The release of a new Plumbing Specification Guide from Safe Piping Matters gives design and construction professionals an additional resource to guide evaluation and selection of pipe and fittings for drinking-water, drain/waste/vent, fire-suppression, and other critical piping applications. The new specification guide will also support municipalities and owners of individual buildings as they work to Read more

drain

The release of a new Plumbing Specification Guide from Safe Piping Matters gives design and construction professionals an additional resource to guide evaluation and selection of pipe and fittings for drinking-water, drain/waste/vent, fire-suppression, and other critical piping applications. The new specification guide will also support municipalities and owners of individual buildings as they work to upgrade piping systems, including replacing infrastructure prioritized in recent federal programs.

“Recent piping crises illustrate the importance of making thoughtful, informed choices,” said Paul Hagar, Executive Director of Safe Piping Matters. “Lead pipes are a prime example – a once widely available, affordable piping material deemed safe for use. Over the last decade, however, communities are investing billions of dollars and countless hours finding and replacing these toxic pipes. Piping systems represent a hidden opportunity to ensure the safety and health of occupants while also supporting the sustainability and resilience of a building.”

Available at SafePipingMatters.org/guide, the specification guide offers straightforward explanations and recommendations based on industry expertise, academic research, and real-world examples. Key topics include:

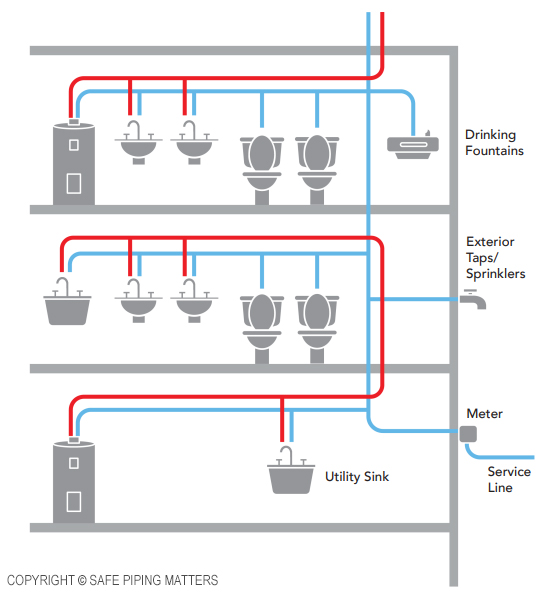

- System configurations

- Piping material strengths and weaknesses

- Plumbing codes, standards, and specification language

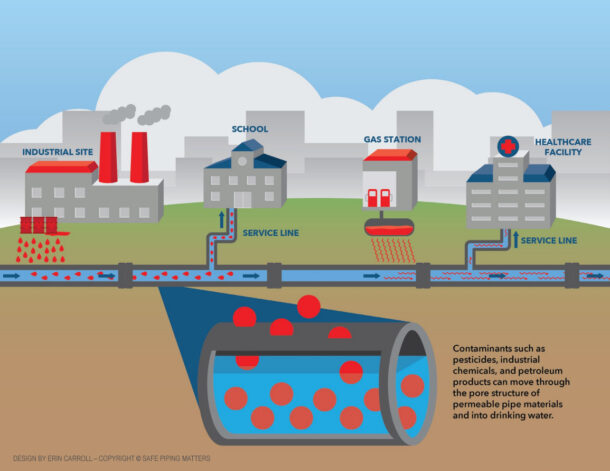

- Safety issues such as permeation, combustibility, and firestopping

- Health risks from leaching and toxicity

- Resilience factors that affect the lifespan of pipe

- Environmental issues related to production and disposal of pipe materials

- Emerging issues

Safe Piping Matters is a nonprofit organization dedicated to providing design and construction professionals the best information on safe, resilient, and sustainable piping. We believe systems should not only improve building performance, but also protect the health of the people who live and work in them. Details at SafePipingMatters.org.

The Drain, Waste and Vent (DWV) piping system in a building is a crucial component of the overall plumbing infrastructure. In a building, the Drain, Waste and Vent (DWV) system is an often overlooked, yet it is an essential component of the plumbing infrastructure. The majority of DWV piping systems are hidden below floors, behind Read more

The Drain, Waste and Vent (DWV) piping system in a building is a crucial component of the overall plumbing infrastructure.

In a building, the Drain, Waste and Vent (DWV) system is an often overlooked, yet it is an essential component of the plumbing infrastructure. The majority of DWV piping systems are hidden below floors, behind walls, and in ceilings. Out of sight, out of mind. That is until your previously fully functional plumbing system has a problem.

Plumbing may be out of sight, but just like any other mechanical system, your DWV piping should be properly and regularly maintained, regardless of the material. Developing a DWV maintenance plan will keep your plumbing system top of mind. This will help facility management to budget effectively for your system maintenance and diminish the likelihood of plumbing emergencies that could send your building occupants reeling.

DWV System Evaluation

There is no one-size-fits-all maintenance program for DWV systems. Building occupancy type and usage, piping material, and other special conditions that are unique to your building requires evaluating your DWV systems as a first step.

Facility management can start by performing a regularly scheduled visual examination of the DWV system. You are looking for proper slope, appropriate support of the piping system and components, suitable venting and clear vents, and of course, any visible leaks in the piping system, among other things. Regular visual inspection is just one step in a larger effort to maintain your DWV system.

If your visual inspection reveals no obvious signs of wear and tear, do not assume that you are in the clear. Many factors outside of the DWV system can have negative effects on it and its long-term functionality. These factors are what are at the heart of the maintenance program. As conditions change, the frequency and the way you maintain your system should change with it.

Once you have completed your visual inspection, consider the risk factors that make your building unique. What are some of the considerations when determining the factors and frequency of your maintenance program?

- Cleaning chemicals Harsh cleaning chemicals having a pH range outside the normal range of expected sanitary effluents could be harmful to the DWV system, unless properly flushed.

- Grease Interceptors These should be serviced in accordance with manufacturer’s recommendations so as not to allow its contents to go septic. Proper disposal of food particles is key to the health of an interceptor.

- Gases from the municipal sewer Some municipalities depend on the building’s vent system to vent gases from the sewer, which can be harmful to the building vent piping because this is not the intended application. When these gases are in the system, regular flushing should be performed to minimize the impacts.

- Building usage Is the buildings occupancy year-round or seasonal? If usage is low, more frequent maintenance of the DWV system may be required.

- Low flow or no flow fixtures The proliferation of low flow and waterless fixtures for conservation have unintended consequences. Not enough water in the lines to self-scour or to float the proverbial boat leaves behind microbes that are potentially harmful to your piping system.

- Soda fountains Sodas are typically low pH fluids. In high concentrations, they can be detrimental to pipe and fittings, especially if they are not properly flushed through the system.

- Commercial kitchens High temperature fluids from pasta stations or commercial dishwashers can exceed the working temperatures of certain piping systems and lead to system failures.

- Special waste Any waste outside the scope of normal sanitary effluents should be treated as such, with piping approved for the materials that they are conveying. Any special chemicals must be properly diluted before being allowed in the city sewer.

- De-icing Agents De-Icing agents (road salts, sand and the like) used on roadways can accumulate in the DWV system in parking garages. This accumulation needs to be assessed and a maintenance schedule developed to flush and clean the system to the municipal sewer.

How To Maintain Your DWV System

There are countless tools available for you to incorporate into a facility maintenance program. Here are just a few:

- Camera inspection allows you to see inside your piping system and identify issues that would otherwise remain hidden until it is too late.

- Jetting, drain cleaning, cabling, or rodding to the municipal sewer are also effective methods for cleaning and clearing your DWV system.

- Solenoid may be installed to introduce water to dilute, wash or clean the DWV system where needed.

- Installing vented running traps to isolate the building’s DWV system from the city sewer will prevent your municipality from relying on your building to vent gases into the city sewer system.

- Follow the manufacturer maintenance recommendations of any dilution tanks the building may have.

- Identify and replace any aggressive cleaners that the building cleaning or maintenance personnel may be using with a neutral pH cleaning alternative.

- Consider installing upstream flush valves on soda fountain lines for proper dilution.

Many factors outside of the DWV system itself can have long-term effects on the system’s performance and functionality. Slope, system design, fixtures, frequency of use, chemicals and cleaners, maintenance, materials, and water levels and quality are just some of the factors that can affect a DWV system. All of these influences and more need to be examined and properly assessed by facility management when creating an effective plastic or cast iron DWV system maintenance program.

The information above is not meant to be a complete list of all factors that need to be considered and are merely suggestions for formulating a maintenance program. Proper flushing of your DWV system on a regular time schedule is crucial to a long service life. It may be necessary to consult a plumbing professional when designing an effective DWV preventative maintenance program to keep your plumbing system from being top-of-mind for all the wrong reasons.

The difference between cast iron soil pipe and plastic is easily understood when it comes to sound. Cast iron drain waste and vent pipe systems are superior when it comes to sound attenuation. For commercial office buildings, hospitals, high-rise condominiums or high-end hotels, no one wants to listen to the flowing of fluids when a Read more

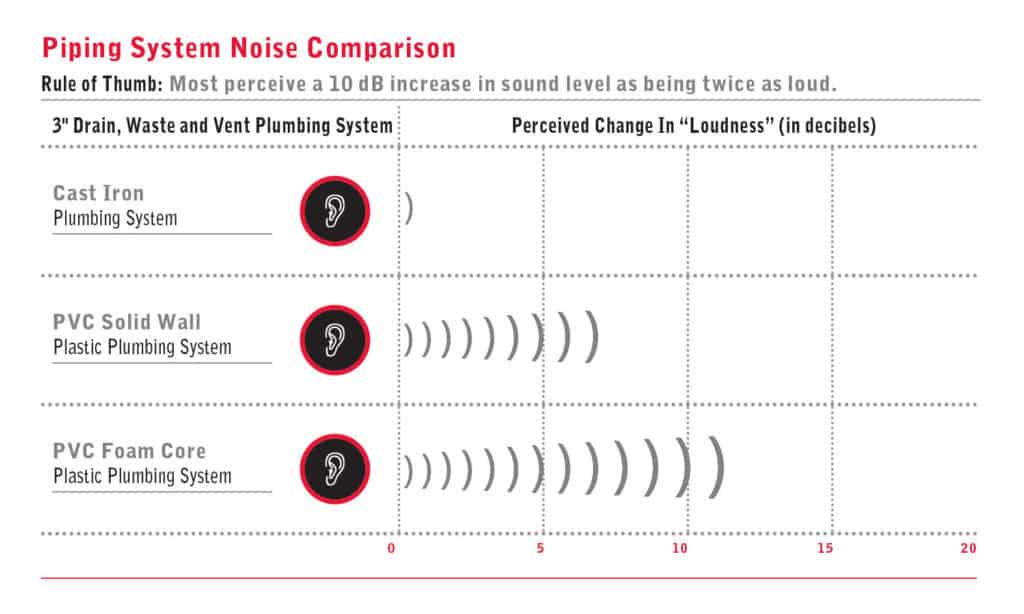

The difference between cast iron soil pipe and plastic is easily understood when it comes to sound. Cast iron drain waste and vent pipe systems are superior when it comes to sound attenuation. For commercial office buildings, hospitals, high-rise condominiums or high-end hotels, no one wants to listen to the flowing of fluids when a toilet is flushed from the floor above.

Specifying cast iron for waste piping provides a plumbing system that is up to 11 times quieter than an all-plastic system. This is how it got its name – the Quiet Pipe®.

A primary factor in cast iron’s sound-dampening quality is its microstructure. Graphite flakes absorb and dampen vibration applied to the iron. The microstructure isn’t the only advantage when it comes to noise.

Cast iron installation plays a primary role in sound attenuation. The use of neoprene rubber gaskets to join sections of cast iron pipe provides additional sound dampening. Sections of pipe do not touch as the rubber gasket creates a buffer, and so contact-related sound is eliminated. In contrast, plastic systems are installed as rigid systems that are solvent cemented. Noise is created as the rigid system expands and contracts with heating and cooling.

A frequently used tactic attempts to create a solid barrier between the pipe and the wall: wrapping plastic pipe in insulation to muffle the sound of rushing water and fluids through pipes. An insulated plastic pipe, however, can be sound-enhancing rather than sound-deadening. The “fix” results in additional installation costs incurred for both product and labor.

A frequently used tactic attempts to create a solid barrier between the pipe and the wall: wrapping plastic pipe in insulation to muffle the sound of rushing water and fluids through pipes. An insulated plastic pipe, however, can be sound-enhancing rather than sound-deadening. The “fix” results in additional installation costs incurred for both product and labor.

Specify cast iron soil pipe and enjoy the benefits of the Quiet Pipe®.

Check out cast iron soil pipe’s other benefits.

Dave Parney is the Executive Vice President of the Cast Iron Soil Pipe Institute (CISPI) and a former Master Plumber in the Chicago area.

Dave Parney is the Executive Vice President of the Cast Iron Soil Pipe Institute (CISPI) and a former Master Plumber in the Chicago area.