Viega Works online training also will continue. Broomfield, Colo. — Viega LLC will reopen its seminar centers in Colorado and New Hampshire on Aug. 1. The centers had been closed since March 2020 due to COVID-19. Viega is reopening them with new safety measures in place, including limiting class size, cleaning stations and mask requirements Read more

PEX

Viega Works online training also will continue.

Broomfield, Colo. — Viega LLC will reopen its seminar centers in Colorado and New Hampshire on Aug. 1.

The centers had been closed since March 2020 due to COVID-19. Viega is reopening them with new safety measures in place, including limiting class size, cleaning stations and mask requirements when appropriate.

“We’re excited to reopen and welcome back our customers, contractors and distributors,” said Jason McKinnon, director oftechnical services. “We moved training online during the pandemic and that’s been successful, but it’s going to be great to work in-person again with people.”

The seminar centers are located at Viega LLC headquarters in Broomfield, Colo., and in Nashua, N.H. Each features classrooms, hand-on workshops and interactive learning displays. Viega offers courses in a variety of subjects, including pressing, design and installation, and each course is customizable to meet the needs of our customers.

In response to customer demand during the lockdown, the company created Viega Works, online sessions largely limited to single companies. These programs, which can be as short as 30 minutes, are custom designed to cover the topics customers request.

“Customers like Viega Works because it’s fast and affordable and gives them the exact information they need without requiring travel or a major time commitment,” McKinnon said. “With the reopening of our seminar centers we offer even more opportunities to engage with our technical consultants than ever before. Customers can attend in-person at one of our seminar centers or contact us to set up a unique virtual experience with content specific to their team. No matter where or how you want to connect with our experts, we will make it easy and valuable for you and your organization.”

Uponor’s Board of Directors has appointed Michael Rauterkus as President and CEO of Uponor Group and Chairman of the Executive Committee. He will join the company and assume the CEO responsibility on 21 August 2021. Michael Rauterkus has long experience, wide knowledge and good networks from the industry, as his most recent operative role was Read more

Uponor’s Board of Directors has appointed Michael Rauterkus as President and CEO of Uponor Group and Chairman of the Executive Committee. He will join the company and assume the CEO responsibility on 21 August 2021.

Uponor’s Board of Directors has appointed Michael Rauterkus as President and CEO of Uponor Group and Chairman of the Executive Committee. He will join the company and assume the CEO responsibility on 21 August 2021.

Michael Rauterkus has long experience, wide knowledge and good networks from the industry, as his most recent operative role was the CEO of Grohe AG, a German sanitary technology manufacturer. During his tenure as CEO in 2015-2019, he developed Grohe into a global leader of bathroom and kitchen solutions. Prior to this, he has worked in various roles at Grohe since 2006. Earlier in his career he has been working for companies like in Hasbro Inc., Levi Strauss & Co., Kraft Jacobs Suchard (now Mondelez).

“I am very pleased that Michael Rauterkus has accepted the assignment to lead Uponor into the next phase and I look forward to working with him. Michael is a seasoned visionary leader with strong strategic competence. He understands the dynamics of our industry inside out,” says Annika Paasikivi, Chair of the Board of Directors, Uponor Corporation.

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect Read more

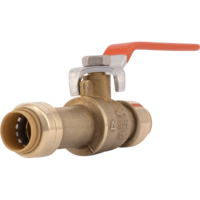

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect slip and transition fittings.

As the deep winter freeze arrives, frozen or burst pipes can become prevalent. Dealing with an unexpected leak is the last thing anyone wants to tackle in the middle of a busy season; but if it happens, there’s a quick solution to restoring ruptured pipes with no specialty tools, soldering, crimping or glue required: SharkBite push-to-connect slip and transition fittings.

“SharkBite gives you a wide range of slip fittings and valves to repair burst copper or CPVC pipes quickly,” said Michael Kornegay, SharkBite Product Manager. “Up to two inches of damaged pipe can be removed using a single fitting, even in wet lines, and a drain valve can be easily added to prevent future freezing.”

Ideal for working with multiple pipe types and in tight spaces, SharkBite’s Brass Push transition fittings can be installed in wet lines and can transition between pipe types, including PEX, copper, CPVC, PVC, polybutylene, HDPE and PE-RT pipes, making them one of the most versatile solutions.

“SharkBite’s push-to-connect transition fittings come with color-coordinated collars for each specific pipe material,” Kornegay continued. “The tool-free transition fittings allow for quick and easy repair of copper pinhole leaks and replacement of brittle polybutylene pipe or broken CPVC.”

Since pipes are at a higher risk of freezing and bursting in the winter, it pays to have a solution like SharkBite’s push-to-connect slip and transition fittings handy for a quick fix. Follow these steps to get the job done fast:

- Cut the pipe cleanly – Be sure the pipe is clean of scratches or debris. If working with copper pipe, use a deburr tool or sandpaper to remove any sharp edges or burrs.

- Measure and mark the insertion depth – Use SharkBite’s Deburr & Gauge Tool to mark the insertion depth on the damaged pipe.

- Make the connection – Push the fitting to the insertion marks. Then, turn on the water and check the connection.

When it comes to repairing a burst, frozen pipe, SharkBite push-to-connect slip and transition fittings save time. Pipe transitions make working with PEX, copper, CPVC, PVC, polybutylene, HDPE and PE-RT pipes hassle free, and SharkBite offers the flexibility of repairing the damaged pipe in wet lines under full flow.

“Just cut, push and done,” Kornegay said. “These SharkBite products allow you to quickly repair those frozen, burst pipes in a short amount of time, so you can finish a job with ease and move on to the next.”

Learn more about SharkBite’s repair options at SharkBite.com.

The Plastics Pipe Institute, Inc. (PPI), has published a new recommendation related to the direct connection of plastic piping materials CPVC, PE-RT, PEX, and PP to tankless water heaters. Available on PPI’s website, PPI Recommendation H Direct Connection of Plastic Piping Materials to Tankless Water Heaters for Domestic (i.e. residential) Applications provides clear guidance on Read more

The Plastics Pipe Institute, Inc. (PPI), has published a new recommendation related to the direct connection of plastic piping materials CPVC, PE-RT, PEX, and PP to tankless water heaters.

Available on PPI’s website, PPI Recommendation H Direct Connection of Plastic Piping Materials to Tankless Water Heaters for Domestic (i.e. residential) Applications provides clear guidance on the question of direct connection of these piping materials to tankless water heaters. PPI is the major trade association representing the plastic pipe industry.

“PPI Recommendation H answers questions which plumbers and builders have been asking about whether it is appropriate for plastic pressure pipe materials to connect directly to the cold-water inlet and hot-water outlet of domestic tankless water heaters, without the use of metallic flex connectors. Based on our research, these direct connections are usually acceptable,” explained Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division.

“To help answer this question, PPI and our members researched Canadian and US model plumbing codes,” he continued, “reviewed the published literature on dozens of tankless water heaters, and confirmed the recommendations of plastic piping system manufacturers. Based on the proven high-temperature capabilities of these piping materials and the relatively consistent water temperature control of modern tankless water heaters, there is no technical reason to prohibit direct connections. Of course, installers must follow local code requirements and the manufacturer installation instructions.”

“As stated in Recommendation H: Piping systems using the materials CPVC, PE-RT, PEX, and PP, which carry a pressure rating of 100 psi at 180°F (690 kPa @ 82°C), and which are intended and certified for hot and cold potable water distribution systems according to industry standards and relevant codes, may be connected directly to tankless water heaters which are intended for domestic (i.e. residential) applications, unless prohibited by local plumbing code or the specific water heater manufacturer.”

According to PPI President David Fink, “The research on this topic was prompted by an inquiry from a major builders group. The rapid development of Recommendation H demonstrates the ability of PPI members to collaborate and respond quickly to industry questions about responsible usage of plastic piping materials.”

Published on PPI’s website directly at recommendation-h-direct-connection-tankless, Recommendation H is one of several PPI documents related to the design and installation of pressure pipe materials for plumbing and mechanical applications, which are all published as a service to the industry. Additional information about PPI’s Building & Construction Division can be found at plasticpipe.org/building-construction/index.html.

Some brands become so popular people begin to refer to all products in the category by that name, such as Kleenex or Band-Aid. Similarly, push-to-connect fittings weren’t quite as popular as they are today until Reliance Worldwide Corporation (RWC) introduced them to the U.S. market nearly 20 years ago. It revolutionized the category and made Read more

Some brands become so popular people begin to refer to all products in the category by that name, such as Kleenex or Band-Aid.

Similarly, push-to-connect fittings weren’t quite as popular as they are today until Reliance Worldwide Corporation (RWC) introduced them to the U.S. market nearly 20 years ago. It revolutionized the category and made the work of contractors and plumbers quicker, more efficient and more reliable. Now, SharkBite brass push fittings are the industry standard for push-to-connect plumbing— so much so that some people refer to fittings from other brands as SharkBite.

SharkBite’s Journey to the U.S.

After seeing the success of its push-to-connect fittings in Australia, water control and plumbing solutions manufacturer RWC introduced the fittings in the U.S. market as the SharkBite push-to-connect plumbing system in 2004. Today, SharkBite has become so popular that it is estimated a fitting connection is made every 2.5 seconds, according to the manufacturer’s data.

Fittings That Pushed the Boundaries of Plumbing Tech

Before push-to-connect technology, plumbers could only rely on soldering, gluing or using a specialized tool to connect pipes. These methods are sufficient in some cases but can be challenging when transitioning between different pipe types or installing in tight spaces.

To address these issues, SharkBite designed its push-to-connect fittings to connect different pipe types such as PEX, copper, CPVC, PE-RT and HDPE in tight spaces without special tools, crimps, glue or soldering.

Further Advancing Push-to-connect Technology

With SharkBite’s success, especially as a solution for emergency repairs and pipe transitions, RWC continued to build upon its innovations in push-to-connect technology:

- SharkBite introduced its own brand of durable yet flexible PEX pipe into North America. The pipe enables quicker leak repairs compared to rigid copper pipe and is often quicker to install in tight spaces.

- The company launched 1-1/4 in., 1-1/2 in. and 2 in. SharkBite fittings, which gives contractors who work on commercial projects the ability to work quicker using push-to-connect technology.

- SharkBite launched EvoPEX fittings. The groundbreaking PEX-only fitting system for meter-to-fixture installation allows for faster and more reliable installations on new construction jobsites.

A Connection You Can Trust

Plumbers can trust the secure fit of a push-to-connect fitting thanks to its tight-sealing o-ring, pipe-locking stainless steel grab ring and corrosion-resistant brass body. All of its parts work together to make a 3-second connection long-lasting, and the fittings require no tools, can be connected in wet lines and are compatible with multiple types of pipe.

SharkBite’s Legacy

Every new product SharkBite introduces is created to empower contractors to work smarter, not harder. By reducing installation times, SharkBite gives contractors time back that they can spend on parts of their job that require more resources, like growing their business and investing in their workforce.

Michael Kornegay is the SharkBite product manager at RWC — a market leader and manufacturer of water control systems and plumbing solutions for residential, commercial and industrial applications.

Michael Kornegay is the SharkBite product manager at RWC — a market leader and manufacturer of water control systems and plumbing solutions for residential, commercial and industrial applications.