The Drain, Waste and Vent (DWV) piping system in a building is a crucial component of the overall plumbing infrastructure. In a building, the Drain, Waste and Vent (DWV) system is an often overlooked, yet it is an essential component of the plumbing infrastructure. The majority of DWV piping systems are hidden below floors, behind Read more

cast iron soil pipe

The Drain, Waste and Vent (DWV) piping system in a building is a crucial component of the overall plumbing infrastructure.

In a building, the Drain, Waste and Vent (DWV) system is an often overlooked, yet it is an essential component of the plumbing infrastructure. The majority of DWV piping systems are hidden below floors, behind walls, and in ceilings. Out of sight, out of mind. That is until your previously fully functional plumbing system has a problem.

Plumbing may be out of sight, but just like any other mechanical system, your DWV piping should be properly and regularly maintained, regardless of the material. Developing a DWV maintenance plan will keep your plumbing system top of mind. This will help facility management to budget effectively for your system maintenance and diminish the likelihood of plumbing emergencies that could send your building occupants reeling.

DWV System Evaluation

There is no one-size-fits-all maintenance program for DWV systems. Building occupancy type and usage, piping material, and other special conditions that are unique to your building requires evaluating your DWV systems as a first step.

Facility management can start by performing a regularly scheduled visual examination of the DWV system. You are looking for proper slope, appropriate support of the piping system and components, suitable venting and clear vents, and of course, any visible leaks in the piping system, among other things. Regular visual inspection is just one step in a larger effort to maintain your DWV system.

If your visual inspection reveals no obvious signs of wear and tear, do not assume that you are in the clear. Many factors outside of the DWV system can have negative effects on it and its long-term functionality. These factors are what are at the heart of the maintenance program. As conditions change, the frequency and the way you maintain your system should change with it.

Once you have completed your visual inspection, consider the risk factors that make your building unique. What are some of the considerations when determining the factors and frequency of your maintenance program?

- Cleaning chemicals Harsh cleaning chemicals having a pH range outside the normal range of expected sanitary effluents could be harmful to the DWV system, unless properly flushed.

- Grease Interceptors These should be serviced in accordance with manufacturer’s recommendations so as not to allow its contents to go septic. Proper disposal of food particles is key to the health of an interceptor.

- Gases from the municipal sewer Some municipalities depend on the building’s vent system to vent gases from the sewer, which can be harmful to the building vent piping because this is not the intended application. When these gases are in the system, regular flushing should be performed to minimize the impacts.

- Building usage Is the buildings occupancy year-round or seasonal? If usage is low, more frequent maintenance of the DWV system may be required.

- Low flow or no flow fixtures The proliferation of low flow and waterless fixtures for conservation have unintended consequences. Not enough water in the lines to self-scour or to float the proverbial boat leaves behind microbes that are potentially harmful to your piping system.

- Soda fountains Sodas are typically low pH fluids. In high concentrations, they can be detrimental to pipe and fittings, especially if they are not properly flushed through the system.

- Commercial kitchens High temperature fluids from pasta stations or commercial dishwashers can exceed the working temperatures of certain piping systems and lead to system failures.

- Special waste Any waste outside the scope of normal sanitary effluents should be treated as such, with piping approved for the materials that they are conveying. Any special chemicals must be properly diluted before being allowed in the city sewer.

- De-icing Agents De-Icing agents (road salts, sand and the like) used on roadways can accumulate in the DWV system in parking garages. This accumulation needs to be assessed and a maintenance schedule developed to flush and clean the system to the municipal sewer.

How To Maintain Your DWV System

There are countless tools available for you to incorporate into a facility maintenance program. Here are just a few:

- Camera inspection allows you to see inside your piping system and identify issues that would otherwise remain hidden until it is too late.

- Jetting, drain cleaning, cabling, or rodding to the municipal sewer are also effective methods for cleaning and clearing your DWV system.

- Solenoid may be installed to introduce water to dilute, wash or clean the DWV system where needed.

- Installing vented running traps to isolate the building’s DWV system from the city sewer will prevent your municipality from relying on your building to vent gases into the city sewer system.

- Follow the manufacturer maintenance recommendations of any dilution tanks the building may have.

- Identify and replace any aggressive cleaners that the building cleaning or maintenance personnel may be using with a neutral pH cleaning alternative.

- Consider installing upstream flush valves on soda fountain lines for proper dilution.

Many factors outside of the DWV system itself can have long-term effects on the system’s performance and functionality. Slope, system design, fixtures, frequency of use, chemicals and cleaners, maintenance, materials, and water levels and quality are just some of the factors that can affect a DWV system. All of these influences and more need to be examined and properly assessed by facility management when creating an effective plastic or cast iron DWV system maintenance program.

The information above is not meant to be a complete list of all factors that need to be considered and are merely suggestions for formulating a maintenance program. Proper flushing of your DWV system on a regular time schedule is crucial to a long service life. It may be necessary to consult a plumbing professional when designing an effective DWV preventative maintenance program to keep your plumbing system from being top-of-mind for all the wrong reasons.

AB&I Foundry, in celebration of women in engineering, manufacturing and the skilled trades, has developed an iron woman character named “Rose.” The foundry has had a long history with their iron man character who is a big burly man. It was time for the company to feature a female character. The new Iron Woman pays Read more

AB&I Foundry, in celebration of women in engineering, manufacturing and the

skilled trades, has developed an iron woman character named “Rose.” The foundry has had a long history with their iron man character who is a big burly man. It was time for the company to feature a female character. The new Iron Woman pays tribute to the iconic Rosie the Riveter—the women civilians who built the warplanes during the WWII effort.

“There is a huge gap in our historical narrative about women in the trades and that is quickly changing as they are starting to fill the void in skilled trades as many baby boomers retire out of industry. While women are stepping into these rolls they are still underrepresented,” said Francesca Venezia Dunbar, Vice President of Group Marketing for McWane. “We hope that the new Iron Woman will pay tribute to the vast opportunities for women in industry.”

According to The Institute for Women’s Policy Research (IWPR), Between 2017 and 2018, the number of women working in construction trades increased by 17.6 percent, rising to well over a quarter of a million women (276,000), according to a recent analysis from IWPR. The American Society of Mechanical Engineers (ASME) shows that women make up about 47 percent of the overall workforce but are still underrepresented in science and engineering occupations. Only 14 percent of engineers are women. Despite these increases, women still only represent 10% of the construction workforce. According to the U.S. Department of Labor Statistics, jobs in the skilled trades are expected to grow by at least 11 percent by 2026, while three out of every four tradespeople are set to retire. This brings opportunity for women seeking employment in engineering, manufacturing and the skilled trades.

“The plumbing industry, as well as other industries, are chalked full of women breaking barriers with their actions. At AB&I we celebrate those individual women who are pushing through to achieve greatness, no matter the obstacles or tasks,” said Shannon Hooper, National Sales Manager of AB&I Foundry. “I feel that Rose is an embodiment of the changes happening in the construction industry and the world. I look forward to seeing Rose and other women meet the future head on and all the great things they will accomplish.”

AB&I Foundry, an Oakland-based company that manufactures cast iron pipe and fittings for the plumbing industry, has a long legacy of manufacturing in East Oakland. The company has been manufacturing quality cast iron soil pipe that is used to convey fluids out of commercial and residential buildings since 1906. Plumbing infrastructure is critical to public health and sanitation and there are only three (3) manufacturers remaining in the United States. We remain OaklandSTRONG. Please follow us on www.ABIOakland, Facebook, Instagram and Twitter to keep current with AB&I events and information.

Located in the East Bay area of Oakland, near the hollow ground of Oakland Alameda Coliseum, AB&I Foundry has been finding ways to build on its legacy and cutting-edge innovations for over a century. In fact, as a leading producer of cast iron soil pipe, fittings and castings with a distinct black and silver look Read more

Located in the East Bay area of Oakland, near the hollow ground of Oakland Alameda Coliseum, AB&I Foundry has been finding ways to build on its legacy and cutting-edge innovations for over a century. In fact, as a leading producer of cast iron soil pipe, fittings and castings with a distinct black and silver look, one may also wonder where and how the Oakland Raiders came about creating their brand identity nearly 70 years ago. It’s said that AB&I’s Boscacci family was vital in assisting the Raiders establish their community footing and possibly sharing their tradition colors.

Community and team are critical to the history and the future of AB&I. When you drive by the foundry, you can’t miss the big mural that runs a city block on the wall outside of the company. It shows the history of the company through various milestones and despite the location in an industrial area, the wall has never been defaced. One might surmise that this is the ultimate type of respect AB&I has built in the community through their commitment of employing, educating and providing for generations of families. How did it start?

Joseph Boscacci

Joseph Boscacci emigrated from Switzerland to the U.S. in the 1890s, bringing with him an artisan craft. In the wake of the Great San Francisco earthquake and fire of 1906, the young Boscacci worked at General Foundry in San Francisco making bronze statuary, brass street lamps and ornate iron work that was needed for the city’s rebuilding effort.

He also ran his own foundry business on the weekends in the backyard of his home in Oakland. Boscacci and his five sons made a variety of castings, including cast iron fittings, window sash weights and cast iron stove tops for wood burning cook stoves. He called his company American Brass & Iron.

As the decades unfolded and American industry grew, so did the need for cast iron pipe and fittings. By the 1920s, all the Boscacci brothers were involved in the family business. In 1941 the company was moved to their current location on San Leandro Street in Oakland. Just after World War II, brothers Arnold and Eugene took over the foundry and rebranded to AB&I.

American Brass and Iron Foundry in the 1920s

It was the post-war return of the GI’s and housing boom (not too mention ensuing baby boom), that reignited the ever-entrepreneurial Boscacci family back into full production of cast iron pipe and fittings to the ever-increasing demands caused by massive construction boom.

By 1950, AB&I was a leading West Coast foundry and was a founding member of the Cast Iron Soil Pipe Institute (CISPI). Later, AB&I was among the first to champion no-hub cast iron pipe, fittings and couplings, creating its own machines to make no-hub cast iron soil pipe. Ingenuity, forward-thinking and a little risk taking also drove the family to implement automated manufacturing methods.

AB&I in the early 1960s

In the 1960s, the company expanded from selling products mainly in California to distribution across the Western United States. AB&I recognized that establishing relationships was fundamental to the company’s future. They sustained close supply-chain engagement with distributors lasting decades. It was the legacy of those early relationships that still exists today. AB&I believes that integrity is paramount to the company’s success and that you must “do what you say you will do and that best practices in business start with common sense, developing good relationships and attention to detail.”

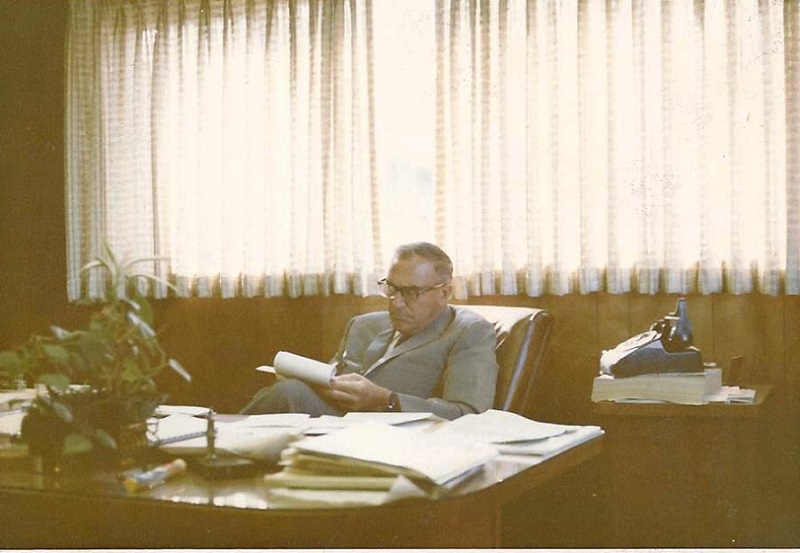

Arnold Boscacci, mid-1960s

By the third generation of Boscacci family leadership, AB&l’s mission was sternly focused on ways to use new technology to make the best cast iron pipe and fittings in the Western US. Allan Boscacci was now making decisions and with most of the work still being completed by hand, he began to introduce higher production levels and enhance modernization efforts. AB&I was predictably ahead of its time environmentally, installing bag houses to capture foundry smoke, and water treatment plants to clean and reprocess foundry water long before it was a requirement.

In 1969, AB&I was the first soil pipe foundry to install a Disamatic (DISA ) molding machine, automating foundry processes which allowed a higher-quality fitting at a much faster rate.

In the 1980s, AB&I was among the first American manufacturers to engage in profit sharing with all team members and to truly practice “open book” management. By the early 1990s, AB&I was the first foundry to totally automate its pipe production.

Overhead at AB&I Foundry in Oakland

The industry has seen its share of attrition. In its glory, America had 39 foundries that and only three remain today. Consistent with being the “Foundry of the Future,” today’s AB&I has the most sophisticated molding machine in the world, a DISA 270A, and is among those making the highest-quality cast iron pipe and fittings in the world.

AB&I joined McWane, Inc., a large family-owned manufacturer, but remains Boscacci family led. Kurt Winter, Allan ‘s oldest son-in-law drives AB&I to be “better, faster and more innovative,” just as the three generations of foundry men before him.

AB&I supports our plumbing industry with vigorous involvement and are highly active with leading national, regional and local industry organizations including: ASA, MCAA, PHCC, ICC, IAPMO, DBIA, ASPE, ASTM and CISPI.

Custom casting at AB&I Foundry

Today’s AB&I, which employs over 200 team members, is a thoroughly modem, technology-driven foundry committed to responsible manufacturing and safety. They are an environmentally conscience U.S. manufacturer that have invested millions in environmental programs involving air, land and water. In fact, AB&’ls water treatment system is set up so that every drop of rainwater that hits their roof is captured and run through a filtration process and recycled. AB&I aims to be great stewards of the environment for future generations.

Next month will will look at the future of AB&I and share a recent Q&A interview with their team.

https://youtu.be/YGu1ydS0-yc This video from CISPI proves best practices for installing a fitting onto a cast iron hub and spigot pipe. The Cast Iron Soil Pipe Institute (CISPI) is dedicated to aiding and improving the plumbing industry. CISPI serves plumbing contractors as a resource for cast iron product questions on installation, proper use, specifications and codes. CISPI representatives are Read more

This video from CISPI proves best practices for installing a fitting onto a cast iron hub and spigot pipe.

The Cast Iron Soil Pipe Institute (CISPI) is dedicated to aiding and improving the plumbing industry. CISPI serves plumbing contractors as a resource for cast iron product questions on installation, proper use, specifications and codes. CISPI representatives are available to visit jobsites as needed and to provide their expertise with regard to the manufacture and use of cast iron soil pipe and fittings.

For more information please visit at www.cispi.org

https://youtu.be/bkpSVBwVTXA This video from CISPI shows you how to remove burrs from cast iron pipe. The Cast Iron Soil Pipe Institute (CISPI) is dedicated to aiding and improving the plumbing industry. CISPI serves plumbing contractors as a resource for cast iron product questions on installation, proper use, specifications and codes. CISPI representatives are available to visit Read more

This video from CISPI shows you how to remove burrs from cast iron pipe.

The Cast Iron Soil Pipe Institute (CISPI) is dedicated to aiding and improving the plumbing industry. CISPI serves plumbing contractors as a resource for cast iron product questions on installation, proper use, specifications and codes. CISPI representatives are available to visit jobsites as needed and to provide their expertise with regard to the manufacture and use of cast iron soil pipe and fittings.

For more information please visit at www.cispi.org