Streamlining HVAC/R connections for safer, faster installs QuickFitting®, a leader in plumbing and HVAC solutions, announces the launch of HVAC/R Push-to-Connect refrigerant fittings, an innovation that simplifies the installation and maintenance of HVAC/R systems. With no flaring, brazing or special tools required, installers can connect refrigerant lines in seconds simply by pushing the fitting onto Read more

Toolbox

Streamlining HVAC/R connections for safer, faster installs

QuickFitting®, a leader in plumbing and HVAC solutions, announces the launch of HVAC/R Push-to-Connect refrigerant fittings, an innovation that simplifies the installation and maintenance of HVAC/R systems. With no flaring, brazing or special tools required, installers can connect refrigerant lines in seconds simply by pushing the fitting onto the pipe. This approach enables contractors and technicians to make leak-free connections in seconds to reduce installation time and simultaneously enhance safety on the jobsite.

QuickFitting’s HVAC Push-to-Connect refrigerant fittings significantly cut back the time and risk involved in installing or repairing refrigerant lines. Compared to traditional methods, push-to-connect technology enables the rapid joining of copper or coated aluminum line sets in seconds. By eliminating the need for an open flame, the fittings enhance safety on the jobsite and provide technicians with greater flexibility to work in confined or sensitive environments. The result is a faster and safer installation process that helps HVAC professionals complete jobs more efficiently and with reduced risk.

“This innovation was derived from a true need in the market,” said Katie Zyra, marketing director at QuickFitting. “By removing the need to braze, obtain a hot work permit, and have fire spotters, you’re reducing risks while saving time and money on the jobsite. Our patented leak-proof technology significantly saves time, reduces the possibility of errors and improves worker safety without compromising performance.”

A patented double O-ring and grip ring seal delivers a secure, leak-free connection that withstands galling, vibration, pulsation and extreme temperature changes. The heavy-duty body is corrosion- and UV-resistant for long-lasting performance, while yellow protective caps keep debris out during handling and installation. These fittings are designed for residential and commercial HVAC/R applications and are compatible with copper and coated aluminum line sets, as well as HVAC/R units and unitary indoor coils. They are approved for use with industry-standard refrigerants, including A2L-class refrigerants R-452B and R-454B. Unlike permanent solder/ brazed fittings, QuickFitting’s Push-to-Connect fittings are removable using the patented HVAC Slip Clip™ Release Tool.

Installation is reduced to a simple four-step process: Clean, Debur, Mark and Push. The process begins with cutting the tube at a straight angle and thoroughly cleaning it using an abrasive cloth. The next step involves deburring the inside and outside edges to achieve a smooth finish. Once prepared, the tube should be marked with the correct insertion depth before pushing the fitting onto the tube up to the marked line – no additional tools are required. To remove installed fittings, the system charge must first be isolated or removed to ensure safety. The Slip Clip™ is then slid onto the fitting end, and once properly aligned, the fitting can be pulled away from the pipe to release the connection.

For more information about SurePress, visit www.quickfitting.com.

Viega North America announces the latest additions to its product portfolio, adding globe, wafer check and butterfly valves to its MegaPress® and ProPress® portfolio. Viega press technology works across a wide range of materials, applications and configurations. These new products integrate seamlessly into Viega’s extensive product portfolio. Using Viega, customers can press everything from PEX Read more

Viega North America announces the latest additions to its product portfolio, adding globe, wafer check and butterfly valves to its MegaPress® and ProPress® portfolio.

Viega press technology works across a wide range of materials, applications and configurations. These new products integrate seamlessly into Viega’s extensive product portfolio. Using Viega, customers can press everything from PEX in residential systems to copper and carbon steel in commercial situations and stainless steel in industrial piping systems with one tool. Viega MegaPress, ProPress and PureFlow® systems are all approved for over 2,500 applications, ensuring a solution for nearly every plumbing need four inches and under.

“With Viega, customers have an entire ecosystem designed to work together seamlessly. Viega products help streamline the installation process, boosting both speed and productivity. Pressing these valves and fittings with one tool saves valuable time and labor costs, all while ensuring that plumbing systems are secure and reliable,” said John Browning, Director, Product Management.

The new products launched are:

- MegaPress 316 Globe Valves

- ProPress and MegaPress Butterfly Valves

- ProPress and MegaPress Wafer Check Valves

The MegaPress 316 Globe Valve is the first globe valve on the market with IPS press ends and features EPDM or FKM sealing elements. Available ½″ – 2″, this globe valve provides precise flow regulation where throttling fluids is essential. Model 5185.1 with the EPDM sealing element features NSF-61 approval for potable water systems. Looking to use this in more challenging environments? Model 5985.1 with FKM sealing elements, 316 stainless steel body and components provide excellent corrosion resistance, enhancing the valve’s durability.

The ProPress and MegaPress Butterfly Valves, available in sizes 2 ½-4″, complete your system with dependable Viega press technology. These butterfly valves provide reliable flow isolation and control and are NSF-61-rated. Model 2979.8ZL is crafted with a ductile iron body and durable epoxy coating, proving more cost-effective than carbon steel while offering higher pressure and temperature ratings than cast iron. Model 5179.8 features a 316 stainless steel body, providing superior corrosion resistance against even the harshest medium. Both versions are equipped with an EPDM seal. These butterfly valves are optimized for use with ProPress and MegaPress flange adapters.

The ProPress and MegaPress Wafer Check Valves are used to prevent reverse flow. Available in sizes 2 ½″ – 4″, these valves feature a dual-disk design to create a more streamlined flow path, reducing pressure drops and increasing energy efficiency. Models 2974.3XL and 5174XL include an NSF-61 rating, making them the ideal choice for installing potable water systems with ease. Model 5974XL has FKM sealing elements for more demanding applications. This compact wafer check valve is optimized for use with ProPress and MegaPress flange adapters.

To learn more about the full line of Viega ProPress, MegaPress and PureFlow valves, visit Viega | viega.us

Don’t be fooled by imitations! Over 50 years of technical advancements make the rugged, all-metal Kinetic Water Ram® the choice for quickly clearing clogged drains. Just pump it up, insert in drain – and snap the trigger. It’s that fast. Lightweight and economical, the futuristic Kinetic Water Ram generates a shock wave that instantly pulverizes Read more

Don’t be fooled by imitations! Over 50 years of technical advancements make the rugged, all-metal Kinetic Water Ram® the choice for quickly clearing clogged drains. Just pump it up, insert in drain – and snap the trigger. It’s that fast.

Lightweight and economical, the futuristic Kinetic Water Ram generates a shock wave that instantly pulverizes stoppages in 1-1/4″ to 4″ lines – yet won’t harm pipes. Quickly clear clogged sinks, toilets and tubs of grease, hair, sediment and debris.

Environmentally friendly, the compact, portable drain cleaning tool is cleaner than snakes – and safer than chemicals. It requires no electrical power or CO2 gas.

The Kinetic Water Ram uses a burst of compressed air that drives a shock wave (kinetic energy) through water to break up the stoppage. The shock wave bypasses vents and stacks to break-up clogs. You get instant impact with no pressure build-up. The built-in pump and pressure gauge lets you choose the right amount of force for each job.

The Kinetic Water Ram is particularly useful when the stoppage is on the far side of a drum trap or series of tight bends, since the shock wave can travel around bends without losing its force.

The sleek and easy-to-handle Kinetic Water Ram is made of durable plated metal components. The unit comes in a sturdy carrying case with molded compartments for the drain cleaning tool and accessories.

Learn more: https://drainbrain.com/en/products/kinetic-water-ram/

Franklin Electric Co., Inc. (NASDAQ: FELE) announced that its Little Giant brand is expanding its condensate removal product line with the addition of a series of condensate neutralizing products. The new products include an integrated condensate neutralizer media, helping to treat acidic condensate before it enters a residential plumbing system. The Little Giant VCMA-20-NPTC Neutralizing Read more

Franklin Electric Co., Inc. (NASDAQ: FELE) announced that its Little Giant brand is expanding its condensate removal product line with the addition of a series of condensate neutralizing products. The new products include an integrated condensate neutralizer media, helping to treat acidic condensate before it enters a residential plumbing system.

The Little Giant VCMA-20-NPTC Neutralizing Condensate Pump is driven by a 1/30 hp high-performance motor and features a specialized blend of neutralizing media made of calcite and magnesium oxide for the best neutralizing effect without clumping or clogging. An easy-to-remove clear cover allows for simple media changing and routine maintenance.

The NC-2 Series tube-style neutralizers from Little Giant feature integral unions with O-ring seals and snap-in mounting brackets. Little Giant offers three different models, accommodating both horizontal and vertical installation–as well as 220,000 and 300,000 BTU/hr of appliance input. The neutralizing media-filled sack allows for easy removal for service and recharging to maintain the effective treatment of acidic condensate to prevent damage to a building’s infrastructure, local sewage systems and the environment.

Easy-to-install replacement media kits will be available for all four Little Giant models.

To learn more about these products and Little Giant’s complete line of industry-leading condensate pumps, visit LittleGiant.com.

Patented HVAC condensate drain line maintenance system prevents blockages of condensation drain lines due to buildup of bacteria, slime, rust, scale, sludge, airborne dust, silt and algae Cool Air Products introduces the Combat P-Trap for achieving constant drain flow maintenance through a unique condensate drain line treatment tablet dispensing method. Adaptable for universal applications, the Read more

Patented HVAC condensate drain line maintenance system prevents blockages of condensation drain lines due to buildup of bacteria, slime, rust, scale, sludge, airborne dust, silt and algae

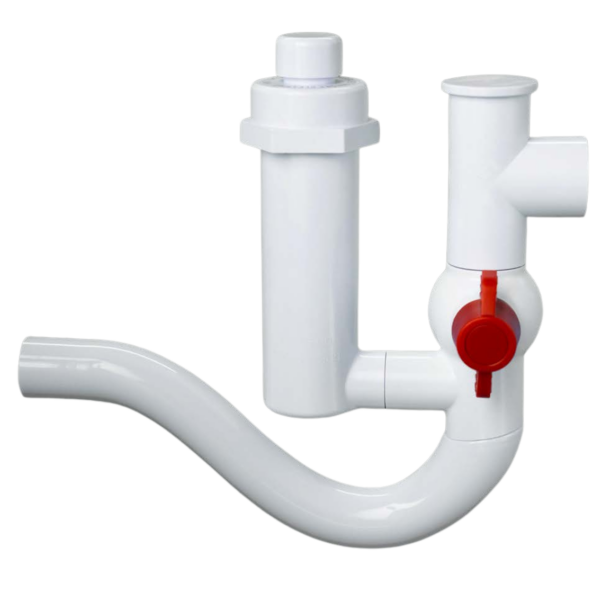

Cool Air Products introduces the Combat P-Trap for achieving constant drain flow maintenance through a unique condensate drain line treatment tablet dispensing method.

Adaptable for universal applications, the Combat P-Trap prevents blockages of condensation drain lines due to the buildup of bacteria, slime, rust, scale, sludge, airborne dust, silt and algae, commonly known as “White Slime” or “Zoogloea.” If clogs do occur because the cartridge of tabs is empty, users can clear blockages by simply turning the shut-off valve and removing the cap and basket and using a preferred type of device–vacuum, CO2 gun or Nitrogen.

“The Combat P-Trap allows for constant drain flow maintenance through the unique condensate drain line treatment tablet dispensing method,” said Mike Walton, president at Cool Air Products. “The adaptable Combat P-Trap provides a universal solution for technicians, that is easily installed, and ideal for service agreements.”

The Combat P-Trap is easily insulated with standard insulation and helps to reduce noise by decreasing reverberations of airflow and draining condensate. The Combat P-Trap fits Cool Air Products’ Combat Tabs and all chlorine tabs on the market.

Currently, sales from the Combat P-Trap provide support to the K9s For Warriors, a nonprofit organization that provides trained service dogs to veterans with both PTSD and TBI at no cost to the veteran.

For more information on the Combat P-Trap, visit: www.coolairproducts.net/products/combat-ptrap.