Tips for taking care of your hoses If you’re a busy HVACR professional, the pieces of equipment that you use most are often hoses. From performing evacuations and refrigerant recharges to hooking them to a manifold for quick diagnostic checks, hoses are used every day. Let’s walk through some of the best ways to care Read more

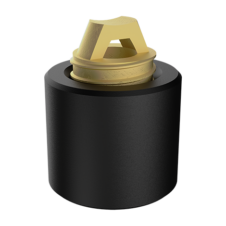

gaskets

Tips for taking care of your hoses

If you’re a busy HVACR professional, the pieces of equipment that you use most are often hoses. From performing evacuations and refrigerant recharges to hooking them to a manifold for quick diagnostic checks, hoses are used every day. Let’s walk through some of the best ways to care for and inspect your HVACR vacuum and charging hoses.

Replacing gaskets

Replacing gaskets

Replacing the small black gaskets in your hose connectors is one of the easiest and fastest ways to maintain your hoses. Normal wear and tear can cause the gaskets to deteriorate and create leaks or incomplete connections. When making connections, inspect the gasket. Also, add a drop of refrigerant oil or Nylog to the gasket. This creates a seal between the gasket and the port. Since they need to be changed frequently, store some new gaskets in your shop and teach your team how to spot wear and tear. It’s important to remind techs of the dangers of a worn gasket on the job site.

Cap your hoses

When you aren’t using hoses, cap them on each end with brass caps. This keeps the seals from drying out and ensures hoses stay clean and dry. With this, it helps to set aside hoses that are used for pulling vacuums and use them only for this task. Don’t use them for recovery or normal service. This ensures that your vacuum hoses are always in good condition.

Using hoses on the job site

Sometimes, HVACR connections aren’t in the most convenient locations, and this can cause unnecessary wear and tear on hoses. Be sure to avoid creating sharp bends or excessively twisting them when connecting hoses to the system. Remember, never leave them out in the sun or expose them to extreme temperatures for extended periods of time.

Store hoses correctly

When you’re moving or storing your hoses, be sure not to step on the fittings or store them under heavy equipment. Make sure to properly hang them in a way that prevents them from getting damaged. Since these hoses need to hold vacuums or maintain pressures between 800 and 4000 PSI, they can develop cracks or weak spots if they aren’t stored properly and safely.

Inspect them every time

When you use a hose on the job, inspect it for signs of wear that could include cracks, bulges or other degradation. Each of these threats has the potential to cause a dangerous situation that may lead to equipment damage or injure a tech. Any hose that shows these signs should be removed from the job site and discarded. When using a hose pay attention to reduced flow, blockages or leaks – some of these problems might not be apparent on first inspection.

Pick up some new hoses

If your hoses are worn out or need replacement, add some new ones to your tool bag right away. Learn more about Fieldpiece hoses and accessories here.