-120 model. We received $20,000 in rebates for each unit that we installed at the Spark Hotel.”

“Going from a gas-fired water heater to the CHP-120 HPWH, the savings are dramatic. Customers could be wasting thousands of dollars a year by not making the switch,” said Anthony Sun, Delco salesman. “Once the CHP-120 unit is installed, it can run in efficiency mode by using just the compressor, the cool air and the hot air in the room to heat the water, saving the hotel money and energy.”

Find more information about the CHP-120 HPWH and other products at www.hotwater.com.

https://vimeo.com/1012594655 In today’s edition, we’ll talk mandates on circulator efficiency as we welcome back Taco’s John Barba. We’ll scratch the surface with heat pump water heaters, and Eric Aune talks about our weekly podcasts, and a cool incentive from Navien Read more

In today’s edition, we’ll talk mandates on circulator efficiency as we welcome back Taco’s John Barba. We’ll scratch the surface with heat pump water heaters, and Eric Aune talks about our weekly podcasts, and a cool incentive from Navien.

https://vimeo.com/1008155465?share=copy On this week’s update we address the fear of Friday the 13th, chat with AHR Expo director of marketing Nicole Bush about the AHR Expo 2025 in Orlando in February, and highlight Taco After Dark with Joha Barba, Taco Comfort Solutions’ director of training. We finish up with sharing the latest Make Trades Great Read more

On this week’s update we address the fear of Friday the 13th, chat with AHR Expo director of marketing Nicole Bush about the AHR Expo 2025 in Orlando in February, and highlight Taco After Dark with Joha Barba, Taco Comfort Solutions’ director of training. We finish up with sharing the latest Make Trades Great Again and Appetite For Construction podcasts and how to connect with Mechanical Hub Media on ideas and topics that resonate in the industry. Make it a lucky Friday the 13th!

Energy Poverty

Energy Poverty