New PEX-B Pipe to Expand Piping System Product Line Jones Stephens, an industry leader in the manufacture and distribution of plumbing products, introduces PEX-B pipe, an addition that develops the company’s pipe system product line. Manufactured in cross-linked polyethylene, PEX-B pipe is durable, corrosive-resistant, and flexible, ensuring that the installation of PEX-B piping is simple Read more

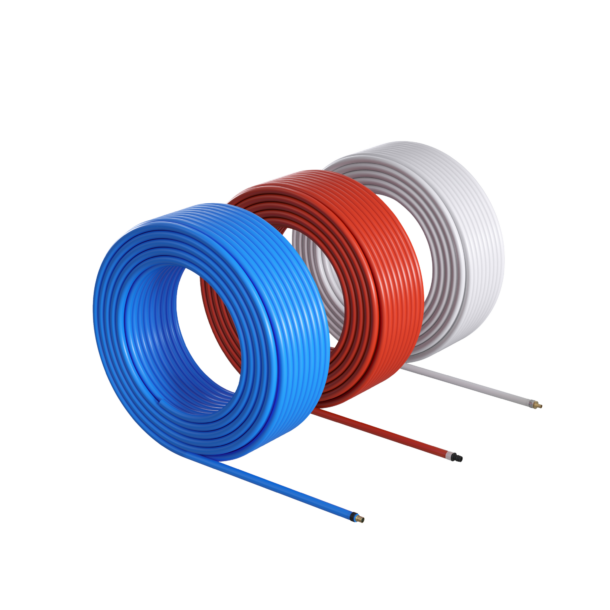

PEX-B pipe

New PEX-B Pipe to Expand Piping System Product Line

Jones Stephens, an industry leader in the manufacture and distribution of plumbing products, introduces PEX-B pipe, an addition that develops the company’s pipe system product line. Manufactured in cross-linked polyethylene, PEX-B pipe is durable, corrosive-resistant, and flexible, ensuring that the installation of PEX-B piping is simple and quick. Available for potable water applications, the PEX-B pipe is offered in red, white, and blue coils and sticks, up to 1” in size. Additionally, Jones Stephens offers a full range of F1807 brass and F2159 poly crimp fittings, up to 1” in size.

Jones Stephens PEX-B pipe meets all industry standards and compliance, including ASTM F876 and F877 and NSF/ANSI 14, 61, and 372.

Ideal for all new construction and repair jobs, Jones Stephens PEX Piping System is strategically sourced and manufactured. Including both PEX-A and PEX-B, Jones Stephens’ comprehensive PEX product line is proven and guaranteed, with a 25-year warranty. With a wide-ranging PEX product catalog, extensive inventory, fast shipping, and world-class customer service, Jones Stephens PEX products are by far the best choice to make for those wanting not only a superior PEX product, but also, a superior experience.

For more information, please visit https://www.jonesstephens.com/pex-2 .

Two directors discuss how switching from PEX-b pipe with crimp-style fittings to Uponor PEX-a pipe with ProPEX® expansion connections made a big impact on their business. Kimbel Mechanical Systems is one of the nation’s preeminent mechanical contractors, specializing in plumbing, HVAC, and electrical work in more than a dozen states on both sides of the Read more

Two directors discuss how switching from PEX-b pipe with crimp-style fittings to Uponor PEX-a pipe with ProPEX® expansion connections made a big impact on their business.

Kimbel Mechanical Systems is one of the nation’s preeminent mechanical contractors, specializing in plumbing, HVAC, and electrical work in more than a dozen states on both sides of the country — from Montana to Massachusetts. Headquartered in Fayetteville, Ark., Kimbel currently maintains 12 regional offices, including six in Arkansas, three in Colorado, and one each in Tennessee, Missouri, and Oklahoma.

The company was originally established as a one-person, new-residential plumbing shop in 1984 in northeast Ohio. A decade later, founder Miles Kimbel relocated and reconstituted his firm 900 miles southwest to pursue new opportunities in Arkansas. Fast-forward a few more years, and Miles’ son Rob Kimbel took over the reins, broadening the company’s reach to include mid- to large-scale multifamily projects, as well as single-family residential.

Residential plumbing with Uponor PEX-a and ProPEX fittings.

While the residential side of the business is still mainly involved in single-family work, the commercial side encompasses multifamily projects, hotels, schools, military housing, assisted-living facilities, and other types of large-scale structures. The company’s total number of employees exceeds 500, and they also rely on a large pool of subcontractors for their commercial work.

Several years ago, directors in both halves of Kimbel’s business found themselves struggling with “huge” and mounting warranty problems caused by damaging pipe leaks — damaging to the properties in which the product had been installed, as well as to the company’s professional reputation.

As a result, they decided to begin transitioning away from PEX-b pipe with crimp-style fittings and start using Uponor PEX-a pipe with ASTM F1960 ProPEX® expansion connections for their plumbing projects.

Hear Kimbel’s journey firsthand from Ryan Pinkerton, Director of Operations in Colorado and Tennessee, along with his colleague Mark Evans, Director of Pre-Construction – Commercial Housing, as they detail the factors that drove the company-wide shift, as well as the beneficial impact Uponor PEX-a and the ProPEX expansion method have subsequently had on both sides of their business.

Residential plumbing with Uponor PEX-a and ProPEX fittings.

Residential: Ryan Pinkerton, Director of Operations, Colorado and Tennessee

What is the primary piping product your company uses?

PEX is the known method among the single-family homebuilders we work with today. We might use Schedule 80 CPVC for pipe runs larger than two inches — mains and so forth. But, the majority of our single-family housing work is PEX.

How long have you been using PEX?

We began using PEX not long after I entered the plumbing trade 15 years ago. At that time, for our residential work, we were using PEX-b from another brand. However, we were having so many leaks with the crimp-style connections.

What were some of the issues you encountered with PEX-b crimp connections?

Over-calibrating was an issue. Because you can over-calibrate crimpers, it created a weak spot in the fitting that can crack under use. Also, if you position the crimp ring too far back, it can hold under the air test, but blow off when you turn on the water. The problems were huge, ongoing, and cost us hundreds of thousands of dollars in repairs.

Why did you switch to Uponor PEX-a pipe and the ProPEX® fitting system?

We needed to decrease our warranty costs to repair crimp connections as well as improve the relationships with the homebuilders we served. We also liked the increased water flow that the Uponor system provided. Crimp-style connections reduce the diameter of the PEX-b pipe and, as a result, lower the flow rate. That’s not the case with the ProPEX expansion-type fitting on PEX-a pipe. That has been a key, positive factor for us with the switch.

Commercial: Mark Evans, Director of Pre-Construction – Commercial Housing

Why did your commercial team choose to make the switch?

We use contract installers, and we had so many different people doing the work, it was hard to maintain quality with crimp. The Uponor ProPEX expansion method and the simplicity of the expansion tool for making PEX-a connections worked a lot better for us.

Were there issues with other piping products?

We had numerous leak issues with our larger water mains where we used CPVC at the time. CPVC joints are only as good as the installer who glues them. Once we learned Uponor offered PEX-a in larger diameters, that opportunity to reduce our water-main leak problems also helped drive the switch to Uponor.

Was it difficult for your workers to switch?

Uponor came to our job sites to train our crews on the ProPEX connection method. This training was quick and simple. Once we got everyone on board, the leaks went down drastically. Additionally, our contract plumbing installers are now faster and more productive with Uponor PEX-a. Although most of our contract installers work only for us, we still pay them for piecework. As a result, installation speed really matters for these independent contractors. They know that if you are not fast, you are not profitable. Thanks to the training they received, these contract installers are now familiar working with PEX-a. They have learned to install it quickly without mistakes.

To learn more about Uponor training opportunities for your team, visit uponor.com/training. To learn how Uponor can help bring greater productivity and performance to your residential or commercial projects, visit uponor.com.