Prioritize Clear, Responsive Communication Streamline Dispatch With Prepared Systems Arrive Ready, Assess Quickly Prioritize Safety — Yours and Theirs Maintain Boundaries and Structure Keep Records and Follow Up Emergency Work, Professional Execution For professional tradesmen, after-hour emergency calls come with the territory — whether it’s a burst pipe at 10 p.m., a furnace that dies during a snowstorm, or an electrical Read more

Industry Blogs

Table of Contents

For professional tradesmen, after-hour emergency calls come with the territory — whether it’s a burst pipe at 10 p.m., a furnace that dies during a snowstorm, or an electrical outage in the early hours. These situations require quick thinking, professionalism, and a clear system to ensure both customer satisfaction and personal well-being.

Prioritize Clear, Responsive Communication

When someone reaches out after hours, they’re likely already stressed. Your job is to respond with clarity and empathy. Set up a professional voicemail or phone routing system that directs emergency calls to the right technician or after-hours line. Use automated text or email confirmations to assure clients their request has been received.

When answering the call directly, focus on tone. Calmly explain the process and provide an estimated response window. Confirm the address, details of the problem, and whether it’s a true emergency. Some issues — like a slow drain or a noisy furnace — can wait until morning, and your role includes helping the client make that call.

Streamline Dispatch With Prepared Systems

Efficiency hinges on preparation. Maintain a system for managing after-hour service calls that includes clear protocols for dispatch. Whether you’re a solo operator or part of a larger team, knowing who’s on call and when helps eliminate confusion. A shared calendar, an internal messaging tool, and a well-organized CRM can keep your system running smoothly.

Have a pre-packed service vehicle or tool bag ready with the essentials you’re most likely to need on an emergency call. Make sure parts, PPE, and lighting are readily accessible.

Arrive Ready, Assess Quickly

Once you’re on-site, time and professionalism matter. Greet the client confidently, explain your approach, and begin with a quick assessment of the problem. Clients value tradesmen who can outline the issue, explain risks, and provide a short-term fix or containment strategy if a full repair isn’t possible until morning.

Bring the same attention to detail you would during a regular-day call. It’s easy to let fatigue or stress cut corners during late-night jobs, but it’s your consistent professionalism that builds loyalty and trust.

Prioritize Safety — Yours and Theirs

Working outside of standard hours introduces unique risks. Always ensure the work environment is safe before proceeding. Poor lighting, unfamiliar areas, and hurried clients can lead to unsafe conditions. Use headlamps, wear reflective gear if working outdoors, and be cautious when entering homes or buildings alone.

Maintain regular check-ins with a dispatcher, team member, or even a family member when heading out to a call late at night. Share your schedule and expected return time. It may seem excessive, but tradesmen working alone during odd hours are at higher risk, and safety should never be compromised.

Also, ensure your licensing, insurance, and emergency preparedness protocols are current. This protects not only your physical safety but also your professional reputation.

Maintain Boundaries and Structure

After-hours calls shouldn’t become the norm unless you’ve built your business model around 24/7 service. If you’re available for emergencies, make sure clients understand the terms — including pricing, scope of services, and response time. Publish your after-hour policy on your website and confirm these details with clients before dispatching.

Boundaries protect your time, reduce burnout, and allow you to continue offering top-tier service. Set clear expectations around what constitutes an emergency and have a plan for rotating on-call responsibilities if you’re part of a team.

Keep Records and Follow Up

Documentation is just as important during an emergency as it is during regular hours. Log client concerns, your diagnosis, parts used, and any temporary or permanent repairs made. These records can be vital for warranty discussions, repeat calls, or future estimates.

After the job, consider a brief follow-up — even if it’s just a text or email. A quick check-in reassures the client and reinforces your professionalism. It’s also a prime opportunity to recommend further service if needed, such as a full inspection or planned maintenance.

Emergency Work, Professional Execution

After-hour service calls can be intense, but they’re also opportunities to prove your value. Whether you’re dealing with a heating failure, electrical hazard, or plumbing emergency, clients remember the tradesmen who show up ready, work safely, and solve problems calmly under pressure.

Consistent training, thoughtful planning, and strong communication practices will help you set your business apart in a crowded market.

Presence of Water Location of Stains, Mold, or Mildew Timing Signs of Damage Water Consumption When there are signs of water damage in a building, it can be easy to assume that the roof is the problem. Leaks are a common issue that can lie dormant and create serious damage over time, so it is important not to make Read more

Table of Contents

When there are signs of water damage in a building, it can be easy to assume that the roof is the problem. Leaks are a common issue that can lie dormant and create serious damage over time, so it is important not to make incorrect assumptions about the cause. Tradespeople who aim to provide the most effective solutions may need to collaborate with plumbers on these aspects of leaks to find the culprit and address it.

Presence of Water

Many leaks do not have any standing or dripping water to lead property owners to find the problem, but the presence of water can help identify the likely cause. Leaking pipes sometimes result in standing water, such as a small pool of water in the basement. By comparison, roof leaks do not tend to release so much water that pooling is common. Instead, property owners are more likely to see dripping water coming from the ceiling, particularly on the top floor of the building. The presence of water is a delayed symptom of a leak, calling for a prompt solution.

Location of Stains, Mold, or Mildew

Property owners often discover a leak by observing water damage in the structure, and the location provides information about the source. If left unresolved, roof leaks may result in stains in the ceiling or cause the paint on the ceiling to bubble or peel. In contrast, plumbing leaks usually cause staining near the damaged pipe, commonly under the floor or in the walls. Owners can also direct the search based on the accumulation of mold or mildew in these areas, which may show up faster than stains.

Timing

The timing of the leaking and the persistence of symptoms may provide additional insight into the cause of the leak. Roofing leaks usually only create dripping and other signs for a short period of time surrounding weather patterns. By comparison, if the skies have been clear for days but the pool of water in the laundry room keeps getting bigger, the cause likely stems from a plumbing leak. Additionally, plumbing leaks tend to result in greater water damage in a shorter period of time. Serious water damage from roofing leaks can happen, but it is a sign that happens much later in the process.

Signs of Damage

Leaks cause significant damage to a structure over time, but the location of that damage makes a difference in the approach and solution. Long term, roof leaks can weaken the roof decking and cause it to sag or even collapse in extreme situations. The roof may have other, smaller indications of damage, such as damaged shingles or leaks around the flashing. A roofing company can identify these issues quickly. For water damage resulting from plumbing, property owners should look at the floor and foundation. Cracks in the foundation, uneven or warped flooring, or unexplained green spots in the landscaping may reflect a plumbing leak. Plumbers use soil probes to assess soil moisture and detect underground leaks.

Water Consumption

Absent other visible determiners, plumbers can guide property owners to look at their water consumption. These professionals can also use tools to assess water pressure throughout the structure. A significant plumbing leak can cause thousands of gallons of water flow per hour and keep that pace until the leak is resolved or the water supply is shut down. Even minor pipe leaks may trigger hundreds of gallons of water waste per day. If water consumption appears to be consistent and appropriate for the typical uses of water on the property, a roof leak is much more likely to be the cause.

Finding the cause of a leak requires care because water leaks can create significant water damage. Mistakenly presuming that the trigger is a roof leak instead of a plumbing leak may result in costly repairs that do not actually address the problem. By working with plumbers to provide a thorough evaluation of the property, professionals can increase the likelihood of a successful fix.

Author bio: Ricky Salyers is the founder of Lane’s Contracting, a top-quality roofing, siding, and window replacement services company dedicated to providing reliable and professional solutions. Established in 2005, Lane’s Contracting serves the greater Raleigh and Fayetteville, NC areas.

Duct Systems Specifically: Why It’s a Different Ball GameFundamental Differences: What You Probably Already Know and What You Need to KnowCompatibility and Installation ConsiderationsConclusion: When to Use Which? The selection of duct system materials determines the success or failure of a project because it directly affects the structure. The general distinctions between polyvinyl chloride (PVC) Read more

Table of Contents

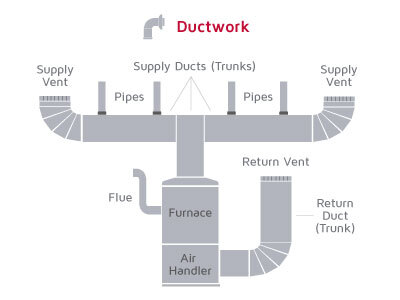

The selection of duct system materials determines the success or failure of a project because it directly affects the structure. The general distinctions between polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC) are familiar to most plumbers, yet ductwork applications require additional evaluation.

The performance of PVC and CPVC ducts under various conditions requires knowledge from plumbers who work with HVAC technicians or manage complete retrofit jobs to achieve safe, efficient, and code-compliant systems.

The article examines the essential technical distinctions between PVC and CPVC duct systems, focusing on aspects most relevant to field plumbers, including temperature resistance, chemical compatibility, ease of installation, and regulatory requirements.

Duct Systems Specifically: Why It’s a Different Ball Game

Ductwork isn’t just piping. The primary purpose of pipes is to transport water and waste, but ducts serve to distribute air and, occasionally, toxic fumes or hot exhaust. The design requirements for ductwork, including pressure and materials, differ significantly from those of standard plumbing applications.

According to Lennox, ductwork is “a system of channels used to distribute air throughout a building.” The work of plumbers requires them to handle components that need to be both lightweight and corrosion-resistant, particularly when working with exhaust in mechanical rooms and fume extraction in laboratories or industrial settings. Your responsibility will include duct connection and material maintenance throughout their entire operational period, even though you will not be responsible for constructing the whole HVAC system.

Fundamental Differences: What You Probably Already Know and What You Need to Know

Let’s get the basics out of the way. Most plumbers already know this, but here’s a refresher in the context of ductwork:

- Temperature Tolerance: PVC is rated up to 140°F, while CPVC can handle up to 200°F. If you’re dealing with warm exhaust or chemical fumes, that extra 60 degrees can be a dealbreaker.

- Chemical Resistance: Both are good, but CPVC outperforms PVC in terms of resistance to acids, bases, and corrosive gases.

- Strength & Sizing: Both come in standard duct sizes, but CPVC tends to be more rigid and stable under stress.

- Cost: CPVC is generally 25–40% more expensive than PVC. However, when a failure could result in system-wide contamination or code violations, it can pay off in the long run.

The process becomes difficult because plumbing and mechanical codes do not match. The International Residential Code (IRC) permits PVC ducts, but the Uniform Mechanical Code (UMC) bans their use in commercial buildings. CPVC passes both flame and chemical tests because of its superior ratings.

The legal status of building materials varies across different areas, so check local regulations at the city, county, and state levels. NSF 61, ASTM F441, and UL 94 V-0 ratings should be checked.

CPVC meets higher standards of fire and chemical safety, which makes it a safer choice for many duct applications. It also meets inspector requirements more effectively in high-risk or regulated environments, such as hospitals or laboratories, particularly when there is uncertainty.

Compatibility and Installation Considerations

Plumbers often overlook material compatibility checks, particularly when working with PVC or CPVC ducts that need to be connected to metals, or when using untested gaskets or sealants.

The connection of galvanized steel components to CPVC ducts through direct contact without an isolating gasket may lead to galvanic corrosion. The installation requires connectors and sealants, which are specifically designed for CPVC applications.

PVC cement does not function properly with CPVC materials. The solvent used for CPVC requires stronger properties and slower curing time.

Plumbers perform PVC cutting operations and gluing tasks. The installation process for CPVC follows the same steps as PVC but requires additional procedures:

- CPVC requires an extended curing period, which becomes more significant during cold weather conditions, thus affecting project schedules.

- The cutting process for both materials remains straightforward but CPVC requires more precise and cleaner cuts because it breaks easily.

- The use of fine-tooth blades, combined with support cuts, will prevent CPVC from cracking during the cutting process.

- Metal saw blades should be used with caution when working with plastics

In long duct runs, expansion and contraction can cause buckling or cracking.

- PVC expands about 3x more than CPVC over the same temperature rise.

- If you’re working in a facility with frequent temperature swings, CPVC offers better dimensional stability and less maintenance down the line.

CPVC generally earns higher marks for flame and smoke resistance. It typically meets UL 94 V-0 standards, which means it self-extinguishes quickly and produces less toxic smoke in a fire scenario.

This is especially important in:

- Healthcare facilities

- Schools

- Commercial kitchens

- Anywhere with life-safety code requirements

PVC, on the other hand, can produce thick black smoke and continues to burn once ignited.

While ductwork doesn’t usually carry fluid pressure, static pressure still matters—especially in exhaust or fume systems.

- PVC ductwork typically handles lower pressure (up to 10 inches of water column).

- CPVC ducts can manage slightly higher pressures, and with better rigidity, they resist collapse under vacuum.

For high-performance fume extraction or long vertical runs, CPVC has the edge.

Conclusion: When to Use Which?

Here’s the bottom line:

| Scenario | Recommended Material |

| Low-temp air movement | PVC duct |

| Chemical fume exhaust | CPVC duct |

| High-temp or steam ventilation | CPVC duct |

| Tight budget, low risk | PVC duct |

| Hospitals, labs, or code-heavy installations | CPCV duct |

| Jurisdictional uncertainty | CPVC duct |

Plumbers who perform HVAC installations or manage crossover systems should understand the distinction between PVC and CPVC ducts, as it represents essential knowledge for proper job execution. Knowledge of performance boundaries, installation characteristics, and regulatory standards for each material helps prevent both expensive callbacks and inspection failures, as well as system breakdowns in the future.

Your knowledge enables you to select appropriate ductwork with confidence while improving your collaboration with HVAC technicians and maintaining system integrity through all joints, runs, and transitions under both physical and actual pressure.

Author Bio: Mark Ligon is the marketing manager at Commercial Industrial Supply, a supplier of commercial & industrial piping, fittings, valves, filtration products, and accessories. Ligon enjoys educating businesses on the specific parts of piping systems so managers can make informed decisions.

By Jenny Benbrook Home service contractors put serious money into field service management (FSM) software and other digital tools, expecting them to streamline operations, boost profits, and create a better experience for both technicians and customers. But too often, they fall into the “perceived efficiency” trap, assuming that just having the software in place will Read more

By Jenny Benbrook

Home service contractors put serious money into field service management (FSM) software and other digital tools, expecting them to streamline operations, boost profits, and create a better experience for both technicians and customers. But too often, they fall into the “perceived efficiency” trap, assuming that just having the software in place will deliver results.

The reality? Without a strategic approach to budgeting, implementation, training, and ongoing management, that investment can become an expensive headache instead of a game-changer. Technology should serve the business, not the other way around. The right tools, aligned with business goals and managed effectively, can maximize efficiency, improve workflows, and drive real revenue growth.

Why Implementation is Just the Beginning

FSM platforms like ServiceTitan and FieldEdge are powerful tools that can transform a business—when properly set up, used, and maintained. These platforms provide insights into operations, from tracking inventory and equipment maintenance to optimizing technician scheduling and following up on unsold estimates.

Take unsold estimates as an example. Contractors spend a fortune on marketing, lead generation, and technician dispatch just to get an estimate in front of a potential customer. But if that estimate isn’t followed up on, it’s money wasted. Leveraging FSM software to track, automate follow-ups, and increase close rates can unlock millions in revenue, turning lost opportunities into booked jobs.

But software success doesn’t stop at implementation. Without a proper training plan, standardized workflows, and dedicated oversight, even a well-implemented system can fall apart. Poor training leads to inconsistent usage, undocumented workflows create confusion, and a lack of tech stack management causes inefficiencies that negate the software’s benefits. A tool is only as good as the process it supports. If you don’t have a plan, technology just becomes another expense.

Common Roadblocks to Long-Term Software Success

Many contractors struggle with software adoption and optimization due to several key challenges:

Time Commitment: Learning a new platform takes time, and so does training a team to use it correctly. Without dedicated effort, even the best software won’t deliver its full potential.

Change Resistance: Asking a seasoned team to adopt new workflows can be tough. People get comfortable with how they work, and changing that, even for the better, can be met with pushback.

Lack of a Clear Plan: Many businesses invest in software without defining what success looks like. Without clear goals, implementation lacks direction, and the software’s value isn’t fully realized.

No Dedicated Tech Stack Management: Software is not a one-and-done purchase, it requires an ongoing financial commitment for optimization, training, and troubleshooting. Without a dedicated resource to manage the tech stack, inefficiencies and outdated workflows can creep in, reducing ROI.

Overwhelm from Too Many Tools: Contractors are drowning in technology options, with too many tools and no strategy. The greatest risk isn’t adopting technology too quickly, it’s adopting it without intention.

Getting the Most Out of Your Investment

To avoid these pitfalls, contractors should approach software implementation and long-term success with a structured plan. Here’s how to start:

Set Specific Goals – Identify what you want to achieve with your software. Are you trying to increase technician efficiency? Reduce inventory waste? Close more estimates? Improve customer communication? Define success in measurable terms.

Dedicate Financial Resources – Contractors should allocate 2-5% of projected annual revenue toward technology. This budget should not only cover software licensing but also implementation, training, ongoing support, and a dedicated internal or external resource to manage the tech stack. A clear roadmap prevents wasted time and money. Technology adoption should be intentional, seamless, and impactful.

Develop a Standardized Training Plan – A good implementation won’t matter if your team doesn’t know how to use the software correctly. Learning technology is not a one-and-done activity. Establish a structured training process, provide documentation, and offer continuous learning opportunities to keep employees up to speed.

Document and Maintain Workflows – Standardized processes ensure that every team member is using the software consistently. Powerhouse Consulting Group provides a structured, step-by-step approach to technology adoption with a technology playbook to ensure proper implementation, set expectations, process documentation, training, and more.

Invest in Ongoing Optimization – Success requires ongoing optimization, not just a one-time setup. Technology changes daily, and businesses need structured validation, tracking performance, optimizing workflows, and driving measurable results over time.

Why Professional Guidance Pays Off

Contractors don’t expect customers to install HVAC systems or electrical panels without professional expertise, so why should software be any different? FSM consultants spend thousands of hours mastering these platforms, learning the best configurations, workflows, and integrations to maximize their value.

Trying to implement a major system without expert help is like wiring your house without an electrician. You might get some lights to work, but it won’t be safe, efficient, or built to last. Powerhouse Consulting Group is the trusted guide for technology adoption, ensuring that tools are used efficiently and effectively. We don’t just vet and implement tools; we teach contractors how to maximize their value.

Final Thoughts

The future of the trades isn’t just about fixing what’s broken, it’s about anticipating what’s next. The industry is shifting toward data-driven decision-making, and contractors who strategically implement technology now will lead in the next 5-10 years. Investing in technology isn’t just about tools, it’s about building a scalable business.

Powerhouse isn’t just a consultant; we are a strategic partner helping contractors scale and thrive. Our hands-on, business-first approach ensures that contractors get real value from their technology investments. There is no easy button, but contractors who put in the work and follow the right process will build sustainable, profitable businesses.

Jenny Benbrook is the founder and CEO of Powerhouse Consulting Group. Drawing from more than 20 years of experience in the skilled trades, Jenny provides strategic coaching and consultation for home service businesses seeking to make the most of their software investments. Powerhouse Consulting Group is the first and only ServiceTitan Titanium Partner, and also provides in-depth expertise regarding FieldEdge. More information is available at mypowerhouse.group.

Tracking down leaks quickly and accurately has always been one of the biggest challenges in plumbing. Traditional methods often involve trial and error, cutting into walls or floors just to locate the problem. Not only is this time-consuming, but it also leads to unnecessary property damage. Fortunately, professional plumbers now have access to advanced leak Read more

Tracking down leaks quickly and accurately has always been one of the biggest challenges in plumbing. Traditional methods often involve trial and error, cutting into walls or floors just to locate the problem. Not only is this time-consuming, but it also leads to unnecessary property damage. Fortunately, professional plumbers now have access to advanced leak detection tools that make the process faster, more precise and far less invasive.

Today’s modern techniques eliminate guesswork, allowing tradesmen to identify leaks before they cause significant damage. Whether working in homes, businesses or large-scale municipal plumbing systems, staying ahead of these advancements gives professionals the edge they need.

Why Advanced Leak Detection is a Game-Changer

Integrating advanced leak detection tools into daily operations offers plumbers a major advantage. These cutting-edge technologies help tradesmen:

- Diagnose Leaks Faster: Finding leaks quickly leads to faster repairs and higher customer satisfaction.

- Minimize Property Damage: Non-invasive techniques prevent unnecessary destruction of walls, floors and other structures.

- Reduce Costs: Early leak detection prevents severe water damage, reducing repair expenses for homeowners and businesses.

- Build a Stronger Reputation: Offering state-of-the-art solutions positions plumbers as industry leaders and trusted experts.

For plumbing professionals looking to improve efficiency, accuracy and customer trust, investing in these technologies is a smart move.

Innovations in Leak Detection

Thermal Imaging Cameras: Finding Leaks Without Damage

Thermal imaging has changed the way leaks are detected, allowing plumbers to locate hidden moisture without cutting into walls or floors. These cameras detect temperature variations, highlighting areas where water is escaping.

By speeding up diagnosis and reducing property damage, thermal imaging improves efficiency and prevents minor leaks from becoming costly disasters. Whether dealing with radiant heating systems, concealed pipes or underground water lines, this non-invasive technology provides a smarter way to pinpoint leaks.

Acoustic Leak Detectors: Finding Leaks by Sound

For pressurized plumbing systems, acoustic leak detectors provide unmatched precision. These tools use sensitive microphones to amplify the sound of water escaping from pipes, even when hidden behind walls or underground.

Acoustic detection reduces disruption by identifying leaks without unnecessary digging. It’s highly effective for residential plumbing, gas lines and large-scale municipal systems, where early detection prevents excessive water loss and expensive repairs.

Drone Inspections: Reaching New Heights in Leak Detection

Drones equipped with high-resolution cameras and infrared sensors are changing large-scale plumbing inspections. They provide detailed images of rooftops, water mains and underground systems, helping plumbers detect leaks faster.

By eliminating risky manual inspections and improving accuracy, drones enhance maintenance efforts while reducing downtime. Municipal water departments, industrial facilities and commercial properties are already benefiting from this cutting-edge approach.

Hydrostatic Pressure Testing: Detecting Leaks in Water and Sewer Lines

Hydrostatic pressure testing is a powerful tool for detecting leaks in water and sewer lines. By pressurizing a pipe system with water and monitoring pressure levels, plumbers can quickly determine if there is a leak. If the pressure drops, it signals a problem in the system.

This method is highly effective for testing underground pipes, slab leaks and sewer lines without unnecessary excavation. By identifying leaks early, hydrostatic testing helps prevent extensive damage and costly repairs.

Smart Leak Detection Sensors: Real-Time Monitoring for Early Detection

Smart leak detection sensors are revolutionizing the plumbing industry by providing real-time monitoring for homes and businesses. These sensors are installed near potential problem areas – such as under sinks, near water heaters and along pipelines – to detect moisture and alert homeowners or maintenance teams immediately.

With Wi-Fi connectivity and app-based notifications, these sensors provide an added layer of protection by catching leaks before they become major issues. They are particularly useful in commercial buildings, apartment complexes and industrial facilities where early detection can prevent significant water damage and financial loss.

Smarter Leak Detection for Modern Plumbing

Finding leaks no longer has to mean guesswork and unnecessary damage. With smarter, more precise detection methods, plumbers can diagnose issues faster, cut down on costly repairs and provide a seamless experience for customers. These advancements aren’t just about efficiency – they’re about setting a higher standard for service.

By embracing cutting-edge technology, plumbers can stay ahead of the competition, build trust with clients and tackle even the toughest leaks with confidence.

AUTHOR BIO: Leslie Erickson is the Marketing Manager at Air Mechanical. She has been working for Air Mechanical for most of her life and specializes in marketing. She is dedicated to bringing customers the best experience possible for their family and their homes.