Duct Systems Specifically: Why It’s a Different Ball GameFundamental Differences: What You Probably Already Know and What You Need to KnowCompatibility and Installation ConsiderationsConclusion: When to Use Which? The selection of duct system materials determines the success or failure of a project because it directly affects the structure. The general distinctions between polyvinyl chloride (PVC) Read more

Mark Ligon

Table of Contents

The selection of duct system materials determines the success or failure of a project because it directly affects the structure. The general distinctions between polyvinyl chloride (PVC) and chlorinated polyvinyl chloride (CPVC) are familiar to most plumbers, yet ductwork applications require additional evaluation.

The performance of PVC and CPVC ducts under various conditions requires knowledge from plumbers who work with HVAC technicians or manage complete retrofit jobs to achieve safe, efficient, and code-compliant systems.

The article examines the essential technical distinctions between PVC and CPVC duct systems, focusing on aspects most relevant to field plumbers, including temperature resistance, chemical compatibility, ease of installation, and regulatory requirements.

Duct Systems Specifically: Why It’s a Different Ball Game

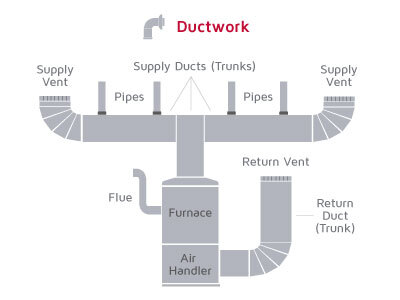

Ductwork isn’t just piping. The primary purpose of pipes is to transport water and waste, but ducts serve to distribute air and, occasionally, toxic fumes or hot exhaust. The design requirements for ductwork, including pressure and materials, differ significantly from those of standard plumbing applications.

According to Lennox, ductwork is “a system of channels used to distribute air throughout a building.” The work of plumbers requires them to handle components that need to be both lightweight and corrosion-resistant, particularly when working with exhaust in mechanical rooms and fume extraction in laboratories or industrial settings. Your responsibility will include duct connection and material maintenance throughout their entire operational period, even though you will not be responsible for constructing the whole HVAC system.

Fundamental Differences: What You Probably Already Know and What You Need to Know

Let’s get the basics out of the way. Most plumbers already know this, but here’s a refresher in the context of ductwork:

- Temperature Tolerance: PVC is rated up to 140°F, while CPVC can handle up to 200°F. If you’re dealing with warm exhaust or chemical fumes, that extra 60 degrees can be a dealbreaker.

- Chemical Resistance: Both are good, but CPVC outperforms PVC in terms of resistance to acids, bases, and corrosive gases.

- Strength & Sizing: Both come in standard duct sizes, but CPVC tends to be more rigid and stable under stress.

- Cost: CPVC is generally 25–40% more expensive than PVC. However, when a failure could result in system-wide contamination or code violations, it can pay off in the long run.

The process becomes difficult because plumbing and mechanical codes do not match. The International Residential Code (IRC) permits PVC ducts, but the Uniform Mechanical Code (UMC) bans their use in commercial buildings. CPVC passes both flame and chemical tests because of its superior ratings.

The legal status of building materials varies across different areas, so check local regulations at the city, county, and state levels. NSF 61, ASTM F441, and UL 94 V-0 ratings should be checked.

CPVC meets higher standards of fire and chemical safety, which makes it a safer choice for many duct applications. It also meets inspector requirements more effectively in high-risk or regulated environments, such as hospitals or laboratories, particularly when there is uncertainty.

Compatibility and Installation Considerations

Plumbers often overlook material compatibility checks, particularly when working with PVC or CPVC ducts that need to be connected to metals, or when using untested gaskets or sealants.

The connection of galvanized steel components to CPVC ducts through direct contact without an isolating gasket may lead to galvanic corrosion. The installation requires connectors and sealants, which are specifically designed for CPVC applications.

PVC cement does not function properly with CPVC materials. The solvent used for CPVC requires stronger properties and slower curing time.

Plumbers perform PVC cutting operations and gluing tasks. The installation process for CPVC follows the same steps as PVC but requires additional procedures:

- CPVC requires an extended curing period, which becomes more significant during cold weather conditions, thus affecting project schedules.

- The cutting process for both materials remains straightforward but CPVC requires more precise and cleaner cuts because it breaks easily.

- The use of fine-tooth blades, combined with support cuts, will prevent CPVC from cracking during the cutting process.

- Metal saw blades should be used with caution when working with plastics

In long duct runs, expansion and contraction can cause buckling or cracking.

- PVC expands about 3x more than CPVC over the same temperature rise.

- If you’re working in a facility with frequent temperature swings, CPVC offers better dimensional stability and less maintenance down the line.

CPVC generally earns higher marks for flame and smoke resistance. It typically meets UL 94 V-0 standards, which means it self-extinguishes quickly and produces less toxic smoke in a fire scenario.

This is especially important in:

- Healthcare facilities

- Schools

- Commercial kitchens

- Anywhere with life-safety code requirements

PVC, on the other hand, can produce thick black smoke and continues to burn once ignited.

While ductwork doesn’t usually carry fluid pressure, static pressure still matters—especially in exhaust or fume systems.

- PVC ductwork typically handles lower pressure (up to 10 inches of water column).

- CPVC ducts can manage slightly higher pressures, and with better rigidity, they resist collapse under vacuum.

For high-performance fume extraction or long vertical runs, CPVC has the edge.

Conclusion: When to Use Which?

Here’s the bottom line:

| Scenario | Recommended Material |

| Low-temp air movement | PVC duct |

| Chemical fume exhaust | CPVC duct |

| High-temp or steam ventilation | CPVC duct |

| Tight budget, low risk | PVC duct |

| Hospitals, labs, or code-heavy installations | CPCV duct |

| Jurisdictional uncertainty | CPVC duct |

Plumbers who perform HVAC installations or manage crossover systems should understand the distinction between PVC and CPVC ducts, as it represents essential knowledge for proper job execution. Knowledge of performance boundaries, installation characteristics, and regulatory standards for each material helps prevent both expensive callbacks and inspection failures, as well as system breakdowns in the future.

Your knowledge enables you to select appropriate ductwork with confidence while improving your collaboration with HVAC technicians and maintaining system integrity through all joints, runs, and transitions under both physical and actual pressure.

Author Bio: Mark Ligon is the marketing manager at Commercial Industrial Supply, a supplier of commercial & industrial piping, fittings, valves, filtration products, and accessories. Ligon enjoys educating businesses on the specific parts of piping systems so managers can make informed decisions.

Installing the right water filtration in industrial applications comes with a long list of benefits. A good filtration system helps lengthen the equipment life, cuts down the maintenance costs, creates a shield against hazardous chemicals, and lowers the effluent costs. It is how meticulously the water filtration process is planned and executed that makes or Read more

Installing the right water filtration in industrial applications comes with a long list of benefits. A good filtration system helps lengthen the equipment life, cuts down the maintenance costs, creates a shield against hazardous chemicals, and lowers the effluent costs.

It is how meticulously the water filtration process is planned and executed that makes or breaks the overall system. Anything could take a faulty turn when executing a filtration process. For instance, a wrong pump might cripple the filtration process, a seemingly harmless glitch during installation can cause irreversible filter damage, or an incorrect filter material can set the filter on a course towards pre-mature failure.

With a myriad of details and calculations involved, employing the right filtration solution for an application is no easy feat. However, becoming familiar with the most common (and frequently occurring) filtration mistakes can help ensure they’re avoided during the process.

This article discusses common pitfalls associated with selecting, installing, and using water filtration in industrial applications.

Getting the Sizing Wrong for Equipment and Filter Elements

As with everything, the planning stages are critical for installing and running a smooth filtration system. This is the stage that typically sees some of the costliest filtration mistakes – including the ones resulting from sizing issues

Faulty Filtration Equipment Sizing

When investing in filtration equipment, it’s paramount that the sizing aligns with what the application needs. The metric to consider when choosing the filter equipment is – the amount of liquid that the production would be running.

For instance, purchasing equipment that can push about 100 gallons a minute will not be of any use if a specific filtration step can only handle 10 gallons a minute. Not factoring in the flow rate during the process can negatively impact the production output.

Faulty Micron Rating

Filter specs can be customized as per the requirements of specific equipment. The customization options here typically include the core material, length, micron rating, diameter, filter media, and end cap configuration.

Among all the given options, micron rating is the trickiest to determine and has complete control over the filtration efficiency. If it’s too large, the contaminates can flow right through the filter. If it’s too small, the flow rate becomes obstructed.

A lot of research goes into finding the appropriate micron size. Most of it is associated with factors like the size and the consistency of the contaminants the equipment aims to filter.

Employing Incompatible Materials For Filter Elements

The core, the seals, and the filter media come together to form a fully-functional filter. For a filter to achieve an optimal outcome, each element needs to be compatible with the fluid’s temperature and chemistry.

The core can be seen as the backbone of a filter. When the core itself is incompatible with the fluid, it can give in to the water pressure and practically crush the filter. This unleashes the trapped contaminants into the downstream fluid.

The filter media is the shield that stands between the fluid and the contaminants. When the fluid temperature or chemicals react negatively with the media, it simply bloats and clogs – impeding the flow rate. The risk reaches its peak when the fluid chemicals are too aggressive for the media to handle, causing it to dissolve completely.

Sealing materials like an o-ring or a gasket practically guard the clean side of the filter from the contaminated side. When the seal itself is dysfunctional, the unfiltered fluid merges with the clean fluid resulting in a situation commonly known as “bypass”. When neglected long enough, these seals can either dissolve or erode – opening a passageway for the unclean fluids to flood in. A great approach to avoid filtration fiascos from filter elements would be to follow a chemical compatibility chart.

Performing A Flawed Installation

One of the common errors that can pop up during the installation process includes the reversal of the pipe housings (when the inlet and outlet housings get swapped).

Typically, filters can only handle fluid flow in a single direction (exceptions include filters that are made for backflushing). Unless the system requires liquid filter bags, the usual flow direction is always from the outside in.

Such an installation flaw can obstruct the flow rate and eventually knock down the filter. Most inlet and outlet pipes are labeled with the flow direction to help installation teams perform the task accurately. The filter equipment manual also comes with comprehensive instructions to maintain high accuracy during installation.

Selecting the Wrong Type of Pump

Pumps are what get the water flowing. In other words, they are the force behind driving the liquid through the filters. The outcome of a filter process depends on the type of pump employed in the system. It’s critical to ask the following questions when researching the right type of pump:

- What is the size of production runs?

- What is the viscosity of the liquid?

- What are the components within the process stream that may cause resistance to the flow rate?

- How far does the liquid travel?

Skipping the Air Venting Process

Once the filtration equipment is up and running, a critical step to remember would be to vent the air from the filter housings as the water seeps into them.

When ignored, the air trapped within the housing can form a bubble. This obstructs the liquid from filling up the housing completely. As a result, the overall flow rate declines.

Filter housings typically come with a built-in vent port or a vent valve that acts as the air’s escape route. To ensure the highest filter efficiency, the valve must be closed only when all the air leaves the housing.

Final Words

Even the smallest of “filtration glitches” can trigger irreversible damages down the line. As far as mistakes with water filtration are concerned, simply installing and running the process successfully is not the end of the task.

A filtration system demands regular maintenance to ensure the filter runs efficiently for a long time. A lack of maintenance can lead to clogged filters and loosened seals – degrading the quality of the final outcome.

Lastly, it’s critical to leave no doubt unaddressed when working with water filtration. In most cases, seeking the help of a professional is the best approach to getting everything “just right” and avoiding expensive losses down the line.

Author Bio: Mark Ligon is the marketing manager at Commercial Filtration Supply. He oversees the development of business strategies and marketing of filtration products, including bag filters, cartridge filters, and strainers. Ligon writes about various liquid filtration applications to educate process and facility managers on best practices, ensuring they properly understand and care for their filter systems.

Author Bio: Mark Ligon is the marketing manager at Commercial Filtration Supply. He oversees the development of business strategies and marketing of filtration products, including bag filters, cartridge filters, and strainers. Ligon writes about various liquid filtration applications to educate process and facility managers on best practices, ensuring they properly understand and care for their filter systems.