Irving, Texas—The Plastics Pipe Institute, Inc. (PPI) has renewed its commitment for financial and technical support for the 2020 U.S. Department of Energy (DOE) Solar Decathlon – Design Challenge. PPI is the major North American trade association representing all segments of the plastic pipe industry. This is PPI’s sixth year supporting this DOE program, formerly Read more

piping

Irving, Texas—The Plastics Pipe Institute, Inc. (PPI) has renewed its commitment for financial and technical support for the 2020 U.S. Department of Energy (DOE) Solar Decathlon – Design Challenge. PPI is the major North American trade association representing all segments of the plastic pipe industry. This is PPI’s sixth year supporting this DOE program, formerly known as Race to Zero.

The 2020 Solar Decathlon Design Challenge will take place at DOE’s National Renewable Energy Laboratory (NREL) in Golden, Colorado on April 17-19, 2020. Lance MacNevin, P.Eng, director of engineering for PPI’s Building & Construction, will return as a juror.

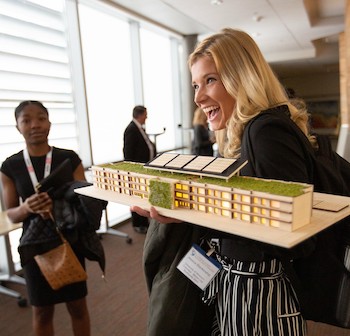

A student from the University of Missouri – Columbia shows a scale model for the Mixed-Use/Multifamily category at the 2019 Solar Decathlon – Design Challenge in Golden, Colo. Photo credit: DOE Solar Decathlon

According to MacNevin, “Buildings in the United States represent 4o% of our country’s total energy consumption and 70% of our electricity use, so there are many opportunities to utilize existing technologies in smart ways to reduce energy costs. At these events, we see future architects and engineers collaborate and compete to design houses and buildings that are so energy efficient that their annual energy use can be offset with renewable energy.”

DOE’s website states, “Qualifying teams complete a design project and attend the Solar Decathlon Design Challenge Weekend, where they present their designs to a panel of industry expert jurors, compare their projects to those of other teams, learn from presentations by thought leaders and collegiate peers, and engage with a variety of organizations about energy careers. Winning teams are recognized at an Awards Banquet, and winning project presentations are published on the website.” https://www.solardecathlon.gov/event/challenges-design.html

PPI President David Fink said, “PPI encourages design teams to incorporate innovative plumbing and mechanical systems to improve the health, safety and welfare of building occupants and the efficiency of buildings. This includes technologies such as hydronic radiant heating and cooling, ground source geothermal, hot- and cold-water plumbing using plastic piping solutions, and fire protection for occupant safety. These systems can benefit the entries in practically all categories of judging, including energy performance, engineering, architecture, market appeal, financial affordability, operation, comfort & environmental quality, and innovation.”

Added MacNevin, “It’s always so exciting to see the creative designs and technological ideas of the student teams from around the world. We can’t wait to see what they’ll present at the 2020 event!”

PPI has developed resources to help students design their projects available at https://plasticpipe.org/building-construction/bcd-2020-solar-decathlon.html

For additional information, also visit the Plastics Pipe Institute’s website at: www.plasticpipe.org.

Uponor North America and San Diego, Calif.-based Pestan North America (PNA), a supplier of PP-RCT pipe and fittings, today announced the signing of an agreement naming Uponor the exclusive distributor of PNA’s proprietary PP-RCT (polypropylene, random copolymer, with modified crystallinity and temperature resistance) products throughout the U.S. and Canada. Beginning in 2020, Uponor will market more than 270 of PNA’s Read more

Uponor North America and San Diego, Calif.-based Pestan North America (PNA), a supplier of PP-RCT pipe and fittings, today announced the signing of an agreement naming Uponor the exclusive distributor of PNA’s proprietary PP-RCT (polypropylene, random copolymer, with modified crystallinity and temperature resistance) products throughout the U.S. and Canada.

Uponor North America and San Diego, Calif.-based Pestan North America (PNA), a supplier of PP-RCT pipe and fittings, today announced the signing of an agreement naming Uponor the exclusive distributor of PNA’s proprietary PP-RCT (polypropylene, random copolymer, with modified crystallinity and temperature resistance) products throughout the U.S. and Canada.

Beginning in 2020, Uponor will market more than 270 of PNA’s products, making it the only North American company to offer hybrid systems including PEX and PP-RCT. Products will range from 1/2-inch to 12 inches in diameter; up to 24 inches for special product requests. PP-RCT is used in an array of commercial plumbing and hydronic projects.

“We worked diligently to find a partner who offers a quality, differentiated product that is in alignment with Uponor’s business mission and vision. I’m confident we’ve found this and more in Pestan North America,” said Bill Gray, president, Uponor North America. “We’re excited to discover the new doors this partnership will open for our company in the commercial construction market.”

“At Pestan North America, we believe that the transition from metal piping to leading-edge polymer piping is still in its early stages and foresee a significant increase in demand for PNA products in the North American markets,” said Nenad Nastic, co-CEO, PNA.

“Based on the strength of our technology and the world-class team at Uponor, we are confident we will achieve and maintain a leadership role in this sector for years to come,” added Marko Radovanovic, co-CEO, PNA.

Gray also said that the agreement signifies a huge step toward affirming Uponor’s position as the leading polymer pipe solutions provider for commercial plumbing and HVAC, and that the company plans to proceed thoughtfully throughout the next year, building a long-term, sustainable competitive advantage.

“Our approach is to strategically evolve our skills and resources related to this new offering by way of a staggered market approach, as we believe a measured rollout will help ensure both a positive customer experience and long-term business success.”

Cross-linked polyethylene (PEX) is manufactured using three different methods of cross-linking. PEX-A is produced by the peroxide (Engel) method. Common brands sold in North America produced under the Engel method would be Uponor, Rehau & MrPEX. One unique property of PEX-a is its ability to be heated, using a heat gun, and repaired if kinked Read more

Cross-linked polyethylene (PEX) is manufactured using three different methods of cross-linking. PEX-A is produced by the peroxide (Engel) method. Common brands sold in North America produced under the Engel method would be Uponor, Rehau & MrPEX.

One unique property of PEX-a is its ability to be heated, using a heat gun, and repaired if kinked in the handling process which eliminates the need to cut the tubing and install a coupling. This information is widely known by plumbers having experience with this type PEX but for those not familiar I thought I’d take a couple minutes and put it all in a quick video. The total time it took to make this simple repair was about 5 minutes using the cordless heat gun. I edited the video to speed up the process, using a corded heat gun would also quicken the process. No manufacturer condones the use of a flame (torch) as a heat source.

John Guest has always been a trusted name in push-to-connect fittings. But with JG ProLock, they’ve reached for a new level. An advanced thermoplastic fitting usable with copper, PEX, and CPVC, JG ProLock introduces Twist-to-Lock technology for ultimate control. ProLock’s responsive design ensures a secure fit at unprecedented insertion depth – and because it’s safe Read more

John Guest has always been a trusted name in push-to-connect fittings. But with JG ProLock, they’ve reached for a new level.

John Guest has always been a trusted name in push-to-connect fittings. But with JG ProLock, they’ve reached for a new level.

An advanced thermoplastic fitting usable with copper, PEX, and CPVC, JG ProLock introduces Twist-to-Lock technology for ultimate control. ProLock’s responsive design ensures a secure fit at unprecedented insertion depth – and because it’s safe for behind-wall use, it’s a unique combination of strength and versatility.

- No tools or master installer needed for installation

- Audible click sound and visible alignment arrows assure a secure fit

- 45% more insertion depth than traditional joining solutions

- Certified for ASSE1061 and NSF61(G)

- In compliance with the UPC® (Uniform Plumbing Code), IPC® (International Plumbing Code) and the National Plumbing Code of Canada

- Available for copper, PEX and CPVC tube sizes (CTS) 3/8” through 1”

The best way to see the power of ProLock is to try it yourself. Get your free sample coupler today at JGProLock.com.

https://youtu.be/OKchhHbl2SA The Hub’s Eric Aune visits with Uponor’s head of training Wes Sisco to discuss some new plumbing applications Read more

The Hub’s Eric Aune visits with Uponor’s head of training Wes Sisco to discuss some new plumbing applications.