JM-1000 X Mini-JetEasy PeasyWhat Customers Say JM-1000 X Mini-Jet The JM-1000 X Mini-Jet™ from General Pipe Cleaners, an upgrade to the toolbox jetter, offers a more efficient motor and a new balanced design. The lightweight, compact Mini-Jet™ provides 1500 psi of cleaning power, yet weighs just 23 lbs. Ideal for clearing clogged sinks, tubs, and laundry Read more

Toolbox

Table of Contents

JM-1000 X Mini-Jet

The JM-1000 X Mini-Jet™ from General Pipe Cleaners, an upgrade to the toolbox jetter, offers a more efficient motor and a new balanced design.

The lightweight, compact Mini-Jet™ provides 1500 psi of cleaning power, yet weighs just 23 lbs. Ideal for clearing clogged sinks, tubs, and laundry drains, the toolbox jetter clears grease, sand, and ice from 1-1/2″ to 3″ lines up to 50 feet long.

Easy Peasy

The JM-1000 X is easy to carry to and from the job. The pump and motor are centered in the metal case, allowing the jetter hose, integral stainless steel water supply hose, and power cord to wrap neatly around it to create an ergonomically balanced unit.

Designed to resist jobsite abuse, the jetter’s pump and motor assembly are safely contained in a rugged, metal diamond-plate case that can easily be stored in a small space on a truck.

This powerful little water jet hits the stoppage with high-pressure, wall-to-wall water spray–and flushes it away. Vibration helps slide the hose around tight bends and farther down lines.

What Customers Say

“Our customers have found that our new JM-1000 X Mini-Jet is perfect for spot-clearing kitchen stoppages,” said Angela Grieb, National Sales Manager. “It’s a tough little tool, and its versatility and compact size make it great for one-man operations.”

The portable JM-1000 X Mini-Jet includes a Super-Flex™ high pressure jet hose, four-piece nozzle set, and water supply hose. An optional stainless steel braid jetter hose with Teflon core is available for even greater cleaning power.

For more information, visit drainbrain.com/jets

Sign up for our FREE weekly newsletter, https://mechanical-hub.com/enewsletter/

COMBI-BOILERS provide endless hot water as well as whole home heating for all size homes. They prioritize hot water over hydronic heating. With Standard Hot Water Recirculation, hot water can be achieved but whole home heating is sacrificed. The solution is the AquaMotion Combi-Guard, the pat. Pending innovative New Control. How is this accomplished? With Read more

COMBI-BOILERS provide endless hot water as well as whole home heating for all size homes. They prioritize hot water over hydronic heating. With Standard Hot Water Recirculation, hot water can be achieved but whole home heating is sacrificed. The solution is the AquaMotion Combi-Guard, the pat. Pending innovative New Control.

How is this accomplished? With the Combi-Guard, the homeowner can set the “ON and OFF” times tailored to the size of his system. General Guidelines provided for these settings allow the homeowner to fine tune his heating system.

These “ON/OFF” times determine how quickly the AquaMotion recirculation pump runs to deliver hot water to every fixture (ON), as well as how long the recirculation system sits dormant (OFF). Once these settings are dialed-in, the homeowner then sets the desired time interval(s) when he wishes to have instant hot water via the built-in timer. With Combi-boilers, the homeowner never has to sacrifice home heating. Set it and forget it.

Use the AquaMotion Comfort Control TM App and go to Control Combi-Guard from any mobile device, including tablets and smart phones. It uses the same technology as the AquaMotion Watchdog WIFI Smart Controller™

This APP is used to program AquaMotion Hot Water Recirculation kits for maximum water, energy savings and comfort. The SMART controller plugs into a grounded wall socket. It is paired with the APP. The pump cord plugs into the controller. Mobile device users prefer this method of scheduling hot water needs and heating comfort.

The WATCHDOG Smart Controller AMK-SC is compatible with Android and Apple iOS mobile devices. This product requires 2.4 GHz WIFI connection.

The entire pump kit number is AMH1K-RODRNCG. The AMH1K-RODRNCG is sold through plumbing and heating wholesalers and E- Commerce.

AquaMotion is the Innovation Leader in Hot Water Recirculation with kits for tanks, tankless, outdoor tankless, pumps and pressure boosters. AquaMotion products are covered by 17 Patents.

Fujitsu General America introduces the all-new Infinite Comfort Pro App, a powerful project planning and system selection tool for HVAC professionals working with AIRSTAGE H-Series and J-Series products.The app delivers a streamlined, intuitive interface for selecting systems, managing projects, and accessing the latest technical and marketing resources. It supports both new R-32 products and legacy Read more

Fujitsu General America introduces the all-new Infinite Comfort Pro App, a powerful project planning and system selection tool for HVAC professionals working with AIRSTAGE H-Series and J-Series products.

The app delivers a streamlined, intuitive interface for selecting systems, managing projects, and accessing the latest technical and marketing resources. It supports both new R-32 products and legacy R-410A systems, offering seamless compatibility across product generations.

Users can explore the latest multi-zone system combinations, browse expanded accessory options, and leverage advanced features like a line-set checker that validates piping lengths and system logic. The app also includes an intuitive project management suite that enables users to create, edit, and share project files with ease.

Enhanced filtering options let users search by unit type, capacity, efficiency, and other critical specs. A comprehensive Resource Hub simplifies access to product registration, warranty lookup, marketing tools, and technical documentation.

Contractor support tools, including direct links to a rebate finder and contractor locator, are integrated into the platform, while the app’s one-click access to brochures, application guides, and client-ready reports enhances productivity in the field.

The Infinite Comfort Pro App is now available on the iOS App Store, Google Play, and via web browsers. To learn more, contact your local Fujitsu representative, distributor, or regional sales manager.

NIBCO INC. announces its first-ever partnership with DEWALT on a 24kN tool and jaw kit that is designed to crimp NIBCO PressACR fittings. The tool has been optimized for one-handed use and the jaws have a gray galvanized coating to provide corrosion protection. The products will be sold by DEWALT and include the following: A tool Read more

NIBCO INC. announces its first-ever partnership with DEWALT on a 24kN tool and jaw kit that is designed to crimp NIBCO PressACR fittings.

The tool has been optimized for one-handed use and the jaws have a gray galvanized coating to provide corrosion protection. The products will be sold by DEWALT and include the following:

- A tool kit that consists of the press tool (DCE210D2), USB-C cable, shoulder strap, charger and two 20V MAX® DCB203 2.0 Ah batteries.

- PressACR jaw kit (DCE214K) which includes one each of the following jaws sizes: ¼”, 3/8″, ½”, 5/8″, ¾” and 7/8″.

PressACR end connections reduce installation time while the patented interior groove design and HNBR seal make them suitable for high pressure HVACR applications rated up to 700 psi.

“At DEWALT, we are committed to providing the best end-to-end workflow solutions for the heating, cooling, and plumbing trades,” said Justin Burke, senior product manager, DEWALT. “Launching the DEWALT Compact Jaws for NIBCO’s PressACR system is another step in providing world class solutions for the HVACR trades.”

“We’re excited to partner with DEWALT for the first time to bring this 24kN tool and jaw kit, designed for compatibility with our PressACR line, to the market,” said Marilyn Morgan, senior product manager-fittings, NIBCO. “NIBCO’s high-quality PressACR fittings offer contractors a more efficient, reliable solution for high-pressure HVACR installations.”

Made in Stuarts Draft, Va., of the highest quality, globally sourced pure copper, PressACR fittings meet stringent certification and compliance standards that support the higher-pressure requirements of HVACR systems.

For more information, visit nibco.com/pressacr.

The new Webstone FTG fittings feature a DZR brass union with a Type K copper tailpiece, allowing you to connect any press or sweat copper fitting or device directly onto a G-Series body. These fittings are a practical addition to any G-Series kit. These fittings are certified lead free and available in sizes ½” through Read more

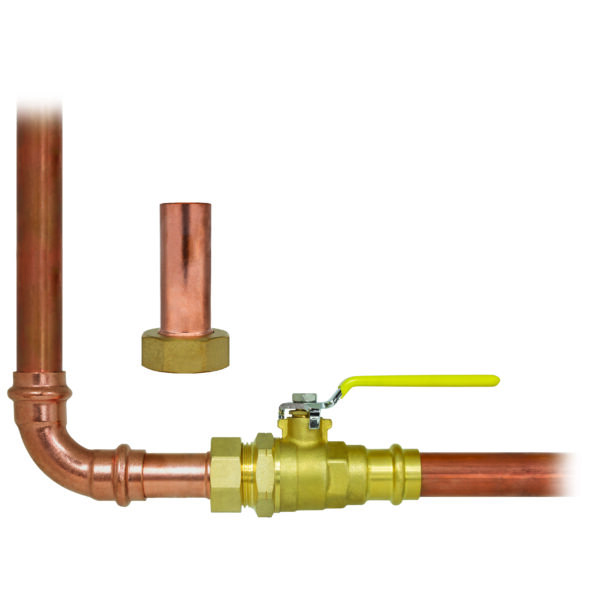

The new Webstone FTG fittings feature a DZR brass union with a Type K copper tailpiece, allowing you to connect any press or sweat copper fitting or device directly onto a G-Series body. These fittings are a practical addition to any G-Series kit.

These fittings are certified lead free and available in sizes ½” through 2”, including reducing options.

For more information on Webstone’s G-Series product line, visit: www.nibco.com/brands/webstone/g-series/