Donations Make a Difference NIBCO INC. has donated two custom-built boiler and water heater system training boards to support hands-on education at two leading trade education institutions: Chicago Pipefitters Training Center, Local 597, in Mokena, Ill., and ABC Construction Prep Academy in Fort Wayne, Ind. Designed to promote collaboration across the plumbing and HVAC industry, these Read more

Industry News

Table of Contents

NIBCO INC. has donated two custom-built boiler and water heater system training boards to support hands-on education at two leading trade education institutions: Chicago Pipefitters Training Center, Local 597, in Mokena, Ill., and ABC Construction Prep Academy in Fort Wayne, Ind.

Designed to promote collaboration across the plumbing and HVAC industry, these builds were originally part of the Community Over Competition Build showcased at AHR Expo 2025. The initiative was led by Impetus Media with NIBCO as the title sponsor.

At Local 597, NIBCO commercial sales manager Aaron Kilburg presented the training system to Erik Bergman, apprentice coordinator. In Fort Wayne, Aaron Edds, NIBCO’s director of product management, presented the training system to Jason Sartain, instructor, and Justin Fidler, area lead instructor, at ABC Construction Prep Academy.

Donations Make a Difference

“The donation of the boiler and water heater system training board is a game-changer for our training academy,” said Justin Fidler, area lead instructor, ABC Construction Prep Academy. “It provides our students with invaluable hands-on experience, allowing them to build real-world skills in a safe, controlled environment.”

“Donations like this make a real impact in the classroom by giving our students valuable hands-on experience before they enter the field,” said Erik Bergman, apprentice coordinator at Local 597. “We’re always looking for ways to provide more practical training opportunities, and with this build, we’ll be able to use it across multiple classes, including hydronics and boiler systems.”

“These donations are part of NIBCO’s ongoing commitment to investing in the future of the plumbing and HVAC trades through enhanced training opportunities,” said Joe Choflet, vice president, sales and marketing, NIBCO. “By supporting programs like these, we’re helping ensure the next generation of professionals enters the workforce with the knowledge, confidence and hands-on experience they need to succeed.”

This effort reinforces NIBCO’s mission to strengthen the skilled trades through meaningful investments in education and hands-on learning.

Sign up for the Mechanical Hub FREE weekly newsletter, https://mechanical-hub.com/enewsletter/

ServiceTitan Partners with Associated Builders and Contractors to Empower Construction Professionals

Advanced TechnologyEmpowering Businesses ServiceTitan, the software platform that powers the trades, announced a new partnership with Associated Builders and Contractors (ABC), a national construction industry trade association. ServiceTitan is a member of ABC’s Tech Marketplace, which provides innovative digital solutions to contractor members looking to advance and grow their technology strategies, offerings and abilities. The Read more

Table of Contents

ServiceTitan, the software platform that powers the trades, announced a new partnership with Associated Builders and Contractors (ABC), a national construction industry trade association. ServiceTitan is a member of ABC’s Tech Marketplace, which provides innovative digital solutions to contractor members looking to advance and grow their technology strategies, offerings and abilities.

The addition to ABC’s Tech Marketplace underscores its commitment to advancing technology adoption across the construction industry. By combining robust, purpose-built construction capabilities with powerful, battle-tested service functionality, ServiceTitan delivers a platform for specialty contractors who do a mix of long-term projects and short-term services. Through this partnership, ABC members gain easy access to powerful tools for scheduling, billing, and real-time tracking. This initiative includes a member-exclusive benefit of three complimentary months of ServiceTitan subscription, enabling participating companies to experience its transformative capabilities firsthand. ServiceTitan aims to drive innovation and operational excellence in a traditionally underserved sector.

Advanced Technology

As a national trade association with 23,000 members, ABC is renowned for advancing key industry trends and fostering innovation. The Tech Marketplace serves as a hub for digital solutions that empower contractors to navigate complexity and deliver exceptional results. ServiceTitan’s joining the Marketplace provides ABC members with access to a comprehensive platform optimized for the unique demands of construction projects, bringing operational visibility and efficiency from the job site to the back office.

Empowering Businesses

By joining ABC’s Tech Marketplace, ServiceTitan solidifies its position as a leader in construction technology, setting new standards for what contractors can achieve with a fully integrated software platform. This collaboration signals a future where the construction industry is empowered by technology to maximize productivity and deliver superior outcomes.

For additional information, visit http://www.servicetitan.com.

Sign up for the Mechanical Hub weekly newsletter, https://mechanical-hub.com/enewsletter/

Skilled Careers Coalition Unites Industry, Educators, Policymakers and Parents on Need to Work Together to Inspire Youth, Skilled Trades, Engage Mentors, and Disrupt Dated Recruitment Practices Skilled Careers Coalition Unites Industry, Educators, Policymakers and Parents on Need to Work Together to Inspire Youth, Skilled Trades, Engage Mentors, and Disrupt Dated Recruitment PracticesConversation and Content Yield Read more

Skilled Careers Coalition Unites Industry, Educators, Policymakers and Parents on Need to Work Together to Inspire Youth, Skilled Trades, Engage Mentors, and Disrupt Dated Recruitment Practices

Table of Contents

Skilled Careers Coalition (SCC), the fast-growing, big-tent alliance, is spearheading collaboration and breaking down silos within the highly fragmented skilled trades to encourage cross-industry support of a common goal to close the skilled labor gap.

Said Mark Hedstrom, Executive Director, Skilled Careers Coalition, “We have reached a crossroads as a nation. The skilled trades are the backbone of America’s economic engine, but the widening skilled labor gap – at a time when demand is growing at a rapid rate – could cripple entire industries if we don’t come together to rebuild the great American workforce. We have an obligation to roll up our sleeves to elevate and promote the skilled trades as a third path to career success.”

To meet the moment, SCC has steadily assembled a robust community of cross-sector stakeholders that includes businesses, educators, pros, policymakers, parents and youth.

Conversation and Content Yield Consensus and Inspiration

Against the backdrop of the SkillsUSA National Leadership & Skills Conference held in Atlanta, GA on June 23-27, 2025, SCC engaged with more than 100 leading businesses and organizations and thousands of students and advisors around three critical areas: inspiring youth by meeting them where they are on social media; encouraging more skilled pros to become actively involved as mentors and teachers; and bringing recruitment efforts up-to-date with technologies that streamline the hiring process.

During the week-long series of activities, SCC hosted student-led panels, shared round-the-clock content on social media, presented a ‘state of the skilled trades’ gathering for leading business and education sector leadership, and brought television personality Ty Pennington back for the second year in a row to reprise his role as host and mentor of the third season of SCC’s for-youth, by-youth YouTube series SKILLS JAM.

Further catalyzing efforts was SCC’s facilitation of remarks from federal, state and local policymakers including the Secretary of the U.S. Department of Labor Lori Chavez-DeRemer and Congressman Rick Allen (Georgia, District 12), who shared their commitment to addressing the skilled labor gap via video; and Senator Raphael Warnock and Congresswoman Lucy McBath (Georgia, District 6) who sent staff members to the high-level gathering to listen and learn.

The coalescence of the industry’s leading voices achieved over the week’s events was a big step forward by SCC in realizing its mission to bring unity to the skilled trades and ultimately, help reverse the rising rate at which demand for skilled talent is outpacing supply.

By forging new pathways to engage and recruit talent using social media and technology, advocating for workforce readiness education opportunities such as apprenticeships; and encouraging the intergenerational transfer of knowledge and experience, the skilled trades can meet the opportunities that lie ahead.

Background

Skilled Careers Coalition conducted the Skilled Trade Insight Research Study in 2023 which surveyed parents, guidance counselors and students. The study found that a lack of knowledge, not interest, keeps young people from pursuing skilled careers. In fact, 43% of students surveyed said they would consider a skilled career if they had more information and guidance. With 65+ million youth between the ages of 10-24 in the U.S. and millions more working age adults out of the workforce, we need to organize and mobilize, across all sectors, to inspire and engage.

Skilled Careers Coalition (SCC) is on a mission to bring the youth of today to the skilled careers of tomorrow by revolutionizing this critical part of the American workforce. A dramatic paradigm shift is taking place in both employment and education. With industries and organizations operating in silos, SCC is driving the connectivity needed between parents, skilled trade professionals, youth, educators, policymakers, businesses, and brands to build a dynamic ecosystem that harnesses the talent needed to close the widening skills gap. To inspire, mentor and empower students to navigate the skilled careers landscape, Skilled Careers Coalition launched the social entertainment brand, SKILLS JAM in 2023. For more information or to get involved visit https://skilledcareers.org.

Donate demo models, extra inventory, tools and building materials during the month of August in support of Greater Cleveland’s Habitat for Humanity. Sonnhalter, a communications firm marketing to the professional tradesman in construction, industrial and MRO markets, will be hosting its Annual Tool Drive. This year marks its sixteenth year in partnering with Greater Cleveland Habitat for Read more

Donate demo models, extra inventory, tools and building materials during the month of August in support of Greater Cleveland’s Habitat for Humanity.

Sonnhalter, a communications firm marketing to the professional tradesman in construction, industrial and MRO markets, will be hosting its Annual Tool Drive. This year marks its sixteenth year in partnering with Greater Cleveland Habitat for Humanity. Since 2010, Sonnhalter has raised $567,000—more than half a million in donations for this cause.

Sonnhalter’s Annual Tool Drive runs Friday, August 1 through Sunday, August 31. All organizations, businesses and manufacturers are encouraged to donate demo models, extra inventory, tools and building materials to the Tool Drive. Donations will benefit Greater Cleveland Habitat’s mission of building homes and empowering families with safe and affordable home ownership.

“Each year, we are incredibly impressed by the remarkable generosity of Northeast Ohio and the trades community. It is a powerful testament to what can be accomplished in the name of a greater cause such as supporting Habitat for Humanity,” said Matt Sonnhalter, vision architect at Sonnhalter. “With the annual outpouring of donations and commitment to the Tool Drive, we have been able to donate more than $567,000 to this shared purpose. With continued support and momentum, we are setting our sights even higher this year!”

The Sonnhalter Tool Drive encourages those within the trade industry to look through their warehouses for extra inventory and overstocked tools or items that they would be willing to donate.

Greater Cleveland Habitat for Humanity has helped more than 300 Habitat homeowners, including over 1,000 children, have a safe and decent place to live. The donated items will be used for Habitat for Humanity projects or will be sold at one of the organization’s three ReStores, discount home improvement stores that serve Cuyahoga and Lorain Counties. Proceeds from ReStore sales are used to help Habitat build and rehabilitate homes for those in need.

“This partnership is a testament to Sonnhalter’s deep commitment to both the community they serve and the environment through the items they help divert from landfills,” said Laura Potter-Sadowski, director of ReStores at Greater Cleveland Habitat for Humanity. “Their Annual Tool Drive is something we look forward to every year. It’s a meaningful way to engage with supporters beyond the walls of the ReStore.”

To watch the Sonnhalter Annual Tool Drive video: https://www.youtube.com/watch?v=YC79aXUTD1A

For information on how you can participate in the Sonnhalter Tool Drive, or to coordinate larger shipments, i.e., pallet size, please contact Rosemarie Ascherl-Lenhard from Sonnhalter at 216.242.0420 x130 or rascherl@sonnhalter.com. To make a monetary donation, please make checks payable to “Greater Cleveland Habitat for Humanity.”

For more information on the Tool Drive, visit: www.Sonnhalter.com/tooldrive.

Exhibit: U.S. Water for Data Centers Expenditure, 2025–2030Hyperscale Data Centers Reshape the Water Infrastructure LandscapeAlternative Approaches to Water ManagementA Market in Transition The role of water in the high-growth data center market is fast becoming a critical factor in site selection, design, and operations. By 2030, annual water-related capital and operational expenditures are forecasted to reach Read more

Table of Contents

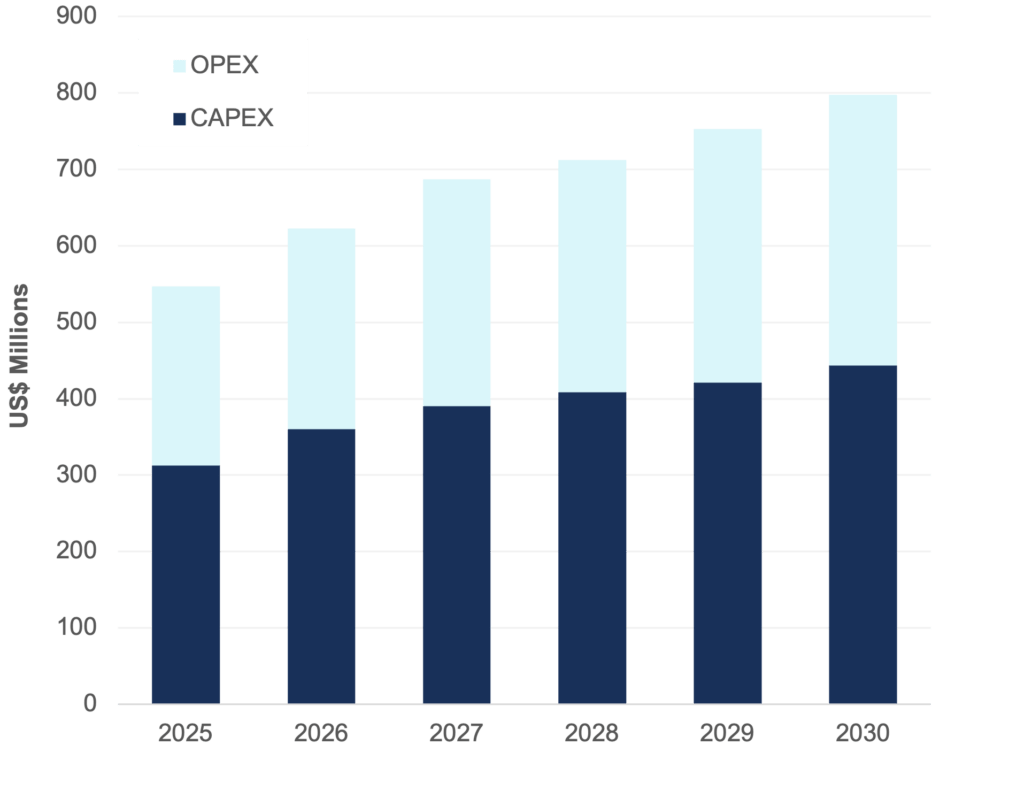

The role of water in the high-growth data center market is fast becoming a critical factor in site selection, design, and operations. By 2030, annual water-related capital and operational expenditures are forecasted to reach US$797.1 million, representing a 31.4% increase from today.

According to a new report from Bluefield Research, U.S. Water for Data Centers: Market Trends, Opportunities, and Forecasts, 2025–2030, this surge in activity is accelerating—driven by artificial intelligence (AI)-fueled growth, mounting local concerns over water availability, and the tech sector’s urgent push to safeguard operational resilience amid growing environmental scrutiny.

Hyperscale data centers, which currently represent 51.4% of total market demand, are forecasted to withdraw 150.4 billion gallons of water between 2025 and 2030. This volume is equivalent to the annual water withdrawals of 4.6 million U.S. households.

“Data centers are no longer just digital infrastructure—they’re increasingly part of the water infrastructure equation,” says Amber Walsh, a senior analyst at Bluefield Research. “The scale of this demand is incredible, and the primary reason for solution providers rushing into the market with offerings to capitalize on the growing utilization of reuse and advanced treatment.”

Exhibit: U.S. Water for Data Centers Expenditure, 2025–2030

Source: Bluefield Research

Hyperscale Data Centers Reshape the Water Infrastructure Landscape

With more than US$100.0 billion in announced data center development from leading operators, the sector’s growing water footprint (estimated at US$4.1 billion in capital and operational expenditures by 2030) is reshaping how and where communities invest in water-related infrastructure. These facilities, sometimes spanning over 1 million square feet and housing up to 300+ megawatts of IT load, are not only driving unprecedented energy demand but also placing new pressure on municipal water systems as AI-fueled growth accelerates.

“Hyperscalers, once viewed primarily as power-intensive operations, are now helping redefine a new water infrastructure paradigm,” says Walsh. “As water-stressed and underfunded municipalities confront drought, permitting delays, and resource constraints, tech companies are playing an increasingly influential role in shaping local decisions.”

While much of the spotlight remains on Big Tech hyperscalers (i.e., Amazon Web Services [AWS], Google, and Meta), a growing cohort of third-party data center developers and operators is reshaping the landscape. Firms such as QTS Realty Trust, Vantage Data Centers, Aligned Data Centers, Digital Realty, Stack Infrastructure, and Compass Datacenters are playing a larger, more critical role in shaping new water demand.

To date, water-intensive traditional cooling systems have been the dominant solution for addressing temperature management in these server farms. However, given the increasing size of data centers and heat loads, innovative liquid cooling systems are gaining traction. Liquid cooling deployments are expected to reach nearly half of new builds by 2030, up from 33.2% today, transforming the industry’s water use outlook.

More than 97% of the water used by major data center operators is purchased from municipal drinking water systems—many of which are already under strain. In The Dalles, Oregon, for example, Google’s water withdrawals accounted for over a quarter of the city’s supply in 2023. The company’s water withdrawals increased by 52% from 2020 to 2023, highlighting the growing tension between digital infrastructure development and local water resilience.

Alternative Approaches to Water Management

As water stress and regulatory scrutiny intensify, leading data center operators are evolving from passive consumption to active resource management. The utilization of reclaimed water (i.e., water reuse), especially in high-demand areas, is prompting this shift.

A key example is Loudoun County, Virginia—home to one of the world’s densest data center clusters—where Loudoun Water delivers over 800 million gallons of reclaimed water annually via its expanded purple pipe (water reuse) network. Operators like AWS and Equinix are leveraging this infrastructure; Equinix has invested US$1.4 million to expand its connections and has reported annual water and wastewater charges of over US$590,000.

“Utilities benefit from infrastructure improvements, while hyperscale companies can quantify ‘avoided water loss’ as part of their sustainability metrics,” says Walsh. “These win-win collaborations offer scalable paths to align community water needs with corporate growth strategies.”

Capital investment is accelerating across three key fronts, supporting these shifts. Municipal utilities are being upgraded to handle larger water loads, on-site treatment systems are being developed to support reuse and compliance, and companies are investing in advanced technologies, such as pumps, sensors, filtration, and pretreatment units, that enhance operational efficiency and resilience.

A Market in Transition

The data center market segment is undergoing a structural shift across the board, from legacy evaporative air cooling and ad hoc water use to more sophisticated, digitally monitored, and locally integrated solutions. “As the market matures, leading companies will be those that treat water as a core asset—not just a utility bill,” notes Walsh. “Whether it’s through reclaimed water, closed-loop systems, or remote sensors, the winners will be those aligning technical innovation with operational sustainability.”