Housing projects are complex enough, these stylish products can streamline the furnishing process Multifamily housing projects can get expensive but knowing what fixtures to use may reduce overhead costs and help contractors simplify the furnishing process in the kitchen and bath. From sleek modern fixtures with clean lines to timeless traditional styles that exude classic Read more

fixtures

Housing projects are complex enough, these stylish products can streamline the furnishing process

Multifamily housing projects can get expensive but knowing what fixtures to use may reduce overhead costs and help contractors simplify the furnishing process in the kitchen and bath. From sleek modern fixtures with clean lines to timeless traditional styles that exude classic charm, Peerless® Faucet provides contractors multifunctional options to complement any kitchen or bathroom renovation. The brand’s designs also feature quality materials, bold finishes, and user-friendly functionality, ensuring every fixture combines beauty and practicality.

Beautiful Designs for Every Style

Peerless fixtures are celebrated for their stylish aesthetics, which range from modern minimalism, contemporary, and even timeless traditional styles. Whether it’s a sleek chrome finish for a contemporary kitchen or a brushed nickel fixture for a cozy bathroom, the brand offers contractors a wide variety of options to complement any unit’s look and feel.

By focusing on clean lines and thoughtful design elements, Peerless creates faucets and fixtures that do more than just function — they elevate spaces, making them visually striking. This appeal is not only popular among contractors aiming to bring on-trend looks to their multifamily projects, but also renters who are looking to upgrade their fixtures without the hefty price tag.

This year, Peerless launched its new Ezra™ Kitchen and Bath Collections — with an array of unique finish options to choose from. In the kitchen, the Ezra Single-Handle Pull-down Kitchen Faucet offers striking lines paired with soft, sweeping curves. This faucet completes a traditionally modern aesthetic that pairs nicely with chestnut brown cabinetry and black/silver finishes alike. In fact, introducing the current mixed metals design trend into the kitchen is easy with Ezra. One can accessorize around the faucet with soap dispensers, cabinetry handles, lifestyle pieces or even other appliances — pairing the finish with a contrasting metal.

The EZRA™ Single-Handle Pull-down Kitchen Faucet (Matte Black)

Quality Materials Without the Big Spend

A successful commercial build starts with strong foundations, and to ensure projects provide long-lasting renovations, contractors should prioritize durable, high-quality materials are present across their kitchen and bath fixtures.

Peerless is renowned for its commitment to quality, crafting fixtures from durable materials (i.e. ceramics within most faucet disk valves) designed to withstand the demands of daily use. The brand’s faucets are built with long-lasting finishes that resist tarnishing and corrosion, ensuring they maintain aesthetic appeal for years. For contractors working on multifamily projects, Peerless offers ceramic valves across many fixtures, so no matter what collection contractors choose, they’re always guaranteed quality and durability.

Functional Affordability Without Compromise

One of Peerless standout qualities is its affordability. Renters on a budget and professionals managing large-scale renovations alike benefit from the brand’s cost-effective, yet functional offerings.

Beyond its stylish, on-trend designs, the brand also offers fixtures that are equipped with useful functionalities that contractors should be aware of. Peerless strives to ensure it provides additional value to the end user, by offering affordable, smart solutions in the kitchen and bath:

- POWERinse™: When money is tight, this technology is a great option to save contractors and renters additional spend on sink washing alternatives. More than a typical spray mode, Peerless’ POWERinse™ utilizes extremely narrow ports to create back pressure. That back pressure, in turn, results in a blast of water that easily powers away food residue.

- Push Pop-Up Drain Assembly: Included in a wide range of Peerless bath fixtures, this complimentary feature saves contractors both time and money while delivering on-trend details. Unlike other drain assemblies that require multiple parts (and purchases), this user-friendly accessory works seamlessly with the faucet itself and comes with all necessary parts for easy installation.

- MultiChoice® Universal Valve: This nifty valve gives contractors the freedom to decide on what type of shower valve function and trim style they want — without altering the plumbing behind walls. It also works with an array of shower trim styles. MultiChoice Universal Valve also pairs with shower trims across the Delta Faucet Company portfolio, making redesigning a breeze.

MultiChoice® Universal Valve

Peerless understands that no two customers are the same. Contractors value its dependability and efficiency, while homeowners love the brand’s ability to transform their kitchens and bathrooms affordably. In today’s world, where functionality and design must coexist seamlessly, Peerless stands out as a brand that delivers on all fronts. Whether you’re a seasoned contractor or learning the ropes, Peerless keeps trade pros happy by offering fixtures that are stylish, durable, easy to install and affordable, proving that elegance and affordability can indeed go hand in hand.

For more information about Peerless and its multifamily offerings, visit www.peerlessfaucet.com/faucet-professionals or follow Peerless on Instagram, Facebook, or Pinterest.

The latest stud finder design virtually eliminates false positives with multiple sensors and high-tech signal processing Plumbers are responsible for many tasks such as installing, repairing, and maintaining pipes, valves, fixtures, fittings, and drainage systems. To work safely and productively, plumbing contractors need as accurate a picture as possible of everything in the wall. Expediting Read more

The latest stud finder design virtually eliminates false positives with multiple sensors and high-tech signal processing

Plumbers are responsible for many tasks such as installing, repairing, and maintaining pipes, valves, fixtures, fittings, and drainage systems. To work safely and productively, plumbing contractors need as accurate a picture as possible of everything in the wall. Expediting plumbing work while minimizing costly mistakes, the stud finder is deemed an essential tool.

Plumbing contractors have long utilized stud finders with a design based on unrefined capacitive technology. While this technology can indicate the location of wood stud framing, it also discovers metal, plastic, wiring, and other objects in walls just as easily. Furthermore, constantly active, hypersensitive “deep scanning” models further increase the potential for “false positives” – objects mistakenly identified as studs. The result is that traditional stud finders frequently chirp or flash LED lights to indicate something was sensed, but it is not clear what that is.

Today, the challenge of quickly and accurately assessing what is within walls is only increasing. There is more behind the drywall than ever, including network cabling, plastic pipes, and tubing. Complicating matters, not all construction follows standard stud spacing practices of 16 inches or 24 inches on-center, and there are often additional support beams, fire blocks, and other framing features that can further muddy the picture.

In addition, piping may change directions to avoid studs, wiring, and other obstructions. Plumbing location also varies depending on the home’s style and layout.

Now, newer, and more refined technology is being introduced to the popular stud finder category, and it promises to redefine the standards for stud finder performance. The next generation “intelligent” models incorporate multiple sensors and sophisticated signal processing technology to alert the presence of false positives. Using a sophisticated, selectable deeper scan mode, the technology can also be used to quickly identify metal pipes and even plastic pipes or PEX tubing behind the walls when this is desired.

For professional plumbing contractors, this innovative technology will provide a more accurate representation of what is behind the drywall.

Increasing Plumbers’ Productivity and Profitability

For plumbers, maximizing their work efficiency and profitability involves knowing as clearly as possible what is inside a wall before cutting into it. They do not want to create damage. They want to reduce the risk of costly mistakes that need to be repaired.

To work safely and productively, plumbers typically rely on stud finders to accurately find the studs within a wall. This can be important to support long pipe runs and heavy fixtures. Plumbers also need to avoid wood studs, since most of the work involves remodeling rather than new construction.

Finding the voids between studs is necessary to quickly assess how much room there is within the wall space to reroute pipe or mount a new fixture. When remodeling a kitchen or bathroom, it can be particularly important to understand if the studs are plumb, or whether fire blocking runs horizontally.

To better address these needs, plumbers now can use advanced, second-generation stud finders like a new unit by Zircon Corporation that utilizes multiple sensors and sophisticated signal processing to filter out false positives.

Zircon, a wholly owned subsidiary of ZRCN Inc., has been in the stud finder game for more than 40 years. In 1980, the company manufactured the original StudSensor™ stud finder and invented the category. The Silicon Valley-based company produces more than just stud finders. They design and manufacture an extended range of sensor technologies in electronic hand tools including wall scanners, metal detectors, circuit breaker finders, drill guides, water detectors, and leveling tools.

The company’s latest innovation is the Wood Stud SuperScan® advanced stud finder with Target Control® Technology and FILTERz™ cancellation. By analyzing the complex data streams from multiple sensors and controlling the result using sophisticated intelligence, the stud finder can find wood studs and filter out metallic objects such as plumbing, conduit, straps, brackets, screws, protector plates, or ductwork in the wall.

DeepScan® mode locates the center of wood studs and metal up to 1½ inches (38 mm) deep within walls. A MetalliWarning® indicator will display when metal is detected.

Additionally, the technology can alert the user to the presence of other low density, non-metallic targets, like plastic pipe and PEX tubing. To prevent cutting into dangerous electrical wires, the device also provides WireWarning® Detection, which indicates the presence of live, unshielded AC electricity.

The stud finder has a new and improved user interface that provides an intuitive “go/no go” indication in response to what is being sensed. A new haptic vibration and a patented SpotLite® Pointer that shines an arrow-shaped beam on the wall.

For plumbers, the ability to quickly identify what is inside the wall before cutting into it will substantially increase their productivity and safety.

Given the opportunity to see a much clearer picture of what is in the wall, plumbers would do well to upgrade their existing stud finder with an affordable, next-generation model that is sure to become the new standard in scanning.

For more information, call Zircon Corporation at (408) 963-4550, e-mail: info@zircon.com, or visit www.zircon.com

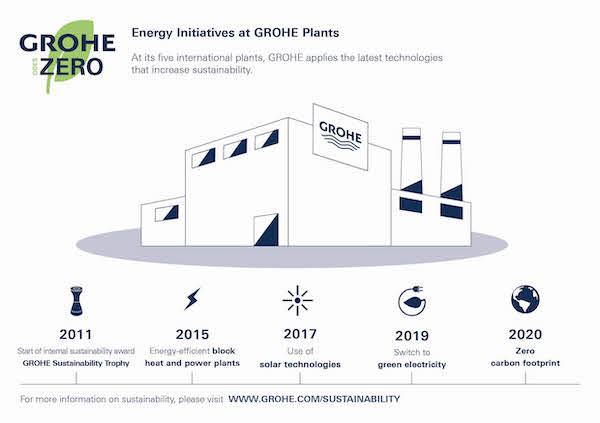

GROHE has been able to increase its energy efficiency by 24% and reduce greenhouse gas emissions by 40%, far exceeding its sustainability targets In July 2019, the global brand converted all of its production plants to run on green electricity In the future, GROHE will offset unavoidable CO2 emissions with compensation projects Piscataway, N.J. — Read more

- GROHE has been able to increase its energy efficiency by 24% and reduce greenhouse gas emissions by 40%, far exceeding its sustainability targets

- In July 2019, the global brand converted all of its production plants to run on green electricity

- In the future, GROHE will offset unavoidable CO2 emissions with compensation projects

Piscataway, N.J. — Sustainability has been an essential element of GROHE’s corporate strategy for almost 20 years now. As early as 2000, the global brand for complete bathroom solutions and kitchen fittings committed itself in its “principles and guidelines for sustainability” to continuously improving all products, processes and services in terms of protecting the environment and conserving resources. Since then, GROHE has set new industry standards, applying its 360-degree sustainability approach that incorporates employees, suppliers, customers, processes, products and the company’s social contribution alike. With the aim of becoming the first leading manufacturer of the sanitary industry to achieve carbon-neutral production by 2020, GROHE has once again stepped up its pledge. In July, as part of the “GROHE goes ZERO” initiative, all five production plants worldwide as well as the logistics centers in Germany were converted to run on green electricity. With the start of the new fiscal year in April 2020, the sanitary manufacturer will offset unavoidable CO2 emissions through two compensation projects.

“More than ever, manufacturers like GROHE are in demand to take on responsibility and strive towards more sustainability,” says Thomas Fuhr, CEO Grohe AG. “For years now, we have been investing not only in research and development in order to produce intelligent, sustainable solutions, but also to a large degree in a resource-saving value chain. With GROHE goes ZERO, we are now setting an example for the entire industry: We are actively addressing the CO2 challenge by increasingly avoiding emissions and, if this is not possible, compensating for them.”

The sustainability initiative is seamlessly linked to numerous measures that are taking place at the GROHE plants, promoting the long-term reduction of the carbon footprint and conserving resources: The brand has invested in block heat and power plants, was awarded the silver certificate by the German Sustainable Building Council for the plant extension in Klaeng, Thailand, and built a state-of-the-art test laboratory in Hemer, Germany. GROHE also uses advanced technologies that increase sustainability, such as the material-saving 3D metal-printing process which has been launched this year.

As a result, GROHE has been able to increase its energy efficiency by 24% and reduce its greenhouse gas emissions by around 40% since the introduction of its sustainability program in 2014. This means that the global brand has already far exceeded its 2021 targets of 20% respectively.

GROHE Supports Two Water Projects in India and Malawi

Supporting two offsetting projects is another logical step for GROHE to compensate for so far unavoidable CO2 emissions: In the north of India, the operation of a hydroelectric power plant replaces electricity that mainly comes from coal-fired power plants. In the African non-coastal state of Malawi, a project repairs and maintains boreholes that are used to produce drinking water. With the help of selected offset projects, GROHE will support activities based on extremely stringent criteria, such as the Gold Standard, developed under the aegis of the WWF. In addition to avoiding CO2, the measures also contribute to a more sustainable, ecological and social development within the projects’ environments.

“With GROHE goes ZERO, we are further expanding our leading position as one of the most sustainable brands in the sanitary industry,” says Thomas Fuhr. “But at the same time, we have by no means reached all of our sustainability goals; we can and must get even better.”

GROHE has received numerous awards for its commitment. Currently, the brand is one of three major companies that have been nominated for the German Sustainability Award. GROHE CEO Thomas Fuhr was recently awarded for his commitment to sustainability by the corporate network B.A.U.M., the German Environmental Management Association.

GROHE’s parent company, LIXIL, is committed to improving the quality of people’s lives by delivering safe and comfortable products and services through responsible, sustainable innovations. LIXIL focuses on three strategic sustainability pillars: Global Sanitation & Hygiene, Water Conservation & Environmental Sustainability, and Diversity & Inclusion. In addition to providing solutions to enable access to safe and hygienic sanitation practices, LIXIL’s efforts also aim to conserve water, energy and other natural resources utilized in its products and services, from procurement through production, distribution, end use and product disposal.

Woodridge, Ill. — Gerber has expanded its domestic assembly and light manufacturing facilities in Laredo, Texas. Gerber has had an operational presence in the U.S. since 1932 and specifically in Laredo since 2003. The Laredo team can now enjoy nearly 40 percent additional space to take on even more assembly and light manufacturing work. The operation Read more

Woodridge, Ill. — Gerber has expanded its domestic assembly and light manufacturing facilities in Laredo, Texas. Gerber has had an operational presence in the U.S. since 1932 and specifically in Laredo since 2003.

The Laredo team can now enjoy nearly 40 percent additional space to take on even more assembly and light manufacturing work. The operation focuses on assembling faucets, accessories and bath drains, in addition to light manufacturing jobs such as cutting and threading its brass tubing. All products leaving this facility are 100 percent tested on site to ensure the highest of quality, before heading to the warehouse and distribution center in Woodridge, Ill.

“Our team in Laredo is so loyal, dedicated and hard-working,” says Bob Walsh, vice president of global supply chain for the Gerber brand. “We knew we wanted to increase our U.S. operational footprint – and in particular stay in the Laredo area so we can keep this amazing team of people and grow from here.”

According to Walsh, the new facility will allow the team to handle even more product skus of brass assembly starting the first part of August. With the enhanced location, Gerber will be able to improve lead times and responsiveness – a benefit that has wide reaching impact across its distributors, plumbers and other professionals in the plumbing products category.

For more information on the Gerber brand or its products, visit www.gerberonline.com.