The COVID-19 pandemic is causing commercial buildings such as day care facilities, hotels, schools and health clubs to remain closed for abnormally long periods. When the coast is clear to begin reopening, ensuring safe and sanitary plumbing water will be of utmost importance. Plumbing systems left idle can be susceptible to harmful bacteria such as Read more

Caleffi

The COVID-19 pandemic is causing commercial buildings such as day care facilities, hotels, schools and health clubs to remain closed for abnormally long periods. When the coast is clear to begin reopening, ensuring safe and sanitary plumbing water will be of utmost importance. Plumbing systems left idle can be susceptible to harmful bacteria such as Legionella which can proliferate to dangerous concentrations.

Experienced water maintenance managers know susceptible systems should be flushed before reusing. Important considerations should not be overlooked such as ensuring all service lines are purged and dead legs drained.

Several factors determine if the system equipment requires treatment such as how long a system is left idle, the temperature of the stagnated water and condition of the internal surfaces. This is so bacteria that are resistant to simple purging/draining and have become resident in biofilm can be addressed. Common methods include thermal treatment or treating with chemicals such as chlorine, chlorinated gas and chlorine dioxide.

A significant benefit of thermal treatment is that it’s a proven, cost-effective method for bacteria management on an ongoing basis in the hot side of the plumbing system. The cold side doesn’t typically require ongoing treatment unless water remains stagnated for extended periods within the temperature range that Legionella grows which is 68°F to 122°F.

Thermal treatment requires little additional maintenance compared to chemical treatment. Also, common plumbing equipment such as seals, gaskets and polymer components are not exposed to potentially incompatible life-shortening chemicals.

Residual chemicals in the water can also be a human health concern if acceptable concentration values are exceeded. In contrast, most common plumbing materials can withstand, without effect, thermal shock temperatures such as 160°F.

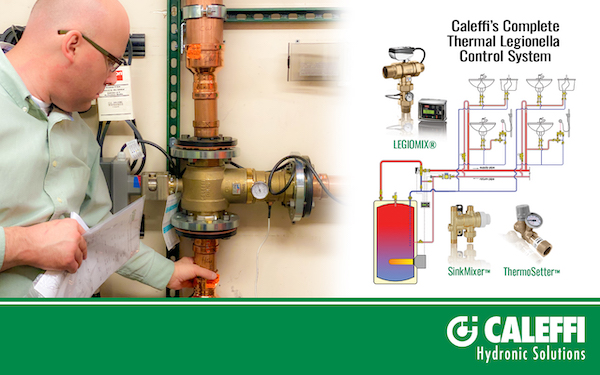

Thermal treatment consists of periodically circulating elevated water temperature such as 160°F through the entire system for a specific and measured period of time, thereby killing harmful bacteria and restoring the water to a safe and usable condition. During this period it is important to ensure all point-of-use fixtures are either disabled for access or equipped with anti-scald devices. An example is the Caleffi scald-protection valve SinkMixerTM — an innovative, easy to install valve for under-sink applications.

Often the most difficult portions of the hot water side to circulate sufficiently through is the recirculation return risers. This because they are sized and balanced to a relatively low flow rate such as 0.5 GPM. The Caleffi ThermoSetterTM thermal balancing valve automatically responds when it senses high temperature water by fully opening an internal by-pass, thereby allowing a sufficient return riser flushing during treatment. It then automatically returns to standard operation state when water temperature decreases to normal.

If a building is equipped with a Caleffi LEGIOMIX digital mixing valve, it will enjoy highly accurate mixed water temperature 24/7. The LEGIOMIX has industry-unique, calendar- based automatic thermal disinfection programs. For thermal monitoring, it has data logging capabilities and can connect to a building automation system for remote monitoring and access.

LEGIOMIX combined with SinkMixer anti-scald valves and ThermoSetter recirculation balancing valves offer an innovative total thermal solution for control of safe and sanitary domestic hot water.

The importance of proper domestic hot water (DHW) temperature control in providing comfort, safety and convenience cannot be overstated. Delivering it remains one of the most important responsibilities of plumbing system designers. Kevin Freidt, Caleffi director of product management and technical support, will discuss temperature control at the hot water source, at the point-of-use, in the Read more

The importance of proper domestic hot water (DHW) temperature control in providing comfort, safety and convenience cannot be overstated. Delivering it remains one of the most important responsibilities of plumbing system designers. Kevin Freidt, Caleffi director of product management and technical support, will discuss temperature control at the hot water source, at the point-of-use, in the balanced secondary circuits and in the system as a whole.

You’ll learn:

→ What methods are used to control temperature at the DHW source?

→ What is different about controlling hot water temperature at the source vs. at the point-of-use?

→ Mixing valve standards ASSE 1017, ASSE 1070 and other related ASSE standards.

→ Can an instantaneous heater take the place of a mixing valve?

→ Are electronic mixing valves more accurate than thermostatic mixing valves?

→ How do I properly size and install a mixing valve to assure accuracy?

→ What are some causes of the loss of accuracy in a mixing valve?

→ What about temperature control and balancing of secondary piping circuits when I have recirculation?

→ What does accurate temperature control have to do with preventing Legionella bacteria issues?

Freidt is the intellect behind sizing up the best product offerings in a moving target market and manages an exceptional technical support team. He has a B.S. in Mechanical Engineering Technology, 35+ years’ of experience in the commercial HVAC industry and is a LEED AP. Our audience will thoroughly appreciate his academic passion and concise content delivery.

Coffee with Caleffi technical training webinars are free and intended for contractors, designers and wholesalers. By submitting your webinar registration, you are consenting to email communications to keep you up-to-date on industry news. A Certificate of Attendance is emailed to attendees following the webinar.

Missed a webinar? No problem, our webinar archive is available 24/7 for your convenience.

If you have questions on webinar content, please direct them to bob.rohr@caleffi.com.

Caleffi North America, Inc. announces the promotion of Cody Mack to training and education manager. In this role Mack, working with Caleffi U.S. and Canadian manufacturers’ representative networks, will conduct product and application training for contractors, designers and other influencers. “Cody has nearly 20 years’ of experience as an installation contractor, service tech and application Read more

Cody Mack, training and education manager for Caleffi North America.

Caleffi North America, Inc. announces the promotion of Cody Mack to training and education manager. In this role Mack, working with Caleffi U.S. and Canadian manufacturers’ representative networks, will conduct product and application training for contractors, designers and other influencers.

“Cody has nearly 20 years’ of experience as an installation contractor, service tech and application engineer,” says Caleffi sales director, Roger Corrente. “He’s known for taking technical concepts and making them clearly understood. When Cody educates, whether in person or virtually via a webinar, we get unsolicited compliments. That says a lot”.

Prior to Mack’s five years at Caleffi, he installed and serviced HVAC and plumbing systems throughout southern Wisconsin. Mack may be contacted at (414) 238-2371 or cody.mack@caleffi.com.