Ever walked into a commercial kitchen or industrial facility and noticed those long, narrow drains running along the floor? They’re not just there for looks—they’re trench drains, and when installed properly, they’re game changers for drainage performance and safety. For plumbers and project managers alike, trench drains are often overlooked until it’s too late. But Read more

commercial kitchen

Ever walked into a commercial kitchen or industrial facility and noticed those long, narrow drains running along the floor? They’re not just there for looks—they’re trench drains, and when installed properly, they’re game changers for drainage performance and safety.

For plumbers and project managers alike, trench drains are often overlooked until it’s too late. But when you consider the volume of water, debris, and grease that can accumulate in high-traffic commercial areas, it becomes clear – an efficient trench drain system isn’t a luxury, it’s a necessity.

Why Trench Drains Matter in High-Use Environments

Commercial spaces like restaurants, breweries, warehouses, and car parks deal with far more runoff than residential properties. A basic point drain won’t cut it. Trench drains offer:

- Wide surface capture for rapid drainage

- Customisable grates to suit load ratings and slip resistance

- Durability under constant foot or vehicle traffic

They don’t just collect water, they control it. And in a commercial setting, that kind of control prevents costly downtime, water damage, or worse, a slip-and-fall injury.

Grate Selection and Slip Ratings: More Than Just Looks

Choosing the right grate isn’t just about strength—it’s also about safety. Grates come in a range of materials like stainless steel, ductile iron, galvanised steel, and plastic composites. The best option depends on your application. For example, stainless steel is corrosion-resistant and ideal for food-grade areas, while ductile iron handles heavy traffic with ease.

Slip resistance matters too. In Australia, AS 4586 governs slip resistance testing, while the U.S. refers to ANSI/NFSI B101.3. Look for grates that meet R11 or higher slip ratings in wet areas to reduce accident risk. Serrated surfaces, heel-proof slots, and even anti-slip coatings can enhance performance in greasy or moisture-prone environments.

Understanding Load Classes: AS 3996 vs. AASHTO M306

Load ratings help ensure your grate system won’t crack under pressure—literally. In Australia, AS 3996 outlines load classes from A (pedestrian use) to G (aircraft traffic). In the U.S., AASHTO M306 and EN 1433 provide similar guidance.

- Class A (AS): Light pedestrian use, garden paths, patios

- Class C (AS)/H-20 (US): Car parks, light vehicular traffic

- Class D–E (AS)/HS-25 (US): Industrial facilities, loading docks, emergency vehicle access

Always match the drain to the application. Misjudging load class is one of the most common and costly mistakes in trench drain installations.

Design Considerations: Flow Rate, Slope, and Materials

Planning a trench drain system requires more than just digging a channel. Are you working with forklifts or foot traffic? In food prep areas, hygiene and cleanability come first. For outdoor carparks, galvanised steel or polymer concrete channels are ideal for weather resistance.

And then there’s slope. A typical 1% grade (10mm per metre) allows water to flow efficiently, but higher volumes or debris-heavy areas may require a steeper gradient. The U.S. International Plumbing Code (IPC) and Australia’s AS/NZS 3500 both emphasise correct slope for sanitary and stormwater drainage.

Installation Best Practices for Long-Term Performance

Installing trench drains isn’t complex, but it does demand precision. A few centimetres off-level can compromise the entire system. So how do you get it right?

- Plan for the outlet points before pouring concrete

- Use rebar or brackets to stabilise channels during the pour

- Ensure waterproof seals between each channel section

- Match trench depth and width to expected flow rates

Rushed installs and poor preparation often result in weak joins or incorrect elevations. And once the concrete sets, the fix isn’t easy or cheap.

Maintenance Matters: Keeping Drains Functional

Like any system, trench drains need upkeep. Food particles, sediment, or debris can build up quickly. Routine inspection and cleaning is critical, especially in kitchens or auto service bays where fats or oils can cause slow flow or blockages.

Use wet vacs, pressure cleaning, or enzyme-based drain cleaners depending on your environment. And make sure removable grates are regularly checked for corrosion, cracks, or warping.

Case Study: Drainage That Doesn’t Quit

We’ve seen our share of trench drain disasters, but we’ve also helped businesses turn things around. One recent project involved retrofitting a faulty drainage system in a Queensland car wash. Water used to pool around vacuum bays, causing rust and customer complaints. After assessing the layout, the team at Drain Masters Plumbing installed a sloped trench drain system with heavy-duty grates and dual outlets. Not only did the flooding stop, but the owners also saw a boost in online reviews almost immediately.

It’s proof that when drainage works, nobody notices. But when it doesn’t, everyone does.

Final Thoughts: Why Planning Ahead Pays Off

Trench drains might not be glamorous, but they’re critical infrastructure in any commercial plumbing system. The best time to think about drainage is before problems start—not after.

Whether you’re working on a new build or fixing someone else’s mistake, thoughtful trench drain design and installation can mean the difference between a seamless operation and a costly mess. So ask yourself: is your next project built to drain – or built to fail?

The staff at Spark by Hilton™ in Redlands, California, turned to A. O. Smith for a water heater capable of providing ample hot water to their hotel. It’s no simple task to supply hot water all day, every day, to a hotel with 85 rooms, a kitchen and multiple commercial laundry facilities. But for A Read more

The staff at Spark by Hilton™ in Redlands, California, turned to A. O. Smith for a water heater capable of providing ample hot water to their hotel. It’s no simple task to supply hot water all day, every day, to a hotel with 85 rooms, a kitchen and multiple commercial laundry facilities. But for A. O. Smith, it was the perfect opportunity to showcase the power of the CHP-120 Fully Integrated Commercial Heat Pump Water Heater (HPWH).

The hotel chose to install four CHP-120 HPWH units—all of which function as part of a single fully integrated water heating system. It was critically important to the specifying engineer that the system be integrated as it makes installation significantly easier and is more cost-effective for the hotel.

“I prefer the CHP-120 model’s integrated system because it makes installation and piping easier than other competitive technologies,” said Peter Yoon, lead specifying engineer and owner of American Power Solutions. “The CHP-120 unit is more compact, which means our team does not have to worry about the typical mechanical room space constraints associated with an average commercial unit. We also do not have to worry about additional space for insulation or the need for a large pipe for the system, which makes my job very simple and easy.”

“It takes two days to install the units, with only 10 hours of water shutoff required. After those ten hours of work, your machine will be set to run,” noted Yoon. “There is not much maintenance needed except a filter replacement every year or every other year, so I love it.”

Features & Benefits:

- Industry-leading 4.3 Co-efficient of Performance (COP)

- ENERGY STAR®-certified

- Heat pump technology provides a more energy-efficient way to heat water with electricity

- Integrated 119-gallon tank enables heat pump to operate more frequently, saving money

- Three operating modes (Efficiency, Hybrid, and Electric) maximize efficiency while meeting specific hot water demands

- First-hour delivery exceeds 194 GPH

- Dual 6 kW heating elements provide additional heating capability for periods of high demand

- Maximum water temperature of 150° F in Efficiency and Hybrid modes, and 180° F in Electric mode

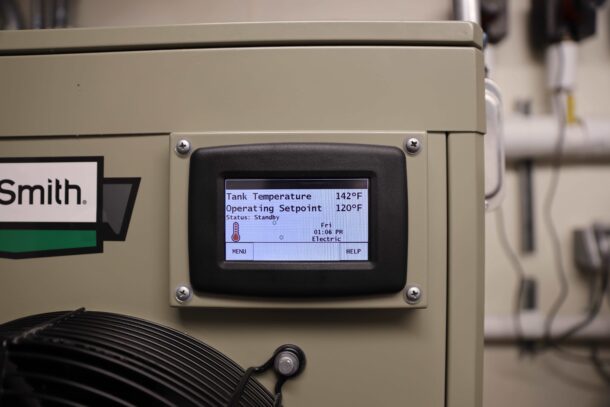

- Large touchscreen LCD display allows for mode selection, provides run information, and includes troubleshooting alerts and detail

Beyond improving the installation process, the CHP-120 HPWH provides the hotel with incredible cost savings on energy. The CHP-120 unit is four times more efficient than a standard electric water heater, saving the hotel up to $3,000 per unit on their annual electric bills. The CHP-120 does this by moving heat from the surrounding air rather than creating heat, allowing it to run at an industry-leading 4.3 Coefficient of Performance (CoP).

The CHP-120 HPWH comes with three different operating modes for maximum efficiency. The three operating modes (Efficiency, Hybrid, and Electric) allow facility managers to adjust as needed to meet the hotel’s varying hot water demands. Facility managers can easily switch between modes due to the CHP-120 unit’s large touchscreen LCD display, which allows for mode selection, and displays run information, including troubleshooting alerts and details. Dual 6 kW heating elements integrated into the unit provide additional heating capability for periods of high demand. This feature ensures that even when the hotel reaches maximum capacity, it can still supply ample hot water to customers, even those staying on the highest floors.

“We used to get customer complaints about not getting hot water on the higher floors of the hotel, but since installing A. O. Smith’s CHP-120 units there have been no customer complaints,” said the hotel manager. “The hot water on the first floor is the same temperature hot water that guests experience on the third floor of the hotel.”

In addition to improving the guest experience, the CHP-120 unit also qualifies for significant utility rebates in the state of California. Payback time on the investment of installing a unit is expected to be just under two years.

“With the current rebate program, it’s almost cost-free to the customer,” said Yoon. “When replacing an old boiler, the investment in new technology is typically the biggest barrier, but with the CHP-120 HPWH we received a big rebate upfront. California has aggressive energy savings goals, so they provide generous rebates on high-efficiency technology like the CHP-120 model. We received $20,000 in rebates for each unit that we installed at the Spark Hotel.”

“Going from a gas-fired water heater to the CHP-120 HPWH, the savings are dramatic. Customers could be wasting thousands of dollars a year by not making the switch,” said Anthony Sun, Delco salesman. “Once the CHP-120 unit is installed, it can run in efficiency mode by using just the compressor, the cool air and the hot air in the room to heat the water, saving the hotel money and energy.”

Find more information about the CHP-120 HPWH and other products at www.hotwater.com.