Taco Comfort Solutions’ VT Series vertical turbine pumps provide the ultimate in reliability and ease of installation. With six-inch to 18-inch bowl diameters, the VT Series provides quiet, dependable performance for cooling tower, chilled water, water transfer, pressure boosting and water supply applications. The Taco VT Series vertical turbine pumps offer upgraded materials of construction as Read more

Product Spotlight

Taco Comfort Solutions’ VT Series vertical turbine pumps provide the ultimate in reliability and ease of installation. With six-inch to 18-inch bowl diameters, the VT Series provides quiet, dependable performance for cooling tower, chilled water, water transfer, pressure boosting and water supply applications.

Taco Comfort Solutions’ VT Series vertical turbine pumps provide the ultimate in reliability and ease of installation. With six-inch to 18-inch bowl diameters, the VT Series provides quiet, dependable performance for cooling tower, chilled water, water transfer, pressure boosting and water supply applications.

The Taco VT Series vertical turbine pumps offer upgraded materials of construction as standard features. All impellers are investment cast stainless steel to provide longer life and better abrasive and corrosive resistance. All bowls and discharge heads are ductile iron for higher hanging weight and better tensile strength.

For more information, visit www.TacoComfort.com

Grundfos has released the Dosing Skid Configurator, a new, interactive digital tool featuring thousands of configuration variants to serve an array of markets with complete chemical dosing solutions. By answering a few simple way-of-use questions to configure the best solution, the Dosing Skid Configurator generates an interactive 3-D model of a pre-engineered dosing skid system—one Read more

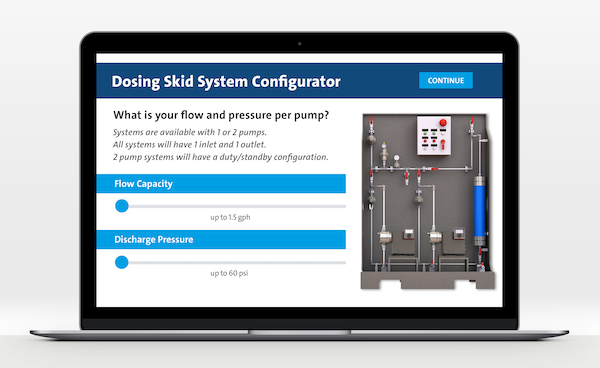

Grundfos has released the Dosing Skid Configurator, a new, interactive digital tool featuring thousands of configuration variants to serve an array of markets with complete chemical dosing solutions.

By answering a few simple way-of-use questions to configure the best solution, the Dosing Skid Configurator generates an interactive 3-D model of a pre-engineered dosing skid system—one of 16,000 possible configuration variants—a materials list, dimension drawings, list pricing, a downloadable submittal package, and a contact form to reach a Grundfos distributor to learn more about ordering and availability.

“Engineers and end-users who use dosing skid systems for water treatment or PAA dosing for food and beverage facilities can now design and select complete dosing solutions based on their needs, then visualize their customized system,” said Jay Stellmacher, vice president of sales for industry. “They can change any of their answers on the fly with the available drop-down tabs and instantly see a new customization.”

Historically, chemical dosing pump skid systems would require someone to have in-depth knowledge of a dosing pump manufacturer’s variations and related capabilities to fit into specific applications along with the right know-how to correctly install them. In the new tool, Grundfos has integrated recommendations provided by the company’s dosing experts for materials of construction that are based on the selection of the chemical being pumped.

“When we set out to design the Dosing Skid Configurator, we knew that system integrators and engineers had enough on their plates, so the goal was to make their lives easier,” said Jared Gabel, Grundfos business development manager for water treatment. “At Grundfos, we want to be simple to do business with, and this tool is proof of that.”

The Dosing Skid Configurator allows the user to design their custom skid system by selecting the flow capacity and discharge pressure per pump, and pumped liquid for applications that include 12.5% Sodium Hypochlorite, 93% Sulfuric Acid, 10% Hydrochloric Acid, 50% Sodium Hydroxide, Sodium Bisulfate, or Peracetic Acid. In the future, Grundfos plans to add more chemicals for the pumped liquid section based on customer feedback. Additionally, selections are available to factor in controls and functionality, from remote Start/Stop to graphical display, Field Bus Protocol, number of pumps (simplex or duplex), floor or wall mounting, and pipe material or choice between standard/vented ball valves.

“The focus on packaged pump solutions is increasing as system providers look upon the expertise of pump manufacturers,” said Gabel. “This is especially true in the mystical world of chemical feed systems.”

Grundfos Engineered Systems and packaged Dosing Skid System solutions for industrial, municipal and commercial buildings applications are designed and manufactured in the company’s Brookshire, Texas, facility. Solutions include optimized pumping systems with intelligent controls and packaged plants that include a selection of the most efficient equipment technology available for each application.

Start customizing your Grundfos Dosing Skid System at grundfos.us/dosingskids.

Neutra-Safe Corporation, based in Stoughton, Mass., has redesigned its four-inch, tube-style condensate neutralizers. The high capacity neutralizers now include all the same features that make Neutra-Safe’s two-inch models so easy to install and service. Features of the new design include full opening integral union ends, bi-directional condensate flow, ¾” Female NPT inlet/outlet tappings and ¾” Read more

Neutra-Safe Corporation, based in Stoughton, Mass., has redesigned its four-inch, tube-style condensate neutralizers. The high capacity neutralizers now include all the same features that make Neutra-Safe’s two-inch models so easy to install and service.

Neutra-Safe Corporation, based in Stoughton, Mass., has redesigned its four-inch, tube-style condensate neutralizers. The high capacity neutralizers now include all the same features that make Neutra-Safe’s two-inch models so easy to install and service.

Features of the new design include full opening integral union ends, bi-directional condensate flow, ¾” Female NPT inlet/outlet tappings and ¾” male NPT x socket fittings. The unit also comes with snap-in mounting brackets included.

The redesigned CN4B-600C, CN4B-850C, CN4B-1200C, CN4B-2000C four-inch neutralizers are designed to facilitate the use of Neutra-Safe’s proprietary media sacks for simple recharging of the unit. This Neutra-pH media blend is a blend of blend of 99 percent pure calcite and magnesium oxide, provides the most efficient neutralization possible. It eliminates clumps that can clog traditional neutralizers. The sack can be opened to release the media for use in Neutra-Safe’s older four-inch tube models.

The best features of the original four-inch neutralizer remain, including a clear tube for easy visual inspection and patented integral union ends with O-ring seals for a leak-proof connection.

Neutra-Safe’s tube style condensate neutralizer line includes seven models, serving high-efficiency, gas-fired appliances up to 2 million BTUH input capacity.

For more info, www.NeutraSafe.com.

Advanced sensors deliver better in-pipe images while reporting the pitch of the camera in-pipe Experience the first true data-enabled plumbing diagnostic cameras with the new line of RIDGID® SeeSnake® cameras powered by TruSense™ technology. TruSense establishes a two-way datalink path between the camera head and a connected RIDGID SeeSnake CSx series Wi-Fi enabled monitor. With Read more

Advanced sensors deliver better in-pipe images while reporting the pitch of the camera in-pipe

Experience the first true data-enabled plumbing diagnostic cameras with the new line of RIDGID® SeeSnake® cameras powered by TruSense™ technology. TruSense establishes a two-way datalink path between the camera head and a connected RIDGID SeeSnake CSx series Wi-Fi enabled monitor. With TruSense, advanced sensors on the camera head convey valuable information about the in-pipe environment.

SeeSnake cameras with TruSense technology include a high dynamic range (HDR) image sensor that takes the next leap forward in diagnostic imaging. A common challenge faced by diagnostic professionals is being able to see far down the pipe as well as the image just in front of the camera’s lights. An HDR image sensor expands the camera’s dynamic range, allowing a greater ratio of bright and dark areas to be displayed in the same image at the same time without reducing visibility. This means fewer blown-out areas and sections of the pipe that are too dark to see, offering superior clarity and detail.

TiltSense is an on-camera inclinometer that is included on SeeSnake cameras with TruSense technology. The inclinometer measures the camera’s angle. When connected to a SeeSnake CSx series monitor, the camera can convey the camera’s degree of tilt on the monitor display – giving you a useful indicator of the pitch of the camera in-pipe.

“RIDGID SeeSnake cameras are trusted for having the clearest in-pipe picture along with features that help our customers work smarter and faster,” said Tim Dunphy, RIDGID Marketing Director of Underground Technologies. “With TruSense technology, HDR sensors and TiltSense deliver the image quality and information contractors need to see.”

SeeSnake cameras with TruSense technology are available in self-leveling models, which keeps the image upright, and non self-leveling models. All RIDGID SeeSnake cameras come with the RIDGID Full Lifetime Warranty.

To purchase or learn more about SeeSnake cameras with TruSense contact your local distributor, visit RIDGID.com, or call toll-free: 1-800-769-7743.

Lochinvar, an industry leader in high-efficiency boiler and water heater technology, today announced the expansion of its commercial gas water heater family with the most durable and powerful SHIELD™ models yet. Available in standard and ASME construction, the models now range from 125,000 to 500,000 Btu/hr and offer up to 96 percent thermal efficiency. “The Read more

Lochinvar, an industry leader in high-efficiency boiler and water heater technology, today announced the expansion of its commercial gas water heater family with the most durable and powerful SHIELD™ models yet. Available in standard and ASME construction, the models now range from 125,000 to 500,000 Btu/hr and offer up to 96 percent thermal efficiency.

Lochinvar, an industry leader in high-efficiency boiler and water heater technology, today announced the expansion of its commercial gas water heater family with the most durable and powerful SHIELD™ models yet. Available in standard and ASME construction, the models now range from 125,000 to 500,000 Btu/hr and offer up to 96 percent thermal efficiency.

“The recent SHIELD upgrades mark new strides in engineering. Our research and development teams have been working hard to design a new system that will boast even better efficient technology,” said David George, Lochinvar product manager. “With the highest durability built into every SHIELD commercial gas water heater, facility managers and contractors can count on solid performance and reliability for projects ranging from multi-family developments to universities.”

The SHIELD product family is designed to minimize lime scale buildup in the tank and on heating surfaces. By controlling and creating high water velocity through the heat exchanger, lime scale buildup is reduced, and the heating surfaces and tank are kept clean, so thermal efficiency remains high for the life of the product.

Designed for a variety of commercial applications, the newly upgraded SHIELD models feature a fully modulating burner with a 5:1 turndown ratio. The new design can fire as low as 20 percent of maximum input when water heating demand is lowest and increases to 100 percent for peak demand periods. This results in better overall efficiency and less cycling compared to “on-off” tank-type units that only fire at 100 percent.

The new models also offer multiple connectivity platforms with optional CON•X•US®, MODBUS® and BACNET™ modules. Lochinvar’s CON•X•US remote connectivity platform gives commercial facility managers and building owners the ability to monitor and adjust equipment controls from a mobile app. The MODBUS and BACNET capabilities allow building managers to monitor and manage the units through their local building management systems.

These models feature Lochinvar’s advanced SMART CONTROL™ System, providing a bright, backlit LCD display with soft-key buttons and a wide variety of advanced control functions, including readouts of setup, system status and diagnostic information.

All utility and water connections are located at the top of the appliance to reduce equipment room footprint and increase installation flexibility.

The SHIELD family now features 10 models, ranging from 125,000 to 500,000 Btu/hr. For more information about the SHIELD product line, visit www.Lochinvar.com.