If you have experience installing gas appliances, you have installed a sediment trap. It’s an assembly that many plumbers have fabricated hundreds of times in the field, lauded for its simple design that protects expensive gas appliances like water heaters and boilers. It is even required by code in the United States and many other Read more

gas sediment trap

If you have experience installing gas appliances, you have installed a sediment trap. It’s an assembly that many plumbers have fabricated hundreds of times in the field, lauded for its simple design that protects expensive gas appliances like water heaters and boilers. It is even required by code in the United States and many other places across the world. So, why is it so important?

All gas appliances rely on a supply line to receive fuel from a building’s main utility source. This line, however, exposes the appliance to certain vulnerabilities. Debris such as dirt, metal, or other foreign matter can accumulate in this line during installations and repairs. If these loose particles enter the appliance, they can cause serious damage including malfunctions or even fires. Because of this, every gas appliance installation is required by code to ensure protection from sediment.

Plumbers have protected against gas sediment for years using the simple law of gravity and a clever assembly of fittings. With the understanding that debris will naturally settle at the lowest point in the piping line, a strategically placed tee with an elongated, capped branch is installed between the supply and the appliance to form a trap. The flow travels downstream from the gas supply, entering the tee through the top and continuing through the side branch at a 90° angle to the appliance. This sharp change in direction causes the loose particles to separate from the flow and drop into the capped nipple.

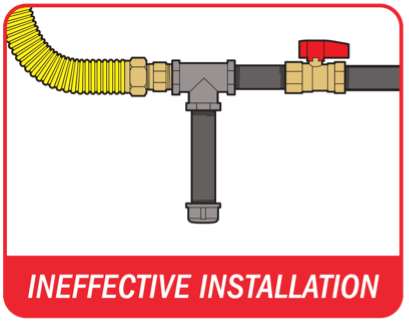

This trap assembly is widely accepted as the solution to guarding against gas sediment, but it has room for improvement. Assembling individual components not only takes time and introduces leak paths to the system, but it also aesthetically leaves much to be desired. Most importantly, the design is only functional if installed correctly, by a plumber who understands the significance of the 90° directional change. Unfortunately, it’s not uncommon to see sediment traps assembled with an improper tee orientation, resulting in ineffective horizontal flow path that allows particles to bypass the trap and enter the unit.

Enter the Gas Sediment Trap from Webstone®, a brand of NIBCO®. It’s the industry’s first integral trap solution – a forged brass tee with an elongated capped branch that meets the 3” length that’s required by code. Created as an all-in-one installation kit, it includes a CSA-certified full port gas ball valve, with the choice of an optional flex line. It’s available in ½” or ¾” connections, making it ideal for a wide array of applications including high BTU appliances.

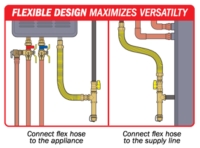

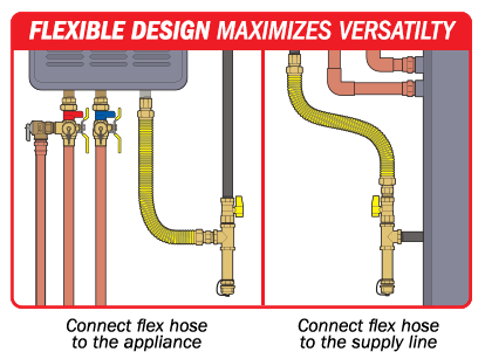

Choosing the Gas Sediment Trap has several advantages over field fabrication. Its attractive forged brass design results in cleaner, consistent quality professional installations that eliminate the possibility of an ineffective flow path. It saves time, replaces several components, and eliminates multiple leak paths. Kit models provide everything needed to complete the job, including a versatile flex hose that connects to the appliance or the supply line. For more information and other products that help you work smarter, visit webstonevalves.com.