If you buy an ECM circulator later this summer, you’re likely to see something new stuck to it: an Efficiency Rating label courtesy of the Hydraulic Institute. The labeling represents independent, third-party verification of each circulator’s overall electrical efficiency.

That sounds pretty cool, but what does it all mean?

Well, for starters, it means you don’t have to rely on marketing claims or sales mumbo-jumbo to determine who has the most advanced and efficient circulators. And you don’t have to rely on vague math to determine how much less an ECM circulator will cost to run compared to its standard efficiency counterpart.

In other words, it’s there in black and white.

There’s a lot to unpack here, so let’s get started.

First Off, Just What Is the Hydraulics Institute?

The Hydraulics Institute, or HI for short, touts itself as the global authority on pumps since 1917. It’s an industry association working on behalf of the pump industry and works with the U.S. Department of Energy to establish guidelines and regulations for pumps of all types and sizes. Most recently, its efforts with the DOE led to commercial pump efficiency regulations that went into effect in January of 2020, covering all pumps 1 H.P. and above.

The new labeling on ECM’s under 1 HP can be considered a pre-cursor to DOE regulations that will ultimately phase out standard efficiency circulators. However, don’t expect those regulations to go into effect for at least two, maybe three more years.

The new labeling on ECM’s under 1 HP can be considered a pre-cursor to DOE regulations that will ultimately phase out standard efficiency circulators. However, don’t expect those regulations to go into effect for at least two, maybe three more years.

While HI is an organization made up of pump and circulator manufacturers, it’s important to note that all of its guidelines and regulations are set in concert with the DOE. In its most basic form, the DOE says, “this is what you have to do.” HI, in turn, develops guidelines, test procedures and processes manufacturers need to follow in order to be rated.

HI also certifies each manufacturer’s test lab, and it fully audits all test results. Yes, manufacturers test their own pumps, but only if their test lab is certified. HI creates all testing procedures and guidelines, including machinery calibration, personnel training and record keeping. Labs are periodically inspected, and all test results are reviewed and audited.

The whole process is set up so there’s no scamming the system. The results are the results.

But What About the Ratings?

You’ve no doubt seen those ubiquitous yellow EnergyGuide stickers on just about every appliance under the sun. They’re not only on fridges, dryers and other everyday items, they’re also on boilers, furnaces, A/C units and heat pumps. The Federal Trade Commission requires those stickers to give consumers an idea of relative energy efficiency compared to similar units.

The new HI Energy Rating stickers on circulators are pretty much the same thing, only different.

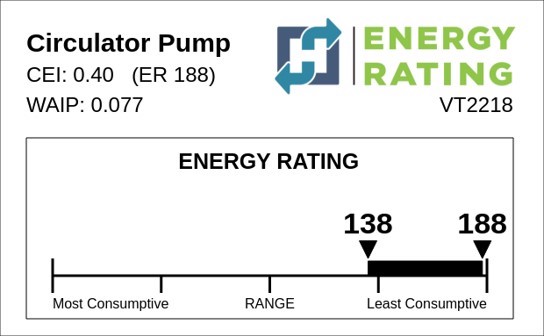

Instead of giving you an estimated yearly energy cost, the new HI Energy Rating stickers give each circulator an Energy Rating score, or an ER. It’s a pretty easy rating to decipher: the higher the number, the more efficient the circulator.

For example, an ECM circulator with an ER of 188 consumes 10 percent less energy than a circulator with an ER of 178.

By comparison, a common standard efficiency circulator, such as a Taco 007 or a Grundfos 1558, would have an ER in the neighborhood of 48 to 50.

The math to calculate the ER is fairly detailed, so it would take someone way smarter than me to walk you through it. The ultimate value of ER, however, is to provide a simple way to show a customer how much less an ECM circulator will cost to operate compared to its standard efficiency counterpart based on independent, third-party testing.

Let’s Do THAT Math!

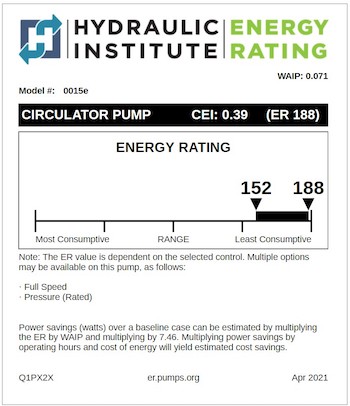

Let’s look at the ER label for the Taco 0015e3. The 0015e3 is a variable speed Delta-P circulator with three settings, two for constant pressure and one for full-speed, fixed speed. It’s the perfect pump to use for zone valve applications and does a dandy job as a zone circulator as well.

As you can see, the 0015e3 has an ER ranging from 152 in its least efficient mode, which is that full speed, fixed speed setting. In its most efficient operating mode setting – variable speed, constant pressure Delta-P – the ER goes to 188.

And not for nothing, Taco has four circulators with 188 ratings (and a fifth rated at 187). Those are the highest rated circulators on the HI database (Armstrong also has a circulator rated at 188. No one else is within six ER points). You can access the HI database here.

The full ratings label provides you with the math to determine how much a particular circulator will save. You first multiply ER by something called WAIP, which stands for Weighted Average Input Power. WAIP represents the average input power in horsepower for an ECM circulator without controls:

188 x 0.071 = 13.348

Next, to convert horsepower to watts, you’d multiply by 7.46:

13.348 x 7.46 = 99.58 watts

From here on it, it’s a simple kWh/cost calculation. To convert watts to kilowatts, you divide by 1000, and then multiply by the estimated number of run hours over a heating season. For this example, we’ll use 2500.

99.58 ÷ 1000 = 0.09958 kilowatts

0.09958 kW x 2500 hours = 248.95 kWh

Last, multiply kWh by your cost per kilowatt hour. That will tell you how much less the 0015e3 would cost to operate compared to a 007 or 1558:

248.95 kWh x 0.15 per kWh = $37.34

Is that a Lot?

Well, it depends. If you’re trying to justify replacing four perfectly good and not terribly old circulators with four ECMs, you’ll save just under $150 per heating season. Depending on how much you charge for the swap out, it might be a hard sell. And there’s nothing “green” about dumping four perfectly good circulators before their time.

However, if you’re trying to show a customer (or yourself, for that matter) that replacing a dead circulator with a more expensive ECM is worth it, you now have something to sink your teeth into.

However, if you’re trying to show a customer (or yourself, for that matter) that replacing a dead circulator with a more expensive ECM is worth it, you now have something to sink your teeth into.

Say a standard efficiency 007 or 1558 dies and you want to replace it with a 0015e3. Yes, the 0015e3 costs more. But just channel your inner Cosmo Castorini from Moonstruck and tell them, “it costs money, because it saves money.”

Without getting into wholesale costs, profit margins and selling prices (those are your business), it’s fair to say that based on a $37.34 annual savings, the 0015e3’s higher selling price will be offset in less than two heating seasons. After that, the homeowner pockets the rest.

And if you want to talk about how a properly programmed ECM, particularly one that operates on a fixed Delta-T, will help the overall system work better, let’s make an Outlook appointment. There’s a LOT more to discuss.

What’s the Point?

So, why HI is doing this labeling thing in the first place? Simple: to give the industry an easy—and independent—way to show the value of converting from standard efficiency to ECM.

In markets where local utilities do not offer incentive rebates to drive conversion, ECM conversion has been snail’s pace slow. Some of it is a little of the “if it ain’t broke, don’t fix it,” mindset. Some of it has been ridiculous claims of “magic” and the misguided promise that these circulators somehow mean you don’t have to know how to size a pump. No one with half a mind believes that nonsense.

And some of it is, to put it gently, giving new technology a healthy—and distant —respect.

But for the most part, it’s been price resistance.

What the ER label does is give you an easy way to show a customer a fundamental truth: they’re going to be paying for the ECM circulator one way or another. The only question is whether they actually get it or not.

Remember Cosmo’s words.