Identifies hard to see problems and saves homeowners money

For many years, utilities and large companies used thermal imaging to uncover potential heat problems across large areas and to keep track of heavy machinery. But more recently, thermal imaging has truly become a game changer for most contractors and others in the building trades. Thermal cameras help contractors find and document energy loss and other problems they could not otherwise easily find. This saves them time and money – which ultimately results in homeowners saving money. Most recently, contractors have begun to combine portable thermal imaging cameras with moisture meters. Using thermal imaging to find the issue and the moisture meter to verify it saves time and helps avoid surprises that will ultimately cost homeowners more.

Thermal imaging benefits contractors and homeowners

Thermal imaging detects heat given off by an object or person. It takes the energy and translates it into light that can be seen. Using the typical “Ironbow” color palette, the viewer sees the light in a range of colors: red, orange, and yellow indicates heat, while dark blue, black, or purple signifies colder temperature. Cold can represent air leaks through door and window frames, missing insulation, and water – especially evaporating water. No other technology can provide this information. Using radiation energy, contractors can now actually “see” energy loss. It is like giving contractors a super power! Thermal imaging is extremely sensitive; potential problems stand out and can be found and documented in real time.

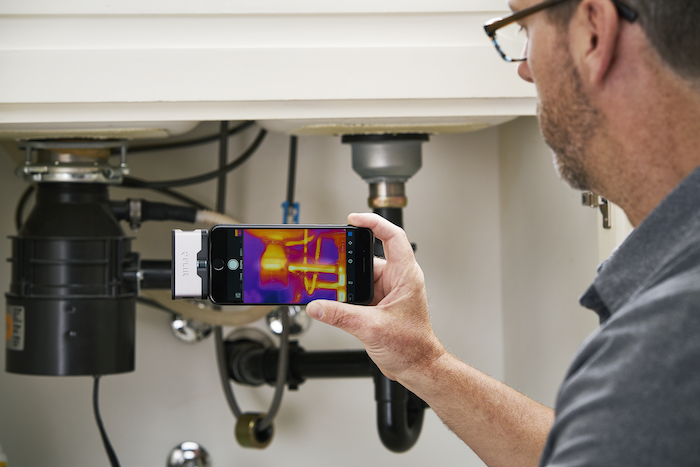

Thermal imaging camera in action.

Home inspectors were the first to adopt the use of thermal imaging, but all the building trades are now jumping on board. Most recently electricians, HVAC technicians, and plumbers have started to use thermal imaging to find problem areas quicker—and from a safer distance. In essence, thermal imaging can be used by all trades – if they are not using it now they should start using it.

The number one application contractors use thermal imaging for is to locate energy loss in hotter and colder months caused by missing insulation and poor sealing around doors and windows. Interestingly, the number two use is to locate pest infestations, including termites and rodents. While thermal imaging cannot “see” a single termite, it is excellent for locating termite nests, because of the massive amount of heat generated by huge numbers of termites living together. The third most common application is for detecting water intrusion in houses and business. Thermal imaging points contractors in the right direction, and moisture meters are then used to isolate the problem.

One other essential feature of thermal imaging is that it can be used to document issues to show customers. As a contractor who works closely with clients, I believe it is absolutely crucial that customers have a clear and in-depth understanding of what is going on with their project. Thermal imaging gives contractors the ability to proactively bring up and demonstrate issues. If the issue is something they should be concerned with, it is important to be able to document that issue with a picture or video. The more information homeowners have, the better off they will be.

Pairing thermal imaging with moisture meters offers a one-two punch

Recently, many in the building trades have begun to realize the benefits of pairing thermal imaging with moisture meters. This combination is especially effective because thermal imaging by itself does not distinguish between cold temperatures and moisture. Both show up as a dark blue image, so contractors cannot tell if the image indicates moisture or cold air. Using the two technologies together, they can simultaneously find energy loss and moisture intrusion – giving contractors a real one-two punch.

Thermal imaging can reveal issue regarding missing insulation or poor sealing around window or door.

Using thermal imaging to find the issue and the moisture meter to verify it saves time – by taking the moisture meter to the area of concern a contractor can isolate the problem and quickly determine its seriousness and extent. Before the ability to pair the two technologies, contractors had moisture meters, but they had to tear the entire wall down to address a suspected problem. Using the non-contact or non-invasive/non-destructive detection methods together helps contractors confine the problem to a smaller area so they can avoid taking that wall down. The moisture meter will indicate if the spot is a matter for concern.

New affordable technology makes combining thermal imaging and moisture reading a snap

In the past few years I have been bringing thermal imaging and moisture reading equipment to every job site I visit. I use the FLIR ONE® PRO thermal imaging camera attachment in combination with the FLIR MR40 moisture meter. Both are extremely easy to use, which is especially helpful for those contractors who are not particularly tech savvy. You can attach the thermal camera to your smart phone, and the phone becomes the viewer.

I started using FLIR thermal imaging technology some years ago and this latest third generation technology has significantly improved, with even better image quality. At a cost of only $399, the FLIR ONE Pro is much more affordable for contractors than in the past. It also pays off quickly because of the money saved by finding problems more quickly.

Especially useful is the multi spectral dynamic imaging (MSX) technology, which enables users to overlay the visual with the thermal to get a clear image that the contractor can then decipher. This means users are not just seeing a screen of colors, they are seeing the definition of what they are looking at.

FLIR MR40 moisture meter in use.

MSX incorporates real-time thermal video enhanced with visible spectrum definition. It produces exceptional thermal clarity to highlight exactly where the problem is. MSX ensures easier target identification without compromising radiometric data. The quality of the thermal images is excellent, with almost no need for a separate digital image. With MSX, thermal images look sharper, the orientation of the target is done more quickly and the reports are clutter-free. Users can see the results of MSX technology directly on the touchscreen of the camera, in real time.

Another practical feature of the FLIR ONE Pro is the 1-fit connector. This allows users to adjust the camera’s fit, so they can use the attachment with thicker cell phone cases.

The FLIR MR40 moisture meter is my go-to option, primarily because it is so easy to use. Anyone can operate it easily, even if they have never used a moisture meter before. The portable, rugged moisture meter comes with an integrated flashlight. It is also small and tough, fitting easily in a pocket. I have used it in tight spaces and I have dropped it, and the meter remains accurate and incredibly reliable. It is affordable and a quick tool to find and quantify moisture content. When used in combination with a thermal camera, MR40 can help confirm whether a cold spot in a thermal image is moisture, and measure the severity of the problem. If it measures in the 20 percent range or above, it would be considered a problem. Below 10 percent it would not be considered a problem.

Other all in one imagers plus moisture meter options include the FLIR MR160 and the MR176. With these options there is no need to carry two separate pieces of equipment.

New technology provides contractors with peace of mind

Using the FLIR ONE Pro in combination with the FLIR MR40 moisture meter has made a big difference in my business. I look on them as tools like all the others that would be used on a job, but they are especially important in the initial phase of dealing with customers and quoting jobs. In the past unforeseen issues would arise that would bring higher costs. Now, contractors can virtually see the invisible, reducing unforeseen and unwelcome surprises often costing more money to repair.

As a contractor, the tools provide peace of mind, and also ensure the situation has been thoroughly examined. I never leave home without them.

By Jason Cameron, licensed contractor and host of DIY Network’s Desperate Landscape, Man Caves and Sledgehammer.