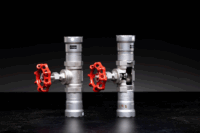

MegaPress® FKM and MegaPress® 316 Globe Valves The new MegaPress® globe valves offer exceptional performance, reliability, and durability for your commercial and industrial systems. This is the only press globe valve with Iron Pipe Size (IPS) ends. These valves feature adjustable PTFE stem seals and are available in sizes ½” to 2”. The globe valves Read more

MegaPress

MegaPress® FKM and MegaPress® 316 Globe Valves

The new MegaPress® globe valves offer exceptional performance, reliability, and durability for your commercial and industrial systems. This is the only press globe valve with Iron Pipe Size (IPS) ends. These valves feature adjustable PTFE stem seals and are available in sizes ½” to 2”. The globe valves are engineered for precise flow control, offering a rising stem and multi-turn design that allows for visual confirmation of the valve’s open or closed position.

These valves are an ideal solution for systems that require more precise modulation, unlike quarter-turn valves. The adjustable PTFE packing nut provides excellent corrosion resistance and makes maintenance and replacement easier, reducing downtime and labor costs. The MegaPress®316 Globe Valve is a perfect choice for systems that demand both reliability and ease of maintenance.

Learn more about the MegaPress® FKM and MegaPress® 316 Globe Valves.

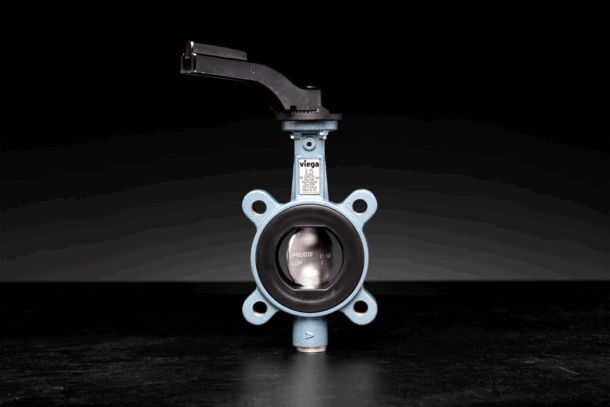

MegaPress®316 and ProPress® Butterfly Valve

Viega’s new ProPress® and MegaPress® butterfly valves provide a simple and reliable solution for flow isolation and control in commercial and industrial plumbing systems. These valves are available in sizes 2 ½” to 4” and are designed for compatibility with Viega ProPress® and MegaPress® flange adapters, ensuring a secure and efficient connection. They are available in 316 stainless steel and epoxy coated ductile iron materials.

These butterfly valves are ideal for a wide range of applications, providing flow isolation and helping to regulate pressure throughout the system. NSF 61 approval ensures that these valves can be used in potable water systems, making them versatile and suitable for a variety of plumbing projects

Learn more about the MegaPress®316 and ProPress® Butterfly Valves.

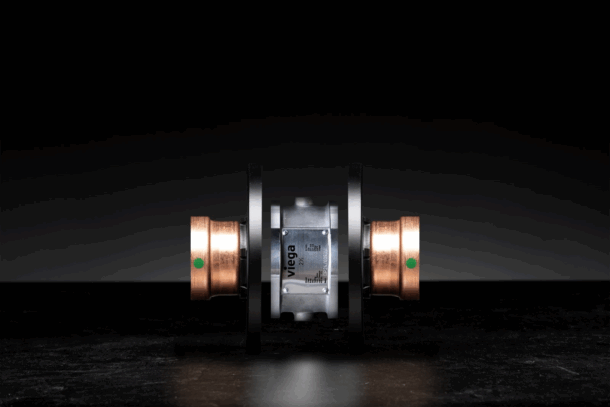

ProPress® and MegaPress® Wafer Check

Preventing reverse flow is a critical aspect of any piping system, and Viega’s new wafer check valves are designed to do just that. These valves feature a dual-disk design that promotes a streamlined flow path, reducing pressure drops and increasing energy efficiency. Available in sizes 2 ½” to 4”, these compact valves are optimized for use with Viega MegaPress® and ProPress® flanges. They are available in 316 stainless steel and epoxy coated ductile iron materials.

With over 2,500 approved applications, these wafer check valves are ideal for creating potable water systems, as model 2974.3XL and 5174XL carry NSF 61 approval. The durable and reliable construction of these valves ensures that your systems remain functional and energy-efficient, while also offering the flexibility to adapt to a wide variety of piping configurations.

Viega North America announces the latest additions to its product portfolio, adding globe, wafer check and butterfly valves to its MegaPress® and ProPress® portfolio. Viega press technology works across a wide range of materials, applications and configurations. These new products integrate seamlessly into Viega’s extensive product portfolio. Using Viega, customers can press everything from PEX Read more

Viega North America announces the latest additions to its product portfolio, adding globe, wafer check and butterfly valves to its MegaPress® and ProPress® portfolio.

Viega press technology works across a wide range of materials, applications and configurations. These new products integrate seamlessly into Viega’s extensive product portfolio. Using Viega, customers can press everything from PEX in residential systems to copper and carbon steel in commercial situations and stainless steel in industrial piping systems with one tool. Viega MegaPress, ProPress and PureFlow® systems are all approved for over 2,500 applications, ensuring a solution for nearly every plumbing need four inches and under.

“With Viega, customers have an entire ecosystem designed to work together seamlessly. Viega products help streamline the installation process, boosting both speed and productivity. Pressing these valves and fittings with one tool saves valuable time and labor costs, all while ensuring that plumbing systems are secure and reliable,” said John Browning, Director, Product Management.

The new products launched are:

- MegaPress 316 Globe Valves

- ProPress and MegaPress Butterfly Valves

- ProPress and MegaPress Wafer Check Valves

The MegaPress 316 Globe Valve is the first globe valve on the market with IPS press ends and features EPDM or FKM sealing elements. Available ½″ – 2″, this globe valve provides precise flow regulation where throttling fluids is essential. Model 5185.1 with the EPDM sealing element features NSF-61 approval for potable water systems. Looking to use this in more challenging environments? Model 5985.1 with FKM sealing elements, 316 stainless steel body and components provide excellent corrosion resistance, enhancing the valve’s durability.

The ProPress and MegaPress Butterfly Valves, available in sizes 2 ½-4″, complete your system with dependable Viega press technology. These butterfly valves provide reliable flow isolation and control and are NSF-61-rated. Model 2979.8ZL is crafted with a ductile iron body and durable epoxy coating, proving more cost-effective than carbon steel while offering higher pressure and temperature ratings than cast iron. Model 5179.8 features a 316 stainless steel body, providing superior corrosion resistance against even the harshest medium. Both versions are equipped with an EPDM seal. These butterfly valves are optimized for use with ProPress and MegaPress flange adapters.

The ProPress and MegaPress Wafer Check Valves are used to prevent reverse flow. Available in sizes 2 ½″ – 4″, these valves feature a dual-disk design to create a more streamlined flow path, reducing pressure drops and increasing energy efficiency. Models 2974.3XL and 5174XL include an NSF-61 rating, making them the ideal choice for installing potable water systems with ease. Model 5974XL has FKM sealing elements for more demanding applications. This compact wafer check valve is optimized for use with ProPress and MegaPress flange adapters.

To learn more about the full line of Viega ProPress, MegaPress and PureFlow valves, visit Viega | viega.us

RIDGID offers full line of standard and compact press tool options RIDGID®, the leader in pressing tool technology, is bringing game-changing innovation to the skilled trades with the RP 351, its first in-line standard press tool. Engineered from the ground up to deliver reliability and efficiency, this tool operates with an advanced brushless motor requiring Read more

RIDGID offers full line of standard and compact press tool options

RIDGID®, the leader in pressing tool technology, is bringing game-changing innovation to the skilled trades with the RP 351, its first in-line standard press tool. Engineered from the ground up to deliver reliability and efficiency, this tool operates with an advanced brushless motor requiring no scheduled maintenance.

The RP 351 with SlimGrip™ handle for enhanced balance and control weighs only about eight pounds with battery. It joins the RIDGID RP 350 Press Tool, a drill grip standard press tool introduced to help professionals get more done on every job with less fatigue and no timeouts. Together, the advanced, long-running press tools are built for the most demanding situations and give professionals maximum standard press tool versatility on the job site. Both tools are ideal for making connections on carbon steel, copper, PEX and stainless-steel pipe on residential, commercial and industrial jobs.

The RP 350 and RP 351 feature an advanced brushless motor, known for maximizing tool longevity, efficiency and durability. Their 360-degree swivel is an industry-first and comes paired with brightest-in-class LED lights to let users not only access tight spaces but see them more clearly in low and no-light applications. And no scheduled maintenance means less downtime.

Both tools are also compatible with the full line of RIDGID standard series jaws and rings, including: ½ – 4-inch ProPress® for copper and stainless steel, ½ – 2-inch PureFlow® for PEX, and ½ – 2-inch MegaPress® for carbon steel. They also offer maximum versatility, pairing with the RIDGID Press Booster for 2 ½ -inch, 3-inch, and 4-inch carbon steel, StrutSlayr™ Strut Shear Head and the Press Snap™ Soil Pipe Cutter. Each tool’s 18V battery platform includes chargers for on-the-go battery charging including a 12V car charger cord that is compatible with vehicles; the unit also pairs with the RIDGID Link app to track tool usage, service needs, battery life and last known location.

All RIDGID press tools come with the RIDGID Full Lifetime Warranty.

Viega LLC will reduce paper waste by 32 tons a year by eliminating printed instructions in favor of QR codes Beginning in October, the printed instructions inside the packages of most ProPress, MegaPress and PureFlow products made in the United States will be removed in favor of a QR code printed on the product label. A Read more

Viega LLC will reduce paper waste by 32 tons a year by eliminating printed instructions in favor of QR codes

Beginning in October, the printed instructions inside the packages of most ProPress, MegaPress and PureFlow products made in the United States will be removed in favor of a QR code printed on the product label. A scan of the code will send the user to the product instruction page on viega.us. It’s estimated that this will eliminate more than 6 million pieces of paper a year, paper which often wound up littering jobsites.

Having the instructions in digital format means any updates are immediately and automatically reflected, another benefit.

“Viega LLC is committed to reducing its environmental impact in ways big and small,” said Adam Botts, Portfolio Manager for piping systems. “This is an example of a simple measure that, in total, will save an enormous amount of paper without inconveniencing customers. This absolves them of having to recycle or dispose of the instruction sheets properly. We look forward to rolling out additional initiatives, both seen and unseen, that will have positive impacts on our company footprint.”

Earlier this year, Viega Holding GmbH & Co., parent company of Viega LLC, was named one of the 50 Sustainability & Climate Leaders by TBD Media Group.

Bigger, better truck delivers mobile tradeshow experience Viega LLC is bringing its tradeshow experience to customers across the country with a new and bigger demo truck. The new Viega Roadshow truck displays a complete line of Viega products, including the ProPress, MegaPress and PureFlow fittings, PureFlow tubing, as well as valves, radiant heating systems and Read more

Bigger, better truck delivers mobile tradeshow experience

Viega LLC is bringing its tradeshow experience to customers across the country with a new and bigger demo truck.

The new Viega Roadshow truck displays a complete line of Viega products, including the ProPress, MegaPress and PureFlow fittings, PureFlow tubing, as well as valves, radiant heating systems and marine fittings. The 30-foot vehicle has two slideouts, a folding stage to safely accommodate more visitors and an island for hands-on demonstration of Viega tools and products.

“Viega put a lot of time and thought into designing this vehicle,” said Jim DeBroeck, the project manager. “As a result, it virtually duplicates the tradeshow experience for customers without them having to travel. Rather, we bring it to them.”

“Viega put a lot of time and thought into designing this vehicle,” said Jim DeBroeck, the project manager. “As a result, it virtually duplicates the tradeshow experience for customers without them having to travel. Rather, we bring it to them.”

The new black-and-yellow truck replaces a smaller vehicle that was pulled off the road last year when the pandemic began. The customized V8-powered Ford F-650 has been on the road since August. It will continue to travel throughout the continental United States, visiting distributors, tradeshows, construction sites and plumbing associations.

The wall displays have been designed to not only highlight the products, but also educate visitors about how to use the products and how Viega can benefit their businesses.

“The truck delivers the ‘a-ha’ moment for customers. When they see the range of Viega products, pull the trigger on a press tool and learn about the efficiencies Viega delivers, they will have what they need to incorporate Viega systems into their work and begin realizing the benefits,” DeBroeck said.