By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Read more

PEX

By joining forces with Uponor, GF is set to become a global leader in sustainable water and flow solutions. To support this ambition, complementary businesses will be grouped together under one roof: the new division GF Uponor will focus on Building Technology, whereas the infrastructure and utility business will move to GF Piping Systems. Michael Rauterkus will join GF’s Executive Committee and will lead the new division together with his Uponor leadership team.

After all conditions of the tender offer have been fulfilled, GF closes the transaction as of 13 November 2023.

To accelerate the implementation of GF Piping Systems’ Strategy 2025 and to further benefit from global megatrends, GF will start an ambitious value creation program to unleash the full potential of this acquisition. GF Piping Systems will focus on the industrial and utility business, providing its customers with sustainable leak-free piping solutions for numerous end markets such as microelectronics, water treatment, energy, chemical processing, marine, data centers or water & gas utilities. Uponor’s infrastructure business will become part of GF Piping Systems and will further strengthen the division’s portfolio to provide customers with combined solutions.

In the new division, GF Uponor, the building technology businesses will be combined to offer a complementary portfolio for safe and clean water, as well as energy efficient heating and cooling. The consolidation of complementary businesses provides an ideal platform to develop markets with high potential for both divisions. As the brand Uponor stands for high quality and innovation, it will drive growth in intelligent Building Flow Solutions.

These organizational changes will be implemented during the course of 2024 while GF will ensure operational excellence and business continuity to customers.

“We will continue to implement our strategy, and leverage powerful global trends, such as the need for safe and clean water, or more efficient energy use,” GF CEO Andreas Müller said. “On behalf of all my colleagues, I am happy to welcome Uponor employees and start this new chapter together.”

New Technical Document and Details Proper Steps for Use A new technical document that addresses techniques for the safe and proper use of spray polyurethane foam insulation on and around plastic pressure pipe materials has been published by the Plastics Pipe Institute, Inc. (PPI) with input from the Spray Polyurethane Foam Alliance (SPFA). Prepared by Read more

New Technical Document and Details Proper Steps for Use

A new technical document that addresses techniques for the safe and proper use of spray polyurethane foam insulation on and around plastic pressure pipe materials has been published by the Plastics Pipe Institute, Inc. (PPI) with input from the Spray Polyurethane Foam Alliance (SPFA).

Prepared by PPI’s Building & Construction Division, PPI TN-69 Recommendations when Applying Spray Polyurethane Foam Insulation on and around Plastic Pressure Pipes & Fittings discusses the proper application of spray polyurethane foam insulation to avoid damage due to heat generated by the foam. Pipe and fitting materials include CPVC, PEX, PEX/AL/PEX, PE-RT, PP-R, PP-RCT, PSU, PPS, PPSU, and PVDF.

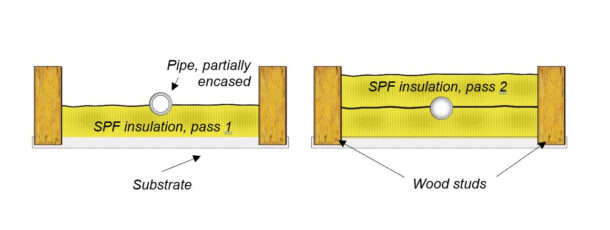

Figure 1: The first layer of SPF insulation is stopped when it reaches the pipe (left), just barely touching or encasing it. After sufficient cooling time, the second layer of SFP insulation is sprayed over the pipe to the required thickness (right).

PPI and SPFA recommend that when there are plastic pipes and fittings in a wall, ceiling, or floor cavity, the SPF installer should apply one layer of foam until it touches the pipe but does not encase the pipe. SPF installers should let the first layer of foam cure for a sufficient amount of time while heat is released from the foam and the pipe remains partially exposed before installing the second layer of foam. These procedures are described in detail within PPI TN-69.

Plastic pressure pipes and fittings are commonly used in applications such as hot- and cold-water plumbing, fire protection, and hydronic heating and cooling systems, including radiant distribution systems. In certain instances, pipes and fittings are installed inside areas that must be insulated, such as within a ceiling or wall cavity. In other installations, the pipes and fittings themselves must be insulated to reduce the transfer of heat through the pipe wall.

According to the SPFA, Spray Polyurethane Foam, or SPF, is a high-performance insulation material commonly used in homes and buildings of all types, and has been used as insulation for decades.

“The spray polyurethane foam curing reaction is exothermic,” explained Richard Duncan, Ph.D., P.E., executive director of SPFA, “which means that heat is generated during the foam reaction. The heat of reaction is highly dependent on the SPF formulation and is also based upon the overall intended application or lift (i.e., layer) thickness installed. Peak temperature within the layer of foam typically occurs within 5 to 15 minutes of application, followed by gradual cooling.”

According to SPFA documents, the chemical reaction that takes place during the application and curing of SPF will generate exothermic temperatures above the 120°F – 130°F setpoint temperatures of the proportioner and hoses. Peak temperatures at the mid-thickness of a pass can exceed 200°F for several minutes and reach peak temperatures 250°F – 275°F for a minute or two, especially for closed-cell SPF, when applied at the maximum pass thickness.

“Plastic pipes and fittings in both residential and commercial plumbing, residential fire protection, and most hydronic applications are typically required to have pressure ratings at 180°F (82°C) operating temperature,” explained Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division.

MacNevin continued, “The plastic pipes and fittings referenced in PPI TN-69 will withstand short-term exposure to temperatures above 180°F. However, exposure to temperatures above the rated operating temperature of each material, which may occur if pipes are encased in a thick pass of closed-cell SPF, are likely to have negative effects on these materials, potentially leading to premature failure. It is important that SPF insulation is installed correctly to prevent overheating of pipes and fittings.”

Access the full content of PPI TN-69 at https://plasticpipe.org/common/Uploaded%20files/Technical/TN-69/PPI%20TN-69.pdf or by scanning:

Additional information and data about pressure pipe materials used for plumbing and mechanical systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

Additional information and data about pressure pipe materials used for plumbing and mechanical systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

Uponor TotalFit™ is the professional-grade, engineered polymer (EP), push-to-connect fitting system that provides greater value for residential projects with the same versatility and speed as brass push-to-connect fittings. Designed for use with copper, CPVC, PE-RT, and PEX piping systems, TotalFit is ideal for service repair, maintenance, remodels, and retrofits for hot and cold potable-water piping Read more

Uponor TotalFit™ is the professional-grade, engineered polymer (EP), push-to-connect fitting system that provides greater value for residential projects with the same versatility and speed as brass push-to-connect fittings.

Designed for use with copper, CPVC, PE-RT, and PEX piping systems, TotalFit is ideal for service repair, maintenance, remodels, and retrofits for hot and cold potable-water piping systems in single-family homes, townhomes, apartments, condominiums, dormitories, and more.

With an innovative design for a strong, long-lasting, trusted connection, a 25-year product warranty, and durable EP materials that offer an average of 30% savings over brass push-to-connect fittings, TotalFit is fit for a pro.

The complete offering includes 33 of the highest-volume push-to-connect fittings in sizes from ½” to 1″ to meet the greatest market need. TotalFit also meets or exceeds all performance requirements for ASTM F877 and ASSE 1061 and is approved by the IPC and UPC for direct burial in soil or concrete (with 4 to 6 mil poly wrap) as well as behind walls without access panels.

Within the plumbing industry, there are so many different products and materials that are critical to carrying out the tasks needed. They say a shoddy workman blames their tools but, in fact, the better the tools, the better the work they can carry out. So how can plumbers check that their equipment is of a Read more

Within the plumbing industry, there are so many different products and materials that are critical to carrying out the tasks needed. They say a shoddy workman blames their tools but, in fact, the better the tools, the better the work they can carry out. So how can plumbers check that their equipment is of a high quality and how can they maintain it?

Examine Build Quality

One of the best approaches is very simply to inspect the build quality of the equipment. While many organizations will have very strict welding and manufacturing capabilities you should inspect the build quality to ensure there is attention to detail and solid construction. Any equipment that’s poorly built is more likely to wear out.

Any beginner plumber needs to remember that the more you invest at the outset in terms of quality equipment, the better the results will be. Plumbing tools are subjected to tough conditions, so they must withstand wear and tear. Equipment made from materials that are built to handle the demands of plumbing work is about the overall build quality that you should examine and, more importantly, examine prior to purchasing.

Researching Trusted Brands

If there is one problem many tradespeople make at the very outset of their journey, it’s that they opt for cheaper items rather than trusted ones. It’s obvious as to why, but when we go for brands with a history of producing reliable equipment, this will result in better products. The plumbing industry has a number of top plumbing brands such as American Standard, but you also need to ensure that you have an understanding of how these brands will translate to the right end products.

When looking for equipment, you should see if there’s any relevant approvals or certifications from industry standards organizations. In the plumbing industry, standards such as the Uniform Plumbing Code (UPC) are in place to govern the installation and inspection of plumbing systems to promote the public’s health and safety welfare. Additionally, the International Plumbing Code provides requirements for plumbing systems in a wide variety of buildings, including commercial and residential. Plumbing providers that have approvals from these industry standards will naturally indicate the equipment meets specific safety and quality standards.

Evaluate the Warranty and Support

Any equipment will come with guarantees or warranties. Manufacturers’ willingness to stand behind their products will always be a testament to their quality. A very simple thing but these warranties will give you a far better understanding of the company and what they do to provide great customer support. The customer support part is always another key area to understand in case of any potential problems or if you have any questions.

Checking for Compatibility

We all need to ensure that when we are conducting specialized tasks, we need the appropriate equipment. Specialized tools are going to improve efficiency and bring about more accurate results. For example, if the equipment is part of a larger plumbing system, we need to make sure that it’s not just compatible with those specialized systems but is also able to work in tandem with our existing tools and systems.

Testing the Equipment

If possible, we should test the equipment prior to purchasing. We need to have an understanding as to whether a tool like a pipe cutter is able to cut accurately and smoothly, which can maximize safety and precision. Equipment is subject to tough conditions, so it has to withstand wear and tear. We need to ensure the equipment is made from materials that can handle the demands of the job in question. Equipment that requires precise adjustments or measurements should provide easy and accurate markings. Ensuring that we test for functionality, but also look for ergonomic designs, can make life easier for us.

Plumbing is a labor-intensive practice, and therefore, we need to reduce fatigue during long jobs. An understanding of how user-friendly that equipment is will naturally have an impact on its cost, but we must give great consideration as to whether it’s a worthwhile investment. Lower prices may indicate lower quality, but excessively high prices don’t always guarantee great quality either. We should always seek recommendations from plumbing suppliers or stores who will have insights into what is popular amongst professionals, but is actually built for purpose.

The task of checking for the right equipment and ensuring you have the tools you need for a successful job is about the overall recommendations made by industry professionals, but it’s important to trust your instincts as well. The right equipment should inspire confidence in you and feel reliable from the moment you handle it.

Webstone®, a brand of NIBCO, announces enhancements to its Pro-Pal T-Valve line, including 17 new lead-free dezincification-resistant brass models. FIP x press models are now available in sizes up to 1¼”. The new G-thread option is compatible with a host of fittings and accessories. New 3/8” and ¼” OD compression branch models are perfect for Read more

Webstone®, a brand of NIBCO, announces enhancements to its Pro-Pal T-Valve line, including 17 new lead-free dezincification-resistant brass models. FIP x press models are now available in sizes up to 1¼”. The new G-thread option is compatible with a host of fittings and accessories. New 3/8” and ¼” OD compression branch models are perfect for humidifiers and ice makers. Available in your choice of PEX, push, or press system runs, these models are compatible with a variety of compression fittings to customize your installation.

“This line expansion is a direct response to our customers’ feedback,” said Lisa Lyon, Senior Product Manager. “After introducing the original set of T-Valves, the case for additional models was made immediately clear by our partners in the field. They loved the idea of a compact tee that could isolate its branch for service, and they wanted a solution to fit a broader range of applications. With the introduction of these new size and connection options, that’s now possible. We’re proud of our commitment to continuously enhance the Webstone product line to meet the needs of our customers.”

For more information, visit www.webstonevalves.com.