As they say in one of the world’s most popular television shows: winter is coming. With winter comes the inevitable rise in the number of burst pipe calls all plumbers will be tasked with repairing. Pipes are generally more likely to burst when the temperature drops below 20 degrees Fahrenheit. It is suggested that those Read more

PEX

As they say in one of the world’s most popular television shows: winter is coming. With winter comes the inevitable rise in the number of burst pipe calls all plumbers will be tasked with repairing. Pipes are generally more likely to burst when the temperature drops below 20 degrees Fahrenheit. It is suggested that those living in cold-weather climates keep their homes heated to a minimum of 36 degrees if they are not going to be using their water for an extended period of time. However, no matter how present these warnings are, some winter pipe bursts are unavoidable.

As they say in one of the world’s most popular television shows: winter is coming. With winter comes the inevitable rise in the number of burst pipe calls all plumbers will be tasked with repairing. Pipes are generally more likely to burst when the temperature drops below 20 degrees Fahrenheit. It is suggested that those living in cold-weather climates keep their homes heated to a minimum of 36 degrees if they are not going to be using their water for an extended period of time. However, no matter how present these warnings are, some winter pipe bursts are unavoidable.

Fortunately, John Guest has committed time and effort to developing the products necessary to tackle this problem. The John Guest Speedfit slip connectors provide plumbers with a quick, simple, and easy fix for burst pipes.

Their slip connectors come in two sizes and can be used to fix pipe bursts on PEX, CPVC, and copper pipes, providing an efficient solution to a litany of burst-pipe problems. John Guest slip connectors have push-fit connections, allowing for rapid installation that should at least temporarily solve one of the major issues with burst pipes: leakage. The push-fit fitting allows all of this to be accomplished without any additional pipe work.

Their slip connectors come in two sizes and can be used to fix pipe bursts on PEX, CPVC, and copper pipes, providing an efficient solution to a litany of burst-pipe problems. John Guest slip connectors have push-fit connections, allowing for rapid installation that should at least temporarily solve one of the major issues with burst pipes: leakage. The push-fit fitting allows all of this to be accomplished without any additional pipe work.

Slip connectors are also built to work with both hot and cold pipes, again providing coverage across the entire spectrum of possible burst-pipe issues that one may encounter. John Guest slip connectors are made with lead-free, non-toxic, and non-flammable materials so you can feel secure in installing these connectors for any issue and leave them to run without constant monitoring. Like all John Guest products, the Speedfit slip connectors are made with an advanced polymer material, assuring our customers that they are receiving only the highest-quality performance.

For more visit John Guest Speedfit slip connectors.

For residential plumbers, there have been two schools of thought for plumbing a house: home run and trunk and branch. Both have their positives and negatives, depending on what you’re trying to accomplish with the plumbing system. However, you may not know there’s a new (and smarter) way to design and install a residential plumbing Read more

For residential plumbers, there have been two schools of thought for plumbing a house: home run and trunk and branch. Both have their positives and negatives, depending on what you’re trying to accomplish with the plumbing system.

For residential plumbers, there have been two schools of thought for plumbing a house: home run and trunk and branch. Both have their positives and negatives, depending on what you’re trying to accomplish with the plumbing system.

However, you may not know there’s a new (and smarter) way to design and install a residential plumbing system that installs faster, uses less materials, requires fewer connections, minimizes your liability and operates more efficiently.

It’s called Logic plumbing.

A Logic plumbing design can only be used with PEX piping, but since PEX is now used in more new-home construction than copper and CPVC combined, you’re most likely already using it. (And if you’re not, you need to check it out. PEX is highly durable, flexible and more cost-effective compared to copper and CPVC.)

The Logic approach leverages the flexibility of PEX pipe to minimize connections and reduce potential leak points while also incorporating multiport tees located near fixture groupings to both limit the amount of pipe and connections needed while also improving installation efficiencies and system performance.

What’s a multiport tee?

I’m sure right now you’re wondering, “What’s a multiport tee?” It’s essentially a bunch of tees all molded together to create one long tee with multiple outlets. This innovative product minimizes connections and is the heart and soul of a Logic design.

For example, six regular tees will have 18 connections, but a flow-through multiport tee with six outlets will only have eight connections (six connections for the ports, a main flow-through inlet and a main flow-through outlet). Think about how much faster you could install a system when you’re making half the number of connections.

For example, six regular tees will have 18 connections, but a flow-through multiport tee with six outlets will only have eight connections (six connections for the ports, a main flow-through inlet and a main flow-through outlet). Think about how much faster you could install a system when you’re making half the number of connections.

And get this — while multiport tees may resemble a manifold, they have the benefit of being hidden behind walls without the need for an access panel. Yes, you heard that right. No need for an access panel, minimizing costs and labor to help keep your projects on schedule and on budget.

Multiport tees are made of engineered polymer (EP), a thermoplastic material that has been used in plumbing applications for more than 20 years. EP has superior mechanical, chemical and thermal properties that provide dimensional stability in demanding applications, including areas of high stress, heat and moisture.

And, like PEX, the EP material in multiport tees resists corrosion, pitting and scaling, so it creates a highly durable system that’s engineered to last. Best of all, multiport tees (as well as all EP fittings) are approved for direct burial in the soil or concrete slab, so they are ideal for in-slab plumbing applications.

The Logic layout

So what exactly is a Logic plumbing layout? It’s quite simple: a main line connects to a multiport tee with distribution lines going out from the tee. These individual lines extending from the single multiport tee provide water to all fixtures in a single or adjacent grouping.

This design uses significantly less pipe than a home-run layout, with just a few more connections. Plus, it requires considerably fewer connections compared to a trunk-and-branch installation.

This design uses significantly less pipe than a home-run layout, with just a few more connections. Plus, it requires considerably fewer connections compared to a trunk-and-branch installation.

For example, a 2,300-square-foot, two-story home using a Logic design requires only 637 feet of pipe while a home-run system uses 1,515 feet of pipe. That’s more than twice the amount of piping necessary.

In addition to the added costs required to install all that extra pipe, the system performance is also greatly reduced due to added pressure loss and longer wait times for hot water. Plus, all the extra pipe can lead to issues isolating hot and cold water lines. This increases heat transfer and energy inefficiencies within the plumbing system.

And, while it’s true a Logic installation uses slightly more connections than a home-run layout (59 vs. 48 in the 2,300-square-foot, two-story home example above), the amount of pipe savings is significantly more beneficial with the labor and material savings you get with less pipe to install (not to mention the efficiency of the system).

A Logic layout also installs much faster compared to a trunk-and-branch system due to the vast reduction in connections. With the two-story home example above, a Logic layout uses a mere 16 fittings and 59 connections compared to a whopping 96 fittings and 165 connections for trunk and branch. That’s six times the number of fittings and nearly three times the amount of connections!

All those added connections greatly increase your liability with more potential for leaks, plus it also limits the performance of the system with increased pressure loss.

So there you have it! Just a few “logical” reasons why you should consider a smarter approach to plumbing a home that will improve your installation times, limit your liability and offer an all-around better-performing system for the end user.

Kim Bliss is the content development manager at Uponor. She can be reached at kim.bliss@uponor.com.

Gerber, a leader in plumbing products across North America, has launched one of the industry’s most innovative and flexible tub and shower valves. In an effort to help professionals work smarter, not harder, the new Treysta™ rough-in valve system is built to accommodate varying requirements plumbers face on site in a range of installations. “We’ve Read more

Gerber, a leader in plumbing products across North America, has launched one of the industry’s most innovative and flexible tub and shower valves. In an effort to help professionals work smarter, not harder, the new Treysta™ rough-in valve system is built to accommodate varying requirements plumbers face on site in a range of installations.

Gerber, a leader in plumbing products across North America, has launched one of the industry’s most innovative and flexible tub and shower valves. In an effort to help professionals work smarter, not harder, the new Treysta™ rough-in valve system is built to accommodate varying requirements plumbers face on site in a range of installations.

“We’ve worked tirelessly to perfect this valve, fine-tuning it based on input and testing of plumbing professionals in the field,” says Katie Hayes, senior product manager. “With more than 85 years of experience to draw upon, we’re proud to incorporate the Gerber performance and reliability into this product that people have come to expect from all our products.”

Treysta Features and Benefits

Multiple features within the new valve system are patent pending. A complete list of features and benefits include:

- Revolutionary Vertical Inlets – Treysta’s vertical inlets allow for maximum flexibility in the wall, and can install next to a stud in PEX applications greatly reducing the need for re- framing

- Easy Installation and Access – With an easy-access mounting system and an innovative plaster guard with integrated depth indexing, Treysta is engineered for smooth and quick installation

- Intuitive Quarter-turn Service Stops – Treysta features quarter-turn service stops that open and close with a flat head screw driver in the slot or pliers on the flat sides for ease of maintenance

- Easy Pressure Testing Capability – The unique, reversible test plug accommodates full system tests, as well as hot, cold and cross-flow tests

- Flexible and Adaptable for Different Environments – Treysta has a solution for “with” and “without” stops, and accommodates back-to-back installations and reversed hot and cold inlets, as well as IPS / sweat, Cold Expansion PEX, and Crimp PEX applications

- Secure and Level Mounting – The compact, brass-forged body of the valve features integrated mounting holes for a firm and secure hold, and the flat top plane of the plaster guard allows it to install level with the floor

- Innovative Common Platform – Treysta uses a common platform of pressure balance cartridge for all configurations, meaning a single cartridge fits in all valve bodies

- Fully Compatible Danze® by Gerber Trim – Danze by Gerber trim has been updated to include the Treysta pressure balance cartridge, which will ultimately minimize cartridge damage during rough-in installation

For more information about the Treysta valve from Gerber, visit treysta.gerberonline.com.

Sometimes its fun to step back and see the whole process from start to finish. Here’s a time lapse video of the prep and install for the radiant in-floor heating at the #duluthbuild project in Northern Minnesota. I’ve been trying to document each step along the way for this project we are building for my Read more

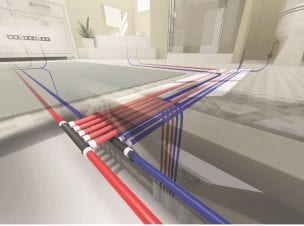

Sometimes its fun to step back and see the whole process from start to finish. Here’s a time lapse video of the prep and install for the radiant in-floor heating at the #duluthbuild project in Northern Minnesota.

I’ve been trying to document each step along the way for this project we are building for my little sister and brother-in-law and I’m starting with the over 7K sq ft of radiant. If you’d like to follow along you can search the hashtag #duluthbuild on either Facebook or Instagram, doing so will show you all the posts from the project.

If social media isn’t your thing or you’d just rather stay put here on The Hub check out these recent videos:

What is permanent? What will be there in 100 years?

Uponor Ecoflex pre-insulated job site install

#WeMeanProgress and #TheQuestforProgress were prominent hashtags and underlying themes at the this year’s Uponor Convention in Las Vegas. “I like the word ‘quest,’ because it represents a journey,” says Bill Gray, president, Uponor North America. “We are on a never-ending journey to bring solutions for everyday problems to our customers. Uponor is never going to Read more

#WeMeanProgress and #TheQuestforProgress were prominent hashtags and underlying themes at the this year’s Uponor Convention in Las Vegas. “I like the word ‘quest,’ because it represents a journey,” says Bill Gray, president, Uponor North America. “We are on a never-ending journey to bring solutions for everyday problems to our customers. Uponor is never going to stop striving to get better and better.”

The biennial show continues to get better, and impress. What began in March 2000 as a customer appreciation event for a couple of hundred radiant installers has grown into one of the industry’s largest networking, educational and advocacy events for professionals who install, design and specify PEX in the residential and commercial building markets. Uponor customers, including wholesale distributors, home builders, specifying engineers and plumbing and mechanical contractors, as well as Uponor personnel, independent sales agents and media from both the U.S. and Canada were in attendance.

Today, more than 1,200 participants learned, connected and were entertained. The framework of the show features a one-day, all-in educational experience to not only learn more about Uponor’s direction in North America and across the globe, but also features breakout sessions taught by some of the best in the industry.

A few of the educational break-outs I attended included Milwaukee Tools’ Increasing Productivity Through Innovation, where senior product manager, Alex Boll, showed off some of Milwaukee’s latest products and discussed advancements in batteries, motors and electronics, and how Milwaukee is revolutionizing the industry with innovative, trade-specific solutions.

Milwaukee Tool senior product manager, Alex Boll, discusses the latest product offerings from the company.

In addition, it is always a good listen to sit in on anything Robert Bean—the comfort guru—teaches. Bean, president of Indoor Climate Consultants Inc., teaches courses related to the business and engineering of buildings, indoor climates and radiant-based HVAC systems. He shares everything he knows at www.healthyheating.com. The breakout, “Designing with Distinction: Strategies for high-performing radiant systems,” was a welcome addition to this year’s Uponor Convention line-up.

In addition to educational seminars, Uponor features a “mini” trade show with industry partners, with Taco, Milwaukee Tools, Navien, Grundfos, Rinnai, Greyter Water Systems, Trimble, among others.

But front and center of the trade show floor was Uponor’s Phyn Plus, which protects your home from leaks the moment it is connected. It then begins to learn how your family uses water as you go about your routine. Over time it gets smarter, unlocking new capabilities and offering you insights. And in the future, it will help you understand and better manage your water.

https://youtu.be/4fvecIjHpSY

The convention was the site of the first official training session for an initial group of 100 professional plumbing installers who qualified to join the Uponor Pro Squad. More than 2,500 additional plumbers will participate in training in coming weeks via online and in-person sessions.

“This training was an exciting and important milestone in the launch of Phyn Plus,” said Dena Mayne, vice president, Marketing & Customer Experience, Uponor North America. “Not only did it mark the official commercialization of the device in North America, but the session also enabled us to help this network of professionals advance the plumbing industry into the digital era by using data and insights to change the way consumers think about the water in their homes.”

One of the newest participants in the Uponor Pro Squad network is plumbing and HVAC contractor Rich Trethewey, the plumbing and heating expert on the national home-improvement show “This Old House” and its two popular spinoffs, “Ask This Old House” and “Inside This Old House.” Trethewey, who attended the training session in Las Vegas, will feature the Phyn Plus device on a This Old House episode scheduled to air in the fall.

While spending most of the immersing myself in keynotes and breakout sessions, one thing was abundantly clear, the future is coming, and in many cases, it is already here.

Duh, the future is coming, no kidding! In any event, things like driverless cars to artificial intelligence and robotics to augmented and virtual reality are here already or not too far off in the distant future.

“The best way to predict the future is to create it,” said keynote speaker, Jack Uldrich, a leading global futurist, as he was quoting management consultant Peter Drucker. “The world can change quickly and we need to be aware of it,” continued Uldrich, addressing the convention crowd on the ever-evolving construction industry.

What will the future look like? “Predictably unpredictable,” says Uldrich. The key is embracing paradox, learn to unlearn, recognizing failure as a key to one’s success and understanding that an awareness of one’s experience is a key component to true wisdom. Experience doesn’t really mean a thing if you continue to work or view the workplace the same every day, suggests Uldrich. For example, “Reverse mentor someone with less experience than you to help you see the world differently.”

As leaders, says Uldrich, we need to be adaptable and be flexible to change, and it’s time to start thinking about the future. As professionals, we need to—what Uldrich calls—“jump the curve” to understand how the following trends are transforming the economy and altering our future:

• Artificial Intelligence: SmartVid.IO built out its technology which applies sophisticated algorithms to study video footage of construction sites, says Uldrich. For example, if a worker isn’t wearing a hard hat or a set of stairs doesn’t have a safety railing, the system alerts the site supervisor. “The technology is like having a job site inspector who never sleeps. Even if it prevents one accident, the technology more than pays for itself,” said Uldrich.

• Robotics: One innovative application comes from Built Robotics which uses its ability to excavate foundations. “Instead of using equipment operated by human drivers, why not employ a system that can work around the clock without sleeping or taking coffee breaks?” said Uldrich.

• Virtual Reality: “We need to leverage virtual reality to train the next generation of workers,” says Uldrich. Mortenson Construction is already employing Daqri Technologies’ “smart helmet” technology to allow construction workers to overlay digital information onto actual construction site locations. In a hands-free manner, the technology allows pipefitters, electricians, plumbers and other construction professionals to better understand how to most efficiently complete their jobs.

• Prefabrication: Industry leaders are using innovative technology to inspire collaboration and design, says convention breakout speaker, James Benham, CEO, JBKNOWLEDGE. For instance, “Prefab is the future of construction,” says Benham.

Tom Palange, J.C. Cannistraro, has said, more and more projects have creative applications for prefabricated components, and the company is well-positioned to adapt as a result of years of training, planning and process improvements. “We’ve fully embraced the modular movement and have made significant investments in equipment and facilities to maximize our capacity to produce modular bathrooms, piping systems, mechanical rooms, hospital headwalls, pump skids, and more … the possibilities are endless,” says Palange

According to Uldrich, these examples are the not only ones revolutionizing the construction industry. 5G technology, social media, Internet of Things (IoT) and big data will continue to converge and, in the process, transform the construction industry.

The message was clear at this event: in terms of tool innovation, construction disruption and high-performance radiant and water systems, it’s time to start looking to the future and think about “jumping the curve.”

For a recap of the convention, check out this link to the video:

https://vimeo.com/265202186/ba1ec09f5c