Located in the East Bay area of Oakland, near the hollow ground of Oakland Alameda Coliseum, AB&I Foundry has been finding ways to build on its legacy and cutting-edge innovations for over a century. In fact, as a leading producer of cast iron soil pipe, fittings and castings with a distinct black and silver look Read more

AB&I Foundry

Located in the East Bay area of Oakland, near the hollow ground of Oakland Alameda Coliseum, AB&I Foundry has been finding ways to build on its legacy and cutting-edge innovations for over a century. In fact, as a leading producer of cast iron soil pipe, fittings and castings with a distinct black and silver look, one may also wonder where and how the Oakland Raiders came about creating their brand identity nearly 70 years ago. It’s said that AB&I’s Boscacci family was vital in assisting the Raiders establish their community footing and possibly sharing their tradition colors.

Community and team are critical to the history and the future of AB&I. When you drive by the foundry, you can’t miss the big mural that runs a city block on the wall outside of the company. It shows the history of the company through various milestones and despite the location in an industrial area, the wall has never been defaced. One might surmise that this is the ultimate type of respect AB&I has built in the community through their commitment of employing, educating and providing for generations of families. How did it start?

Joseph Boscacci

Joseph Boscacci emigrated from Switzerland to the U.S. in the 1890s, bringing with him an artisan craft. In the wake of the Great San Francisco earthquake and fire of 1906, the young Boscacci worked at General Foundry in San Francisco making bronze statuary, brass street lamps and ornate iron work that was needed for the city’s rebuilding effort.

He also ran his own foundry business on the weekends in the backyard of his home in Oakland. Boscacci and his five sons made a variety of castings, including cast iron fittings, window sash weights and cast iron stove tops for wood burning cook stoves. He called his company American Brass & Iron.

As the decades unfolded and American industry grew, so did the need for cast iron pipe and fittings. By the 1920s, all the Boscacci brothers were involved in the family business. In 1941 the company was moved to their current location on San Leandro Street in Oakland. Just after World War II, brothers Arnold and Eugene took over the foundry and rebranded to AB&I.

American Brass and Iron Foundry in the 1920s

It was the post-war return of the GI’s and housing boom (not too mention ensuing baby boom), that reignited the ever-entrepreneurial Boscacci family back into full production of cast iron pipe and fittings to the ever-increasing demands caused by massive construction boom.

By 1950, AB&I was a leading West Coast foundry and was a founding member of the Cast Iron Soil Pipe Institute (CISPI). Later, AB&I was among the first to champion no-hub cast iron pipe, fittings and couplings, creating its own machines to make no-hub cast iron soil pipe. Ingenuity, forward-thinking and a little risk taking also drove the family to implement automated manufacturing methods.

AB&I in the early 1960s

In the 1960s, the company expanded from selling products mainly in California to distribution across the Western United States. AB&I recognized that establishing relationships was fundamental to the company’s future. They sustained close supply-chain engagement with distributors lasting decades. It was the legacy of those early relationships that still exists today. AB&I believes that integrity is paramount to the company’s success and that you must “do what you say you will do and that best practices in business start with common sense, developing good relationships and attention to detail.”

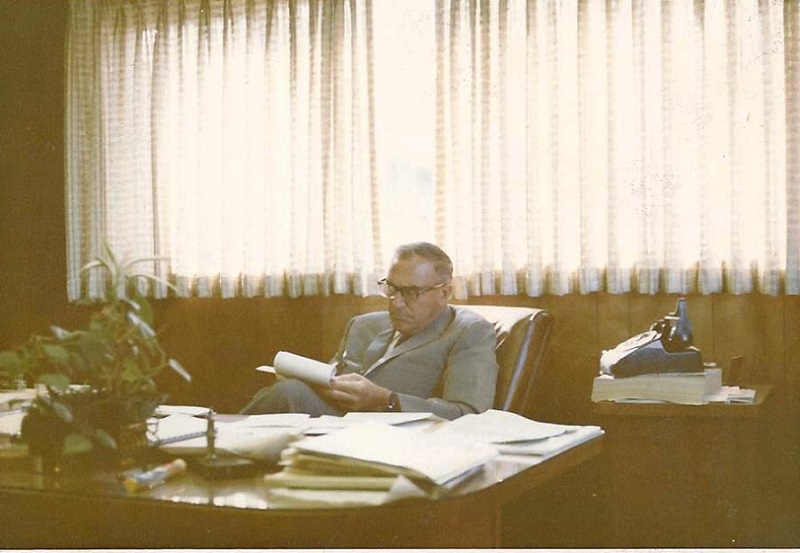

Arnold Boscacci, mid-1960s

By the third generation of Boscacci family leadership, AB&l’s mission was sternly focused on ways to use new technology to make the best cast iron pipe and fittings in the Western US. Allan Boscacci was now making decisions and with most of the work still being completed by hand, he began to introduce higher production levels and enhance modernization efforts. AB&I was predictably ahead of its time environmentally, installing bag houses to capture foundry smoke, and water treatment plants to clean and reprocess foundry water long before it was a requirement.

In 1969, AB&I was the first soil pipe foundry to install a Disamatic (DISA ) molding machine, automating foundry processes which allowed a higher-quality fitting at a much faster rate.

In the 1980s, AB&I was among the first American manufacturers to engage in profit sharing with all team members and to truly practice “open book” management. By the early 1990s, AB&I was the first foundry to totally automate its pipe production.

Overhead at AB&I Foundry in Oakland

The industry has seen its share of attrition. In its glory, America had 39 foundries that and only three remain today. Consistent with being the “Foundry of the Future,” today’s AB&I has the most sophisticated molding machine in the world, a DISA 270A, and is among those making the highest-quality cast iron pipe and fittings in the world.

AB&I joined McWane, Inc., a large family-owned manufacturer, but remains Boscacci family led. Kurt Winter, Allan ‘s oldest son-in-law drives AB&I to be “better, faster and more innovative,” just as the three generations of foundry men before him.

AB&I supports our plumbing industry with vigorous involvement and are highly active with leading national, regional and local industry organizations including: ASA, MCAA, PHCC, ICC, IAPMO, DBIA, ASPE, ASTM and CISPI.

Custom casting at AB&I Foundry

Today’s AB&I, which employs over 200 team members, is a thoroughly modem, technology-driven foundry committed to responsible manufacturing and safety. They are an environmentally conscience U.S. manufacturer that have invested millions in environmental programs involving air, land and water. In fact, AB&’ls water treatment system is set up so that every drop of rainwater that hits their roof is captured and run through a filtration process and recycled. AB&I aims to be great stewards of the environment for future generations.

Next month will will look at the future of AB&I and share a recent Q&A interview with their team.

AB&I Foundry teamed up with local California authorities and melted down hundreds of confiscated firearms. The foundry has been in partnership with local law enforcement for over 30 years. The gun melt program was designed to permanently remove guns and weapons from the streets of California to reduce violence in our communities. At AB&I’s Open House event, residents were invited Read more

AB&I Foundry teamed up with local California authorities and melted down hundreds of confiscated firearms. The foundry has been in partnership with local law enforcement for over 30 years. The gun melt program was designed to permanently remove guns and weapons from the streets of California to reduce violence in our communities.

Mayor Libby Schaaf of Oakland Taking Part in the Gun Melt at AB&I Foundry.

At AB&I’s Open House event, residents were invited in to take foundry tours, and were able to witness law enforcement melting down these weapons. During the event, guns and weapons – including rifles, handguns, shotguns, knives and automatic rifles – that have been confiscated by law enforcement – are melted down and recycled into new products such as cast iron soil pipe and fittings. Even Mayor Libby Schaaf participated with the destruction of a handgun helping to make the streets of Oakland safer.

“We receive calls from agencies as far north as Redding, California, south into the Central Valley and east all the way to the Nevada border,” said Michael Lowe, the General Manager of AB&I Foundry.

Local agencies like the Oakland Police Department have referred other agencies including the Department of Justice out of Sacramento and the Sacramento Sheriff’s Department to AB&I to dispose of their seized or confiscated weapons. Multiple law enforcement agencies contributed confiscated weapons that could not be returned to their owners or sold to the gun melt operation.

Mayor Libby Schaaf of Oakland Throwing Guns Into the Furnace for the Gun Melt at AB&I Foundry.

Lowe continued, “We here at AB&I Foundry do our part by working with law enforcement agencies to help them dispose of the confiscated weapons which ultimately helps to make our cities safer.”

Everyone at AB&I is proud of their commitment to the community and to law enforcement, working hand in hand to make things better for the community. AB&I melts all sorts of confiscated weapons including; shotguns, hand guns, rifles, swords and even machetes. To participate in the program, an agency simply must call the foundry to make arrangements.

This past weekend, AB&I Foundry teamed up with Argent Materials and Alameda County Supervisor to Nate Miley to take on the challenge for “Battle for the Bay” cleanup day. Oakland’s AB&I Foundry and Argent Materials joined the effort with dozens of team members pitching in to help. Volunteers from The Beautification Council, Cypress Mandela Training Read more

This past weekend, AB&I Foundry teamed up with Argent Materials and Alameda County Supervisor to Nate Miley to take on the challenge for “Battle for the Bay” cleanup day. Oakland’s AB&I Foundry and Argent Materials joined the effort with dozens of team members pitching in to help. Volunteers from The Beautification Council, Cypress Mandela Training Center and Men of Valor provided additional on-the-ground-support. These passionate volunteers showed up to cleanup in their East Oakland neighborhoods.

Battle for the Bay volunteers prepare to cleanup in their East Oakland neighborhoods.

“This illegal dumping remediation is paramount to the local community. By working as a team with local businesses, residents, and community leadership, we are collectively finding ways to combat the disheartening behavior of illegal dumping while improving the community where people both live and work”, said Michael Lowe, the General Manager of AB&I Foundry.

Both AB&I and Argent will support projects planned that include trash removal in the cities and on beaches, tree planting, and habitat restoration. This cleanup effort is part of the largest volunteer day in California and the world. On September 21, thousands of volunteers in the Bay Area and beyond removed litter from waterways and shorelines, as well as upstream areas across California, the nation, and in about 100 participating countries.

“This is part of our commitment to Oakland. We clean over 2 miles of streets around our business every day alongside industry partners like AB&I Foundry. We’re glad the mayors are working together to address the challenge of dumping along our shorelines and throughout our communities, and we’re proud to partner with Alameda County Supervisor Nate Miley to support the Battle for the Bay.” said Bill Crotinger, President of Argent Materials

Michael Lowe, General Manager of AB&I Foundry, Mayor Schaaf, and Bill Crotinger, President of Argent Materials at Battle for the Bay.

Oakland Mayor Libby Schaaf expressed appreciation: “One of the many things I love about Oakland are companies like AB&I and Argent Materials that really step up for our community. With their help, I hope Oakland can win this Battle for the Bay cleanup competition, and more importantly, make progress in the daily battle against litter and illegal dumping in our communities.”

Oakland says it has at least 100 illegal dumping hot spots. This is a plague to our community that needs to be addressed with rigorous enforcement for violators.

Alameda County Supervisor Nate Miley added: “Illegal dumping knows no boundaries, which is why I’m glad the mayors are addressing it as a regional issue. I look forward to working with Argent Materials big East Oakland cleanup on September 21, because cleaning up our streets and waterways is a major priority!”

Oakland’s Metropolitan Chamber of Commerce has awarded AB&I Foundry with the Deep Roots Award in recognition as a longtime steward of the local economy helping build the city’s foundation. The chamber award was presented at their 114th annual Luncheon on June 26, 2019. The event celebrated the businesses, nonprofits, and community members who have collectively Read more

Oakland’s Metropolitan Chamber of Commerce has awarded AB&I Foundry with the Deep Roots Award in recognition as a longtime steward of the local economy helping build the city’s foundation. The chamber award was presented at their 114th annual Luncheon on June 26, 2019. The event celebrated the businesses, nonprofits, and community members who have collectively contributed to the betterment of “The Town 2019”.

AB&I’s Michael Lowe and Zeydi Gutierrez Receive Deep Roots Award from Oakland Metropolitan Chamber of Commerce.

“It is important for the community to know that AB&I Foundry is not only a manufacturer of plumbing products, but also plays a tremendous role in giving back to the community,” said Michael Lowe, GM of AB&I. “We are creating jobs and have made our community a better place through a multitude of community programs.”

The company believes in being good stewards to the environment and their community and has spearheaded many programs including a massive neighborhood clean-up in East Oakland, has cleaned up the Elmhurst Creek in support of Oakland Creek to Bay Clean and Green Initiative. Has participated in an Annual Thanksgiving Giveaway with Acts Full Gospel congregation, and the company has provided countless hours of volunteerism at local schools, libraries, and the Alameda Food Bank.

AB&I has been in Oakland since 1906 and is part of the fabric of the community. The company continues to evolve through innovation with state-of-the-art manufacturing processes and environmental conscience manufacturing. The company proudly boasts of being as clean and green as possible, not only meeting but often exceeding, all regulatory standards with manufacturing.

AB&I employs over 200 team members, where 37% reside in Oakland. The economic impact is more than $71 Million which is injected back into the local economy through payroll, taxes and local purchases. AB&I Foundry has been an American manufacturer of cast iron soil pipe and fittings for storm and sanitary drain, waste, and vent (DWV) plumbing systems since 1906. For more information please visit ABIFoundry.com.

AB&I Foundry is pleased to announce the promotion of Shannon Hooper to National Sales Manager of AB&I Foundry, a leading manufacturer of cast iron soil pipe and fittings and couplings for the plumbing industry. Hooper, along with his new duties as the National Sales Manager is responsible for the management of AB&I’s sales team and Read more

AB&I Foundry is pleased to announce the promotion of Shannon Hooper to National Sales Manager of AB&I Foundry, a leading manufacturer of cast iron soil pipe and fittings and couplings for the plumbing industry.

Hooper, along with his new duties as the National Sales Manager is responsible for the management of AB&I’s sales team and manufacturer’s representatives and, will continue his responsibilities managing the McWane Plumbing Technical team. His primary goals will be to enhance AB&I’s value and relationships with distribution and mechanical contractors. During his six-year tenure, Shannon has served in the Technical Group where he has demonstrated expert knowledge on engineering and technical projects, training, and industry codes and standards. He has also served as an AB&I Regional Sales Manager where he has demonstrated an ability to grow enduring relationships and preference for AB&I’s products.

Hooper, along with his new duties as the National Sales Manager is responsible for the management of AB&I’s sales team and manufacturer’s representatives and, will continue his responsibilities managing the McWane Plumbing Technical team. His primary goals will be to enhance AB&I’s value and relationships with distribution and mechanical contractors. During his six-year tenure, Shannon has served in the Technical Group where he has demonstrated expert knowledge on engineering and technical projects, training, and industry codes and standards. He has also served as an AB&I Regional Sales Manager where he has demonstrated an ability to grow enduring relationships and preference for AB&I’s products.

“We are pleased to welcome Shannon Hooper as National Sales Manager of AB&I Foundry. Hooper has 20 years of experience in both the building and plumbing industries. His understanding of our product offering and customer base will further enhance our commitment to providing an outstanding customer experience,” said Michael Lowe, General Manager of AB&I Foundry.

“AB&I makes great products that I can confidently stand behind. Being part of the McWane Plumbing Group has allowed me to learn and understand how our products contribute to the overall safety and performance of a building,” said Hooper. “The positions I have held and the education I have received has afforded me a tremendous amount of insight which I’m looking forward to sharing with our team.”

Hooper in previous positions worked as a Project Manager for a Construction Company in Colorado.

Shannon is an Indiana native who enjoys spending quality time with his wife Jen and his two children Peyton and Chase. As a family, they enjoy skiing, swimming and other outdoor activities. Shannon attended the Colorado State University system and recently completed his M.B.A at The University of Colorado.