The water you rely on for drinking and cleaning should be just as pure and clear as essential. While a slightly higher mineral content may not directly harm you, it can cause significant issues for your plumbing over time. Ensure the water flowing from your taps is safe for consumption. Water quality plays a key Read more

Plastic Pipes

The water you rely on for drinking and cleaning should be just as pure and clear as essential. While a slightly higher mineral content may not directly harm you, it can cause significant issues for your plumbing over time. Ensure the water flowing from your taps is safe for consumption. Water quality plays a key role in many aspects of your life. Clean water is essential for your health and daily routines, as well as for maintaining the condition of your clothes and dishes.

Schedule a Plumbing Pipe Inspection

Even today, many homes still rely on outdated and hazardous lead pipes. Some also use cast iron pipes, which are less harmful than lead and prone to rust over time. Signs like brownish tap water or visible rust particles often indicate that your home’s metal pipes are deteriorating.

Additionally, rust in your water supply might stem from an aging water heater, where corrosion can occur within the tank or on components in tankless systems. To address these issues, consult a plumber to explore updated plumbing solutions like PVC or durable plastic pipes, which are excellent long-term replacements.

Set Up a Water Filtration System

Water treatment systems improve the quality of the water in your home. Many water supplies contain hardness, which causes scales to accumulate on appliances, block showerheads, make fabrics feel coarse, and reduce water flow through pipes.

Adding a water softener can resolve these issues by removing hardness. These systems use a unique material to eliminate magnesium and calcium ions responsible for scaling. They can be installed to treat the water supply for your entire home, providing an affordable way to enjoy soft water. Get San Antonio water softeners installed soon to take advantage of these benefits for your home.

Schedule Your Septic Tank Cleaning

If you own a septic tank, have it emptied before it overflows into your yard. An overflow could cause raw sewage to seep into the groundwater, and potentially even your well water. For older septic tanks, consider speaking with a plumber about upgrading to a newer system that directs greywater, like the water from washing laundry, dishes, or bathing, out into your yard instead of into the septic tank. This setup can help water your lawn while reducing the tank’s filling speed. However, this option may not be permitted in certain states.

Flushing

Let cold water taps run for two minutes before using it for drinking or cooking. The quality of water can decrease when it sits unused in pipes for several hours. Alternatively, everyday household activities can help flush the pipes and draw fresh water from the distribution system into your home. These activities include:

- Running the dishwasher

- Taking a shower

- Doing laundry

- Flushing the toilet

Replace Your Tap Aerators

Tap aerators are small screens attached to the ends of taps. While they don’t filter water as thoroughly as dedicated water filters, they do help screen the water passing through. Over time, contaminants and sediment can build up in the aerators, impacting the water’s taste, flow, and pressure.

Replacing tap aerators occasionally is a good idea to maintain water quality and performance. They’re affordable and simple to install, just screw them on or off. You can either swap out the screens or replace the entire aerator when replacing.

Endnote

There are many ways to enhance your water quality, and this post covers just a few of them. By applying these approaches, you can ensure your water is clean and safe. Your water quality plays a key role in both your health and overall quality of life. Taking steps to improve it will lead to meaningful improvements in your well-being.

New Technical Document and Details Proper Steps for Use A new technical document that addresses techniques for the safe and proper use of spray polyurethane foam insulation on and around plastic pressure pipe materials has been published by the Plastics Pipe Institute, Inc. (PPI) with input from the Spray Polyurethane Foam Alliance (SPFA). Prepared by Read more

New Technical Document and Details Proper Steps for Use

A new technical document that addresses techniques for the safe and proper use of spray polyurethane foam insulation on and around plastic pressure pipe materials has been published by the Plastics Pipe Institute, Inc. (PPI) with input from the Spray Polyurethane Foam Alliance (SPFA).

Prepared by PPI’s Building & Construction Division, PPI TN-69 Recommendations when Applying Spray Polyurethane Foam Insulation on and around Plastic Pressure Pipes & Fittings discusses the proper application of spray polyurethane foam insulation to avoid damage due to heat generated by the foam. Pipe and fitting materials include CPVC, PEX, PEX/AL/PEX, PE-RT, PP-R, PP-RCT, PSU, PPS, PPSU, and PVDF.

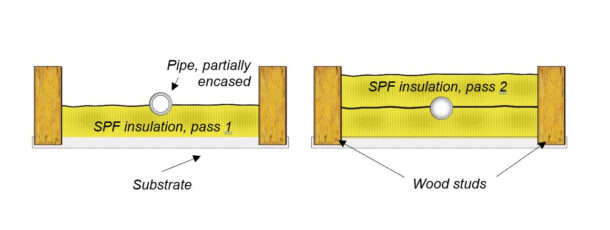

Figure 1: The first layer of SPF insulation is stopped when it reaches the pipe (left), just barely touching or encasing it. After sufficient cooling time, the second layer of SFP insulation is sprayed over the pipe to the required thickness (right).

PPI and SPFA recommend that when there are plastic pipes and fittings in a wall, ceiling, or floor cavity, the SPF installer should apply one layer of foam until it touches the pipe but does not encase the pipe. SPF installers should let the first layer of foam cure for a sufficient amount of time while heat is released from the foam and the pipe remains partially exposed before installing the second layer of foam. These procedures are described in detail within PPI TN-69.

Plastic pressure pipes and fittings are commonly used in applications such as hot- and cold-water plumbing, fire protection, and hydronic heating and cooling systems, including radiant distribution systems. In certain instances, pipes and fittings are installed inside areas that must be insulated, such as within a ceiling or wall cavity. In other installations, the pipes and fittings themselves must be insulated to reduce the transfer of heat through the pipe wall.

According to the SPFA, Spray Polyurethane Foam, or SPF, is a high-performance insulation material commonly used in homes and buildings of all types, and has been used as insulation for decades.

“The spray polyurethane foam curing reaction is exothermic,” explained Richard Duncan, Ph.D., P.E., executive director of SPFA, “which means that heat is generated during the foam reaction. The heat of reaction is highly dependent on the SPF formulation and is also based upon the overall intended application or lift (i.e., layer) thickness installed. Peak temperature within the layer of foam typically occurs within 5 to 15 minutes of application, followed by gradual cooling.”

According to SPFA documents, the chemical reaction that takes place during the application and curing of SPF will generate exothermic temperatures above the 120°F – 130°F setpoint temperatures of the proportioner and hoses. Peak temperatures at the mid-thickness of a pass can exceed 200°F for several minutes and reach peak temperatures 250°F – 275°F for a minute or two, especially for closed-cell SPF, when applied at the maximum pass thickness.

“Plastic pipes and fittings in both residential and commercial plumbing, residential fire protection, and most hydronic applications are typically required to have pressure ratings at 180°F (82°C) operating temperature,” explained Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division.

MacNevin continued, “The plastic pipes and fittings referenced in PPI TN-69 will withstand short-term exposure to temperatures above 180°F. However, exposure to temperatures above the rated operating temperature of each material, which may occur if pipes are encased in a thick pass of closed-cell SPF, are likely to have negative effects on these materials, potentially leading to premature failure. It is important that SPF insulation is installed correctly to prevent overheating of pipes and fittings.”

Access the full content of PPI TN-69 at https://plasticpipe.org/common/Uploaded%20files/Technical/TN-69/PPI%20TN-69.pdf or by scanning:

Additional information and data about pressure pipe materials used for plumbing and mechanical systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

Additional information and data about pressure pipe materials used for plumbing and mechanical systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction