The 20-story, terra cotta Standard Building has graced the cityscape of downtown Cleveland, OH, since 1924. Constructed by The Brotherhood of Locomotive Engineers—the oldest union in the nation—the Standard Building was their Cooperative National Bank Building. (See overview video at the end of the story.) Throughout most of its long life, the Standard Building functioned Read more

Aquatherm Piping

The elegant Standard Building has been a part of the landscape in downtown Cleveland since 1924. It recently underwent an extensive office-to-apartment conversion.

The 20-story, terra cotta Standard Building has graced the cityscape of downtown Cleveland, OH, since 1924. Constructed by The Brotherhood of Locomotive Engineers—the oldest union in the nation—the Standard Building was their Cooperative National Bank Building. (See overview video at the end of the story.)

Throughout most of its long life, the Standard Building functioned admirably as an office building in a prime downtown location. Today, the urban trend of office-to-apartment conversions is transforming the business districts of many cities, including Cleveland’s. Weston Inc., the building’s owners, knew the time was right to capitalize on that trend and convert the Standard Building into a completely renovated, 281-unit luxury apartment building.

Begun in April 2016 and completed in December 2017, part of the Standard Building renovation features a revamped piping system for both potable water and HVAC water-source heat pump piping for the building’s new comfort system, which includes 290 WaterFurnace water-source heat pumps.

For Lee Tucker, project manager, Marous Brothers Construction, the company’s Design/Assist approach at the Standard Building was to “go with what you know.”

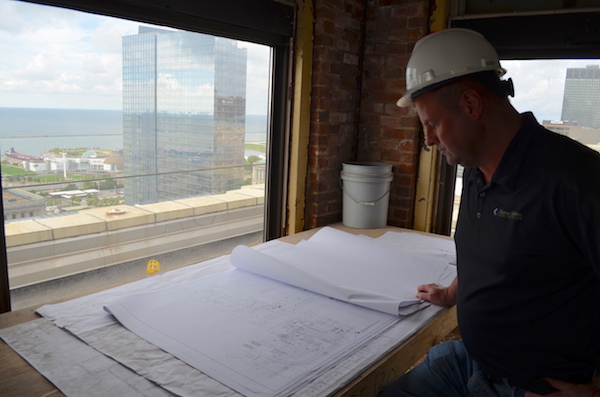

Lee Tucker, project manager, Morous Brothers Construction, peruses the blueprints for the project. (And that view!)

“We budgeted the project and negotiated the contract based on what we felt comfortable with,” said Tucker. “We generally are not early adopters of new products unless we do extensive research. We explored the use of Aquatherm with the mechanical engineer and visited another project of similar size and interviewed the employees of the installing mechanical contractor. After our research, we felt comfortable with using Aquatherm.”

Ultimately, more than 8,300 ft. of Aquatherm polypropylene-random (PP-R) piping—ranging from ¾ to 12 in.—and more than 800 fittings were used on this project.

The project’s tradesmen appreciated Aquatherm pipe because it is lighter and cleaner to work with than steel pipe.

Blue and green come up golden

The Standard Building project incorporates Aquatherm Green Pipe® for the building’s potable water applications and Aquatherm Blue Pipe® for its HVAC applications.

Aquatherm Blue Pipe is ideal for HVAC applications, offering longevity and consistent performance. It is hydrophobic, which means it will not corrode or scale over time.

Aquatherm Green Pipe is chemically inert and is potable water (NSF 61) and food safety (NSF 51) rated. It will not leach, corrode, or erode. In addition, the heat fusion method of joining Aquatherm pipe does not create any VOCs and does not introduce any lead or other toxic materials into the system. Nor does it involve and open flame or hot work permit as does welding carbon steel.

The residents of this office-to-apartment conversion will probably never see the Aquatherm pipe that takes care of their potable water and HVAC needs, but it will be working behind the scenes for decades to come.

Both Blue Pipe and Green Pipe are available with optional multi-layer, faser-composite (MF) which allows the pipe to remain rigid at high temperatures and significantly reduces linear expansion. The MF extrusion process creates a middle layer in the pipe that is a mixture of glass fibers and Aquatherm’s proprietary fusiolen. Along with the benefit of reduced expansion, Aquatherm MF pipes are still flexible, and require fewer and smaller expansion controls.

Overcoming the challenges

A major reason Aquatherm was selected for the Standard Building is the pipe’s light weight—up to 70% lighter than carbon steel pipe, depending on the pipe size—and ease of use on the job site.

The Standard Building presented some challenges that Aquatherm helped solve.

More than 8,300 ft. of Aquatherm piping, ranging from ¾ in. to 12 in., helped make this project a success.

“Construction of the building is unique,” Tucker said. “The floors are actually 18-in. thick per floor. We took the pipe up to the top floor where we fused the pipe and dropped it through the stacked mechanical rooms, with core drills, all throughout the building.”

The piping contractor, T.H. Martin Inc., would fuse the pipe on the 19th floor and drop it all the way down the building. This made the lightweight nature of the pipe critical.

“You’re not moving stuff as heavy so the guys can be more productive all day long. That’s essentially what it comes down to.” — Ryan Pepper, piping project manager, T.H. Martin Inc.

“They just set up on one floor and drop, drop, drop,” Tucker said. “They set up a kind of chain fall. We couldn’t do this with steel pipe.”

A lightweight, effective solution

“After working with Aquatherm and having installed it, the cleanliness is by far a long-term benefit to wherever you would install it,” said Ryan Pepper, piping project manager, T.H. Martin Inc.

Pepper also noted the light weight is a huge benefit to his crew.

The light weight of Aquatherm pipe allowed finished sections of the new piping to be dropped down through the building’s stacked mechanical rooms.

“You’re not moving stuff as heavy so the guys can be more productive all day long. That’s essentially what it comes down to,” he said.

Shaun Swaney, pipefitter, Local 120 Pipefitters Union, agreed.

“It’s a lot easier on the guys, on your body,” he said. “It makes it an easier day, and you’re not exhausted at the end of it.”

Aquatherm’s ease of use helped Swaney and the other installers at the Standard Building get the job done quickly and efficiently.

Ease of use and overall savings

Unlike welding, the heat fusing process used for Aquatherm pipes physically turns the two pieces of plastic pipe into one piece. The heat fusion tools and process are both easy to learn and work with.

“The Aquatherm representatives came right out to the jobsite [to provide training],” Swaney noted.

“It’s a very easy system to put together,” Pepper said. “Guys that are used to welding, grooving and even soldering a lot, when they go to do this the tools make it easy. The tooling, combined with the simplicity of how to put it together, really makes it a fantastic product.”

The Standard Building offers tenants spectacular views of downtown Cleveland and the lakefront.

Tucker said the Design/Build contractor on the project provided a credit of $250,000 to Marous Brothers Construction for using Aquatherm piping. The credit was based on the estimated combined labor and material cost savings compared to using metal pipe.

Tucker added that he often expects to see a sort of resistance to new technology, but what he finds is exactly the opposite with Aquatherm.

“It’s a lot easier on the guys, on your body. It makes it an easier day, and you’re not exhausted at the end of it.” — Shaun Swaney, pipefitter, Local 120 Pipefitters Union

In the end, a combination of Aquatherm’s light weight and ease of use in the field made it the clear choice for this renovation project.

“I didn’t just push for Aquatherm, I required it,” Tucker concluded.

The Standard Building is up and running and occupied, and has begun its new life as prime downtown Cleveland apartments. Marous Brothers Construction and T.H. Martin are proud to have played a role in the successful renovation of this historic and beautiful structure, and both companies said they planned to use Aquatherm pipe on other projects in the future.

Check out the video of the Standard Building project here: