Pro-Pal® 3-way ball valves from Webstone®, a brand of NIBCO, are designed to divert, select, or mix fluids based on your application needs. Flow options include a 90° handle operation to divert or select, or a 180° handle operation to divert, select, or mix. A dual stem seal incorporates both an O-ring and PTFE packing Read more

Product Spotlight

Pro-Pal® 3-way ball valves from Webstone®, a brand of NIBCO, are designed to divert, select, or mix fluids based on your application needs. Flow options include a 90° handle operation to divert or select, or a 180° handle operation to divert, select, or mix. A dual stem seal incorporates both an O-ring and PTFE packing with an adjustable packing gland for extra leak protection. Products are forged from lead-free dezincification-resistant brass and can withstand up to 250 PSI CWP and 200°F. Available in ½” to 2” end connections that are compatible with popular press tools. Work smarter and save time, labor, and leak paths.

- Divert, select, or mix fluids based on your application needs

- Dual stem seal design incorporates both an O-ring and PTFE packing with adjustable packing gland for extra leak protection

- Compatible with popular press tools

Learn more at www.webstonevalves.com/propal.

Basement flooding isn’t a worry Wayne®, a Scott Fetzer Consumer Brand and leading maker of water management solutions, has developed and released its latest IoT intelligent product, the Wayne Basement Guardian HALO™ smart sump pump. It is the world’s first smart home, Alexa-compatible device to give homeowners real-time control of and information about the operation Read more

Basement flooding isn’t a worry

Wayne®, a Scott Fetzer Consumer Brand and leading maker of water management solutions, has developed and released its latest IoT intelligent product, the Wayne Basement Guardian HALO™ smart sump pump. It is the world’s first smart home, Alexa-compatible device to give homeowners real-time control of and information about the operation of their basement sump pump.

“The mantra for our Basement Guardian HALO is connect, monitor and trust,” said Eric Tinnemeyer, president of Scott Fetzer Consumer Brands. “A wet or flooded basement is how the other guys’ pumps tell you something’s wrong. The Basement Guardian HALO sends a text, email, and alert via our free iOS and Android mobile apps when it detects an anomaly in the pump’s operation that needs attention or could cause the pump to fail. With a HALO, homeowners never have to worry about their basement flooding again.”

An embedded IoT controller constantly monitors the pump’s electrical signature for issues and transmits the analysis wirelessly to a homeowner’s Basement Guardian HALO mobile app. The dashboard displays metrics on the sump pump’s frequency and duration of use and tracks its operating history. If there is ever an operating issue the app provides troubleshooting instructions. Using the electrical signature, HALO will give the homeowner advance warning to replace their pump before the pump stops working and a flood occurs.

According to the National Association of the Remodeling Industry, the average cost to remodel after a basement flood is approximately $40,000. After remodeling, homeowners typically buy a new sump pump, forget about it, and the pump eventually fails again and floods a basement. Or homeowners know the potential for flooding and spend more money than they have to – replacing their sump pump as often as every two years – in fear of the pump failing and their basement flooding.

“No sump pump lasts forever,” said Tinnemeyer. “We’re analyzing the power consumption of the pump to look for indications of when the device is breaking down and notifying the homeowner to replace it far in advance of failure.”

“The Basement Guardian HALO uses a patented Air Switch, instead of a mechanical flow switch, to sense the water level in the sump pump pit by detecting a pressure difference,” added Don Williams, vice president of engineering at Scott Fetzer Consumer Brands. “The Basement Guardian HALO then relays data to the IoT controller, which starts or stops the pump.”

“The consumer research we conducted with Wayne informed our IoT engineering design and gave us a laser-beam focus to design the function and layout of the mobile app,” said Adam Justice, chief executive officer of Grid Connect, Inc., which manufactures the IoT controller. “We built a system from the ground up by analyzing customers’ concerns and what would reassure them.”

Scott Fetzer Consumer Brands manufactures the Wayne Basement Guardian HALO with a corrosion-resistant, stainless-steel housing and cast-iron volute. Like most Wayne sump pumps, plumbers and even homeowners can easily install this pump in about 15 minutes. To purchase the Wayne Basement Guardian HALO, visit Amazon or www.basement-guardian.com.

Scott Fetzer Consumer Brands manufactures the Wayne Basement Guardian HALO with a corrosion-resistant, stainless-steel housing and cast-iron volute. Like most Wayne sump pumps, plumbers and even homeowners can easily install this pump in about 15 minutes. To purchase the Wayne Basement Guardian HALO, visit Amazon or www.basement-guardian.com.

About Wayne

With more than 70 years in the business, Wayne has become a dominant brand in the water pump industry. We continue to bring market leading innovation to homeowners who need worry-free water management solutions. Wayne offers a full line of basement protection systems, sump, multi-use, sewage, effluent, well, lawn, specialty pumps and systems, and accessories. Learn more at www.waynepumps.com

Adds Four Hydronic Solutions, Reintroduces Braukmann Product Name to Global Product Offering Resideo Technologies Inc. (NYSE: REZI), a leading global provider of home comfort and security solutions, today announced new hydronic heating components that complement its full water solutions portfolio. Resideo’s world-class hydronic portfolio offers the ultimate in performance, comfort and consistency, and works together seamlessly Read more

Adds Four Hydronic Solutions, Reintroduces Braukmann Product Name to Global Product Offering

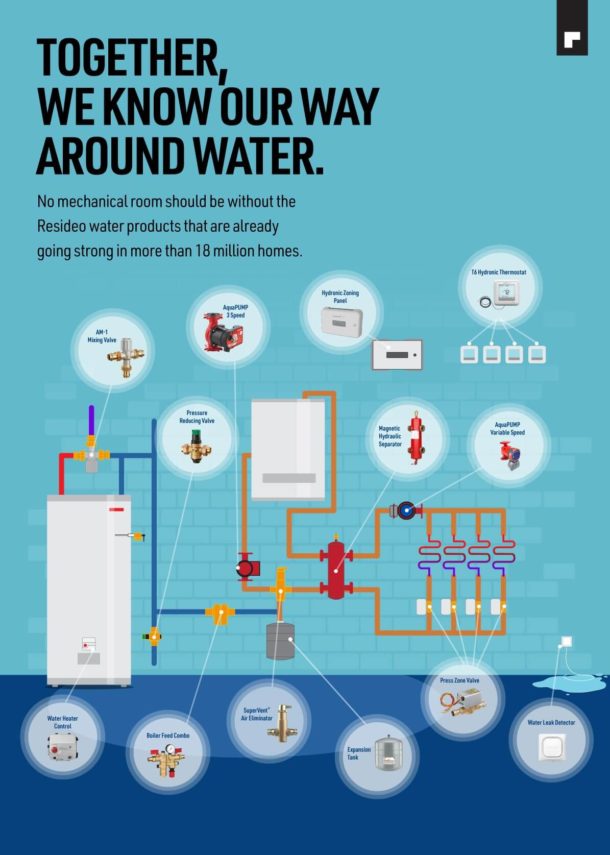

Resideo Technologies Inc. (NYSE: REZI), a leading global provider of home comfort and security solutions, today announced new hydronic heating components that complement its full water solutions portfolio. Resideo’s world-class hydronic portfolio offers the ultimate in performance, comfort and consistency, and works together seamlessly to offer an end-to-end hydronic control system.

“Our professional contractors’ time and energy are precious, so we’re looking forward to offering them a complete, easy-to-install hydronics system from Resideo that is engineered for accuracy, safety and reliability,” said Matthew Robbins, vice president global product management, Comfort & Care. “Our new hydronics solutions are our first Resideo-branded offerings and serve as a true example of what our professionals can expect from Resideo’s behind-the-wall solutions: quality solutions that help save our professionals time, money, labor, and parts.”

Resideo Hydraulic Separator

Resideo’s new hydronic solutions include:

- AquaPUMP Variable Speed Circulating Pumps are offered in both cast iron and stainless-steel models for closed- and open-looped applications. Available in five different modes of operation, the pumps provide versatility to cover the performance of fixed- and variable-speed circulators and utilize pressure responsive control. These quiet and energy-efficient pumps are backed by a five-year warranty.

- Magnetic Hydraulic Separators regulate pressure, reduce flow velocity, minimize audible noises with air elimination and protect the boiler system from ferrous sediment with a standardized magnet. Magnetic Hydraulic Separators are ideal for greater boiler efficiency and protection in various applications from residential homes to multi-family housing. Hydraulic Separator bodies are offered with union connections from one-to two-inch for sweat, threaded, or press fitting. Flanged bodies are available with connections from two to six inches.

- Press PV SuperVent® Air Eliminators easily vent out the air in hydronic systems with the most secure connection offered in the industry. SuperVent® Air Eliminators have debris baffles to control dirt fouling and to prevent failing. The adjustable collar ring allows for easy installation and application flexibility.

- Press Boiler Trim Kits offer a high-quality Press PV SuperVent® Air Eliminator, Press NK300 boiler feed combination and expansion tank with service check valve all in one box. Best-in-class fittings make for a simple, seamless and high-quality installation.

The newly expanded hydronic portfolio is now available in the U.S. and Canada through Resideo’s distribution network.

Resideo Braukmann

Resideo is reintroducing the Braukmann product name to its global potable water products, such as pressure reducing valves and mixing valves. The changes reflect the company’s ongoing opportunity to build and strengthen the Resideo brand and product portfolio.

“Our European and North American customers have known and trusted the Braukmann name for more than 40 years, and we’re honored to bring back the well-known potable water product family,” said Lisa Goldson Armstrong, vice president of global marketing at Resideo. “Reintroducing the Braukmann name acknowledges our proud heritage and gives us an opportunity to take another step in our Resideo brand journey.”

The company acquired Braukmann in 1980 from its founder, and with more than 75 years of experience in the European residential water control market it’s become well-known for demonstrating proven reliability. The water products can be found in more than 18 million households and are trusted by more than 100,000 installers.

Resideo Braukmann solutions are available globally through Resideo’s distribution network.

Designed to complement the company’s E-Tronic® 80 Series touchless faucets, Chicago Faucets has added a new touch-free soap dispenser to the E-Tronic® family. The E-Tronic® 80 contemporary soap dispenser matches the form of the popular E-Tronic® 80 faucet and features durable, all-metal construction for public and commercial restrooms. The E-Tronic® 80 delivers a contemporary single-hole Read more

Designed to complement the company’s E-Tronic® 80 Series touchless faucets, Chicago Faucets has added a new touch-free soap dispenser to the E-Tronic® family. The E-Tronic® 80 contemporary soap dispenser matches the form of the popular E-Tronic® 80 faucet and features durable, all-metal construction for public and commercial restrooms.

The E-Tronic® 80 delivers a contemporary single-hole design with dependable touchless convenience. A simple wave in front of the built-in sensor automatically dispenses a pre-measured amount of foam or liquid soap – no touching or adjustment required. Hands-free operation means improved hygiene and a cleaner, more convenient restroom.

The E-Tronic® 80 delivers a contemporary single-hole design with dependable touchless convenience. A simple wave in front of the built-in sensor automatically dispenses a pre-measured amount of foam or liquid soap – no touching or adjustment required. Hands-free operation means improved hygiene and a cleaner, more convenient restroom.

“With the E-Tronic® 80 suite of matching fittings, it’s easier than ever to offer a completely touchless handwashing experience in any restroom,” says Greg Hunt, Commercial Product Manager at Chicago Faucets. “The E-Tronic® soap dispenser and faucet combination gives you touch-free handwashing from start to finish. You can rely on safe, convenient operation.”

Power choices include AC, DC, and the Chicago Faucets Long Term Power System (LTPS), designed to provide maintenance-free power for 15 years or more in most commercial settings without the need to replace a battery.

Additional information on these products, as well as the entire line of Chicago Faucets products, can be viewed on the company’s website at chicagofaucets.com.

Chicago Faucets, a member of the Geberit Group, is the leading brand of commercial faucets and fittings in the United States, offering a complete range of products for healthcare, schools, laboratories, office buildings, food service, airports, and sports facilities. Whatever the requirements may be, Chicago Faucets offers standard and made-to-order products that are designed to meet any application.

For additional information, contact The Chicago Faucet Company at 2100 South Clearwater Drive, Des Plaines, IL 60018, or call 847-803-5000. You can also visit www.chicagofaucets.com.

New ENERGY STAR®-certified tankless water heater with built-in recirculation pump enhances Infiniti® line’s convenience and performance Bradford White Water Heaters, an industry-leading manufacturer of residential and commercial water heating and storage products, introduces the Infiniti® L, the latest addition to the company’s Infiniti® series of reliable and easy-to-install ENERGY STAR®-certified tankless water heaters. The Infiniti® L Read more

New ENERGY STAR®-certified tankless water heater with built-in recirculation pump enhances Infiniti® line’s convenience and performance

Bradford White Water Heaters, an industry-leading manufacturer of residential and commercial water heating and storage products, introduces the Infiniti® L, the latest addition to the company’s Infiniti® series of reliable and easy-to-install ENERGY STAR®-certified tankless water heaters.

Bradford White Water Heaters, an industry-leading manufacturer of residential and commercial water heating and storage products, introduces the Infiniti® L, the latest addition to the company’s Infiniti® series of reliable and easy-to-install ENERGY STAR®-certified tankless water heaters.

The Infiniti® L includes best-in-class venting and modulation, a 15-year heat exchanger warranty, Bradford White’s Scale Reduction Technology™, field gas conversion, integrated flush ports and top water connections. The Infiniti® L also comes with a built-in recirculation pump that provides instant delivery for an endless supply of hot water, which enhances the heater’s efficient water use and reduces the time and materials required for installation.

“The Infiniti® L is a smart option for anyone who is looking for Bradford White reliability and performance in a high-efficiency, recirculating tankless water heater,” said Louise Prader, senior director-product management for Bradford White. “With the Infiniti® L, we’re able to provide a unique combination of convenience, high performance and extraordinary efficiency that’s suitable for a wide variety of applications.”

Additional innovative features in the Infiniti® L product include:

- STEADISET® technology to help maintain constant water temperature without an internal buffer tank.

- A modulating burner that delivers a 22:1 turndown ratio.

- Intuitive built-in digital controls.

- Active bypass.

- Self-calibrating fan and gas valve.

To learn more about Bradford White Water Heaters, please visit https://www.bradfordwhite.com or call (215) 641-9400.