As fall turns to winter, it becomes more important to have a cozy home to retreat to on cold days. However, it may become challenging to preserve a respectable home within one’s budget, given the rising cost of power. Thankfully, there are many options available to reduce heating costs. Here we’ll go through five tried-and-true Read more

heating

As fall turns to winter, it becomes more important to have a cozy home to retreat to on cold days. However, it may become challenging to preserve a respectable home within one’s budget, given the rising cost of power. Thankfully, there are many options available to reduce heating costs. Here we’ll go through five tried-and-true methods for accomplishing this objective.

Invest in Proper Insulation

Investing in proper insulation is one of the best methods to save money on heating your home. Lack of proper insulation can cause heat to escape, increasing the workload of your heating system. The insulation in your home’s walls, ceiling, and floors should be checked first. Invest in better insulating materials if the current ones are inadequate or damaged. Additionally, ensure that all cracks and openings in windows and doors are sealed. The long-term savings on heating costs from this initial expenditure can be substantial.

Schedule Regular Maintenance

Keeping up with routine maintenance on your heating system is essential to keeping it running smoothly and efficiently. System efficiency decreases with neglect, which in turn increases energy consumption and costs. Get a professional to tune up your furnace to keep it in tip-top shape. They are able to check and clean parts, change filters, and find any problems. Preventing malfunctions and maximizing efficiency can save you a lot of money throughout the life of your system if you maintain it regularly.

Upgrade to Energy-Efficient Heating Systems

An upgrade could be in order if your current heating system is somewhat old. The energy costs associated with heating your home can be greatly reduced by installing a state-of-the-art heating system. You should think about upgrading to a modern, more energy-efficient heating system. Heat pumps and radiant heating are two alternative heating methods worth looking into because of their low energy use. Despite a greater purchase price, this option will prove to be cost-effective over time.

Implement a Programmable Thermostat

You may have greater precision over the temperature in your home by using a programmable thermostat. When you’re not there or asleep, you may set the thermostat to a cooler setting, and when you need it, you can turn it up. When the weather is mild, it’s unnecessary to have the heat on, therefore this helps save electricity. Smart thermostats can optimize energy use by learning your habits and adjusting themselves accordingly. By turning down the heat when it’s not needed, the savings from using a programmable thermostat can be substantial.

Practice Energy-Efficient Habits

A significant reduction in your heating costs may also result from simple lifestyle adjustments. Keeping doors and windows closed when the heat is on, using curtains or blinds to trap heat, and dressing in layers to be warm indoors are all easy ways to reduce your heating needs. Leave the oven door open after you’re done cooking to allow the leftover heat to warm the room. You can save a lot of money in the long run by making these minor adjustments.

Endnote

It is not only conceivable, but also practical, to reduce the cost of heating your home. You can keep your house toasty and warm without breaking the bank if you put money into good insulation, upgrade to energy-efficient heating systems, use a programmable thermostat, adopt energy-efficient practices, and schedule routine maintenance. Your heating costs will go down and your home will be more eco-friendly and sustainable as a result of taking these measures.

Leading plumbing provider offers tips to Brooklyn residents to help ensure their home’s water remains safe and clean Petri Plumbing, Heating, Cooling & Drain Cleaning, a family-owned home service company serving Brooklyn and Manhattan since 1906, says National Water Quality Month is a great time for homeowners to pay special attention to their water quality and Read more

Leading plumbing provider offers tips to Brooklyn residents to help ensure their home’s water remains safe and clean

Petri Plumbing, Heating, Cooling & Drain Cleaning, a family-owned home service company serving Brooklyn and Manhattan since 1906, says National Water Quality Month is a great time for homeowners to pay special attention to their water quality and take proactive steps to help improve it.

“Being able to take a clean shower or drink water from the tap without fear of contamination isn’t a luxury everyone gets to enjoy,” said Michael Petri, owner of Petri Plumbing, Heating, Cooling & Drain Cleaning. “Since August is National Water Quality Month, this is a great time for homeowners to focus on some simple tips to ensure their own water stays safe and clean.”

Petri said that communities can work together by following these tips to improve the water quality in their neighborhoods:

- Don’t dump chemicals down the drain. Whether homeowners are using liquid drain cleaners or other chemicals to clean their pool or rid their homes of pests, they should consider the proper way to dispose of chemicals. By opting for organic drain cleaners and taking items like motor oil, pool chemicals and harsh cleaners to collection centers, homeowners can keep shared municipal drains free of hazardous waste.

- Manage stormwater runoff. By diverting downspouts into yards, cisterns or other containment areas, homeowners can keep pesticides and bacteria from clogging up municipal storm drains.

- Properly maintain sewer lines and septic tanks. Homeowners should regularly service their sewer lines and septic tanks to ensure that pollutants and disease-causing bacteria don’t leach into the groundwater. Septic tanks should have regular cleanings and sewer lines should be maintained so that contaminants can be properly contained and treated. Try to avoid getting chemicals into storm drains.

- Don’t over irrigate lawns. Overwatering a lawn can cause runoff that contains fertilizers and pesticides that can seep into storm drains or an area’s groundwater. This tip provides the added bonus of conserving this natural resource.

- Consider a water filtration system. Because many cities have older pipes that experience failures, even the water that comes into a home may contain contaminants. Using bottled water as a substitute also adds a lot of plastic to local landfills. Homeowners can protect their water quality and the environment by adding a water filtration system to their home’s plumbing system.

“Water is one of our most precious natural resources and is vital to any community,” Petri said. “This August, we should all take some time to consider how we’re dumping contaminated water and work on ways to improve the water quality in our neighborhoods. Following a few simple steps can ensure we all have clean water for years to come.”

For more information about Petri Plumbing, Heating, Cooling & Drain Cleaning, visit https://www.petriplumbing.com/.

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource. As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover Read more

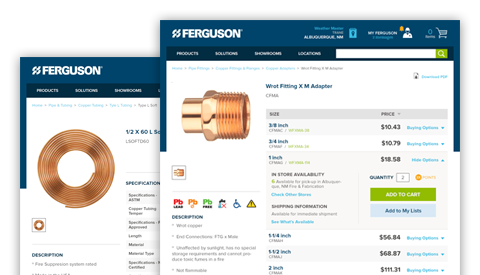

In today’s fast-paced world, leveraging the power of online resources is essential for the success of any plumbing contractor. Ferguson.com is that resource.

As a busy service contractor, time is of the essence. When I plan out my busy week schedule, resource efficiencies are at a premium, and that includes stocking my truck adequately. Moreover, running a successful plumbing business requires access to quality products, reliable suppliers, and expert advice. In today’s digital age, having a robust online platform can significantly streamline your operations and contribute to your business’s growth.

In today’s post-COVID world, especially dealing with disruptive supply chain issues, it almost goes without saying; you can never have too much inventory on the truck or back at the shop. That’s why I rely on Ferguson.com, a comprehensive website that has plumbing contractor-specific resources available, all of which are literally just a click away. And that click provides real-time stock and pricing of more than 200,000 HVAC and plumbing products; I can see what’s in stock and my contract pricing.

My plumbing business relies on my wholesaler to carry a vast range of top-quality products from leading brands, and I trust Ferguson to provide those trusted, reliable, and durable solutions. Whether I’m looking for pipes, fittings, valves, fixtures, boiler parts or specialty items, I look to Ferguson.com.

Some really helpful features include “My Lists.” I am able to customize the order process with just a few clicks, instead of individually searching for the products I purchase regularly and organizing lists of the products I want. This ultimately has saved me time and has helped to streamline my ordering process. Ferguson.com even gives me the ability to share those lists I’ve created and keeps products I purchase under the “Bought Often” tab, which is automatically updated monthly.

The Quick Tools feature is a shortcut that makes it easy for trade professionals to quickly access other popular site features. It gives me the quick ability to order, reorder, find an order, or turn existing quotes into orders, all in one place. In some cases, I can even order online and have the order ready in an hour with Pro Pick-Up 1 Hour (at locations where Pro Pick-Up 1 Hour is available).

While traditional brick-and-mortar purchasing is still a viable wholesale solution, with Ferguson.com, I can gain access to a seamless and convenient online ordering system. This allows me to browse through products, check availability, compare prices, and place orders anytime, from anywhere. By simplifying the procurement process, Ferguson.com saves valuable time and effort, enabling me to focus on serving my customers better.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Furthermore, as a plumbing contractor, staying up to date with the latest industry trends and techniques is crucial. Ferguson.com offers a wealth of resources and expert advice to help me stay ahead of the curve. From informative articles and how-to guides to videos and product demonstrations, the website serves as a knowledge hub for plumbing professionals. Leveraging this wealth of information can enhance one’s expertise, expand a skill set, and ultimately elevate one’s business.

Sometimes I need to know what was on an order or the last time I bought a certain product. I’m able to find all of that online and end any confusion about my orders. If I need to see the status of an order, I can see it on my Ferguson Dashboard or Orders, and even get the proof of delivery. (Proof of delivery may not be available depending on how the order shipped or if it was signed for.)

Forward Thinking

Ferguson understands the importance of competitive pricing for plumbing contractors. By signing up for a Ferguson.com account, one can unlock access to exclusive contractor pricing on a wide range of products. This ensures that I can offer my customers competitive rates while maintaining healthy profit margins for my business. The savings one can achieve through Ferguson.com can significantly impact your bottom line and give you a competitive edge in the market.

It’s pretty simple, really. Creating an account on Ferguson.com provides plumbing contractors with a range of powerful tools to manage their business efficiently. By logging in, one can track his or her order history, access invoices, and manage one’s account settings, all in one centralized location. This streamlined account management feature eliminates the need for tedious paperwork and enables one to stay organized and in control.

What’s also cool about the site is that I can enroll for the free PRO Plus™ program. After I enrolled in this program, I now earn one point for every dollar I spent online. I can then redeem those points for cool prizes and earn Bonus Points faster by purchasing featured products. PRO Plus™ customers are also eligible for discounts with select businesses.

Ferguson.com boasts an extensive inventory of plumbing products, tools, and supplies, as well as expert advice and efficient account management, making it a one-stop solution for all of my business needs. By utilizing the features and capabilities of Ferguson.com, I can streamline my operations, relieve operational stress, and propel my business toward greater success. Sign up today and unlock a world of opportunities for your plumbing contracting business with Ferguson.com.

The Brooklyn home service company offers homeowners advice to cut utility bills and keep their home safe while they are away Petri Plumbing, Heating, Cooling & Drain Cleaning, a family-owned home service company serving Brooklyn and Manhattan since 1906, says that homeowners can save some money and keep their energy costs down while they’re on vacation Read more

The Brooklyn home service company offers homeowners advice to cut utility bills and keep their home safe while they are away

Petri Plumbing, Heating, Cooling & Drain Cleaning, a family-owned home service company serving Brooklyn and Manhattan since 1906, says that homeowners can save some money and keep their energy costs down while they’re on vacation by following a few easy tips this summer.

Brooklyn’s Petri Plumbing, Heating, Cooling & Drain Cleaning offers homeowners advice to cut their utility bills while they are away on summer vacation.

“We remember the big things like hiring someone to watch the pets and getting a neighbor to take in the mail while we’re away on vacation,” said Michael Petri, owner of Petri Plumbing, Heating, Cooling & Drain Cleaning. “But we should also follow a regimen that will help us save some money and energy while we’re off taking a much-needed break. Just because your house is empty doesn’t mean your appliances aren’t running up your utility bill.”

Petri said these tips will help homeowners escape a big utility bill while on vacation:

- Adjust the thermostat. Unless the pets are staying home with a sitter, there is no reason to run the air conditioner to cool the home as often as when it’s inhabited. A programmable or smart thermostat can be adjusted to a vacation setting. These thermostats can also be used to bring the temperature back down on the day the homeowners are set to arrive so they can return to a cool house.

- Turn down the water heater. Some water heaters come with a “vacation mode” setting that allows homeowners to turn down the water heater while they are away. This can save money on heating water while the family is away.

- Close the blinds. Keeping the sun from shining into the home and warming it up can help keep the HVAC unit from turning on more frequently.

- Unplug electronic devices. Taking the time to unplug “energy vampires” like computers, televisions and coffee pots can help homeowners save on energy bills. Many appliances continue to use energy even when they are turned off so unplugging them while the family is on vacation also helps eliminate possible fire hazards.

- Turn off the lights. Make sure all the lights in the home are turned off before leaving for vacation. An even better option is to set up a few lights on a timer so some come on at night. This works as a deterrent to burglars but still saves homeowners money by not running lights during daylight hours.

“We all need a chance to get away from the routine of our regular lives,” Petri said. “And, while we’re away, we don’t need our appliances to continue the same routine as though we were home. Following these tips can help you save a bit of money while you’re gone and can even work to safeguard your home from fires or burglars.”

For more information about Petri Plumbing, Heating, Cooling & Drain Cleaning, visit https://www.petriplumbing.com/.

Falls Church, Va. — Proving the value of constructive collaboration, Plumbing-Heating-Cooling Contractors—National Association (PHCC) leaders and the association’s industry partners and major sponsors exchanged ideas and solutions for mutual benefit during PHCC’s Industry Summit in Dallas, Texas, last month. The Summit – a chance to make a meaningful impact on issues and opportunities facing plumbing and HVACR Read more

Falls Church, Va. — Proving the value of constructive collaboration, Plumbing-Heating-Cooling Contractors—National Association (PHCC) leaders and the association’s industry partners and major sponsors exchanged ideas and solutions for mutual benefit during PHCC’s Industry Summit in Dallas, Texas, last month. The Summit – a chance to make a meaningful impact on issues and opportunities facing plumbing and HVACR contractors and the industry – was hosted by Rheem Manufacturing, a PHCC Corporate Partner.

“I learned early on that constructive collaboration was essential for success,” PHCC—National President Dave Frame told attendees at the Summit. “By exchanging ideas, learning from each other, and establishing new relationships, we can further our mission of advancing the industry not only for our own organizations but also to protect public health, safety, and the environment.”

Indeed, the group of industry leaders spent the day exploring ways to better collaborate on crucial industry initiatives, namely regulatory issues, advocacy, workforce development, education and training, and sustainability.

Regulatory updates—particularly trends in decarbonization/electrification – were a key takeaway for Summit participants. PHCC—National Vice President of Regulatory Affairs Chuck White led a discussion on how PHCC and its industry partners can work together to ensure that contractors and their employees have the information they need to effectively advocate for reasonable regulatory mandates and prepare for upcoming changes. “The complexity of regulations impacting our industry amplifies the need for collaboration on advocacy efforts and to establish effective communication channels to keep industry professionals informed to ensure compliance,” he said.

During the Summit, attendees discussed how to set contractors up with financing options for customers interested in purchasing new HVAC equipment. Other topics addressed included how manufacturers can help develop information on heat pump water heaters (the benefits of new products, when to expect return on investment, etc.) for contractors to pass on to customers, as well as how they can improve hands-on training opportunities through PHCC state and local chapters.

In the area of workforce development, several PHCC partners and sponsors shared some transformative efforts, including supporting an apprentice program for at-risk female high school students, working directly with school guidance counselors to promote the trades, and more. “While workforce challenges are not new to this industry, it remains the number one concern for PHCC members,” said PHCC Vice President of Business Development Elicia Magruder. “PHCC and the PHCC Educational Foundation have numerous resources available to help our chapters and members promote careers in the trades, but we still need to do more to ensure a continuous pipeline of skilled workers.”

Of the event, Rheem Vice President of Residential AC Randy Roberts said, “Manufacturers can’t be successful unless we hear and respond to the challenges and needs of our customers. PHCC’s Industry Summit took that up a level, allowing us to engage with contractors, suppliers, and other manufacturers to focus on the current issues our customer base is experiencing and identify how we can all help each other to support and advance our industry.”

PHCC already is building on the energy and commitment exhibited during the Summit, moving to implement many of the solutions discussed as well as making arrangements for its next Industry Summit. “The ideas shared serve as a strong foundation for future collaboration among PHCC, the PHCC Educational Foundation, and our industry partners,” said Frame. “By working together, we can address industry challenges, foster growth, and ensure a prosperous future for the plumbing and HVACR industry.”