A part of Emerson’s professional tools portfolio, RIDGID hosted winners at their headquarters with an all-expenses paid trip and signature VIP treatment RIDGID®, a part of Emerson’s professional tools portfolio, recently hosted their fifth annual RIDGID Experience trip, a VIP event that invites select members of the skilled trades to gather for fun, camaraderie and Read more

Emerson

A part of Emerson’s professional tools portfolio, RIDGID hosted winners at their headquarters with an all-expenses paid trip and signature VIP treatment

RIDGID®, a part of Emerson’s professional tools portfolio, recently hosted their fifth annual RIDGID Experience trip, a VIP event that invites select members of the skilled trades to gather for fun, camaraderie and hands-on experiences. The event also serves as a “thank you” to the trades for the role they play in building and maintaining our country’s infrastructure.

The contest, which draws entries from tradespeople across the country, concludes with RIDGID treating nine guests to a three-day, all-expenses-paid trip to RIDGID headquarters. The highlight of the visit is a factory tour that invites each guest to build their own iconic RIDGID customized pipe wrench. Guests also received a sneak peek at the latest RIDGID tool innovations and provided their opinions on product that is currently in development. Evening events included treating the guests to a preview of the company’s 100 Year Anniversary celebration plans, set for 2023. Guests also had the opportunity to network with guests of Greenlee® Experience, a similar contest hosted by professional tools brand Greenlee. The two concurrent events created a full-scale celebration of the electrical, mechanical and plumbing trades.

“The excitement around RIDGID Experience, both by trade professionals and the RIDGID team, has grown each year. After every contest our team is always impressed by the pride and commitment each guest has for their profession,” said Becky Brotherton, director of engagement marketing, RIDGID for Emerson. “It’s a privilege to be able to thank each of them for their dedication and hard work with this VIP experience.”

This year’s guests were equally enthusiastic about the trip, with one guest calling it the “bucket list” trip of a lifetime.

“My favorite part was meeting the people behind the brand because that’s what makes the brand,” said Armando Ramos, a service plumber in Phoenix, Arizona. “Now that I think of RIDGID I think of family. Thanks for the opportunity!”

“I can’t say enough about how amazing the past few days were. I’m so grateful to have had the opportunity to go to the RIDGID Experience 2022 and meet so many fantastic people, check out the headquarters and go on some pretty awesome outings. I’m over the moon and still just can’t believe that I got to do this,” said Mary-Anne Bowcott, owner of Westcom Plumbing and Gas in Sooke, British Columbia.

Individuals in the RIDGID Experience Group included (in photo L-R):

- Tyler Dale – Seaside, California

- Armando Ramos – Phoenix, Arizona

- John Snyder – Blue Bell, Pennsylvania

- Derek Newton – Kirland Lake, Ontario

- Colton Henkowski – Denver, Colorado

- Mary-Anne Bowcott – Sooke, British Columbia

- George DeJesus – Stanhope, New Jersey

- Alan Carlson – Wheaton, Illinois

- Christopher Armstrong – Ulster Park, New York

Details on the 2023 RIDGID Experience Contest will be announced early next year.

Emerson’s professional tools business, which includes RIDGID as well as the Greenlee® and Klauke® brands, provides the industry’s broadest portfolio of advanced, reliable tools and technologies for the mechanical, electrical and plumbing trades globally. Visit emerson.com/professionaltools for more information.

A part of Emerson’s professional tools portfolio, RIDGID employs 16 fathers and their children RIDGID®, a part of Emerson’s professional tools portfolio, celebrated Father’s Day by creating a tribute video recognizing how the work fathers do can inspire their children’s career choices. The inspiration behind the video came from RIDGID’s own workforce: currently sixteen RIDGID Read more

A part of Emerson’s professional tools portfolio, RIDGID employs 16 fathers and their children

RIDGID®, a part of Emerson’s professional tools portfolio, celebrated Father’s Day by creating a tribute video recognizing how the work fathers do can inspire their children’s career choices. The inspiration behind the video came from RIDGID’s own workforce: currently sixteen RIDGID employees are considered “legacies” – meaning they have dads that worked for the company’s manufacturing team before them. These “RIDGID Dads” and now their children build RIDGID tools in Elyria, OH, that are used by skilled trade professionals across the country, many by family-owned companies that also include fathers and their children.

“When we ask trade professionals how they got into the industry, learning from their fathers is a common response,” said Becky Brotherton, director of engagement marketing, RIDGID for Emerson. “Passing along their skills to the next generation is a legacy that lasts, not only in their children, but also in the infrastructure built and maintained through their challenging careers. Father’s Day seemed like the ideal time to celebrate the legacy that we see regularly on jobsites and in our manufacturing team.”

The video, shared last week on RIDGID social channels and viewed more than 2,000 times, features Russell and Josh Halstead, co-owners of Valu-Rooter® in Elyria, OH, and Jose and Bryan Gonzalez, RIDGID employees.

“I remember him having this determination and hard work to get the job done, but to do it right the first time,” said Josh Halstead, of his dad. “I started working in high school to make some money, but coming out of school I became more interested in this line of work. I wanted to be the best that I could be. I’ve always had the goal of being the best plumber. I want people to hear our name and think of quality.”

“The number of generations, including fathers and their children, working at our company is a unique aspect of our team,” said Danielle Hart, director of human resources, RIDGID for Emerson. “It’s a distinction that we’re proud of and one that we think contributes to a positive work environment.”

View the video on RIDGID social channels, including Instagram – @ridgidtools – and Facebook – @RIDGIDTools.

RIDGID has released Father’s Day videos the last several years, each a tribute to dads in the trades and the influence they have on their children. Previous videos can also be viewed on their YouTube channel.

RIDGID, a part of Emerson’s professional tools portfolio, invites attendees to stop by their booth as they celebrate more than 25 years as the leader in diagnostics at the show by offering attendees the chance to win a Limited Edition SeeSnake Camera Reel RIDGID®, a part of Emerson’s professional tools portfolio, announced their participation in Read more

RIDGID, a part of Emerson’s professional tools portfolio, invites attendees to stop by their booth as they celebrate more than 25 years as the leader in diagnostics at the show by offering attendees the chance to win a Limited Edition SeeSnake Camera Reel

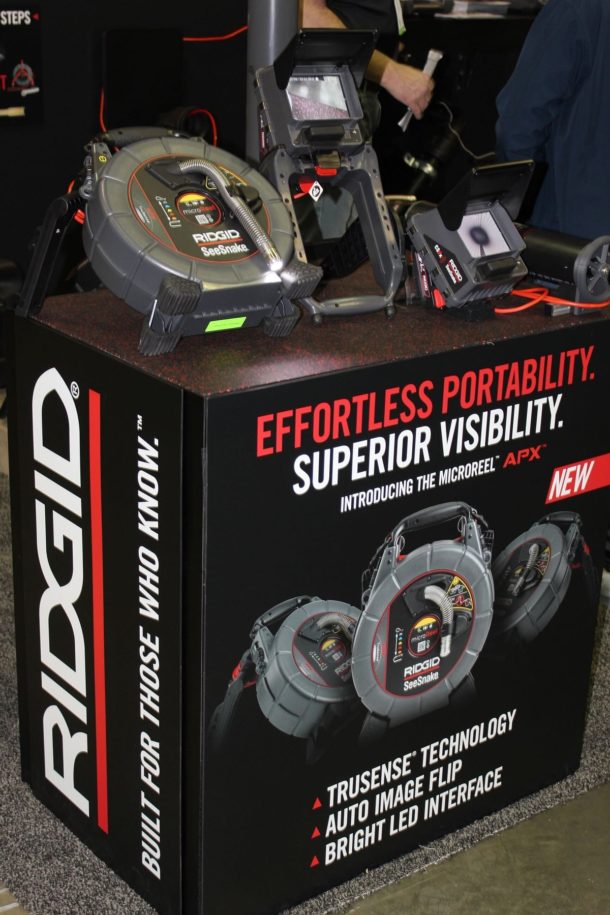

RIDGID®, a part of Emerson’s professional tools portfolio, announced their participation in the WWETT Show, Feb. 21 – 24, in Indianapolis. Their product team will be providing hands-on demos of their latest drain cleaning and inspection tools, including the new SeeSnake® microReel™ APX™ designed to optimize inspections.

Engineered with a lightweight, compact profile for easy portability, the microReel APX features bright LED lights and auto image flip, ensuring clear, upright images. Paired with TruSense® technology, this tool delivers the industry’s best in-pipe image and RIDGID invites tradespeople to stop by the RIDGID booth (#1141) to be one of the first to experience it. The product launch coincides with a milestone for the brand as they celebrate over 25 years in diagnostics.

“The RIDGID SeeSnake microReel APX continues to deliver on our promise to help plumbers find, see and pinpoint problem areas in-pipe. It is our latest camera reel to offer TruSense technology, so plumbers have the enhanced data capabilities they need to see and diagnose issues,” said Laura Wolverton, marketing director, underground technologies, RIDGID for Emerson. “WWETT will be a great opportunity for plumbers to test out this new tool’s durability and imaging and see the product firsthand.”

Additional RIDGID tools available for demo during WWETT include: FlexShaft® Drain Cleaning Machines, sectional machines, drum machines, jetters, SeeSnake camera systems, locators and pressing tools. Greenlee®, also a part of Emerson’s professional tools portfolio, will be joining RIDGID in-booth to showcase select tools, including Knockouts, GSB Series Step Bits, Carbide-Tipped Hole Cutters and the G1 Versi-Tugger™.

Along with product demos, the RIDGID brand has several other interactive booth experiences planned. Attendees can enter to win a SeeSnake 25th anniversary reel and a chance to win a FlexShaft Drain Cleaning Machine being given away each day during the show. The first day of the show will also kickoff entries for the brand’s popular RIDGID Experience, the annual, all-expenses-paid trip has continued to grow in popularity with tradespeople, and the RIDGID WWETT booth will be the first location for attendees to enter for their chance to win a spot.

RIDGID and Greenlee will also be taking their social followers virtually to WWETT. Follow along here: RIDGID – @ridgidtools on Instagram, @RIDGIDTools on Facebook, @RIDGIDToday on Twitter and Greenlee – @greenleetools on Instagram, @GreenleeTools on Facebook, @GreenleeTools on Twitter.

To learn more about RIDGID and Greenlee purpose-built tools, stop by their booth (#1141) during WWETT, contact your local distributor or visit RIDGID.com or Greenlee.com.

Authored by: Georges Mankarious, Product Marketing Manager for Emerson Automation Solutions Lead is a toxic metal that negatively affects the human brain and central nervous system and can result in high blood pressure and decreased kidney function. The effects can be even worse in children and infants and may include learning problems, hearing problems, anemia Read more

Authored by: Georges Mankarious, Product Marketing Manager for Emerson Automation Solutions

Lead is a toxic metal that negatively affects the human brain and central nervous system and can result in high blood pressure and decreased kidney function. The effects can be even worse in children and infants and may include learning problems, hearing problems, anemia, reduced IQ, and slowed growth.

People can be exposed to lead through a variety of means, including paint, dust, air, food and drinking water — or a combination of all of these. While a range of environmental regulations has removed it from many common substances, like gasoline and paint, the Environmental Protection Agency estimates that, depending on where people live, drinking water can account for 20% or more of a person’s total lead exposure. As of 2015, it is estimated that 18 million Americans are served by water systems that violate the EPA’s Lead and Copper Rule.

To address this challenge, new federal regulations were introduced in the past decade with the adoption of the U.S. federal Reduction of Lead in Drinking Water Act that amended Section 1417 of the Safe Drinking Water Act. It established that not more than a weighted average of 0.25% lead be present when used with respect to the wetted surfaces of pipes, pipe fittings, plumbing fittings and fixtures and not more than 0.2% lead content present in solder and flux.

Compliance is required only for new installations or older sites retrofitted with new equipment. Commercial and municipal water companies, as well as companies building and installing various kinds of water automation systems in commercial, institutional and residential facilities, need to consider the materials used to create the components that build the water transport and handling applications.

The challenge is making technology choices that help reduce the prevalence of lead-containing materials in these systems. This impacts not only the piping, but also valves for almost any kind of clean water applications.

THE LEAD-FREE CHALLENGE

Under the law, lead-free is a “cumulative” concept — some parts can be over the 0.25% number, and some can be under it. Specifiers and buyers can “add up” the lead content of all wetted components to get an average system percentage that comes in either at or under the 0.25% lead content requirement. This total wetted surface area calculation can provide a path to compliance, but it involves a series of complex calculations.

For OEMs or equipment builders who have direct access to suppliers, this calculation is possible if the surface area and lead content of all wetted surfaces can be obtained. However, in field installations, where full component information is not readily available to inspectors, they’re more likely to look at each individual component. In these instances, clear marking of lead-free compliance (i.e., an “LF” stamp or embossing mark) eliminates any questions of compliance with the new law.

MORE CONVENIENT, MORE PRACTICAL SOLUTIONS

Products with complex geometries can lead to tricky calculations in an attempt to meet the 0.25% or less lead content requirement. A simpler, safer lead-free solution is often more practical.

A range of lead-free solutions are now available to upgrade existing water systems or for use in new construction, including stainless steel, engineered composites and lead-free brass. Many of these products are being designed as drop-in replacements for traditional brass valves and offer numerous benefits.

Plastic composites

Some companies now offer engineered plastic products that meet the new, stricter regulations. OEMs who choose valves made of engineered plastics don’t need to be concerned about the wetted average surface calculations necessary with traditional brass valves.

Leading manufacturers are engineering a new generation of valves with composite or thermoplastic materials, fabricated using strict quality processes and improved designs, making them both cost-effective and reliable options for a range of applications.

Stainless-steel

Most stainless-steel valves are inherently lead-free and provide the durable, corrosion-resistant performance required in many water system applications. An extremely hard material, stainless steel is a more difficult metal to machine, particularly when fabricating valves and other fixtures with complex geometries — thus increasing cost. There may also be local building and plumbing codes that require stainless steel components in certain applications.

Lead-free brass

It’s important to note that many common, more traditional brass products contain lead along with small amounts of other materials. Lead helps soften the brass alloy, making it easier and less costly to machine. However, this means that common brass valves and other plumbing fixtures have lead content ranging from 1.5% to 2.5%. A system designer or specifier may assume they are reducing the lead content in the wetted path, but that reduction may not be as significant— and could be exposed during a field inspection.

Specially formulated “lead-free” brass alloys, with lead content smaller than the mandated limit of 0.25%, are now available and allow the creation of products like valves that were formerly too difficult to manufacture.

Choosing the right product can help meet safe drinking water requirements and reduce inspection delays — both with the EPA for water safety and UL/CSA for NEC compliance.

IT’S EASIER THAN EVER TO GET THE LEAD OUT

Investing in lead-free from the beginning instead of being “just good enough” is often the smartest — and fastest — solution. Using lead-free components can eliminate complex calculations and immediately reduce inspection delays.

A wider variety of product options meets varying needs, allows for more creative solutions, and helps make the lead-free transition easier while reducing design limitations. Look for fitting options like press fit or NPT end connections for increased versatility, improved efficiency, and reduced labor costs.

Both press fit and NPT have proven to be popular with contractors, and many lead-free options are now available with these connection options. For projects like upgrading or replacing legacy water systems where the labor to dig up and replace the infrastructure is expensive, companies can now choose lead-free valves and other components to help manage cost with less labor-intensive connections.

Products like lead-free brass valves provide a useful and cost-effective tool in the incremental process of providing lead-free water. When updating a system to “lead-free” status, or in the development of a new system, you can either calculate everything or simply use lead-free components.

RIDGID, part of Emerson’s professional tools portfolio, is committed to supporting trade education RIDGID, a part of Emerson’s professional tools portfolio, will award scholarships to four plumbing and HVACR apprentices as part of its partnership with the Plumbing-Heating-Cooling Contractors (PHCC) Educational Foundation and its apprentice contest. Each winner will receive a $1,000 education scholarship, plus Read more

RIDGID, part of Emerson’s professional tools portfolio, is committed to supporting trade education

RIDGID, a part of Emerson’s professional tools portfolio, will award scholarships to four plumbing and HVACR apprentices as part of its partnership with the Plumbing-Heating-Cooling Contractors (PHCC) Educational Foundation and its apprentice contest.

Each winner will receive a $1,000 education scholarship, plus $1,500 of tools from RIDGID and a special recognition at PHCC CONNECT 2021, Oct. 20-22, in Kansas City, Mo. Scholarship winners are selected by the PHCC Educational Foundation Scholarship Committee’s contractor members.

“RIDGID has had a long-standing commitment of supporting trade education and has been a proud sponsor of the PHCC Apprentice Contest for over a decade,” said Denis Hanna, director of sales and vocational training programs, RIDGID for Emerson. “The contest is a great opportunity for apprentices to showcase their skills and learn from others. We’re excited to see the impact each of this year’s RIDGID scholarship winners has on the industry in the coming years.”

2021 scholarship recipients include:

- Christopher Friendly of Anchorage, Alaska, is studying plumbing installation, service and repair at Alaska Vocational Technical Center.

- Paul Kwiecinski of Chicago, Ill., is studying HVACR installation, service and repair at HVAC Technical Institute Chicago.

Paul Kwiecinski

- Martin Gorman of Belmont, Mass., is studying plumbing installation, service and repair at New England Institute of Technology.

Martin Gorman

- Tyler Earle of Forestdale, Mass, is studying plumbing installation, service and repair at Upper Cape Tech Adult & Continuing Education.

Tyler Earle

To learn more about RIDGID, visit RIDGID.com.