Revolutionary, Retrofit Clip Delivers Rapid, Code-Compliant Seismic Rod Stiffening for MEP Systems Using Affordable and Readily-Available Conduit Gripple®, a leading manufacturer of engineered suspension solutions for construction and critical infrastructure applications, is proud to highlight the TecLoc Conduit Claw for seismic stiffening within Mechanical, Electrical, & Plumbing (MEP) applications. This revolutionary and innovative seismic rod stiffener, is Read more

Product Spotlight

Revolutionary, Retrofit Clip Delivers Rapid, Code-Compliant Seismic Rod Stiffening for MEP Systems Using Affordable and Readily-Available Conduit

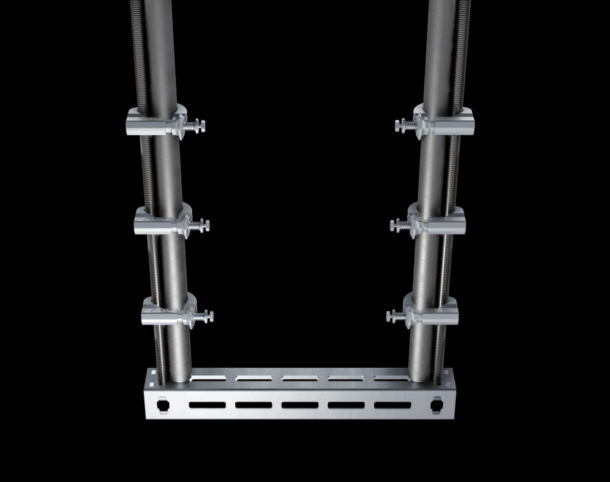

Gripple®, a leading manufacturer of engineered suspension solutions for construction and critical infrastructure applications, is proud to highlight the TecLoc Conduit Claw for seismic stiffening within Mechanical, Electrical, & Plumbing (MEP) applications. This revolutionary and innovative seismic rod stiffener, is designed to deliver the most reliable, rapid and cost effective stiffening solution for MEP systems.

The TecLoc Conduit Claw is a fast and secure, IAPMO-approved seismic rod stiffening clip, designed to be quickly installed using pipe or conduit to secure suspended services and prevent buckling in seismic conditions in a variety of MEP system applications.

One-of-a-kind, this groundbreaking new product has been specifically engineered to be retrofittable, allowing it to be installed after services are fully suspended. This makes it an ideal solution for late-stage modifications or unexpected changes during construction and a true game-changer for contractors.

The TecLoc Conduit Claw is designed for easy, one-person installation, minimizing labor requirements and simplifying the process. Its universal compatibility with 1″ EMT, 1″ Schedule 40 Pipe, and 3/8″, 1/2″, and 5/8″ rod sizes eliminates the need for multiple SKUs, streamlining inventory and ensuring coverage for a broad range of MEP applications.

Safety and compliance are at the core of the TecLoc Conduit Claw’s design. The clip prevents rod buckling under seismic conditions, maintaining structural integrity and supporting code compliance in critical infrastructure such as hospitals, data centers, and commercial buildings. The robust construction, featuring a zinc die cast body manufactured in-house by Gripple, provides assurance of quality, reliability and traceability, giving users peace-of-mind.

With pre-engineered compression loads, TecLoc Conduit Claw provides reliable support for even the most demanding seismic requirements. Featuring a shear-off bolt design to guarantee correct installation and performance, it also allows for easy on-site inspection. As always, Gripple’s in-house engineering team is available to help with any project-specific requirements.

Supplied in convenient packaging, the TecLoc Conduit Claw streamlines handling, storage, and site logistics. Clear installation guidance and spacing recommendations are provided to support best practices and guarantee effective installation. For project-specific needs, clip spacing and design strength values can be modified with engineer approval, offering adaptability for custom requirements.

Manufactured in ISO-certified facilities, Gripple’s continued commitment to quality includes a 100% inspection to ensure the utmost quality. With the TecLoc Conduit Claw, Gripple reinforces its reputation for delivering innovative, efficient solutions tailored to the needs of diverse industries. This game-changing product exemplifies Gripple’s dedication to enhancing safety, simplifying the installation process, and supporting code-compliant seismic solutions in MEP systems.

MegaPress® FKM and MegaPress® 316 Globe Valves The new MegaPress® globe valves offer exceptional performance, reliability, and durability for your commercial and industrial systems. This is the only press globe valve with Iron Pipe Size (IPS) ends. These valves feature adjustable PTFE stem seals and are available in sizes ½” to 2”. The globe valves Read more

MegaPress® FKM and MegaPress® 316 Globe Valves

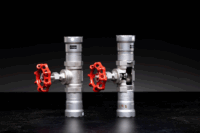

The new MegaPress® globe valves offer exceptional performance, reliability, and durability for your commercial and industrial systems. This is the only press globe valve with Iron Pipe Size (IPS) ends. These valves feature adjustable PTFE stem seals and are available in sizes ½” to 2”. The globe valves are engineered for precise flow control, offering a rising stem and multi-turn design that allows for visual confirmation of the valve’s open or closed position.

These valves are an ideal solution for systems that require more precise modulation, unlike quarter-turn valves. The adjustable PTFE packing nut provides excellent corrosion resistance and makes maintenance and replacement easier, reducing downtime and labor costs. The MegaPress®316 Globe Valve is a perfect choice for systems that demand both reliability and ease of maintenance.

Learn more about the MegaPress® FKM and MegaPress® 316 Globe Valves.

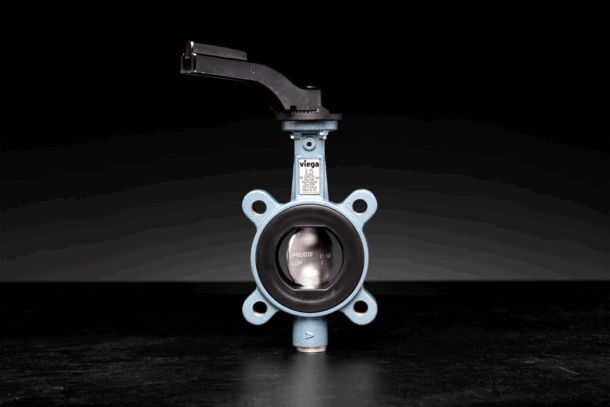

MegaPress®316 and ProPress® Butterfly Valve

Viega’s new ProPress® and MegaPress® butterfly valves provide a simple and reliable solution for flow isolation and control in commercial and industrial plumbing systems. These valves are available in sizes 2 ½” to 4” and are designed for compatibility with Viega ProPress® and MegaPress® flange adapters, ensuring a secure and efficient connection. They are available in 316 stainless steel and epoxy coated ductile iron materials.

These butterfly valves are ideal for a wide range of applications, providing flow isolation and helping to regulate pressure throughout the system. NSF 61 approval ensures that these valves can be used in potable water systems, making them versatile and suitable for a variety of plumbing projects

Learn more about the MegaPress®316 and ProPress® Butterfly Valves.

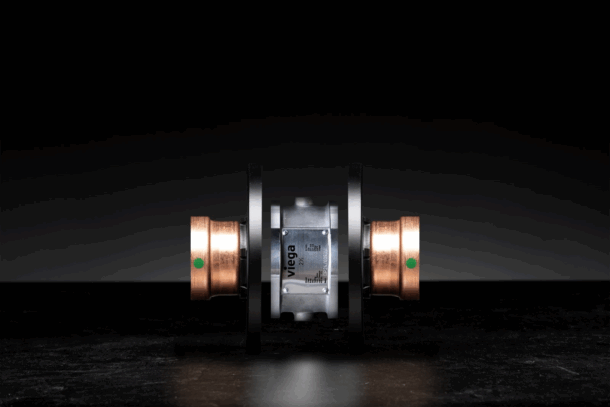

ProPress® and MegaPress® Wafer Check

Preventing reverse flow is a critical aspect of any piping system, and Viega’s new wafer check valves are designed to do just that. These valves feature a dual-disk design that promotes a streamlined flow path, reducing pressure drops and increasing energy efficiency. Available in sizes 2 ½” to 4”, these compact valves are optimized for use with Viega MegaPress® and ProPress® flanges. They are available in 316 stainless steel and epoxy coated ductile iron materials.

With over 2,500 approved applications, these wafer check valves are ideal for creating potable water systems, as model 2974.3XL and 5174XL carry NSF 61 approval. The durable and reliable construction of these valves ensures that your systems remain functional and energy-efficient, while also offering the flexibility to adapt to a wide variety of piping configurations.

Releases Updated Version PVI, a Watts brand, introduces enhanced Conquest® compact, condensing, semi-instantaneous, firetube water heaters that have improved thermal efficiency, optimized pump placement, and superior return on investment (ROI). Available in a range of inputs from 399 MBH to 1200 MBH and offering natural gas and propane options, the new Conquest water heaters are also available in Read more

Releases Updated Version

PVI, a Watts brand, introduces enhanced Conquest® compact, condensing, semi-instantaneous, firetube water heaters that have improved thermal efficiency, optimized pump placement, and superior return on investment (ROI). Available in a range of inputs from 399 MBH to 1200 MBH and offering natural gas and propane options, the new Conquest water heaters are also available in indoor and outdoor configurations, including a CSD-1 version, to meet diverse installation needs.

The new Conquest offers commercial facility owners and managers three key benefits:

- Enhanced Thermal Efficiency: The upgraded straight firetube heat exchanger design increases the Conquest’s thermal efficiency to an impressive 98% across all inputs, making it one of the most energy-efficient models available.

- Optimized Pump Placement: The pump is now strategically positioned at the front and side of the water heaters, for easier access and improved reliability.

- Made in the USA: The Conquest 400-1200 water heaters are designed and assembled at PVI’s state-of-the-art facility in Fort Worth, TX, ensuring high-quality, American-made craftsmanship.

In announcing the new models, Helen Ringle, Product Manager at PVI, said, “We’re excited to launch the updated Conquest, which builds on our commitment to providing energy-efficient, reliable, and affordable water-heating solutions. With its enhanced design, this enhanced water heater family offers greater energy savings while maintaining the durability our customers have grown to trust and rely upon. The Conquest 400-1200 delivers significant value and reinforces PVI’s dedication to long-lasting, high-performance products.”

Industry-leading Efficiency and Durability

The Conquest 400-1200 series features two compact, condensing, semi-instantaneous, firetube water heaters that offer superior ROI with warranties 3-5 times longer than those offered by competitors. They feature up to 98% thermal efficiency, seamless modulation for improved performance under low loads, and low NOx emissions of <20 ppm.

The tank and heat exchanger are crafted from PVI’s proprietary AquaPLEX® duplex stainless steel alloy, providing resistance to chloride stress corrosion cracking and eliminating the need for tank linings or anode rods. Additionally, the series is backed by a 15-year corrosion warranty on the tank and heat exchanger.

Equipped with an advanced electronic operating control, the Conquest series features a plain-text user interface that displays heater status, modulation rate, operating parameters, and fault information. The control also integrates with building automation systems (BAS) through Modbus RTU and BACnet MS/TP protocols. The Conquest is Department of Energy (DOE), Intertek/ETL, and ANSI certified, Energy Star-qualified, ASHRAE 90.1 compliant, and eligible for LEED certification.

Learn more about the updated Conquest at pvi.com/conquest.

Introducing the RSC Mini, RSC Mid, and RSC Max RainHarvest Systems, a global leader in water harvesting, treatment, and reuse solutions, is proud to announce a complete line of RainFlo System Controllers. The RSC Mini, Mid, and Max controllers offer three levels of functionality for water reclamation systems. Features include the ability to monitor tank levels, UV Read more

Introducing the RSC Mini, RSC Mid, and RSC Max

RainHarvest Systems, a global leader in water harvesting, treatment, and reuse solutions, is proud to announce a complete line of RainFlo System Controllers.

The RSC Mini, Mid, and Max controllers offer three levels of functionality for water reclamation systems. Features include the ability to monitor tank levels, UV intensity, filter pressure differentials, ORP, and much more. RainFlo System Controllers deliver unparalleled performance across residential and commercial applications. Built on state-of-the-art PLC technology, the controllers seamlessly integrate all components and serve as the command center. A touchscreen control panel provides access to preset parameters—minimizing manual intervention and maximizing reliability. These advanced controllers redefine how water resources are managed by offering unmatched automation, monitoring, and control capabilities.

Key Features and Benefits

- Smart Automation: Automatically adjusts water management systems for optimal operation and efficiency.

- User-Friendly Interface: Intuitive color touchscreen HMI provides real-time insights and easy control of system parameters.

- Enhanced Water Management: Intelligent flow and source switching ensure continuous water supply while prioritizing the use of harvested water.

- Customizable: Three versatile models allow users to tailor the system to their specific needs.

- Rugged Design: Durable NEMA 4X-rated enclosures protect controllers in demanding environments.

RainHarvest Systems is dedicated to revolutionizing water harvesting, treatment, and reuse. Our cutting-edge products and solutions empower residential and commercial users to manage water resources sustainably and effectively. Whether you’re looking to conserve water or meet specific reuse requirements, RainHarvest Systems is your trusted partner in bringing water to life. Learn more at www.rainharvest.com.

With a Cold-Shot® Pipe Freezing Kit, you don’t have to drain water lines, sprinkler systems, or hot water systems before cutting pipe or tubing. Our pipe freezing tool keeps a fully pressurized system operating while you make repairs. https://youtu.be/NxLoPlBvaQ8?si=bjvMBlLsHcM0VYRa The Cold-Shot pipe freezing tool freezes liquids in metal and plastic pipes ranging from 1/8″ through Read more

With a Cold-Shot® Pipe Freezing Kit, you don’t have to drain water lines, sprinkler systems, or hot water systems before cutting pipe or tubing. Our pipe freezing tool keeps a fully pressurized system operating while you make repairs.

The Cold-Shot pipe freezing tool freezes liquids in metal and plastic pipes ranging from 1/8″ through 2″ (10mm to 60mm) using carbon dioxide (CO2). Dip tube-type CO2 cylinders are available from any welding supply house.

The Cold-Shot works faster than “refrigerator-type” units, is more compact and less expensive. It’s faster and uses less CO2 than “bag-type” pipe freezers, because the freeze head makes a better seal around the pipe. In five minutes you’re ready to go to work on 1/2″ copper tubing, and just three minutes for cast iron pipe.