Let’s face it. The way that Americans shop has changed. The COVID-19 pandemic has been a boon to online retailers and delivery services. Consumers who are leery about walking into a store will buy online for delivery or order it for curbside pickup. You and your family members probably ordered something online today. There’s a Read more

Industry Blogs

Let’s face it. The way that Americans shop has changed. The COVID-19 pandemic has been a boon to online retailers and delivery services. Consumers who are leery about walking into a store will buy online for delivery or order it for curbside pickup. You and your family members probably ordered something online today. There’s a temptation to let that drift into your professional life as well, but it may not work for securing the brands or quality of products that you are used to securing and providing to your customers.

Plumbing wholesalers must acknowledge that home improvement retailers are not going to go away. But both plumbing wholesalers and plumbing contractors must realize that they, themselves, are offering their customers so much more than a product. Anybody can offer a product for sale but wholesalers and contractors succeed by offering services that the competition either cannot or will not offer.

The big box stores are doing their best to offer services and incentives that mimic those offered by plumbing wholesalers. The issue for now, however, is they can only offer these in a general, corporate way, while the local wholesaler takes great pride in knowing the personality and needs of its contractor customers. A wholesaler knows who those contractors are, what their specialties are, what they want. They know what their customers buy, and they don’t have to look it up in their computer records because they and their counter people have an ongoing business relationship with their contractors. They interact with contractors and their plumbers all the time and deliver to their shops or jobsites.

Another avenue for wholesalers to create relational equity and provide value is to provide on-site training, by leveraging manufacture resources. Heating and plumbing manufacturers and wholesalers realize that one of the best ways to form lasting relationships with contractors is to offer technical training. Contractors will sell products with which they are familiar and comfortable; that’s how they make a profit. If a product is difficult or confusing to install or results in call-backs, they won’t sell it. Homeowners are doing their homework online on space and water heating systems and, while they are well-informed, they certainly don’t know as much as contractors. Contractors must be able to demonstrate a thorough knowledge of their products so that they can discuss, with confidence, why their customers should want to buy what they’re selling.

The way to get that recommendation is through training. Plumbing wholesalers should be set up to offer training, both in-person and virtually. Most training has become virtual because of COVID-19 and we will undoubtedly see some of that continue in the years ahead. It’s incumbent on wholesalers to have the equipment to record video training or to livestream training to their customers. But they should also invest in a proper classroom setup in their facilities in which manufacturers’ trainers and reps can conduct in-person training.

Distributors should emphasize the inventory management and financing services that they offer. They can help contractors keep up with code changes and changes to licensing requirements in their area. They can inform contractors about manufacturers’ rebate offers or give them advice on postcard mailings and other marketing tactics. Everything you do and every bit of information you can provide to help your contractors creates that level of “stickiness” that makes it hard for them to want to go elsewhere.

When thinking about the differences between a local plumbing wholesaler and a big box store, contractors should think about the differences between themselves and a big box store. Any homeowner can walk into a big box store and buy plumbing products. Some will install what they buy on their own and others will reach out to their handy friend. The biggest trend here, however, is that consumers are walking into the box store to buy their plumbing and HVAC needs and the installation that goes with it. It’s one-stop shopping for the consumer. The box stores have swung away to a degree from the DIYers and have now positioned themselves as the seller and installer for today’s consumers.

But what wholesalers offer is individualized support and personal relationships. When one of a contractor’s customers has an emergency on a Saturday night, the contractor has the cell phone number of the wholesaler manager who’s going help them get the replacement equipment they need. Some wholesalers even have formal 24×7 programs to address both residential and commercial emergency installations or repairs. Try doing that through a big box store. And when it comes to a homeowner installing his new bathroom or kitchen, some wholesalers have showrooms they can walk through to find unique fixtures that they will never be able to get in a retail environment.

Bradford White continues to count on wholesale distribution to support the professional specification and installation of its products. Our distributors bring a level of service and support to the equation that keeps contractors coming back and helps them better serve the end-user.

GUEST BLOG BY: Matt Kozak, Vice President – Sales for Bradford White Water Heaters.

GUEST BLOG BY: Matt Kozak, Vice President – Sales for Bradford White Water Heaters.

A graduate of Loyola College in Baltimore, Matt joined Bradford White in 2007 as a regional sales manager in the southeast.

He progressed to become director of sales for the Eastern U.S. and now oversees sales management and business development teams as vice president of sales for the U.S.

Matt has been actively involved in industry organizations such as the American Supply Association (ASA) and the Association of Independent Manufacturers’/Representatives, Inc. (AIM/R).

Oh boy, 2020 was a wild ride! Combining a scary virus and a quarantine led many homeowners to consider worst-case scenarios and what they can do to avoid them. I don’t know about you, but many plumbing service providers experienced some of their busiest months during these “unprecedented” times. In fact, our team at John Read more

Oh boy, 2020 was a wild ride! Combining a scary virus and a quarantine led many homeowners to consider worst-case scenarios and what they can do to avoid them. I don’t know about you, but many plumbing service providers experienced some of their busiest months during these “unprecedented” times. In fact, our team at John the Plumber experienced newfound success in taking a little extra time to educate my customers on unique options for their homes and maybe as we move into 2021, you can too.

I’m not talking about upsells and pushy marketing. While many valued customers only want the service they requested, many others don’t know what’s out there, and they don’t think to ask. After all, in the eyes of many homeowners, the plumbing industry hasn’t changed.

But could they be wrong! Possibly, so take a minute to explain some new and cool fixtures with a client with which you’ve built a rapport? A good sale is one where both the buyer and seller win. This will separate you from being “just” a plumber to being a service provider who adds value. Value is the name of the game, folks!

A Bidet Installation or Bidet Attachment

We can laugh about it now, but it wasn’t long ago that many of us and our neighbors were flocking to the store and buying up all the toilet paper reserves. It was an eye-opening experience! Most of us never expected that toilet paper would be the first thing to go in an apocalypse.

Many businesses slowed down during the quarantine, but we were lucky. We continued to service homes throughout the entire thing, and we took advantage of the opportunity to offer our customers a Bidet installation. Spoiler alert – it was a smart move.

Not only have the locals experienced the fear of depleted toilet paper stock, but we live in a new age of hygiene. Many people feel dirty after using the toilet for an extended period and feel uncomfortable with being intimate afterward without washing up.

Save your customers from this anxiety! Offer them a bidet so they can conveniently shower their nether regions after sitting on the throne.

Not everyone will bite, but the ones who do will appreciate you. I can’t think of anyone who has installed a bidet and regretted it. The plumber who offered it left a mark on their customer and built a relationship. That’s how you earn a customer for life!

A Tap-Activated or Touchless Faucet Upgrade

Have you ever handled raw meat then washed your hands? I bet you have. May I ask if you sanitized the faucet handle afterward? Most people don’t! Not after every use, anyway.

Whether you’re spreading raw meat germs on the kitchen faucet handle or spreading downstairs germs on the bathroom faucet, the result is the same: you’re spreading germs without thinking about it.

Admittedly, many of us now keep Lysol wipes nearby these days. But do you want to use a Lysol wipe every time you wash up?

We’ve been suggesting touchless or tap-activated faucets instead of a standard faucet installation for many months, and we’ve added value to many homes.

They’re not the cheapest option. We all know that. But the ability to activate a faucet by tapping it with your elbow is worth the extra cost for many people. People are willing to pay if they see the value! So the next time you’re in the plumbing supply store, you should ask about the handsfree faucet options! Many of your customers might be interested.

A Water Heater Booster

Growing your family or adding more appliances that use water means more hot water usage. While upgrading to a larger hot water tank or a Tankless Water Heater might be the right solution for many people, some of your customers might not yet be ready to replace their current unit.

A less expensive solution to increased hot water needs is a Water Heater Booster. Water heater boosters connect to your gas or electric hot water tank and boost the heat as needed. Some models connect to the water heater output, while other models can connect to the inlet. As hot water is used, cold water replenishes the water supply and mixes with the tank’s remaining hot water. Over an extended period of use, the tank’s water temperature will drop and require time to recharge.

Water Heater Boosters work by heating the water when it senses a drop in temperature. In some models, the hot water usage capacity nearly doubles! For a fraction of the cost of replacing a water heater system, water heater boosters might be the solution you’re customers have been hoping to find.

A Water Purifier

We live in the new age of organic. Many people are concerned about chemicals in this and pesticides in that. Water supply is no different. People want clean and safe water, free of anything designed to destroy life in the water supply.

While most cities in the country provide adequate water quality, it isn’t good enough for everybody. If you notice empty water bottles around your customer’s home, they may be interested in a water purifier!

Water purifiers, like Reverse Osmosis systems, filter out impurities and pathogens from the water before it reaches the tap. It doesn’t take long before a Reverse Osmosis System pays for itself in bottled water savings.

Anyone who prefers bottled water, grows their own food, buys organic, or generally cares for their body may be interested! While your customer might not be interested during the pitch, if they come around in the future, you’ll probably be the first person come to mind!

Turning a Plumbing Rough-In into an Indoor Garden

Speaking of growing your own food… These days, many people are gaining interest in supplying their own food. The pandemic hysteria proved that it doesn’t take long for a bad situation to change for the worse. Having the ability to provide your own food can save money, offer higher quality and more nutritional ingredients, increase independent sustainability, and it’s just cool!

Since the concept of “Indoor Micro Gardens” has begun catching on, some plumbers have found success in providing services related to indoor gardens.

Converting a basement rough-in into an accessible water supply for a hydroponic gardening system is a unique service that few people offer. However, it doesn’t come without its drawbacks as new indoor gardeners may have many questions which they wish to ask you. Our solution is to suggest books and online references on the subject, then be on our way. Converting a rough-in into a hydroponic water supply is easy, unique, and separates you from everyone else.

Garbage Disposal

Fruit flies are the worst, aren’t they? But we’ve all been there. Maybe you threw a banana peel in the garbage, or you keep a green bin under the sink. Whatever the case, fruit flies are annoying and gross.

Garbage disposals can help! Disposing of waste into a garbage disposal system eliminates the food supply for fruit flies and other pests. It might not be what comes to mind when people think about garbage disposals, but it could be a valuable suggestion from a plumber!

Plumbers may not even come to mind when potential customers think about garbage disposal. Save your leads from unintentionally choosing a different service provider by educating them of your abilities and products. You may not be the hero they deserve, but you’re the hero they need.

Waterline Hookup for new appliances

Any kitchen you service lacking a dishwasher may be a lead. Many young adults grow up with dishwashers, then move out and wash their dishes like a peasant! I’m just kidding around, but I do believe that most people would choose to have a dishwasher than live without one.

So why not offer to run the water supply lines? Many people without dishwashers have considered installing one eventually. But it’s one of those things that gets pushed off again and again. Help them get what they want. The worst thing that can happen is they’ll say no!

Backflow Backwater Valve

If your customers have ever experienced a sewer backup, they’ll be interested in a backwater valve installation. It’s an inexpensive protective device that can save thousands of dollars in maintenance! While a Backflow Backwater Valve installation may not be the most lucrative service that a plumber can offer, it is a top contender for value-added services. Being of better value than your competitors will motivate many customers to spread the word about you. Every customer you earn for free is money saved on marketing and lead generation.

Help them help you! Be the best plumber by adding the most value and educating your customers on how you can help them. Afterward, all you have to do is ask for a review, and you’ve finished a job well done!

Jake Romano is a Project manager for John The Plumber, an Ottawa-based plumbing service provider. Since 2006, we have been offering Ottawa residents a higher level of customer service and satisfaction. These days, we’re proud to offer plumbing services in several Ontario cities as our brand continues to grow. Here’s to another fifteen years!

Jake Romano is a Project manager for John The Plumber, an Ottawa-based plumbing service provider. Since 2006, we have been offering Ottawa residents a higher level of customer service and satisfaction. These days, we’re proud to offer plumbing services in several Ontario cities as our brand continues to grow. Here’s to another fifteen years!

Throughout the years, the forces that have driven the plumbing industry to change and improve have been diverse. From competitors trying new things, to technological advances pushing boundaries, contractors have had to adapt, or get left behind. One driving force that hasn’t always been recognized, however, is the customer. Sure, good contractors and managers have Read more

Throughout the years, the forces that have driven the plumbing industry to change and improve have been diverse. From competitors trying new things, to technological advances pushing boundaries, contractors have had to adapt, or get left behind. One driving force that hasn’t always been recognized, however, is the customer.

Sure, good contractors and managers have always taken into account that customer satisfaction is what keeps a business running, from invaluable word of mouth recommendations to the ever-profitable returning customer strategies, but the fact of the matter is that customers themselves have changed. Tech giants like Amazon and Facebook permeate every aspect of our culture and they’ve reshaped expectations so much that simply doing a good job just isn’t enough anymore.

The fact that customers expect so much from every company they interact with (even if they’re not a tech giant) has already been discussed and dissected. After all, 2020 was the year customer experience became more important than price. Now, the pressure is on plumbing and contracting companies to make sense of these expectations and find a way to implement changes. That, however, is easier said than done. How do you turn a plumbing company into Amazon?

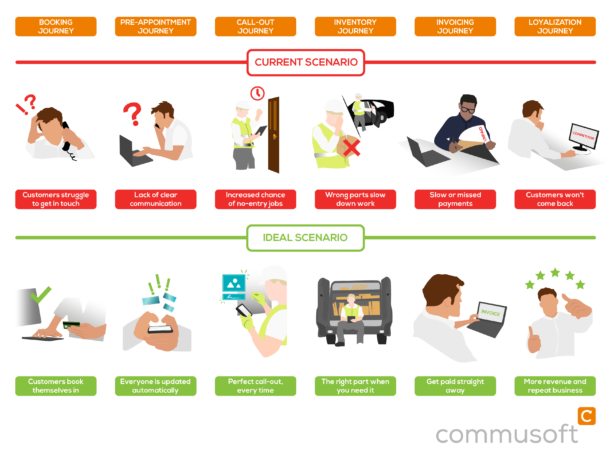

This is where customer journeys come in. And no, that’s not a typo. We do mean customer journeys, as a plural. That’s because the complete sum of interactions between a customer and a field service business is not singular; their experience is made up of many interactions that require individual attention, but ignoring this fact is an error that many managers make.

1. The customer isn’t the most important one, they’re the only one!

For example, what’s the first thing a customer has to do in order to hire you? Book an appointment, right? Well, that’s the booking journey. How many steps are there to go from needing a plumber to having an appointment scheduled? Where do you lose customers along the way? How can you remove friction so that the process is so smooth, the customer never gets a chance to change their mind?

Basically, if you can turn your booking journey into something resembling Amazon’s “1-Click Buy” button, you’ll have significantly improved your lead conversion rate. You’ll earn more money for each dollar spent on getting leads to your website, increase your chances that the customer will continue through to the next journey, and encourage re-bookings in the future.

The same applies throughout each additional journey, as highlighted in the image above. The more points of friction you have, the more negative the overall experience and that’s even if the customer’s problem was fixed! It can be overwhelming (especially to smaller businesses) to take into account every single interaction, but by mapping the customer journey, it becomes far more manageable.

For example, in the booking journey we mentioned above, most people expect to book an appointment the same way they book a dinner reservation. Therefore, an automatic booking portal is the tool you need to offer that experience. A quote? Why would they wait days for the office staff to send one, or even weeks, when they’re so used to seeing prices online?

Providing instant digital quotes will impress the customer, help upsell them on premium plans (because they can clearly see their options and the benefits shown on multiple quotes), and save your admin time.

Learn more about online portals and customer experience here!

2. How do plumbing technicians benefit from great customer journeys?

The reason customer journeys will define 2021 as well as the coming years (a bold claim, we know!) is because despite the name, rather than targeting a single shareholder, it stands as a holistic strategy for a business.

From a technician’s point of view, an easy job is one they can do as efficiently as possible. That means taking as few trips back and forth to the office between jobs (ideally none), for the customer to be aware of the visit & available when they do arrive, and finally: to be able to support any query the customer may have, all whilst in the field.

When you’re aiming to offer a smooth pre-appointment, call-out, and inventory journey to your customers, all these imply having the right tool to make your technician’s day fly by. The customer is kept up-to-date via notifications so they know to be are available, and technicians can expect to know whether the parts the installation needs are available; these are just a few of the benefits that work to make everyone’s lives easier.

3. How does your office staff benefit from great customer journeys?

Frictionless customer journeys are tightly linked to the concept of customer self-service and business automation. Much like booking a stay on Booking.com, the customer does part of the work, whilst software takes care of reminders, invoicing, and even feedback requests.

On the customer side, they’re happy because they feel in control of their experience and can get results quickly with near instantaneous confirmations every step of the way, establishing peace of mind.

The admin side is where the greatest benefits truly lie.

Software automation can’t replace office staff when it comes to complex tasks and building relationships, but it can support them to deliver their best work by removing repetitive and time-consuming parts of their day, like emailing confirmations and double-data entry. More efficient admins means you can hire more technicians, and get more work done with the same amount of resources.

4. The Takeaway

All in all, customer journeys are a complex concept and no one expects a business owner to get it perfect from the beginning. However, as we move into 2021 and learn to live with the challenges we’ve faced in 2020, it’s true that customer expectations will continue to rise, but quality customer journeys can help you face them.

Digital tools are already a mainstay of our everyday lives and Commusoft is one that strives to make remarkable customer journeys a breeze for any contracting business. If you’re looking to learn more, check out our Customer Journeys page.

Cristina Maria is a Marketing Executive at Commusoft, a job management software company, where she helps educate and empower field service businesses to deliver a remarkable customer experience.

Cristina Maria is a Marketing Executive at Commusoft, a job management software company, where she helps educate and empower field service businesses to deliver a remarkable customer experience.

Propane heating systems have an edge when it comes to comfort, efficiency, and emissions On average, more than half of a household’s annual energy consumption is used for space heating and air conditioning, according to the U.S. Energy Information Administration (EIA). Seasonal and energy-intensive uses can vary based on geographic location, home size and structure Read more

Propane heating systems have an edge when it comes to comfort, efficiency, and emissions

On average, more than half of a household’s annual energy consumption is used for space heating and air conditioning, according to the U.S. Energy Information Administration (EIA).

Seasonal and energy-intensive uses can vary based on geographic location, home size and structure, and energy sources used. Because of higher space-heating demand, homes in the Northeast and Midwest regions consume more energy on average than homes in the South and West regions, for example. Additionally, larger homes and families tend to use more energy overall than smaller households.

There are more options than ever for home heating, and there are several different factors to take into consideration when selecting the best system for your customers. Whether your customers are looking to reduce energy consumption and costs, decrease their carbon footprint, or enjoy more comfortable home heating, propane-powered systems can provide a reliable solution for homeowners across the country. According to data from the Propane Education & Research Council (PERC), more than 7.5 million households rely on propane for primary or secondary home heating.

Here are three key advantages of propane-powered systems to share with your customers next time they ask about home heating solutions.

Homeowners can save more on energy costs with propane

The efficiency of a home heating system can greatly impact its utility costs. For homeowners looking to reduce their energy consumption — and their bills — high-efficiency propane furnaces are a great choice. Propane furnaces offer best-in-class efficiency, with ratings from 90 to 98 percent. Further, ENERGY STAR-qualified propane furnaces are up to 15 percent more efficient than standard propane models and can save up to $75 in energy costs each year, according to data from PERC.

In a comparative analysis of residential heating systems, Newport Partners, LLC examined the performance of seven heating systems in 16 different locations for new and existing homes. Each system was analyzed and compared in terms of its first cost, energy cost, emissions, and simple payback period. The research revealed several cost advantages to selecting a propane furnace, including low annual energy costs. Notably, the annual energy costs of a high-efficiency propane furnace were $1,650, which is 10 percent lower than standard-efficiency ASHPs and 14 percent lower than heating oil furnaces. When used as a backup for an air- or ground-source heat pump system in the place of electric heating coils the efficiency of the systems is also improved and further protects homeowners from rising utility costs when temperatures drop.

Beyond annual energy costs, propane systems offer more competitive upfront costs and payback periods, too. High-efficiency propane furnaces typically cost less to purchase and install than heating oil and ground-source heat pump systems. Additionally, homeowners purchasing a high-efficiency propane furnace for a new home in a cold climate could recoup their initial costs in two years due to low equipment and energy costs. By contrast, it could take a homeowner more than 20 years to recoup the initial cost of a ground source heat pump system through energy savings.

Propane systems provide warmth and comfort

Comfort can often be a deciding factor for homeowners. They want systems that can provide comfortable, consistent heat. Fortunately, propane furnaces are perfect for eliminating cold pockets in a home. These systems heat air to a higher initial temperature, getting to a homeowner’s desired temperature faster and maintaining it more effectively.

Because propane-powered furnaces heat air to 115–125 degrees Fahrenheit, they make the indoor air feel warmer and more consistent than heat from air source heat pumps (ASHPs), which often supply temperatures lower than 100 degrees Fahrenheit and are more affected by cold outdoor temperatures.

Propane systems support environmentally-conscious customers

When making decisions for homeowners heating systems remember those customers are placing more of a priority on reducing their carbon footprint. One way that homeowners can decrease emissions is by having their home’s systems and appliances run on propane instead of electricity.

According to data from PERC, residential propane furnaces can emit up to 50 percent fewer greenhouse gas emissions than electric furnaces and 12 percent fewer greenhouse gas emissions than fuel oil furnaces. Further, propane-powered furnaces produce up to 35 percent fewer nitrogen oxide (NOx) emissions and 82 percent fewer sulfur oxide (SOx) emissions than electric furnaces. And in colder and mixed climates, high-efficiency propane-fueled furnaces produce at least 26 percent fewer carbon dioxide emissions compared to standard-efficiency electric air-source heat pumps. It is extremely important for you to be prepared to educate your customers about these differences and not leave them out in the cold.

To learn more about the benefits of propane heating systems, visit Propane.com/Furnaces-Boilers.

Bryan Cordill is director of residential and commercial business development for the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.

Bryan Cordill is director of residential and commercial business development for the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.

Some brands become so popular people begin to refer to all products in the category by that name, such as Kleenex or Band-Aid. Similarly, push-to-connect fittings weren’t quite as popular as they are today until Reliance Worldwide Corporation (RWC) introduced them to the U.S. market nearly 20 years ago. It revolutionized the category and made Read more

Some brands become so popular people begin to refer to all products in the category by that name, such as Kleenex or Band-Aid.

Similarly, push-to-connect fittings weren’t quite as popular as they are today until Reliance Worldwide Corporation (RWC) introduced them to the U.S. market nearly 20 years ago. It revolutionized the category and made the work of contractors and plumbers quicker, more efficient and more reliable. Now, SharkBite brass push fittings are the industry standard for push-to-connect plumbing— so much so that some people refer to fittings from other brands as SharkBite.

SharkBite’s Journey to the U.S.

After seeing the success of its push-to-connect fittings in Australia, water control and plumbing solutions manufacturer RWC introduced the fittings in the U.S. market as the SharkBite push-to-connect plumbing system in 2004. Today, SharkBite has become so popular that it is estimated a fitting connection is made every 2.5 seconds, according to the manufacturer’s data.

Fittings That Pushed the Boundaries of Plumbing Tech

Before push-to-connect technology, plumbers could only rely on soldering, gluing or using a specialized tool to connect pipes. These methods are sufficient in some cases but can be challenging when transitioning between different pipe types or installing in tight spaces.

To address these issues, SharkBite designed its push-to-connect fittings to connect different pipe types such as PEX, copper, CPVC, PE-RT and HDPE in tight spaces without special tools, crimps, glue or soldering.

Further Advancing Push-to-connect Technology

With SharkBite’s success, especially as a solution for emergency repairs and pipe transitions, RWC continued to build upon its innovations in push-to-connect technology:

- SharkBite introduced its own brand of durable yet flexible PEX pipe into North America. The pipe enables quicker leak repairs compared to rigid copper pipe and is often quicker to install in tight spaces.

- The company launched 1-1/4 in., 1-1/2 in. and 2 in. SharkBite fittings, which gives contractors who work on commercial projects the ability to work quicker using push-to-connect technology.

- SharkBite launched EvoPEX fittings. The groundbreaking PEX-only fitting system for meter-to-fixture installation allows for faster and more reliable installations on new construction jobsites.

A Connection You Can Trust

Plumbers can trust the secure fit of a push-to-connect fitting thanks to its tight-sealing o-ring, pipe-locking stainless steel grab ring and corrosion-resistant brass body. All of its parts work together to make a 3-second connection long-lasting, and the fittings require no tools, can be connected in wet lines and are compatible with multiple types of pipe.

SharkBite’s Legacy

Every new product SharkBite introduces is created to empower contractors to work smarter, not harder. By reducing installation times, SharkBite gives contractors time back that they can spend on parts of their job that require more resources, like growing their business and investing in their workforce.

Michael Kornegay is the SharkBite product manager at RWC — a market leader and manufacturer of water control systems and plumbing solutions for residential, commercial and industrial applications.

Michael Kornegay is the SharkBite product manager at RWC — a market leader and manufacturer of water control systems and plumbing solutions for residential, commercial and industrial applications.