The LevelBest offering from Jones Stephens is a complete drainage and cleanout system. LevelBest drains allow for adjustment to floor level after the concrete is poured. The adjustment of the spud eliminates the need to break and repair the floor when the concrete is poured too high. The drainage system is compatible with PVC, ABS Read more

Cast Iron

The LevelBest offering from Jones Stephens is a complete drainage and cleanout system. LevelBest drains allow for adjustment to floor level after the concrete is poured. The adjustment of the spud eliminates the need to break and repair the floor when the concrete is poured too high. The drainage system is compatible with PVC, ABS or Cast Iron drains and cleanouts and feature industry standard IPS threads that are compatible with most adapters and drain bodies. Jones Stephens. For more info on LevelBest Drains and other plumbing products, visit www.jonesstephens.com.

The LevelBest offering from Jones Stephens is a complete drainage and cleanout system. LevelBest drains allow for adjustment to floor level after the concrete is poured. The adjustment of the spud eliminates the need to break and repair the floor when the concrete is poured too high. The drainage system is compatible with PVC, ABS or Cast Iron drains and cleanouts and feature industry standard IPS threads that are compatible with most adapters and drain bodies. Jones Stephens. For more info on LevelBest Drains and other plumbing products, visit www.jonesstephens.com.

Family businesses work when everyone is invested in a common goal. Half-hearted efforts and attitudes, jealousy or near-sightedness are the kiss of death when parents, siblings and in-laws are involved. But when all are engaged and aligned fruitfully, the result can be an uncommonly strong enterprise with long-term potential. AC Plumbing, Heating & Mechanical in Read more

Family businesses work when everyone is invested in a common goal. Half-hearted efforts and attitudes, jealousy or near-sightedness are the kiss of death when parents, siblings and in-laws are involved.

But when all are engaged and aligned fruitfully, the result can be an uncommonly strong enterprise with long-term potential.

AC Plumbing, Heating & Mechanical in Cleveland, OH, seems to have written the handbook for success in family business, though that wasn’t initially the plan. Tony Caruso started the firm with his wife LuAnn, in 1980, while also serving as a professional fireman.

Today, their children operate the 14-person company in Bedford Heights, OH.

Daughter Monica runs the office and her husband, Kelly Miller, is head of the HVAC shop. Anthony, like his father, is a professional fireman and paramedic, working 24 hours on, 48 off. When he’s not on duty at the firehouse, he’s the lead hydronic technician. Michael, who has a construction management degree, is the company’s lead plumber.

Under their direction and Tony’s mentorship and guidance, the business has flourished.

Under their direction and Tony’s mentorship and guidance, the business has flourished.

“I never envisioned all of this with my children,” said Tony Caruso. “I didn’t plan for them to join the company, let alone see the potential for them to propel us forward. But I’ve always believed this profession was something special. Having them join me has been a tremendous source of pride.”

Today, the company’s reputation for outstanding craftsmanship is validated by long-standing customer relationships, both commercial and residential. Some of those clients haven’t changed since the early years, when LuAnn was still writing invoices from notes that Tony scratched in the firehouse breakroom.

As Tony takes a back seat to day-to-day operations, it has given him time for volunteer work, and to tackle personal projects.

Restoring antiquity

“I’m drawn to old things, especially mechanical in nature,” said Tony. “Volunteering at a historic railway has been rewarding, especially when I can involve my grandchildren. I love to bring things back to their proper vintage and grace; cabooses, automobiles, buildings, etc.”

In part to scratch an itch and partly as a long-term investment, Tony and LuAnn purchased a 100-year-old building near downtown Cleveland in 2017. The Detroit Avenue area is slowly experiencing a renaissance of sorts. Young people are moving back in, small businesses are cropping up, and property values are plodding patiently upward.

Caruso bought the old building as a rundown residence. Police were frequently called to the address for one sort of disturbance or another. But with plenty of vision and know how – not to mention the involvement of a team of mechanical technicians – Tony and LuAnn had other plans.

They’re just now finishing the details on the 5,000 square-foot building. An upscale salon and spa occupies the ground level, with floor-to-ceiling windows along the sidewalk. The upstairs is divided into two apartments, with a third being added behind the salon.

Half of the basement slab received a pebble finish called Natural Stone. No sooner had the top coat cured before water backed up into the basement.

“We thought we’d need to hammer out a part of the new floor to access a clog in the old porcelain plumbing, and install a drain at that spot,” said Caruso. “So we purchased a Watts Pronto!™ floor drain because of the ability to do post-pour adjustment between the concrete and finished floor.”

“We thought we’d need to hammer out a part of the new floor to access a clog in the old porcelain plumbing, and install a drain at that spot,” said Caruso. “So we purchased a Watts Pronto!™ floor drain because of the ability to do post-pour adjustment between the concrete and finished floor.”

Then Michael and Zac Wood, one of the company’s plumbers, scoped the pipe. It became apparent that the clog could be remedied without digging up the floor. Jagged edges on the old cast iron pipe within a fitting were catching sewer debris. By snaking the pipe with a heavy cutter tip, the issue was remedied.

In an adjacent basement room without finished flooring, the building had a plumbing stack coming down from the first floor. It was no longer in use, and just in the way.

“We wanted to remove the stack for more storage space,” said Michael. “But in a building like this, where the use of occupied space can easily change in the future, we try not to eliminate sewer connections. We already had the Pronto! drain in the van. It’s a little overkill for an unfinished slab, but it definitely served the purpose.”

Zac hammered-out the floor, installed a new trap, then poured new concrete and installed the drain.

Zac hammered-out the floor, installed a new trap, then poured new concrete and installed the drain.

“The real benefit of the Pronto! floor drain is that the drain can be adjusted twice,” said Zac. “The basin can be raised or lowered to match the initial concrete pour, and then the strainer can be adjusted to match the finished floor grade. It comes with a set of shims to get a perfect level. On this installation, though, we only needed to make one adjustment. Using the drain’s integral bubble level, I was able to plumb-in the drain perfectly just by adjusting it after making my PVC connection.”

The Watts Pronto! floor drain is available in either cast iron or PVC, and comes in grate sizes of 5”, 6” or 8”.

“We’ve used a variety of Watts products since I started the company,” said Tony. “Our hydronic installations are covered in Watts valves, and we often use tekmar controls. We also like their backflow assemblies. We picked the Pronto! drain, despite it being a completely new product, based on the quality of products we’ve come to expect from the brand.”

“We’ve used a variety of Watts products since I started the company,” said Tony. “Our hydronic installations are covered in Watts valves, and we often use tekmar controls. We also like their backflow assemblies. We picked the Pronto! drain, despite it being a completely new product, based on the quality of products we’ve come to expect from the brand.”

With the plumbing issues resolved at the investment property, the Carusos can focus on finishing the final rental unit. The building is now an integral part of the Detroit Avenue urban revitalization effort, inside and out. Two walls on the building feature giant murals, a theme throughout the area. It’s another source of pride.

Doing right

“Not everyone at AC Plumbing is family, but they may as well be,” said Tony. “Every member of our team is vital. We hire people that want to provide service. That is, in my judgement, the finest pursuit. The responsibility to our team is never to do less than the right thing. That may include engineering the correct system, performing the proper replacement or repair, or taking responsibility for mistakes. Good business ethics.”

Tony’s quick to note that the industry and market is changing rapidly, and is thankful that his children are proactively keeping pace with it. Clients have become much more astute in regard to what they want in their homes. Systems are now “on demand,” “green” or otherwise designed primarily for comfort.

“The daily challenge we now face is installing a system that never compromises safety, comfort or efficiency,” Tony continued. “In years’ past, things were simpler, and efficiency wasn’t as critical. These factors have truly raised the bar on what it means to be a plumbing or HVAC professional. Fortunately, manufacturers and reps are providing more support than ever before.”

“I feel that being trusted in a customer’s home is the greatest responsibility,” Tony said. “As my career winds down, I feel that my family has that same passion. At the end of the day we can all rest knowing we’ve done what is dutifully right.”

The difference between cast iron soil pipe and plastic is easily understood when it comes to sound. Cast iron drain waste and vent pipe systems are superior when it comes to sound attenuation. For commercial office buildings, hospitals, high-rise condominiums or high-end hotels, no one wants to listen to the flowing of fluids when a Read more

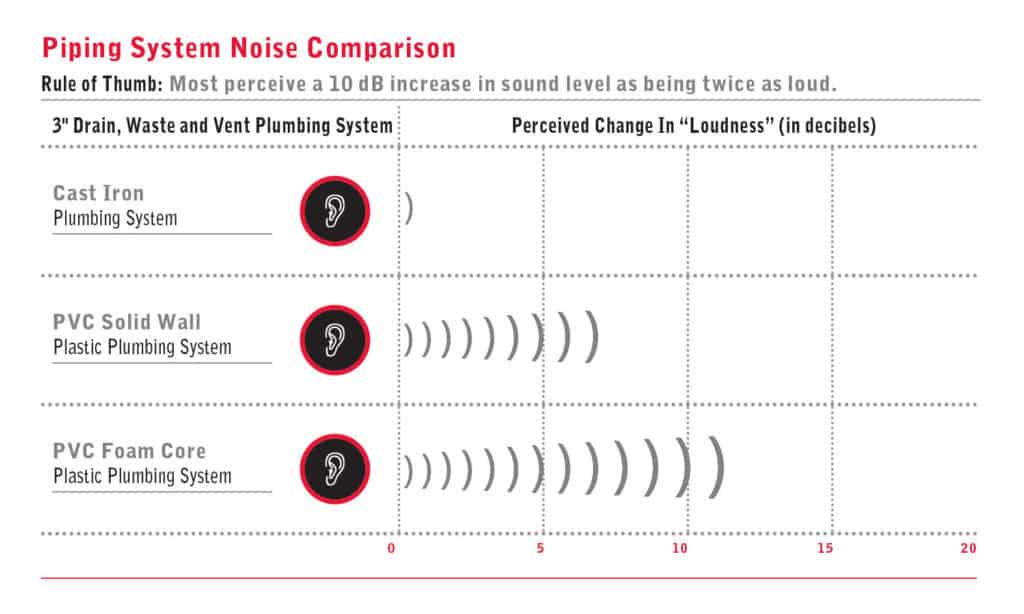

The difference between cast iron soil pipe and plastic is easily understood when it comes to sound. Cast iron drain waste and vent pipe systems are superior when it comes to sound attenuation. For commercial office buildings, hospitals, high-rise condominiums or high-end hotels, no one wants to listen to the flowing of fluids when a toilet is flushed from the floor above.

Specifying cast iron for waste piping provides a plumbing system that is up to 11 times quieter than an all-plastic system. This is how it got its name – the Quiet Pipe®.

A primary factor in cast iron’s sound-dampening quality is its microstructure. Graphite flakes absorb and dampen vibration applied to the iron. The microstructure isn’t the only advantage when it comes to noise.

Cast iron installation plays a primary role in sound attenuation. The use of neoprene rubber gaskets to join sections of cast iron pipe provides additional sound dampening. Sections of pipe do not touch as the rubber gasket creates a buffer, and so contact-related sound is eliminated. In contrast, plastic systems are installed as rigid systems that are solvent cemented. Noise is created as the rigid system expands and contracts with heating and cooling.

A frequently used tactic attempts to create a solid barrier between the pipe and the wall: wrapping plastic pipe in insulation to muffle the sound of rushing water and fluids through pipes. An insulated plastic pipe, however, can be sound-enhancing rather than sound-deadening. The “fix” results in additional installation costs incurred for both product and labor.

A frequently used tactic attempts to create a solid barrier between the pipe and the wall: wrapping plastic pipe in insulation to muffle the sound of rushing water and fluids through pipes. An insulated plastic pipe, however, can be sound-enhancing rather than sound-deadening. The “fix” results in additional installation costs incurred for both product and labor.

Specify cast iron soil pipe and enjoy the benefits of the Quiet Pipe®.

Check out cast iron soil pipe’s other benefits.

Dave Parney is the Executive Vice President of the Cast Iron Soil Pipe Institute (CISPI) and a former Master Plumber in the Chicago area.

Dave Parney is the Executive Vice President of the Cast Iron Soil Pipe Institute (CISPI) and a former Master Plumber in the Chicago area.

This is the first of McWane Plumbing Technical Services ‘How-To’ video series to learn more about cast iron soil pipe and fittings. https://youtu.be/_CZW2ZhhKik McWane Plumbing Technical Services is a full-range service organization that provides educational and technical support on codes and standards as well as regulations that cover cast iron soil pipe and fittings, gaskets and couplings Read more

This is the first of McWane Plumbing Technical Services ‘How-To’ video series to learn more about cast iron soil pipe and fittings.

McWane Plumbing Technical Services is a full-range service organization that provides educational and technical support on codes and standards as well as regulations that cover cast iron soil pipe and fittings, gaskets and couplings, and drainage products for storm and sanitary drain, waste, and vent (DWV) plumbing systems. This service is provided at no cost. Tech Services plays an active role by offering assistance to those interested in better understanding the benefits of using a cast iron plumbing system in a building application.

Cold-Shot® Pipe Freezing Kit from General Pipe Cleaners lets you repair an operating water system without draining water lines before cutting pipe or tubing. The Cold-Shot freezes liquids in steel, copper, cast iron, aluminum or plastic pipes, 1/8” through 2” in diameter, using Carbon Dioxide (CO2) in dip-tube cylinders. It can create an ice plug in Read more

Cold-Shot® Pipe Freezing Kit from General Pipe Cleaners lets you repair an operating water system without draining water lines before cutting pipe or tubing. The Cold-Shot freezes liquids in steel, copper, cast iron, aluminum or plastic pipes, 1/8” through 2” in diameter, using Carbon Dioxide (CO2) in dip-tube cylinders. It can create an ice plug in copper tubing within five minutes – and in steel pipe within three minutes. The Cold-Shot is faster, more compact and less expensive than “refrigerator-type” or “bag-type” units.

Cold-Shot® Pipe Freezing Kit from General Pipe Cleaners lets you repair an operating water system without draining water lines before cutting pipe or tubing. The Cold-Shot freezes liquids in steel, copper, cast iron, aluminum or plastic pipes, 1/8” through 2” in diameter, using Carbon Dioxide (CO2) in dip-tube cylinders. It can create an ice plug in copper tubing within five minutes – and in steel pipe within three minutes. The Cold-Shot is faster, more compact and less expensive than “refrigerator-type” or “bag-type” units.

For details, contact General Pipe Cleaners at 800-245-6200 or 412-771-6300, or visit www.drainbrain.com/coldshot.