Ah, the age-old question: is it duct tape or duck tape? Although often mispronounced, it’s actually duct tape (Duck is a brand of the tape) and covers a class of pressure-sensitive tapes that consists of three layers: polyethylene (plastic), scrim (mesh fabric) and rubberized adhesive. Yet, even with that clarification, the term “duct tape” can Read more

Duct Tape

Ah, the age-old question: is it duct tape or duck tape? Although often mispronounced, it’s actually duct tape (Duck is a brand of the tape) and covers a class of pressure-sensitive tapes that consists of three layers: polyethylene (plastic), scrim (mesh fabric) and rubberized adhesive. Yet, even with that clarification, the term “duct tape” can still be a bit misleading – although it’s considered a fix-all that got its name from early-on usage in HVAC work, duct tape is, today, actually not recommended for use on ducts (though there are some versions that are approved for HVAC applications).

Here’s a rundown of tape types.

- General Purpose Duct Tapes: Typical Thickness: 6-9 mils, handy for DIY home projects or light duty patching and bundling for pros on the jobsite.

- Heavy Duty Duct Tapes: Typical Thickness: 10-17 mils, every tradesperson should keep at least one roll of heavy duty duct tape in the toolbox — and multiple widths or colors won’t hurt.

- Clear Repair Tapes: Typical Thickness: Approx. 7 mils, your go-to tape for airtight, waterproof repairs on any surface that needs to be seen.

- Structural Grade Duct Tapes: Typical Thickness: Approx. 17 mils, the most robust option for extreme jobs, including those that require a rope or chain.

Duct tape is undoubtedly one of those versatile items that’s earned a place in just about any toolbox. It’s flexible, resists tearing, and sticks to just about anything. As contractors know, when it comes to jobsite efficiency, having the right tools for the job at-hand makes all the difference—and saving time means saving money.

Duct tape is undoubtedly one of those versatile items that’s earned a place in just about any toolbox. It’s flexible, resists tearing, and sticks to just about anything. As contractors know, when it comes to jobsite efficiency, having the right tools for the job at-hand makes all the difference—and saving time means saving money.

The Mechanical Hub ProStaff team recently took on the challenge of trying out a new tape to see if it was the one to grab to ensure the fix doesn’t fail and can save time, money and a lot of space in the toolbox.

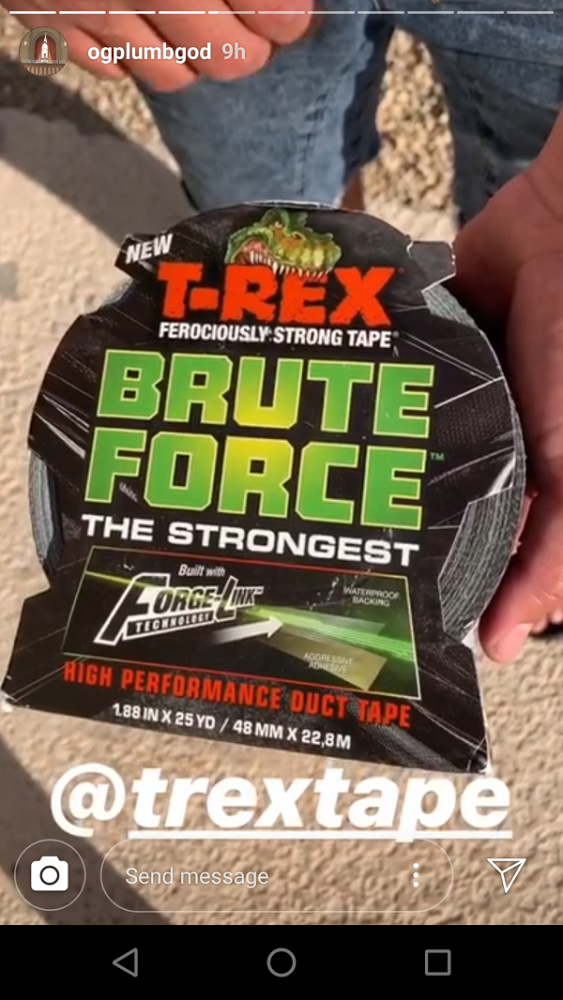

Traditionally, ropes or chains have been the only option for contractors and installers when they encounter jobsite tasks that require intense strength and durability. Until now as one 36-inch loop of new T-Rex® Brute Force® can hold more than 700 pounds of weight and offers superior adhesion, so you can quickly secure, fasten and hold loads that you wouldn’t dare attempt with other tapes.

The high-bond, double-thick adhesive allows the tape to stick to rougher, dirtier surfaces and offers a durable, waterproof backing suitable for all-weather performance. Brute Force® represents the next generation of high-performance duct tapes with patent-pending Forge-Link™ Technology.

ProStaffer Andy Mickelson of Mickelson Plumbing and Heating, Missoula, Montana, was impressed with the strength and said, “T-Rex Brute Force tape has an incredible tear-resistant design, so much so that you’ll require a blade to cut it. The adhesive layer is much thicker than any other tape I’ve used previously. The tape seems to hold well when bonded to itself and smooth surfaces alike, even when the surface is not completely dry. It will make a great addition to any travel box or tool box.”

ProStaffer Andy Mickelson of Mickelson Plumbing and Heating, Missoula, Montana, was impressed with the strength and said, “T-Rex Brute Force tape has an incredible tear-resistant design, so much so that you’ll require a blade to cut it. The adhesive layer is much thicker than any other tape I’ve used previously. The tape seems to hold well when bonded to itself and smooth surfaces alike, even when the surface is not completely dry. It will make a great addition to any travel box or tool box.”

“We have found a number of uses for T-Rex Brute Force! Someone didn’t judge the width of the truck while backing up and managed to rip off a side mirror. The mirror was put back into place and held there with the tape until we were able to get it into the dealership,” said Shay Shepston of Reimagined Renovations, Champaign, Illinois.

Shay added, “It’s been used to hold a foam base cove to metal before installing a pool liner, to hold PVC pipes in place while we work, and many other odd jobs. It has been added to all our trucks and toolboxes!”

According to our ProStaff team, the only drawback—and one they all mentioned—was that you cannot tear it; it must be cut. Contractors are so accustomed to just tearing tape, it required remembering to have a utility knife handy to cut it.

ProStaff member John Thompson with Thompson Family Plumbing & Rooter, with shops in California and Arizona, put it to work with his team and shared, “T-Rex Brute Force tape was fantastic to have on our work trucks. On multiple occasions it was used to build confinement areas with plastic, plus a last-minute repair to hold the casing together on my jackhammer because I broke it during a project. You never know when you might need something of this strength to get out of a jam.”

ProStaff member John Thompson with Thompson Family Plumbing & Rooter, with shops in California and Arizona, put it to work with his team and shared, “T-Rex Brute Force tape was fantastic to have on our work trucks. On multiple occasions it was used to build confinement areas with plastic, plus a last-minute repair to hold the casing together on my jackhammer because I broke it during a project. You never know when you might need something of this strength to get out of a jam.”

He joked, “I have never seen anything this durable. It’s truly remarkable to see the strength this tape has. I wish I could say that I’m putting together a zombie bunker, because I would seriously use it. It’s ‘Ferocious!’”

In addition to needing a utility knife to cut the tape, our ProStaff team suggested they would like to see the tape in more solid and neon construction colors such as red, white, green and possibly even reflective, as well as different roll size options.

T-Rex® Brute Force® is sold in 25-yard rolls and is available at national mass and hardware retailers. For more information, visit www.trextape.com/contractors.

When it comes to jobsite efficiency, contractors know having the right tool for the specific application makes all the difference—and saving time means saving money. Now, a simple new product for the toolbox can help pros do both: T-Rex® Brute Force™, a ferociously strong, high-performance duct tape. Traditionally, ropes or chains have been the only Read more

When it comes to jobsite efficiency, contractors know having the right tool for the specific application makes all the difference—and saving time means saving money. Now, a simple new product for the toolbox can help pros do both: T-Rex® Brute Force™, a ferociously strong, high-performance duct tape.

When it comes to jobsite efficiency, contractors know having the right tool for the specific application makes all the difference—and saving time means saving money. Now, a simple new product for the toolbox can help pros do both: T-Rex® Brute Force™, a ferociously strong, high-performance duct tape.

Traditionally, ropes or chains have been the only option for contractors and installers when they encounter jobsite tasks that require intense strength and durability. Until now as one 36-inch loop of new T-Rex® Brute Force™ can hold more than 700 pounds of weight and offers superior adhesion, so you can quickly secure, fasten and hold loads that you wouldn’t dare attempt with other tapes.

The high-bond, double-thick adhesive allows the tape to stick to rougher, dirtier surfaces and offers a durable, waterproof backing suitable for all-weather performance. Brute Force™ represents the next generation of high-performance duct tapes with patent-pending Forge-Link™ Technology.

“The unmatched holding power and strength of T-Rex® Brute Force™ fundamentally changes what you can do with a duct tape. Where regular duct tape is the go-to for everyday fixes, Brute Force™ is truly an engineering solution,” says Stephen Wagner, product marketer, ShurTech Brands, LLC, the marketers of T-Rex® brand. “The unique technology of Brute Force™ forges the way for the next generation of high-performance tapes.”

T-Rex® Brute Force™ is sold in 25-yard rolls and is available at national mass and hardware retailers. For more information, visit https://www.trextape.com/contractors.

T-Rex® Brute Force™ is sold in 25-yard rolls and is available at national mass and hardware retailers. For more information, visit https://www.trextape.com/contractors.

The term “duct tape” is misleading in that it’s not just one kind of tape (and, ironically, the majority aren’t recommended for HVAC systems). The term generally applies to a classification of pressure-sensitive tapes constructed in three layers: polyethylene (plastic), scrim (mesh fabric) and rubberized adhesive. But the quality, thickness (measured in mils — 1 Read more

The term “duct tape” is misleading in that it’s not just one kind of tape (and, ironically, the majority aren’t recommended for HVAC systems). The term generally applies to a classification of pressure-sensitive tapes constructed in three layers: polyethylene (plastic), scrim (mesh fabric) and rubberized adhesive. But the quality, thickness (measured in mils — 1 mil = 1/1,000 in.), adhesion level and tensile strength vary widely, as do the specific recommended uses for each sub-category. Knowing which tapes to grab for which jobs will ensure your fix doesn’t fail and can save you time, money and a lot of space in your toolbox. Here’s a rundown.

The term “duct tape” is misleading in that it’s not just one kind of tape (and, ironically, the majority aren’t recommended for HVAC systems). The term generally applies to a classification of pressure-sensitive tapes constructed in three layers: polyethylene (plastic), scrim (mesh fabric) and rubberized adhesive. But the quality, thickness (measured in mils — 1 mil = 1/1,000 in.), adhesion level and tensile strength vary widely, as do the specific recommended uses for each sub-category. Knowing which tapes to grab for which jobs will ensure your fix doesn’t fail and can save you time, money and a lot of space in your toolbox. Here’s a rundown.

General Purpose Duct Tapes

Typical Thickness: 6-9 mils

This category covers a range of duct tapes, from the DIY junk-drawer tool for everyday household repairs to pro grade duct tapes that offer slightly thicker polyethylene, stronger adhesive qualities and, in some cases, waterproof backing. General purpose utility tapes have excellent bang for your buck and offer basic performance levels for jobs around the house (like sealing boxes, patching a grill cover or mending a plastic garden tool) or light duty pro applications in which an abundance of tape will be used and discarded in a short time (like hanging poly-sheeting or moisture barriers and bundling jobsite materials to be scrapped). Manufactured in a wide array of colors, they can also come in handy for labeling and color-coding. Because these tapes generally aren’t designed to stick to rough surfaces or withstand extreme fluctuations in temperatures, they’re best in lower-demand applications when you need a lot of tape at a value price. Bottom line: Handy for DIY home projects or light duty patching and bundling for pros on the job site.

Heavy Duty Duct Tapes

Typical Thickness: 10-17 mils

Unlike general purpose tapes, heavy duty duct tapes are formulated with superior adhesive, extra-thick polyethylene and an interwoven fabric scrim that has high tensile strength—but they’re still easy enough to tear by hand, which makes them ideal for fast repairs on the job. They can adhere to a variety of rough (and in some cases dirty) surfaces like brick, concrete, metal, wood and vinyl siding without the corners peeling up. Many offer UV resistance so that sunlight won’t impact their performance over time, and they can stand up to extreme temperature ranges and weather conditions. These are aggressive, highly versatile tapes for on-the-job tasks like attaching plastic sheeting to exterior surfaces, securing power cables and other tripping hazards on dirty floors or bundling construction materials. As a bonus, they can save the day in unexpected worksite mishaps — mending a broken tool handle, sealing a cracked wet/dry vacuum cleaner hose, or even patching a hole in your work boot or a torn truck seat. Bottom line: Every tradesperson should keep at least one roll of heavy duty duct tape in the toolbox — and multiple widths or colors won’t hurt.

Clear Repair Tapes

Typical Thickness: Approx. 7 mils

Clear repair tapes are not technically duct tapes in construction, but they offer similar performance and application, so it’s natural to compare them. Plus, they’re valuable tools for pros. Designed primarily for non-porous surfaces like glass, fiberglass or plastic, these tapes have long-lasting, airtight holding power, are waterproof and UV-resistant and, most importantly, allow the surface underneath to show through. That makes them ideal for repairing cracked cell phones screens, skylights, windows, mirrors and headlights. Bottom line: Your go-to tape for airtight, waterproof repairs on any surface that needs to be seen.

Structural Grade Duct Tapes

Typical Thickness: Approx. 17 mils

This is a relatively new category in tape technology. Super-aggressive adhesion and extremely high tensile strength make tapes like this less a tool for mending and patching and rather a quick engineering solution. Structural grade duct tapes are for projects that require intense strength, durability and holding power: think hoisting a heavy tool bucket up scaffolding, towing heavy construction materials short distances, or strapping and securing a heavy tool or appliance for transport. Currently, only one product exists in this category—T-Rex® Brute Force™. One loop of it can hold more than 700 pounds (yes, 700), making it the strongest duct tape on the market. It’s so strong you can’t tear it by hand. For some jobs, it’s even strong enough to take the place of rope or chain (and a roll of Brute Force is significantly lighter and more compact). Bottom line: Job requires a rope or chain? Consider a roll of Brute Force instead.

Steven Wagner is an eight-year veteran of ShurTech® Brands, Wagner currently serves as Category Manager for T-REX® and DIY Tapes. He has played an integral role in the development of the T-Rex® tape brand and has spearheaded advancements in new and innovative tape solutions for the contractor and residential markets. Wagner holds a bachelor’s degree from Capital University and a master’s degree from the University of Akron.

A broken bucket handle or cracked shop-vac aren’t just minor annoyances on the job site – they’re common frustrations that can lose you money in delays, unnecessary trips to the hardware story and expensive repairs or replacements. Instead of falling behind on your next project, consider keeping a professional grade duct tape on hand as Read more

A broken bucket handle or cracked shop-vac aren’t just minor annoyances on the job site – they’re common frustrations that can lose you money in delays, unnecessary trips to the hardware story and expensive repairs or replacements.

Instead of falling behind on your next project, consider keeping a professional grade duct tape on hand as your backup. It’s the tool you don’t realize you need until you need it. Here are seven tips for using different types of duct tapes for unexpected, on-the-fly repairs and improvised tools.

Instead of falling behind on your next project, consider keeping a professional grade duct tape on hand as your backup. It’s the tool you don’t realize you need until you need it. Here are seven tips for using different types of duct tapes for unexpected, on-the-fly repairs and improvised tools.

1) Create a makeshift chain

Rope and chain are handy tools for unforeseen jobsite tasks — but they’re also cumbersome and they take up a lot of space. Which means they’re often left behind at the shop when you need something for tasks like hoisting tool boxes and materials to a roof or platform. Enter heavy-duty duct tape. A product like T-Rex® Brute Force™, which can hold 700-plus pounds of weight with one 36” loop, can easily handle the job and be cut to the size you need.

2) Keep your socks dry

Torn boot uppers or holes in the sole are one of the most common annoyances you can experience. If you’re working in wet conditions, those annoyances can become hazards. Some rubberized pro-grade tapes are specifically designed with waterproof and extreme adhesive qualities, which makes them perfect for keeping sand, dirt, water, mud and other liquids out.

3) Repair or replace that broken bucket handle

Buckets always seem to break in the most inconvenient situations. Don’t let a busted handle force you to make a 20-minute work detour for a trip to the hardware store – tape it up, reinforce it, and get back to work with a high-strength tape.

4) Keep a hammer hammering

Tools aren’t indestructible, and when they break you can lose money in delayed work if you don’t have a backup on site. If a hammer handle snaps or the head comes off mid-job, wrap it with an extra-strength duct tape to get you through the rest of the day.

Tools aren’t indestructible, and when they break you can lose money in delayed work if you don’t have a backup on site. If a hammer handle snaps or the head comes off mid-job, wrap it with an extra-strength duct tape to get you through the rest of the day.

5) Keep the paint flowing

Paint sprayers are a real time saver — until you accidentally puncture the hose. Instead of reaching for a brush or roller to finish the job, try wrapping the hose with multiple layers of a high-adhesive duct tape to help keep it sealed until you can pick up a new one.

6) Patch your truck’s interior

Contractors often reach for duct tape to patch holes in truck seats. But standard duct tapes tend to curl in extreme temperatures, moisture and constant wear. Reach for a stronger alternative like the original T-Rex® Tape, which won’t curl or peel even in extreme temperatures.

7) Unspring a sprung leak

A cracked, torn or ill-fitting vacuum hose is a recipe for a mess. Use a waterproof tape to patch it up, reinforce the connection of the hose to the main vacuum chamber, or, combined with caulk, even patch a crack in the chamber itself.

A cracked, torn or ill-fitting vacuum hose is a recipe for a mess. Use a waterproof tape to patch it up, reinforce the connection of the hose to the main vacuum chamber, or, combined with caulk, even patch a crack in the chamber itself.

Instead of falling behind on your next project, reach into your toolkit for a professional grade tape. The repairs may not be permanent, but having a tape on hand as backup on the job site can help keep you on schedule and on budget.

We’ve all been there, so let us know some of the cool ways that you’ve used tape on the job.