Three considerations for right-sized tankless installations–and increased customer satisfaction Propane tankless water heaters use less energy, cost less to operate, and produce fewer emissions than other options, which is why a growing number of homeowners are requesting these systems. As contractors know, determining the right configuration for their projects isn’t always straightforward. Whether considering a Read more

Bryan Cordill

Three considerations for right-sized tankless installations–and increased customer satisfaction

Propane tankless water heaters use less energy, cost less to operate, and produce fewer emissions than other options, which is why a growing number of homeowners are requesting these systems.

As contractors know, determining the right configuration for their projects isn’t always straightforward. Whether considering a single unit for the whole home or multiples that run in tandem, knowing how to predict demand is key to giving customers a setup that meets their performance and cost expectations.

Here are three factors to consider when right-sizing a tankless system for projects.

How much water will the customer need?

Knowing how many people will live in the home, who will be using hot water, and for what purposes is the first step toward installing a system that will fulfill their specific needs. Additionally, understanding a customer’s lifestyle and habits–when they shower, how often they do laundry, and whether they expect to install radiant heating–can help determine expected peak demand times.

Take stock of the number and type of appliances and systems requiring hot water and note their water delivery rates. To calculate peak demand, the Department of Energy (DOE) recommends counting the number and gallons per minute (GPM) rate of faucets, showers, and appliances that could be in use in the home at any given time. Features such as in-floor radiant heating and spas can considerably raise a home’s hot water demands. Propane tankless water heaters provide an endless supply of hot water, averaging roughly 222 gallons per hour, compared with an average first-hour delivery rating of just 62 gallons per hour for electric storage tank models.

How much will the water need to be heated?

It’s important for contractors and installers to know the difference between outdoor ground temperatures and the desired indoor hot water temperature. That will reveal how much the water will need to heat and, therefore, how quickly the unit can deliver hot water.

For example, a typical shower head delivers 2.5 GPM, so a 9.4 GPM unit would run three to four showers depending on the inlet ground water temperature. According to the DOE, the average groundwater temperature across the U.S. is 50 degrees. In most cases, water should be heated to at least 120 degrees, so the home will need a tankless unit that can heat 2.5 GPM by 70 degrees. Lower flows can be heated to a bigger temperature rise and higher flows to a smaller temperature rise. Most propane or natural gas tankless water heaters on the market can handle a rate of 5 GPM at a 70-degree temperature rise. As fixtures are added, demand on the system increases and that 5 GPM rating can quickly get overwhelmed.

While a tankless unit will provide hot water almost instantly at the unit, the water still has to travel to the faucet, so location of the units is an important part of system design. Oftentimes, two smaller units, each placed closer to the end use site, can provide the project a higher level of satisfaction than one large or two smaller units installed in a single location. This also provides some redundancy if a unit or fixture needs to be serviced.

What can the home accommodate?

Peak demand scenarios are why contractors shouldn’t assume an undersized system will cover their client’s full range of needs. Oversizing isn’t as big of a concern with tankless systems. While oversizing a traditional tank water heater would result in significant wasted energy over the life of the unit, tankless units vary their flow rates based on demand and, therefore, having excess capacity doesn’t necessarily mean a tankless system is using more energy.

New projects can more easily accommodate tankless units at the point of use than existing homes, which are often designed for a central tank system–and may be better suited for one or more units installed in the basement. For most projects, one unit is sufficient. Multiple units may be used to handle larger loads or as homeowners scale up in the future as their hot water needs change. Because of the popularity and dependability of propane tankless water heaters, new products are available on the market that would allow customers to have “multiple” heaters in a single cabinet, or on a single rack that comes to the project ready for installation making system design easier still.

To determine the optimal number of tankless units for a home, help customers understand their consumption habits and how the system can be sized to meet their expectations. Determine peak demand and gauge actual usage and lifestyle habits. Then, compare prices for systems that meet those needs relative to a client’s budget. Put in as much capacity as those factors will allow to balance cost and comfort. By simply installing a propane system, customers will see optimal cost savings. That’s because propane tankless water heaters offer reduced energy costs, a lower total cost of ownership, and a longer service life compared with other options. Notably, propane tankless systems can reduce energy costs by up to 50 percent and eliminate standby energy loss from the tank.

To learn more about propane water heating systems, visit Propane.com/Water-Heating.

Bryan Cordill the director of residential and commercial business development for the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.

Bryan Cordill the director of residential and commercial business development for the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.

Propane heating systems have an edge when it comes to comfort, efficiency, and emissions On average, more than half of a household’s annual energy consumption is used for space heating and air conditioning, according to the U.S. Energy Information Administration (EIA). Seasonal and energy-intensive uses can vary based on geographic location, home size and structure Read more

Propane heating systems have an edge when it comes to comfort, efficiency, and emissions

On average, more than half of a household’s annual energy consumption is used for space heating and air conditioning, according to the U.S. Energy Information Administration (EIA).

Seasonal and energy-intensive uses can vary based on geographic location, home size and structure, and energy sources used. Because of higher space-heating demand, homes in the Northeast and Midwest regions consume more energy on average than homes in the South and West regions, for example. Additionally, larger homes and families tend to use more energy overall than smaller households.

There are more options than ever for home heating, and there are several different factors to take into consideration when selecting the best system for your customers. Whether your customers are looking to reduce energy consumption and costs, decrease their carbon footprint, or enjoy more comfortable home heating, propane-powered systems can provide a reliable solution for homeowners across the country. According to data from the Propane Education & Research Council (PERC), more than 7.5 million households rely on propane for primary or secondary home heating.

Here are three key advantages of propane-powered systems to share with your customers next time they ask about home heating solutions.

Homeowners can save more on energy costs with propane

The efficiency of a home heating system can greatly impact its utility costs. For homeowners looking to reduce their energy consumption — and their bills — high-efficiency propane furnaces are a great choice. Propane furnaces offer best-in-class efficiency, with ratings from 90 to 98 percent. Further, ENERGY STAR-qualified propane furnaces are up to 15 percent more efficient than standard propane models and can save up to $75 in energy costs each year, according to data from PERC.

In a comparative analysis of residential heating systems, Newport Partners, LLC examined the performance of seven heating systems in 16 different locations for new and existing homes. Each system was analyzed and compared in terms of its first cost, energy cost, emissions, and simple payback period. The research revealed several cost advantages to selecting a propane furnace, including low annual energy costs. Notably, the annual energy costs of a high-efficiency propane furnace were $1,650, which is 10 percent lower than standard-efficiency ASHPs and 14 percent lower than heating oil furnaces. When used as a backup for an air- or ground-source heat pump system in the place of electric heating coils the efficiency of the systems is also improved and further protects homeowners from rising utility costs when temperatures drop.

Beyond annual energy costs, propane systems offer more competitive upfront costs and payback periods, too. High-efficiency propane furnaces typically cost less to purchase and install than heating oil and ground-source heat pump systems. Additionally, homeowners purchasing a high-efficiency propane furnace for a new home in a cold climate could recoup their initial costs in two years due to low equipment and energy costs. By contrast, it could take a homeowner more than 20 years to recoup the initial cost of a ground source heat pump system through energy savings.

Propane systems provide warmth and comfort

Comfort can often be a deciding factor for homeowners. They want systems that can provide comfortable, consistent heat. Fortunately, propane furnaces are perfect for eliminating cold pockets in a home. These systems heat air to a higher initial temperature, getting to a homeowner’s desired temperature faster and maintaining it more effectively.

Because propane-powered furnaces heat air to 115–125 degrees Fahrenheit, they make the indoor air feel warmer and more consistent than heat from air source heat pumps (ASHPs), which often supply temperatures lower than 100 degrees Fahrenheit and are more affected by cold outdoor temperatures.

Propane systems support environmentally-conscious customers

When making decisions for homeowners heating systems remember those customers are placing more of a priority on reducing their carbon footprint. One way that homeowners can decrease emissions is by having their home’s systems and appliances run on propane instead of electricity.

According to data from PERC, residential propane furnaces can emit up to 50 percent fewer greenhouse gas emissions than electric furnaces and 12 percent fewer greenhouse gas emissions than fuel oil furnaces. Further, propane-powered furnaces produce up to 35 percent fewer nitrogen oxide (NOx) emissions and 82 percent fewer sulfur oxide (SOx) emissions than electric furnaces. And in colder and mixed climates, high-efficiency propane-fueled furnaces produce at least 26 percent fewer carbon dioxide emissions compared to standard-efficiency electric air-source heat pumps. It is extremely important for you to be prepared to educate your customers about these differences and not leave them out in the cold.

To learn more about the benefits of propane heating systems, visit Propane.com/Furnaces-Boilers.

Bryan Cordill is director of residential and commercial business development for the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.

Bryan Cordill is director of residential and commercial business development for the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.

Use these tips to keep customers comfortable this winter Do you know how to ensure your tankless water heater installations perform optimally this winter? Tankless water heaters — known for their on-demand hot water, low energy use, and compact size — are popular among homeowners. Propane-powered systems offer an additional advantage: they can be installed Read more

Use these tips to keep customers comfortable this winter

Do you know how to ensure your tankless water heater installations perform optimally this winter?

Tankless water heaters — known for their on-demand hot water, low energy use, and compact size — are popular among homeowners. Propane-powered systems offer an additional advantage: they can be installed virtually anywhere.

For customers located in regions that experience snow and frigid temperatures, there are a few considerations for HVAC professionals to keep in mind to ensure their customers’ comfort year-round.

Here are eight tips for specifying, installing, and maintaining tankless systems in cold climates:

- Size the unit for the cold. As temperatures drop, more time and energy are needed to heat water to the desired level. To ensure customers’ tanks meet demand throughout the year, it’s important to know how they’ll perform in cold weather. For example, in Washington D.C., a unit that can produce 8.5 GPM on a hot summer day will only produce 5 to 6 GPM on a cold winter day.

- Design for the coldest conditions. Be aware of how low ground temperatures can go and how much water a household will need. Also consider the difference between the set unit temperature and the ground temperature, also known as the Delta T. The bigger the gap, the lower the unit’s flow rate will be.

- Bring it inside. Many tankless systems have some degree of built-in freeze protection. Check the product specs, and your region’s historical weather patterns, to determine where to install the tank.

- Vent smart. Proper venting is important. Installations should avoid freezing winds and have sufficiently long vent runs. In cold areas, the minimum vent run recommendation is six feet.

- Keep vents clear of snow. Before a snowstorm, remind customers to keep a few feet around the vent clear of snow. Some tankless models offer air intake from the outer pipe — if that’s blocked, the unit may turn itself off.

- Educate customers with recirculators. For customers whose systems have a recirculating loop, remind them to turn off that function when bad weather is on the way. If the vent termination is snowed under, the unit will eventually power off with an error code.

- Consider condensation. Drain condensate from condensing units into a conditioned space to avoid drain freezes, which will cause the unit to turn off.

- Be ready with backup power. Many tankless systems need electricity for freeze protection and ignition. A propane standby generator can help ensure that customers’ hot water will continue to flow, even during a power outage.

For more information about propane tankless water heaters, visit Propane.com/Water-Heating.

Bryan Cordill is director of residential and commercial business development for the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.

Bryan Cordill is director of residential and commercial business development for the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.

Rinnai webinar discusses hydronic air handler features, benefits, installation, and more The Propane Education & Research Council is offering a new webinar for construction professionals as part of its “Propane Presents Technology Series”. The webinar, created in partnership with Rinnai, will take place at 2 p.m. EDT on Sept.10. During the webinar, Rinnai will discuss the Read more

Rinnai webinar discusses hydronic air handler features, benefits, installation, and more

The Propane Education & Research Council is offering a new webinar for construction professionals as part of its “Propane Presents Technology Series”. The webinar, created in partnership with Rinnai, will take place at 2 p.m. EDT on Sept.10.

During the webinar, Rinnai will discuss the features and advantages of hydronic air handlers, discuss installation and service fundamentals for construction professionals, and provide best practices for approaching the ideal customer. Hydronic heating systems, which can be part of new and retrofit projects, offer a smaller carbon footprint and increased efficiency than comparable products. They also provide increased comfort, backup and emergency heat with a heat pump, and improved efficiency when paired with Rinnai tankless condensing products.

“We are excited to be partnering with Rinnai for this webinar, which is jam-packed with educational, engaging content for contractors and construction professionals,” said Bryan Cordill, director of residential and commercial business development at PERC. “We hope attendees walk away with a new understanding of how propane equipment can benefit their customers — and, ultimately, their business.”

PERC’s “Propane Presents Technology Series” focuses on new and emerging propane technologies, education, and best practices to approach the ideal customer. Hosted and facilitated by PERC, in partnership with various OEMs, the series aims to showcase various propane products across multiple markets, answer questions directly from the industry and end users, and provide relevant resources and training information.

To learn more about the benefits of propane systems, visit Propane.com. Click here to register for the webinar with Rinnai.

Increase customer satisfaction with efficient, right-sized propane HVAC systems Navigating the world of HVAC systems can be daunting for homeowners. It’s a big reason why homeowners tasked with selecting the right HVAC system — either in a new build or as a replacement to an existing system — will often turn to the pros for Read more

Increase customer satisfaction with efficient, right-sized propane HVAC systems

Navigating the world of HVAC systems can be daunting for homeowners. It’s a big reason why homeowners tasked with selecting the right HVAC system — either in a new build or as a replacement to an existing system — will often turn to the pros for guidance.

Customers often prioritize quality and price, but there’s another component that’s equally important: size. Selecting and installing a right-sized HVAC system is key to keeping customers comfortable and satisfied year-round.

Installing incorrectly-sized systems can underperform, waste energy, and increase utility costs for homeowners. More specifically, a system that’s too small might not be able to regulate the temperature of the home. An oversized unit, on the other hand, will not work as efficiently, may wear out faster, and could have dehumidification problems.

Most importantly for professionals, is that a well-performing HVAC system can ensure a lifetime customer, so knowing what to recommend when homeowners come calling can have lasting benefits for the business.

It’s all in the details

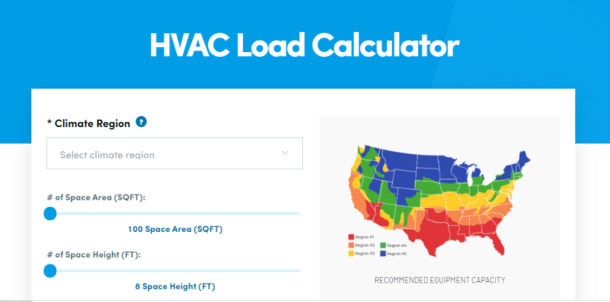

Determining heating and cooling loads plays an essential role in sizing HVAC systems like A/Cs, heat pumps, and furnaces. Many existing homes have over-sized heating oil or propane furnaces, resulting in heating systems that blast warm air, almost too quickly, when the thermostat calls for heat. Furnaces that are properly sized for the home’s heating load, on the other hand, offer greater comfort — often with a smaller, less expensive unit. HVAC contractors can use a load calculator, which considers the home’s climate region, square footage, insulation grade, sun exposure, and more.

Every home is different, which is why it’s important that heating and cooling systems are designed for the correct load. Did you know that the same house, rotated just 90 degrees, could vary in cooling load by 25 percent or more? These calculations take time and require attention to detail, but will greatly impact a home’s performance, a customer’s satisfaction, and potentially your business’ reputation.

Understand and evaluate load size

A home’s heating and cooling loads drive how much an HVAC system needs to operate to keep a home — and your customers — comfortable year-round. It’s important for HVAC contractors to understand the three different types of loads, the amount of heating or cooling a home needs, and how they relate to a unit’s capacity to provide the best HVAC experience for their customers.

Heating load and capacity can often be easily confused. Heating load refers to the amount of heating or cooling a building needs, while heating capacity is the amount of heating or cooling an HVAC appliance can provide. HVAC professionals base the size of the systems they install on their capacity to satisfy three different kinds of loads — design load, extreme load, and part load.

Design load

The design load includes the layout of a home, its overall energy efficiency, its insulation levels, and its orientation to the sun. Homes with adequate insulation, thermal windows, and little air infiltration have lower design loads. Conditioning loads will differ between single- and two-story homes. If HVAC professionals size a home’s heating and cooling equipment to meet design loads exactly, they may unintentionally specify and install wrong-size equipment.

Extreme load

The extreme load occurs when experiencing the hottest and coldest temperatures in any given location. This load, unlike the design load, carries little weight when HVAC professionals calculate the appropriate HVAC equipment size. Plus, extreme weather conditions rarely last long enough to significantly impact a home’s overall performance and comfort.

Part load

Partial loads are the most common. During much of the day and throughout the year, heating and cooling loads fall between the design load and the extreme load. Properly-sized equipment may cycle on and off, which can impair comfort, energy efficiency, and humidity control. Fortunately, modern HVAC systems often come with variable-speed and level components that allow the equipment to adapt its running speed or level to current conditions.

Consider the energy source

Once an HVAC professional has determined the correct load and unit capacity, they can select which energy source will power the system. Propane has become an increasingly popular choice among homeowners across the U.S. because it delivers energy savings, reduced emissions, and comfort — all at an affordable cost. In fact, in some regions, high-efficiency furnaces are the most commonly installed system for new homes. In regions where an air-source heat pump is specified, pair it with a propane auxiliary unit instead of electric coils and the unit still provides comfort when outside temperatures fall below 45 degrees Fahrenheit.

High-efficiency propane furnaces offer best-in-class efficiency with ratings from 90 to 98 percent and the versatility to provide space heating to both small floor plans and large custom homes — making them a valuable addition to any project.

To learn more about propane HVAC systems, visit Propane.com/Furnaces-Boilers.

Bryan Cordill is the director of residential and commercial business development at the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.

Bryan Cordill is the director of residential and commercial business development at the Propane Education & Research Council. He can be reached at bryan.cordill@propane.com.