Whether completing repairs, a remodel or a new build, having the right pipe connections is paramount to completing a quality project. There are a lot of plumbing technologies available to pros, but not every option improves a project’s quality and efficiency like push-to-connect fittings. The leader of push-to-connect plumbing, SharkBite, wants to reiterate the importance of using Read more

PE-RT

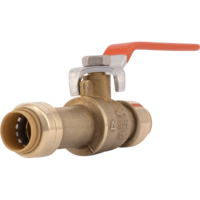

Whether completing repairs, a remodel or a new build, having the right pipe connections is paramount to completing a quality project. There are a lot of plumbing technologies available to pros, but not every option improves a project’s quality and efficiency like push-to-connect fittings. The leader of push-to-connect plumbing, SharkBite, wants to reiterate the importance of using the best tools available, knowing quality products will help plumbers complete jobs fast and with confidence. In doing so, the Reliance Worldwide Corporation (RWC) brand is underscoring the reasons its fittings are always an asset on pros’ trucks:

- They’re compatible with PEX, copper, CPVC, HDPE and PE-RT, polybutylene and PVC pipes, allowing pros to transition from one pipe to another in any combination.

- Fittings don’t require tools, soldering or glue.

- They can be installed without having to wait for pipes to dry.

- Fittings can be buried once wrapped in self-adhering silicone tape.

- They can be installed behind the walls.

- They’re easy to install in tight spaces.

With these capabilities, push-to-connect fittings save time on the job site, improving versatility, efficiency and quality for pros. If you’d like more details to share with your audience, please reach out. I’d be happy to set up an interview, discuss a byline opportunity or provide further information.

NIBCO’s Wrot Racer® C8 Corvette kicks off its tour at AHR Expo 2022 before visiting qualified distributors throughout the United States to celebrate the introduction of Wrot Racer push fittings. NIBCO INC. announces its Wrot Racer® “Start Me Up” promotion to celebrate its next generation of push fittings that it recently launched. The multi-faceted promotion centers on Read more

NIBCO’s Wrot Racer® C8 Corvette kicks off its tour at AHR Expo 2022 before visiting qualified distributors throughout the United States to celebrate the introduction of Wrot Racer push fittings.

NIBCO INC. announces its Wrot Racer® “Start Me Up” promotion to celebrate its next generation of push fittings that it recently launched. The multi-faceted promotion centers on the Wrot Racer C8 Corvette that will tour the U.S., making stops at distributor locations that have qualified.

The “Start Me Up” promotion provides a quick and easy way for distributors to take on immediate inventory of the new Wrot Racer copper push fittings. Distributors who meet the minimum stocking order requirement will receive a free marketing kit that includes POP merchandising.

NIBCO’s Wrot Racer Corvette began its tour at AHR Expo in Las Vegas on January 31, before moving to the West Coast, making various stops along the way, including Phoenix and Los Angeles. The “Start Me Up” promotion runs through 2022.

“We’re excited for our Wrot Racer Corvette to head out on the road to visit qualifying distributors across the U.S.,” said Ashley Martin, executive vice president, NIBCO INC. “This is a great opportunity for distributors to create additional coverage for their businesses and for everyone attending to have fun!”

Introduced in 2021, Wrot Racer push fittings are a line of premium copper push fittings that are engineered to join copper, CPVC-CTS, PEX and PE-RT (with stiffeners) for easy transition between piping systems. With a patented fitting design, installations are easily made within seconds.

Wrot Racer push fittings are made with 99.9 percent pure wrot copper. Naturally lead free, the fittings feature antimicrobial properties and are dezincification resistant, providing for safe, clean drinking water connections for both residential and commercial applications.

Available in 1/2″ to 1″ sizes, the lightweight and compact Wrot Racer fittings are able to be installed wet or dry and can handle applications up to 200 psi and 200 degrees. The new fittings feature stainless steel gripper rings to ensure a secure connection. Wrot Racer fittings are ideal for tight-space installations and can also be removed and reused, avoiding wasted materials.

To learn more about how NIBCO’s Wrot Racer Corvette can make an appearance, contact your local NIBCO sales representative, visit nibco.com/wrotracer/ or email Customerservice@nibco.com. Contractors should contact their local distributor to see if it is on the Wrot Racer tour list.

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect Read more

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect slip and transition fittings.

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect slip and transition fittings.

“SharkBite gives you a wide range of slip fittings and valves to repair burst copper or CPVC pipes quickly,” said Michael Kornegay, SharkBite Product Manager. “Up to two inches of damaged pipe can be removed using a single fitting, even in wet lines, and a drain valve can be easily added to prevent future freezing.”

Ideal for working with multiple pipe types and in tight spaces, SharkBite’s Brass Push transition fittings can be installed in wet lines and can transition between pipe types, including PEX, copper, CPVC, PVC, polybutylene, HDPE and PE-RT pipes, making them one of the most versatile solutions.

“SharkBite’s push-to-connect transition fittings come with color-coordinated collars for each specific pipe material,” Kornegay continued. “The tool-free transition fittings allow for quick and easy repair of copper pinhole leaks and replacement of brittle polybutylene pipe or broken CPVC.”

Since pipes are at a higher risk of freezing and bursting in the winter, it pays to have a solution like SharkBite’s push-to-connect slip and transition fittings handy for a quick fix. Follow these steps to get the job done fast:

- Cut the pipe cleanly – Be sure the pipe is clean of scratches or debris. If working with copper pipe, use a deburr tool or sandpaper to remove any sharp edges or burrs.

- Measure and mark the insertion depth – Use SharkBite’s Deburr & Gauge Tool to mark the insertion depth on the damaged pipe.

- Make the connection – Push the fitting to the insertion marks. Then, turn on the water and check the connection.

When it comes to repairing a burst, frozen pipe, SharkBite push-to-connect slip and transition fittings save time. Pipe transitions make working with PEX, copper, CPVC, PVC, polybutylene, HDPE and PE-RT pipes hassle free, and SharkBite offers the flexibility of repairing the damaged pipe in wet lines under full flow.

“Just cut, push and done,” Kornegay said. “These SharkBite products allow you to quickly repair those frozen, burst pipes in a short amount of time, so you can finish a job with ease and move on to the next.”

Learn more about SharkBite’s repair options at SharkBite.com.

The Plastics Pipe Institute, Inc. (PPI), has published a new recommendation related to the direct connection of plastic piping materials CPVC, PE-RT, PEX, and PP to tankless water heaters. Available on PPI’s website, PPI Recommendation H Direct Connection of Plastic Piping Materials to Tankless Water Heaters for Domestic (i.e. residential) Applications provides clear guidance on Read more

The Plastics Pipe Institute, Inc. (PPI), has published a new recommendation related to the direct connection of plastic piping materials CPVC, PE-RT, PEX, and PP to tankless water heaters.

Available on PPI’s website, PPI Recommendation H Direct Connection of Plastic Piping Materials to Tankless Water Heaters for Domestic (i.e. residential) Applications provides clear guidance on the question of direct connection of these piping materials to tankless water heaters. PPI is the major trade association representing the plastic pipe industry.

“PPI Recommendation H answers questions which plumbers and builders have been asking about whether it is appropriate for plastic pressure pipe materials to connect directly to the cold-water inlet and hot-water outlet of domestic tankless water heaters, without the use of metallic flex connectors. Based on our research, these direct connections are usually acceptable,” explained Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division.

“To help answer this question, PPI and our members researched Canadian and US model plumbing codes,” he continued, “reviewed the published literature on dozens of tankless water heaters, and confirmed the recommendations of plastic piping system manufacturers. Based on the proven high-temperature capabilities of these piping materials and the relatively consistent water temperature control of modern tankless water heaters, there is no technical reason to prohibit direct connections. Of course, installers must follow local code requirements and the manufacturer installation instructions.”

“As stated in Recommendation H: Piping systems using the materials CPVC, PE-RT, PEX, and PP, which carry a pressure rating of 100 psi at 180°F (690 kPa @ 82°C), and which are intended and certified for hot and cold potable water distribution systems according to industry standards and relevant codes, may be connected directly to tankless water heaters which are intended for domestic (i.e. residential) applications, unless prohibited by local plumbing code or the specific water heater manufacturer.”

According to PPI President David Fink, “The research on this topic was prompted by an inquiry from a major builders group. The rapid development of Recommendation H demonstrates the ability of PPI members to collaborate and respond quickly to industry questions about responsible usage of plastic piping materials.”

Published on PPI’s website directly at recommendation-h-direct-connection-tankless, Recommendation H is one of several PPI documents related to the design and installation of pressure pipe materials for plumbing and mechanical applications, which are all published as a service to the industry. Additional information about PPI’s Building & Construction Division can be found at plasticpipe.org/building-construction/index.html.