Duct Systems Specifically: Why It’s a Different Ball GameFundamental Differences: What You Probably Already Know and What You Need to KnowCompatibility and Installation ConsiderationsConclusion: When to Use Which? The selection of duct system materials determines the success or failure of a project because it directly affects the structure. The general distinctions between polyvinyl chloride (PVC) Read more

fittings

Table of Contents

The selection of duct system materials determines the success or failure of a project because it directly affects the structure. The general distinctions between polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC) are familiar to most plumbers, yet ductwork applications require additional evaluation.

The performance of PVC and CPVC ducts under various conditions requires knowledge from plumbers who work with HVAC technicians or manage complete retrofit jobs to achieve safe, efficient, and code-compliant systems.

The article examines the essential technical distinctions between PVC and CPVC duct systems, focusing on aspects most relevant to field plumbers, including temperature resistance, chemical compatibility, ease of installation, and regulatory requirements.

Duct Systems Specifically: Why It’s a Different Ball Game

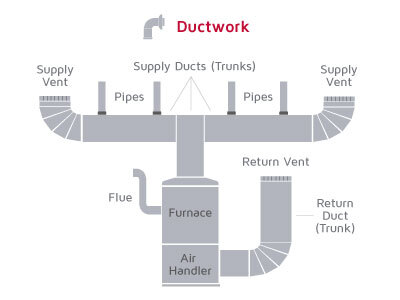

Ductwork isn’t just piping. The primary purpose of pipes is to transport water and waste, but ducts serve to distribute air and, occasionally, toxic fumes or hot exhaust. The design requirements for ductwork, including pressure and materials, differ significantly from those of standard plumbing applications.

According to Lennox, ductwork is “a system of channels used to distribute air throughout a building.” The work of plumbers requires them to handle components that need to be both lightweight and corrosion-resistant, particularly when working with exhaust in mechanical rooms and fume extraction in laboratories or industrial settings. Your responsibility will include duct connection and material maintenance throughout their entire operational period, even though you will not be responsible for constructing the whole HVAC system.

Fundamental Differences: What You Probably Already Know and What You Need to Know

Let’s get the basics out of the way. Most plumbers already know this, but here’s a refresher in the context of ductwork:

- Temperature Tolerance: PVC is rated up to 140°F, while CPVC can handle up to 200°F. If you’re dealing with warm exhaust or chemical fumes, that extra 60 degrees can be a dealbreaker.

- Chemical Resistance: Both are good, but CPVC outperforms PVC in terms of resistance to acids, bases, and corrosive gases.

- Strength & Sizing: Both come in standard duct sizes, but CPVC tends to be more rigid and stable under stress.

- Cost: CPVC is generally 25–40% more expensive than PVC. However, when a failure could result in system-wide contamination or code violations, it can pay off in the long run.

The process becomes difficult because plumbing and mechanical codes do not match. The International Residential Code (IRC) permits PVC ducts, but the Uniform Mechanical Code (UMC) bans their use in commercial buildings. CPVC passes both flame and chemical tests because of its superior ratings.

The legal status of building materials varies across different areas, so check local regulations at the city, county, and state levels. NSF 61, ASTM F441, and UL 94 V-0 ratings should be checked.

CPVC meets higher standards of fire and chemical safety, which makes it a safer choice for many duct applications. It also meets inspector requirements more effectively in high-risk or regulated environments, such as hospitals or laboratories, particularly when there is uncertainty.

Compatibility and Installation Considerations

Plumbers often overlook material compatibility checks, particularly when working with PVC or CPVC ducts that need to be connected to metals, or when using untested gaskets or sealants.

The connection of galvanized steel components to CPVC ducts through direct contact without an isolating gasket may lead to galvanic corrosion. The installation requires connectors and sealants, which are specifically designed for CPVC applications.

PVC cement does not function properly with CPVC materials. The solvent used for CPVC requires stronger properties and slower curing time.

Plumbers perform PVC cutting operations and gluing tasks. The installation process for CPVC follows the same steps as PVC but requires additional procedures:

- CPVC requires an extended curing period, which becomes more significant during cold weather conditions, thus affecting project schedules.

- The cutting process for both materials remains straightforward but CPVC requires more precise and cleaner cuts because it breaks easily.

- The use of fine-tooth blades, combined with support cuts, will prevent CPVC from cracking during the cutting process.

- Metal saw blades should be used with caution when working with plastics

In long duct runs, expansion and contraction can cause buckling or cracking.

- PVC expands about 3x more than CPVC over the same temperature rise.

- If you’re working in a facility with frequent temperature swings, CPVC offers better dimensional stability and less maintenance down the line.

CPVC generally earns higher marks for flame and smoke resistance. It typically meets UL 94 V-0 standards, which means it self-extinguishes quickly and produces less toxic smoke in a fire scenario.

This is especially important in:

- Healthcare facilities

- Schools

- Commercial kitchens

- Anywhere with life-safety code requirements

PVC, on the other hand, can produce thick black smoke and continues to burn once ignited.

While ductwork doesn’t usually carry fluid pressure, static pressure still matters—especially in exhaust or fume systems.

- PVC ductwork typically handles lower pressure (up to 10 inches of water column).

- CPVC ducts can manage slightly higher pressures, and with better rigidity, they resist collapse under vacuum.

For high-performance fume extraction or long vertical runs, CPVC has the edge.

Conclusion: When to Use Which?

Here’s the bottom line:

| Scenario | Recommended Material |

| Low-temp air movement | PVC duct |

| Chemical fume exhaust | CPVC duct |

| High-temp or steam ventilation | CPVC duct |

| Tight budget, low risk | PVC duct |

| Hospitals, labs, or code-heavy installations | CPCV duct |

| Jurisdictional uncertainty | CPVC duct |

Plumbers who perform HVAC installations or manage crossover systems should understand the distinction between PVC and CPVC ducts, as it represents essential knowledge for proper job execution. Knowledge of performance boundaries, installation characteristics, and regulatory standards for each material helps prevent both expensive callbacks and inspection failures, as well as system breakdowns in the future.

Your knowledge enables you to select appropriate ductwork with confidence while improving your collaboration with HVAC technicians and maintaining system integrity through all joints, runs, and transitions under both physical and actual pressure.

Author Bio: Mark Ligon is the marketing manager at Commercial Industrial Supply, a supplier of commercial & industrial piping, fittings, valves, filtration products, and accessories. Ligon enjoys educating businesses on the specific parts of piping systems so managers can make informed decisions.

Elkhart, Indiana-based NIBCO Inc. celebrated in style this week as esteemed guests were invited to dinner, drinks and dancing in what was a wedding reception-like ceremony that included a multi-piece band. The following day, invitees were treated the ribbon cutting of the new Rex Martin NIBCO Interactive Museum, and took the tour. The museum offers Read more

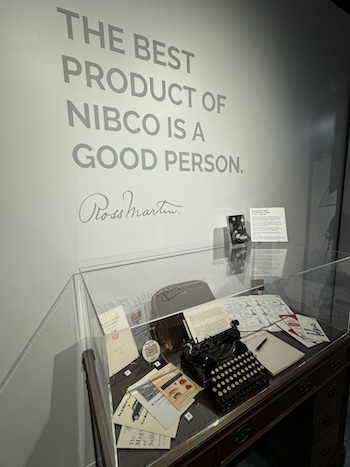

Elkhart, Indiana-based NIBCO Inc. celebrated in style this week as esteemed guests were invited to dinner, drinks and dancing in what was a wedding reception-like ceremony that included a multi-piece band. The following day, invitees were treated the ribbon cutting of the new Rex Martin NIBCO Interactive Museum, and took the tour.

The museum offers a unique and enriching experience from a historical perspective, interactive learning, inspiration, community impact, and career opportunities. Not just a place to learn about the past, it’s a place to get excited about the future of plumbing and the opportunities it holds.

“Our decision to build the NIBCO Interactive Museum and name it after my father is a tribute to his remarkable contributions to the plumbing industry and a continuation of a legacy that began with my great-great-grandfather in 1904,” said NIBCO’s President and CEO Ashley Martin. “This ambitious project was something I wanted to complete and dedicate on NIBCO’s 120th anniversary to make it extra special. The museum is not just about preserving our history; it’s about showcasing the profound impact we’ve had on the evolution of plumbing and our philanthropic efforts within the community.”

“Our decision to build the NIBCO Interactive Museum and name it after my father is a tribute to his remarkable contributions to the plumbing industry and a continuation of a legacy that began with my great-great-grandfather in 1904,” said NIBCO’s President and CEO Ashley Martin. “This ambitious project was something I wanted to complete and dedicate on NIBCO’s 120th anniversary to make it extra special. The museum is not just about preserving our history; it’s about showcasing the profound impact we’ve had on the evolution of plumbing and our philanthropic efforts within the community.”

Martin continued, “I want our NIBCO associated, our customers, local school kids to be able to come here and use this so it needed to be interactive. We also highlighted plumbing: where our products go, how they bring water to you, take waste away, but it also highlights our four manufacturing processes—plastics, copper, bronze and iron.”

Martin continued, “I want our NIBCO associated, our customers, local school kids to be able to come here and use this so it needed to be interactive. We also highlighted plumbing: where our products go, how they bring water to you, take waste away, but it also highlights our four manufacturing processes—plastics, copper, bronze and iron.”

The museum offers a unique and enriching experience from a historical perspective, interactive learning, inspiration, community impact, and career opportunities. Not just a place to learn about the past, it’s a place to get excited about the future of plumbing and the opportunities it holds.

Artifacts, representing various aspects of the history of plumbing, as well as the history of NIBCO, are exhibited throughout the museum, including:

- Early foundry tools

- Original crown jewels of NIBCO

- Original early fittings including the first fitting from 1927 and early valves

- Original product blueprints from the 1930s

- Items from Lee Martin’s collection

- Original printings of Ross Martin’s collection of booklets

- Philanthropic contributions

- Collectibles and promotions

The 8,845-square-foot building was completely renovated beginning in 2023. The museum portion of the space is 3,254 square feet, and additional space in the building will be used as a training area for customers, distributors, and NIBCO associates.

Provides Guidance on Selecting and Installing The Plastics Pipe Institute’s Building & Construction Division has published a major revision of PPI TN-55 “Plastic Piping Materials for Ground Source Geothermal Heating and Cooling Applications”. Originally issued in 2018, the latest edition of TN-55 was published in August 2024 with the input of industry experts including PPI Read more

Provides Guidance on Selecting and Installing

The Plastics Pipe Institute’s Building & Construction Division has published a major revision of PPI TN-55 “Plastic Piping Materials for Ground Source Geothermal Heating and Cooling Applications”. Originally issued in 2018, the latest edition of TN-55 was published in August 2024 with the input of industry experts including PPI members and the International Ground Source Heat Pump Association (IGSHPA).

According to Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division, “Because the piping material is critical to the overall success of the ground heat exchanger (GHX) in a geoexchange system, PPI TN-55 focuses on piping, fittings, and manifold materials. TN-55 lists the technical requirements for systems using HDPE, PEX, and PE-RT piping, plus requirements for PP pipes used as indoor piping, headers, and manifolds.”

A coil of PE4710 HDPE ground loop piping configured as a premanufactured U-bend assembly. Photo courtesy of Centennial Plastics.

The new technical note describes eight types of installation techniques, such as vertical boreholes, inclined or angled configurations, horizontal directional drilling (HDD), and energy piles, and discusses design topics, such as the effects of borehole depth on static water column pressure. It also addresses why oxygen diffusion barrier layers are typically not required for ground heat exchanger piping.

MacNevin continued, “The new TN-55 is intended to be a valuable resource on piping information, but this is just one of the latest tools available to specifiers and designers of geothermal heating and cooling systems. Details about pipe installation and pressure testing are found in PPI Model Specification MS-7, which published in 2023, and industry codes such as CSA/ANSI/IGSHPA C448 and the Uniform Mechanical Code.”

PPI is the non-profit North American trade association representing the plastic pipe industry, including several manufacturers of geothermal pipes, fittings, manifolds, and vaults. PPI formed its Geothermal Steering Committee in 2018 to develop industry publications, collaborate on codes, and create educational information about these systems.

A HDPE vault for connections of ground loop piping. Photo courtesy of PPI.

The revised PPI TN-55 is available directly from PPI at: www.plasticpipe.org/common/Uploaded files/Technical/TN-55.pdf

Additional information and data about ground source geothermal systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

Due to its hot summers and cool winters, planning your kitchen or bathroom renovation in Australia is key to making your home comfortable. Good plumbing is at the heart of this, affecting water use and how cosy your home feels all year round. To help you maintain your Australian home no matter the weather, here Read more

Due to its hot summers and cool winters, planning your kitchen or bathroom renovation in Australia is key to making your home comfortable. Good plumbing is at the heart of this, affecting water use and how cosy your home feels all year round.

To help you maintain your Australian home no matter the weather, here are some plumbing tips that will make your spaces practical and durable, saving you time and money in the long run.

Understand Your Plumbing Layout

Before making any renovations, you should understand your plumbing layout first. This means figuring out where all your pipes and fixtures are located. A handy tip is to look at your house plans for guidance. You could also seek assistance from a professional plumbing service near you.

For example, if you live in Perth or nearby areas, Alpha Sealed WA is just one of many other trusted repair specialists in Australia you can rely on. These professionals can easily map out your system, clarifying the best ways to proceed with upgrades or repairs.

Having the right knowledge ensures that your renovation efforts are both effective and efficient, avoiding unnecessary complications.

Budgeting for Plumbing

Plumbing improvements can be expensive. So, to prevent any financial surprises, it’s advisable to familiarise yourself with these expenses early in the planning process. Begin by itemising your project’s tasks, from simple fixture replacements to extensive pipe overhauls. Early on, solicit detailed quotes from several reputable plumbers to compare costs and services.

Anticipating unexpected expenses is also an essential part of effective budgeting. Therefore, reserve a portion of your budget for issues that may arise during the renovation process. This proactive approach helps mitigate stress and prevents project delays, ensuring you maintain control over your finances.

Additionally, investing in quality materials and skilled labour upfront can save money in the long term by reducing the need for frequent repairs or replacements. Remember, a well-budgeted project is a smoothly executed project, leading to lasting satisfaction and functionality in your home’s plumbing system.

Choosing the Right Materials

Investing in high-quality plumbing materials reduces maintenance and replacement costs over time. Look for durable, efficient options that can withstand Australia’s variable climate. Materials like stainless steel for pipes and fittings are known for their longevity and resistance to corrosion.

Stainless steel is an outstanding choice due to its durability and resistance to corrosion. Besides stainless steel, copper is also known for its long-lasting qualities. Meanwhile, PEX piping is considered for its flexibility and resistance to breaking under cold conditions.

These materials ensure your renovation project remains both reliable and aesthetically pleasing over time, avoiding the frequent updates that lesser quality materials might necessitate.

Incorporating Eco-Friendly Solutions

Choosing eco-friendly plumbing fixtures is a smart move, as these fixtures can help you save water and reduce your bills. For bathrooms, low-flow showerheads, dual-flush toilets, and water-saving faucets can significantly lower your water usage, benefiting your wallet and the environment.

Meanwhile, tap aerators and efficient dishwashers greatly affect kitchen water use. These choices benefit the planet and make your home more sustainable and cost-effective in the long run.

Avoiding Common Mistakes

Making mistakes during plumbing renovations is easy, but avoiding them can save you time and money. One common error is not getting the proper permits for major plumbing work, which can lead to issues with local regulations. Another mistake is overlooking the need for updated fixtures to match new plumbing layouts, leading to mismatches that can affect both function and design.

These oversights not only increase costs but can also delay your renovation project. Always double-check requirements and compatibility to ensure your renovation goes smoothly and doesn’t face unnecessary hurdles.

Professional Inspection

It is essential to have a professional inspect your plumbing before finishing the job. An inspector ensures everything is up to code, checking for leaks, proper installation, and overall functionality.

This step can catch potential problems early, preventing costly repairs down the line. For homeowners, this means peace of mind knowing their plumbing is safe, efficient, and correctly installed. It’s a protective measure that safeguards against future issues, ensuring the longevity and reliability of your renovation project.

Make Maintenance Easier

Some specific design choices can significantly reduce upkeep efforts, ensuring your bathroom and kitchen remain functional.

For example, you can install access panels for hidden utilities, such as plumbing valves or electrical boxes. So, when repairs are needed, you can easily reach what needs fixing without the hassle of cutting into walls.

Opting for fixtures with modular components also allows for straightforward part replacement. If a piece breaks, you can swap it out without dismantling the entire fixture, saving time and cost.

Additionally, compared to a prefabricated unit, a tiled shower base also offers simpler repair and cleaning opportunities, especially with a removable tile insert at the drain, avoiding extensive demolition for simple issues.

Lastly, you can opt for smart leak detectors, which provide an early warning system for water leaks. These devices prevent potential water damage and facilitate prompt repairs.

Planning for Upgrades

Design your plumbing with future upgrades in mind. Opt for modular components that can be easily adjusted or expanded. Anticipate advancements in technology and potential lifestyle changes. This could mean preparing spaces for smart home water systems or additional fixtures.

Such foresight adds value to your home, ensuring it remains adaptable and up-to-date. This also facilitates the integration of new technologies to accommodate evolving household needs.

Wrapping Up

The right plumbing choices allow homeowners to create spaces that are beautiful, efficient, sustainable, and ready to grow with them. Considering these essential tips, renovators can ensure their projects meet current needs and adapt to their lifestyles. Whether you’re a fan of DIY projects or planning to bring in professionals, these expert suggestions will help you have a successful renovation project that stands the test of time.

Allen Stanley has been promoted to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing. Elkhart, Ind. — NIBCO INC. has announced the promotion of Allen Stanley to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing. Both Stanley and Smith will report to Ashley Read more

Allen Stanley has been promoted to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing.

Elkhart, Ind. — NIBCO INC. has announced the promotion of Allen Stanley to vice president, fittings manufacturing and distribution, and Rudy Smith to vice president, valve manufacturing.

Both Stanley and Smith will report to Ashley Martin, president and COO, NIBCO.

Allen Stanley

“Allen and Rudy have long careers with NIBCO and the knowledge and expertise that they both bring to these roles will be valuable for the success of our organization,” said Martin. “Join me in congratulating them on their well-deserved promotions.”

In this new role, Stanley has responsibility for the Stuarts Draft, Virginia manufacturing operations and the Demand Planning department, along with his current responsibilities for the U.S. distribution centers, world headquarters logistics, and all plastic manufacturing facilities.

Stanley began his career in 1997 at NIBCO as administrative manager at the Atlanta Distribution Center. He held a variety of roles of increasing responsibility including operations manager at the Elkhart Distribution Center, manager, distribution and transportation, and most recently, director, plastic fittings manufacturing and distribution.

Stanley holds a bachelor’s degree in marketing from the University of West Georgia in Carrollton, Georgia. He also earned his master’s degree in marketing from Georgia State University in Atlanta, Georgia.

Rudy Smith

In his new role, Smith will have responsibility for NIBCO’s Blytheville, Arkansas, facility, along with the company’s Nacogdoches, Texas, McAllen, Texas, and Reynosa, Mexico facilities.

Smith began his career at NIBCO in 1996 in logistics at NIBCO’s world headquarters. Two years later, he was promoted and transferred as operations manager of NIBCO’s Nacogdoches facility. He held various roles from production superintendent, plant superintendent, plant manager, and most recently, senior plant manager at Reynosa, prior to his new role.

Rudy holds a bachelor’s degree in management from Rice University, in Houston, Texas.