RLS is the manufacturer of the original, patented, proven press-to-connect fittings for high-pressure HVAC and refrigeration applications. These are the same reliable fittings that have been in widespread use – and fully registered and listed to UL207 for pressures up to 700 PSI – since 2015.

Faster and Easier

Using an RLS-approved battery-powered tool and jaws, copper tube connections can be made in less than 10 seconds, resulting in jobs being completed up to 60% faster compared to conventional brazing. So RLS fittings help you get the job done sooner, get to the next job faster and get more jobs done. Plus, no brazing means no hauling brazing equipment and materials from jobsite to jobsite.

Safer

By eliminating the flame from the workplace, RLS press fittings create a safer work environment, removing all the dangers and precautions that come with brazing, as well as eliminating costs:

- No flammable gas

- No fire hazards

- No fire spotters

- No hot work permits

- No nitrogen purging

Reliable

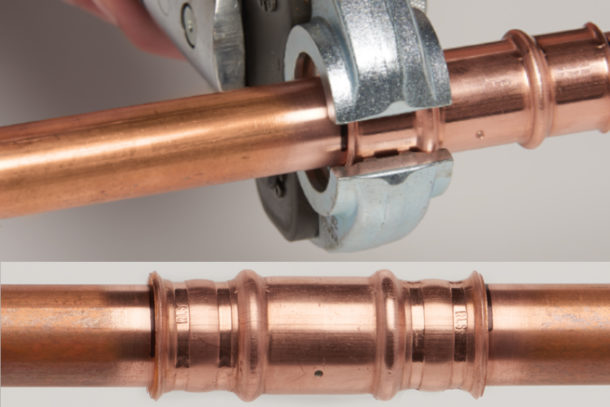

The RLS patented design uses a double circular crimp that work hardens the copper to create a permanent mechanical joint that seals off the O-ring from outside air. The circular crimp also maintains the circular shape of the tube and results in a smooth ID. More than 8 million RLS fittings have been installed worldwide since 2015, so they have a proven track record of dependability. They are also backed by a 10-year limited warranty.

Full Product Line

RLS offers all the products you need to get the job done… couplings, tees, long-

radius elbows, reducers, caps and much more. Current sizes range from ¼” to 1-3/8”, with the “RLS XL” line of 1-5/8" and 2-1/8" press fittings coming later in 2020.

Check with your local distributor for RLS press fittings or visit

www.rapidlockingsystem.com for more information.

Join the conversation: