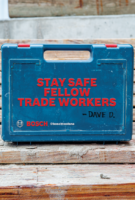

Designed to recognize and thank essential workers, the program will shine a spotlight on those who show up on the front lines, every day Bosch Power Tools, the world market leader for power tools and power tool accessories, will recognize and acknowledge trade workers for their tireless efforts and give them the thanks they deserve Read more

Bosch Tools

Designed to recognize and thank essential workers, the program will shine a spotlight on those who show up on the front lines, every day

Bosch Power Tools, the world market leader for power tools and power tool accessories, will recognize and acknowledge trade workers for their tireless efforts and give them the thanks they deserve. With “Always Essential,” Bosch plans to meet these essential workers where they are, giving back through giveaways and worksite activations.

Recognizing that individuals in the trades couldn’t stay home while facing a global pandemic, Bosch sees workers from HVAC to construction and beyond continuing to perform their essential duties. As many facets of everyday life were shut down, new hospitals and healthcare centers needed to be built, heating and air conditioning systems needed to be repaired, power lines, roads and bridges needed to be maintained. The very framework of our society continues to be managed by frontline workers who stay largely behind the scenes. Until now.

“While ‘essential worker’ has become a buzzworthy phrase in 2020, we understand and celebrate that these trade professionals are, and always have been, essential to our way of life,” said Roger Amrol, president of Bosch Power Tools North America. “Without the commitment, hard work and dedication from each and every one of these individuals, society as we know it could not exist. And for that, we’re forever grateful.”

Over the coming months, teams from Bosch will meet trade workers on their turf at worksites around the country with giveaways and other gear to say “thank you” to the indispensable individuals who are the backbone of the trade industries and the country itself.

Amrol added, “The trades have always been essential and worthy of our gratitude and recognition. Now, it’s time for us as a society to give it to them.”

For more information on Bosch Power Tools and “Always Essential,” please visit www.stories.boschtools.com/always-essential or connect on Facebook and Instagram.

Program is in beta test with industrial users both on the jobsite and off When Bosch introduced its Bluehound asset tracking solution to select customers, the focus was on builders on the jobsite. That’s still the case. But a great beta test site has turned out to be a rental equipment and supply house that Read more

Program is in beta test with industrial users both on the jobsite and off

When Bosch introduced its Bluehound asset tracking solution to select customers, the focus was on builders on the jobsite. That’s still the case. But a great beta test site has turned out to be a rental equipment and supply house that works with its customers.

Cole Breese, inventory warehouse manager, 365 Equipment and Supply, Barrington, Ill., knows an advantage when he sees one. “We’re always looking to get better,” said Breese of the company’s decision to test Bluehound. “We’ve been testing this out on a big project for about seven months. We need to see where equipment has been so that we can optimize asset availability, verify quantity access and monitor records tied to individual assets.”

Getting the Jobsite Running

365 rents everything from power tools and work platforms to cranes and front loaders, in a market area that stretches from Chicagoland to Milwaukee. The company is a one-stop shop for contractors, sub-contractors and municipalities. 365 also sells power tool accessories to support its rentals.

365 rents everything from power tools and work platforms to cranes and front loaders, in a market area that stretches from Chicagoland to Milwaukee. The company is a one-stop shop for contractors, sub-contractors and municipalities. 365 also sells power tool accessories to support its rentals.

Ryan Braschko, warehouse manager at 365 Equipment and Supply, says there are 7,800 pieces of equipment in the company’s fleet. Up to this point, the company has relied on traditional methods to track when products were rented, when they left a site and when they were returned. If a product stays in the field, the 365 team has limited information as it moves from jobsite to jobsite.

With Bosch Bluehound, Braschko can accurately track every job an item has served, as well as duration and status. While 365 hasn’t implemented the entire Bosch solution, the pair notes that Bluehound has been able to complement and enhance their current system. Bosch tracking tags can be placed on every piece of equipment so it’s easier to see where an item is in real time. The 365 goal is to replace the manual tracking/static bar code-following computer software system that captures tool serial number, jobsite name and contact information for the foreman at a single jobsite.

Efficiency of Asset Flow

Bluehound development has pushed the Bosch research team to consult with everyone from jobsite managers to company owners, from site owners and general contractors to developers and sub-contractors. Bosch has also talked to distributors about how sales representatives find products when they’re in the field.

Even with the diverse feedback Bosch has gathered, there’s no test site quite like 365 Equipment and Supply. “Most of the adjustments we’ve made to Bluehound were influenced by our experience at 365,” said Eli Share, mobile and IoT lead, Bosch Power Tools. “We’re working to be the software link between the tool crib and the jobsite. We’ve seen the influence this technology can have here.”

Even with the diverse feedback Bosch has gathered, there’s no test site quite like 365 Equipment and Supply. “Most of the adjustments we’ve made to Bluehound were influenced by our experience at 365,” said Eli Share, mobile and IoT lead, Bosch Power Tools. “We’re working to be the software link between the tool crib and the jobsite. We’ve seen the influence this technology can have here.”

Share notes that one of the biggest challenges for their customers is that tools and equipment walk from jobsite to jobsite. Nothing has been stolen, but no one in the organization knows which site has what products and equipment. There’s no clear reporting, yet some companies generate thousands of pages of paperwork. He observed that many man-hours of manually checking and verifying records doesn’t prevent lost and stolen items.

What’s clear is that companies want to know where tools and equipment are located all the time, including small tools. One of the things that makes Bluehound attractive is that users can immediately tell if a product is lost or stolen due to manual status updates in the system. And that’s related to the tag.

“On the jobsite, people see the tag – that’s a theft deterrent to start,” said Braschko. “But the real value is that it saves time by showing equipment location on a map.” And any discrepancy about tool location can potentially be cleared up with a single phone call.

The Service Angle

In the case of 365, it’s less expensive to repair serviceable tools rather than having to replace them on a regular basis. With Bosch Bluehound, users know what the maintenance history is so repairs can be completed in a proactive manner. The system also reduces the reliance on manual maintenance administration.

“Everything we need is there in Bluehound,” said Breese. “The system was raw when it first came in, but the team has built up a hierarchy of asset tracking, locations and other details. Initially, we didn’t know what to expect, but we knew this was an opportunity to improve our business.”

“Everything we need is there in Bluehound,” said Breese. “The system was raw when it first came in, but the team has built up a hierarchy of asset tracking, locations and other details. Initially, we didn’t know what to expect, but we knew this was an opportunity to improve our business.”

The lifecycle for products at 365 is remarkably consistent: small tools, three-to-five years; larger tools, five years; laser measuring tools, seven to eight years. Efficiency and cost savings come when Breese and Braschko know where tools are located all the time rather than having to purchase replacements.

Today, 365 Equipment and Supply buys more tools than it takes in return, but that’s now a product of growth. Throughout the course of its short history, 365 has seen its business grow and become balanced season to season. With Bluehound, the company has been able to optimize asset availability, quantity access and records tied to individual assets. And these functions can be done from anywhere.

“This is the first time we’ve used a live tracker,” said Braschko. “It’s been good.”

If you’re in the market for a new power tool battery platform, Bosch has an opportunity for you. The Freak ‘N’ CORE18V Contest launching today gives entrants the chance to submit a video about why they need the new battery platform. Winners receive the Bosch CORE18V 6.3 Ah battery along with the company’s Freak two-in-one impact wrench/impact Read more

If you’re in the market for a new power tool battery platform, Bosch has an opportunity for you. The Freak ‘N’ CORE18V Contest launching today gives entrants the chance to submit a video about why they need the new battery platform. Winners receive the Bosch CORE18V 6.3 Ah battery along with the company’s Freak two-in-one impact wrench/impact driver.

If you’re in the market for a new power tool battery platform, Bosch has an opportunity for you. The Freak ‘N’ CORE18V Contest launching today gives entrants the chance to submit a video about why they need the new battery platform. Winners receive the Bosch CORE18V 6.3 Ah battery along with the company’s Freak two-in-one impact wrench/impact driver.

The Bosch CORE18V battery offers maximum power and performance while minimizing weight, an achievement that proves its claim as the best-built battery among leading competitors. The battery employs advanced Lithium-ion technology to deliver 80 percent more power than previous generation Bosch batteries. The Freak impact driver features the socket ready all-in-one tool holder, which combines a 1/4 In. hex and a 1/2 In. drive into one tool for ultimate versatility. The all-in-one tool holder eliminates the need for users to own an impact wrench and impact driver, and also eliminates the need for socket adapters.

“Bosch is committed to giving away 2,000 Freak impact drivers paired with the CORE18V 6.3 Ah battery,” said Roger Amrol, president, Bosch Power Tools North America. “Participants must enter the contest by posting a short video explaining ‘why I need a whole new Freak ‘n’ cordless platform.’ This is something new for the power tool industry, but speaks to the Busch culture of creativity and fun.”

Entrants must post a short video explaining why they need the new Bosch cordless platform using the hashtag #FreakNContest. The contest will end on September 14. Visit boschtools.com/freak for rules and additional information; contest is open to U.S. residents.

The promotion dovetails with the Bosch CORE18V 4.0 Ah battery becoming available at Lowe’s in September. Winners of the Freak contest will be encouraged to post another video with their impact driver and CORE18V battery for a chance to win more prizes.

To learn more about the Bosch, the Freak impact wrench/driver or the CORE18V 6.3 Ah battery, visit www.boschtools.com or call 877-BOSCH-99. Check out www.bethepro.com for additional tips and videos.

Greetings everyone! Let me just say thank you to Mechanical Hub for reaching out to me for another tool review and inviting me to be on their new Pro Staff team! Since my early start in the Trades as a “Seasonal Helper” in residential plumbing and a Commercial HVAC installer to my now current full-time Read more

Greetings everyone! Let me just say thank you to Mechanical Hub for reaching out to me for another tool review and inviting me to be on their new Pro Staff team! Since my early start in the Trades as a “Seasonal Helper” in residential plumbing and a Commercial HVAC installer to my now current full-time career as a Licensed Fire Sprinkler Fitter Foreman, I never thought I would be a part or involved with such a great opportunity and team. I’m grateful for all of it. Now let’s get down to this Bosch GSA18V-083B Reciprocating Saw review.

Greetings everyone! Let me just say thank you to Mechanical Hub for reaching out to me for another tool review and inviting me to be on their new Pro Staff team! Since my early start in the Trades as a “Seasonal Helper” in residential plumbing and a Commercial HVAC installer to my now current full-time career as a Licensed Fire Sprinkler Fitter Foreman, I never thought I would be a part or involved with such a great opportunity and team. I’m grateful for all of it. Now let’s get down to this Bosch GSA18V-083B Reciprocating Saw review.

I was on a recent Retro fitting job for a major Grocery Chain moving into an existing shopping center. Part of my Job scope was the demo of now dead existing main and branch lines. The mains consisted of Schedule 10 and the branch line were threaded schedule 40. Normally we would go into the air with a 100’ cord hanging off the side of the lift (because the outlet was abused and dead in the lift) attached to a porta-band. This would be heavy and clumsy overhead use, as most time two hands are needed to hold the porta-band and try to balance the pipe being cut. So this time around I was excited and yet tempered my expectations to be able to use the Bosch GSA18V-083B Reciprocating Saw.

I was on a recent Retro fitting job for a major Grocery Chain moving into an existing shopping center. Part of my Job scope was the demo of now dead existing main and branch lines. The mains consisted of Schedule 10 and the branch line were threaded schedule 40. Normally we would go into the air with a 100’ cord hanging off the side of the lift (because the outlet was abused and dead in the lift) attached to a porta-band. This would be heavy and clumsy overhead use, as most time two hands are needed to hold the porta-band and try to balance the pipe being cut. So this time around I was excited and yet tempered my expectations to be able to use the Bosch GSA18V-083B Reciprocating Saw.

Some first impressions was that it was beefy yet manageable (4.4lbs) to hold and manipulate with one hand. The handle is large enough for different grips and rubber grips on both the back and front to avoid slipping, which is important when dealing with oil and water. The overall length without blade is 15-3/4” long. The trigger itself is large enough to be activated in most grips and angles. To be honest the look is uncanny identical to the Milwaukee M18 Cordless Hackzall Reciprocating Saw. Some nice features I noticed were the LED Light for the cutting zone and a lock out switch to prevent inadvertent startup.

Working with the Bosch GSA18V-083B I was provided with generic Bi-metal blades. So I already knew any cutting shortfalls could not all be shouldered by Bosch. The tool accepted the generic blades in its easy-to-operate blade-change system without problem. I decided to use the wireless charging batteries from the Bosch EC Brushless Socket-ready Impact Drill/Wrench (IDH182) that I previously reviewed. Maybe the staff will link that review here for you too. So when I previously stated that my expectations were tempered, it was because I expected the saw to fight or stall when cutting into steel. Whereas with a porta-band blade it has the finer teeth with a constant rpm and motion. To my surprise when cutting the 3” main it breezed right through. The schedule 10 steel was an easy cut for the generic blade and the Bosch. It was a nice little warm-up. Now with a little duller blade and a much thicker schedule of pipe, 40, I assumed when cutting I would get the snag and fight. In my head I would probably blame most of it on the cheapness of the bi-metal blade. Again Bosch impressed not only myself but my fellow Journeyman. A fast 3,050 strokes per minute was enough to handle said generic blade and about 12 cuts of 2” to 1-1/2” sched 40 pipe. On a side note; the battery lasted in power on one charge.

Overall in practicality and performance the Bosch GSA18V-083B Reciprocating Saw did the job. It was nice to be able to get into bar joists due to the compact design and make strategic cuts. The beefy weight was not too overwhelming for one handed grip cutting. The rpm was fantastic as it maximized material removal per stroke. The blade guard was not too bulky to get around the pipe and joist spaces. I can definitely see the potential for everyday general uses, and as far as job site use this tool is a must!