Provides Guidance on Selecting and Installing The Plastics Pipe Institute’s Building & Construction Division has published a major revision of PPI TN-55 “Plastic Piping Materials for Ground Source Geothermal Heating and Cooling Applications”. Originally issued in 2018, the latest edition of TN-55 was published in August 2024 with the input of industry experts including PPI Read more

HDPE

Provides Guidance on Selecting and Installing

The Plastics Pipe Institute’s Building & Construction Division has published a major revision of PPI TN-55 “Plastic Piping Materials for Ground Source Geothermal Heating and Cooling Applications”. Originally issued in 2018, the latest edition of TN-55 was published in August 2024 with the input of industry experts including PPI members and the International Ground Source Heat Pump Association (IGSHPA).

According to Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division, “Because the piping material is critical to the overall success of the ground heat exchanger (GHX) in a geoexchange system, PPI TN-55 focuses on piping, fittings, and manifold materials. TN-55 lists the technical requirements for systems using HDPE, PEX, and PE-RT piping, plus requirements for PP pipes used as indoor piping, headers, and manifolds.”

A coil of PE4710 HDPE ground loop piping configured as a premanufactured U-bend assembly. Photo courtesy of Centennial Plastics.

The new technical note describes eight types of installation techniques, such as vertical boreholes, inclined or angled configurations, horizontal directional drilling (HDD), and energy piles, and discusses design topics, such as the effects of borehole depth on static water column pressure. It also addresses why oxygen diffusion barrier layers are typically not required for ground heat exchanger piping.

MacNevin continued, “The new TN-55 is intended to be a valuable resource on piping information, but this is just one of the latest tools available to specifiers and designers of geothermal heating and cooling systems. Details about pipe installation and pressure testing are found in PPI Model Specification MS-7, which published in 2023, and industry codes such as CSA/ANSI/IGSHPA C448 and the Uniform Mechanical Code.”

PPI is the non-profit North American trade association representing the plastic pipe industry, including several manufacturers of geothermal pipes, fittings, manifolds, and vaults. PPI formed its Geothermal Steering Committee in 2018 to develop industry publications, collaborate on codes, and create educational information about these systems.

A HDPE vault for connections of ground loop piping. Photo courtesy of PPI.

The revised PPI TN-55 is available directly from PPI at: www.plasticpipe.org/common/Uploaded files/Technical/TN-55.pdf

Additional information and data about ground source geothermal systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

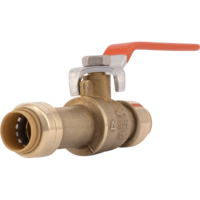

Whether completing repairs, a remodel or a new build, having the right pipe connections is paramount to completing a quality project. There are a lot of plumbing technologies available to pros, but not every option improves a project’s quality and efficiency like push-to-connect fittings. The leader of push-to-connect plumbing, SharkBite, wants to reiterate the importance of using Read more

Whether completing repairs, a remodel or a new build, having the right pipe connections is paramount to completing a quality project. There are a lot of plumbing technologies available to pros, but not every option improves a project’s quality and efficiency like push-to-connect fittings. The leader of push-to-connect plumbing, SharkBite, wants to reiterate the importance of using the best tools available, knowing quality products will help plumbers complete jobs fast and with confidence. In doing so, the Reliance Worldwide Corporation (RWC) brand is underscoring the reasons its fittings are always an asset on pros’ trucks:

- They’re compatible with PEX, copper, CPVC, HDPE and PE-RT, polybutylene and PVC pipes, allowing pros to transition from one pipe to another in any combination.

- Fittings don’t require tools, soldering or glue.

- They can be installed without having to wait for pipes to dry.

- Fittings can be buried once wrapped in self-adhering silicone tape.

- They can be installed behind the walls.

- They’re easy to install in tight spaces.

With these capabilities, push-to-connect fittings save time on the job site, improving versatility, efficiency and quality for pros. If you’d like more details to share with your audience, please reach out. I’d be happy to set up an interview, discuss a byline opportunity or provide further information.

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect Read more

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect slip and transition fittings.

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect slip and transition fittings.

“SharkBite gives you a wide range of slip fittings and valves to repair burst copper or CPVC pipes quickly,” said Michael Kornegay, SharkBite Product Manager. “Up to two inches of damaged pipe can be removed using a single fitting, even in wet lines, and a drain valve can be easily added to prevent future freezing.”

Ideal for working with multiple pipe types and in tight spaces, SharkBite’s Brass Push transition fittings can be installed in wet lines and can transition between pipe types, including PEX, copper, CPVC, PVC, polybutylene, HDPE and PE-RT pipes, making them one of the most versatile solutions.

“SharkBite’s push-to-connect transition fittings come with color-coordinated collars for each specific pipe material,” Kornegay continued. “The tool-free transition fittings allow for quick and easy repair of copper pinhole leaks and replacement of brittle polybutylene pipe or broken CPVC.”

Since pipes are at a higher risk of freezing and bursting in the winter, it pays to have a solution like SharkBite’s push-to-connect slip and transition fittings handy for a quick fix. Follow these steps to get the job done fast:

- Cut the pipe cleanly – Be sure the pipe is clean of scratches or debris. If working with copper pipe, use a deburr tool or sandpaper to remove any sharp edges or burrs.

- Measure and mark the insertion depth – Use SharkBite’s Deburr & Gauge Tool to mark the insertion depth on the damaged pipe.

- Make the connection – Push the fitting to the insertion marks. Then, turn on the water and check the connection.

When it comes to repairing a burst, frozen pipe, SharkBite push-to-connect slip and transition fittings save time. Pipe transitions make working with PEX, copper, CPVC, PVC, polybutylene, HDPE and PE-RT pipes hassle free, and SharkBite offers the flexibility of repairing the damaged pipe in wet lines under full flow.

“Just cut, push and done,” Kornegay said. “These SharkBite products allow you to quickly repair those frozen, burst pipes in a short amount of time, so you can finish a job with ease and move on to the next.”

Learn more about SharkBite’s repair options at SharkBite.com.