Industry sales experts Candy and Mike Cunningham will lead four in-depth live virtual workshops designed to help members navigate the sales landscape and implement a strategic vision for growth Business Development Resources (BDR), the training and business coaching authority for home services industry professionals, announces the return of its Trailblazer Sales Academy, an ongoing sales development Read more

Industry News

Industry sales experts Candy and Mike Cunningham will lead four in-depth live virtual workshops designed to help members navigate the sales landscape and implement a strategic vision for growth

Business Development Resources (BDR), the training and business coaching authority for home services industry professionals, announces the return of its Trailblazer Sales Academy, an ongoing sales development program specifically for territory managers and distribution sales teams.

Trailblazer Sales Academy helps participants develop sales skills, leadership agility, and a strategic vision for territory growth through four live virtual workshops with additional tools and resources for continuing learning. The program is led by BDR trainers Candy Cunningham and Mike Cunningham and is based on their combined four-plus decades of experience as top-performing territory managers.

“We’re preparing territory managers and distribution sales teams to blaze their own trails and make their dream territories a reality,” said Matt MacArthur, Senior Vice President of Training and Marketing for BDR. “Trailblazer Sales Academy equips members with all the tools they need to build and implement the strategies and processes that will help them reach their goals by taking ownership of their sales results.”

Trailblazer Sales Academy kicks off in January 2025 and runs through May. Each four-hour training session teaches participants the best practices for top-performing territory managers. Sessions for the academy include:

- Drive Sales and Help Dealers Win in Q1 (Jan. 7): Discover how to drive first-quarter results and help your dealers check pricing and costs to ensure they are well-positioned for the year.

- Build Your Strategic Sales Call Process (Feb. 11): Learn how to build a checklist to prepare for a sales call and develop a strategic sales process to follow before, during, and afterward.

- Find the Right Dealer Through Targeted Prospecting (April 3): Learn the knowledge and skills to effectively identify and engage with high-potential prospects to maximize your results.

- Help Dealers Install More Jobs Through Labor Leverage (May 8): Discover proven methods for helping dealers install more jobs through leveraging labor and optimizing their workforce effectively.

The academy also includes self-paced courses to help participants continue to develop their skills in between the live sessions, along with targeted podcasts episodes to prepare academy members for their next workshop.

Learn more about the Trailblazer Sales Academy at https://www.bdrco.com/trailblazer-academy/.

GlassHouse, the only outbound sales platform built specifically for home service businesses, today announced an exciting new partnership with Textla, the industry leader in SMS marketing technology. This partnership will empower GlassHouse customers to access the best SMS platform for reaching their target buyers, while providing Textla customers with advanced tools to target homeowners using Read more

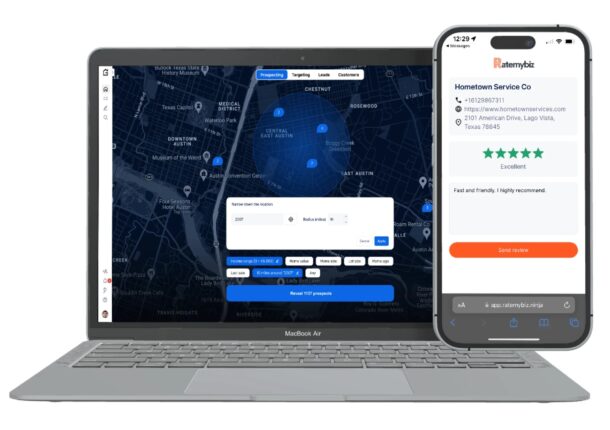

GlassHouse, the only outbound sales platform built specifically for home service businesses, today announced an exciting new partnership with Textla, the industry leader in SMS marketing technology. This partnership will empower GlassHouse customers to access the best SMS platform for reaching their target buyers, while providing Textla customers with advanced tools to target homeowners using GlassHouse’s customer intelligence platform.

Thanks to this partnership, home service businesses using GlassHouse and Textla together will be able to target homeowners in any neighborhood in America and send effective SMS campaigns that drive results. GlassHouse’s customer intelligence capabilities combined with Textla’s expertise in messaging, deliverability, and SMS campaign performance provides a powerful solution for generating new business.

“SMS campaigns have quickly become one of the most effective channels for ‘digital door knocking,’ said Jimmy Speyer, CEO of GlassHouse. “Our clients are driving incredible growth by using targeted messaging to reach their ideal buyers. This partnership with Textla means that our customers can now take their outreach to the next level, leveraging best-in-class SMS capabilities to turn every opportunity into a closed deal,”

GlassHouse customers will benefit from Textla’s industry-leading technology, gaining access to high deliverability rates, performance analytics, and best practices for driving customer engagement through text messaging. Meanwhile, Textla customers in the home services space will be able to leverage GlassHouse’s advanced customer intelligence to build effective audiences for SMS campaigns, ultimately helping them reach the right buyers at the right time.

“Our partnership with GlassHouse is a game-changer for home services businesses looking to scale,” said Luke Brickman, Founder and CEO at Textla. “GlassHouse’s targeting capabilities combined with our SMS technology will empower businesses to turn every door knock into a valuable lead and ultimately drive greater success in their communities.”

The partnership between GlassHouse and Textla comes at a crucial time when home service businesses are seeking efficient ways to generate new leads and grow their revenue without relying solely on traditional channels. By combining Textla’s SMS expertise with GlassHouse’s ability to identify potential customers in targeted neighborhoods, this solution enables home service businesses to conduct highly targeted, effective outreach.

Looking ahead, home service business owners who want to experience this innovative partnership firsthand will have the opportunity to demo the GlassHouse-Textla integration at the Service World Expo from October 15th to 17th in Lake Buena Vista, Florida. Come see how GlassHouse and Textla can transform your outreach strategy and drive growth.

Baltimore, Md. —The Johnny Unitas Golden Arm Educational Foundation alongside presenting partner, A. O. Smith, has pared-down the original 2024 Watch List to the nation’s Top 25 quarterbacks. The quarterbacks that remain in the hunt for this season’s coveted Golden Arm Award represent 10 conferences across the country. The Golden Arm Award annually recognizes the Read more

Baltimore, Md. —The Johnny Unitas Golden Arm Educational Foundation alongside presenting partner, A. O. Smith, has pared-down the original 2024 Watch List to the nation’s Top 25 quarterbacks. The quarterbacks that remain in the hunt for this season’s coveted Golden Arm Award represent 10 conferences across the country.

Baltimore, Md. —The Johnny Unitas Golden Arm Educational Foundation alongside presenting partner, A. O. Smith, has pared-down the original 2024 Watch List to the nation’s Top 25 quarterbacks. The quarterbacks that remain in the hunt for this season’s coveted Golden Arm Award represent 10 conferences across the country.

The Golden Arm Award annually recognizes the top senior or upperclassman quarterback set to graduate with their class. The semifinalists, finalists, and award recipient are selected by the distinguished Johnny Unitas Golden Arm Selection Committee, a group of prominent college football journalists, commentators, announcers, and former players. Candidates are chosen based on player performance on-and-off the field.

2024 Golden Arm Award Top 25 Presented by A. O. Smith

Drew Allar, Penn State

Luke Altmyer, Illinois

Rocco Becht, Iowa State

Carson Beck, Georgia

Brady Cook, Missouri

Jaxson Dart, Ole Miss

Billy Edwards Jr., Maryland

Quinn Ewers, Texas

Noah Fifita, Arizona

Dillon Gabriel, Oregon

Seth Henigan, Memphis

Will Howard, Ohio State

Haynes King, Georgia Tech

Cade Klubnik, Clemson

Riley Leonard, Notre Dame

Kyle McCord, Syracuse

Fernando Mendoza, Cal

Jalen Milroe, Alabama

Behren Morton, Texas Tech

Garrett Nussmeier, LSU

Kurtis Rourke, Indiana

Shedeur Sanders, Colorado

Tyler Shough, Louisville

Brendan Sorsby, Cincinnati

Cam Ward, Miami

The namesake of the Golden Arm Award has a storied history. Johnny Unitas was an 18-year veteran of the NFL, who played his collegiate career at the University of Louisville before joining the Baltimore Colts in 1958. His career passing figures include 2,830 pass completions for 40,239 yards, 290 touchdowns and throwing a touchdown pass in 47 consecutive games.

This year’s award winner will be presented the Golden Arm Award trophy at the Johnny Unitas Golden Arm Award celebration the Four Seasons Hotel in Baltimore, Maryland on Friday, December 6, 2024.

Giving life to the commitment to give back, the Johnny Unitas Golden Arm Educational Foundation, Inc. and presenting sponsor A. O. Smith continue to promote football on all levels by providing financial aid to deserving young scholar athletes.

Sharing a tradition of innovation with Johnny Unitas, who invented football’s two-minute drill, A. O. Smith has been an innovator in its industry for 150 years. What began as a small machine shop in Milwaukee, Wisconsin in 1874, has evolved into a leading global water technology company committed to improving the lives of its customers by ensuring access to clean, safe, hot water.

In addition, the Johnny Unitas Golden Arm Award has been naming a Player of the Week each week to showcase their remarkable talents. This recognition is a testament to the player’s outstanding performance where he showcased outstanding skill, leadership, and poise on the field. Their impressive performances demonstrated their ability to excel under pressure, leading a game-winning drive in the final minutes.

2024 Golden Arm Award Player of the Week:

Week 1: Shedeur Sanders, Colorado Week 2: Cade Klubnik, Clemson Week 3: Jalen Milroe, Alabama Week 4: Cam Ward, Miami

Week 5: Jalen Milroe, Alabama

Peachtree City, Ga. — Rinnai America Corporation announced the grand prize winner of its PRO APPRECIATION Sweepstakes. The winner traveled to Georgia and visited Rinnai’s manufacturing facility in Griffin, Georgia and was later greeted at the company’s headquarters in Peachtree City by Rinnai leadership and city officials including Mayor Kim Learnard. Dave Koval of Dave Read more

Peachtree City, Ga. — Rinnai America Corporation announced the grand prize winner of its PRO APPRECIATION Sweepstakes. The winner traveled to Georgia and visited Rinnai’s manufacturing facility in Griffin, Georgia and was later greeted at the company’s headquarters in Peachtree City by Rinnai leadership and city officials including Mayor Kim Learnard.

Dave Koval of Dave Koval Plumbing & HVAC, located in Mountain Top, Pennsylvania, was presented a new Ford F-150, valued at $70,000, during a live-stream event today at the Rinnai headquarters.

“I’m very fortunate to have won this incredible truck,” said Koval. “A huge thank you to Rinnai for this remarkable opportunity. We’ve recommended and installed Rinnai tankless water heaters for many years because they manufacture the best quality product, provide excellent customer service and an industry-leading warranty.”

Rinnai’s PRO APPRECIATION Sweepstakes was launched as part of an effort to drive excitement about its new SENSEI RX/RXP condensing tankless water heater, the company’s newest innovation in the tankless water heating category achieving an industry leading 0.98 UEF efficiency rating. From May 1 to July 31, each purchase of a SENSEI RX/RXP could be used to enter the sweepstakes for a chance to win more than 200 prizes. PROs could enter as many times as they wanted to increase their chances of winning.

“Our PROs play a critical role in both the development and the launch of our products in the North American Market, and the PRO Appreciation Sweepstakes is our way of recognizing and thanking them for their support of Rinnai, said Frank Windsor, President, Rinnai America Corporation. I’m thrilled for Dave and the many other sweepstakes winners.”

In addition to the Ford F-150, Rinnai also awarded hundreds of other prizes, including a first-place prize of a Tony Stewart Racing Experience trip to Las Vegas.

For over 50 years Rinnai America has been bringing innovative products to the North American market that meet specific needs for the PRO.

The new SENSEI RX Series takes tankless innovation to the next level by offering features and benefits that are market-leading and support Rinnai’s continued brand promise of creating a healthier way of living®.

To learn more about the SENSEI RX/RXP, Built for the PRO, by the PRO™ please visit SENSEI RX (R)-US | Rinnai.

The Ask Caleffi team is back with another insightful Coffee with Caleffi webinar, focusing on pressure-reducing valves (PRVs) and their role in plumbing systems. Cody Mack and Kevin Freidt will explore the various options PRVs offer to designers and installers, highlighting how these valves can assure reliable water pressure in a variety of plumbing applications. Join Read more

The Ask Caleffi team is back with another insightful Coffee with Caleffi webinar, focusing on pressure-reducing valves (PRVs) and their role in plumbing systems. Cody Mack and Kevin Freidt will explore the various options PRVs offer to designers and installers, highlighting how these valves can assure reliable water pressure in a variety of plumbing applications.

Join Kevin and Cody to discover how PRVs contribute to achieving peak performance in domestic water systems. They’ll dive into their benefits and provide practical tips for maximizing efficiency and minimizing water waste. Don’t miss this session packed with valuable insights for improving your plumbing systems.

→Can pressure-reducing valves help building owners control operating costs?

→How does a pressure-reducing valve work?

→How do you size a pressure-reducing valve?

→What symptoms will you see when they’re not sized correctly?

→What are the common signs that a pressure-reducing valve might be malfunctioning?

Cody is the National Training Manager at Caleffi North America. He has nearly 20 years of experience in several roles, which include installation contractor, service technician, application engineer and product manager, across the plumbing and heating industry.

Kevin is the Director of Product Management and Technical Support at Caleffi North America. He has 40 years of engineering experience in the commercial HVAC, plumbing and heating industry.