New Technical Document and Details Proper Steps for Use A new technical document that addresses techniques for the safe and proper use of spray polyurethane foam insulation on and around plastic pressure pipe materials has been published by the Plastics Pipe Institute, Inc. (PPI) with input from the Spray Polyurethane Foam Alliance (SPFA). Prepared by Read more

PP-RCT

New Technical Document and Details Proper Steps for Use

A new technical document that addresses techniques for the safe and proper use of spray polyurethane foam insulation on and around plastic pressure pipe materials has been published by the Plastics Pipe Institute, Inc. (PPI) with input from the Spray Polyurethane Foam Alliance (SPFA).

Prepared by PPI’s Building & Construction Division, PPI TN-69 Recommendations when Applying Spray Polyurethane Foam Insulation on and around Plastic Pressure Pipes & Fittings discusses the proper application of spray polyurethane foam insulation to avoid damage due to heat generated by the foam. Pipe and fitting materials include CPVC, PEX, PEX/AL/PEX, PE-RT, PP-R, PP-RCT, PSU, PPS, PPSU, and PVDF.

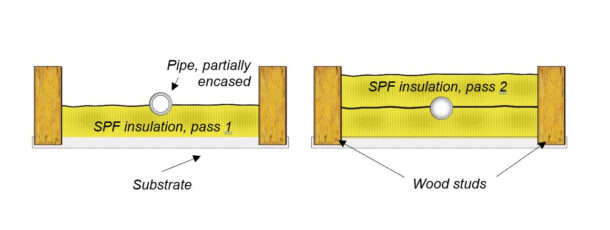

Figure 1: The first layer of SPF insulation is stopped when it reaches the pipe (left), just barely touching or encasing it. After sufficient cooling time, the second layer of SFP insulation is sprayed over the pipe to the required thickness (right).

PPI and SPFA recommend that when there are plastic pipes and fittings in a wall, ceiling, or floor cavity, the SPF installer should apply one layer of foam until it touches the pipe but does not encase the pipe. SPF installers should let the first layer of foam cure for a sufficient amount of time while heat is released from the foam and the pipe remains partially exposed before installing the second layer of foam. These procedures are described in detail within PPI TN-69.

Plastic pressure pipes and fittings are commonly used in applications such as hot- and cold-water plumbing, fire protection, and hydronic heating and cooling systems, including radiant distribution systems. In certain instances, pipes and fittings are installed inside areas that must be insulated, such as within a ceiling or wall cavity. In other installations, the pipes and fittings themselves must be insulated to reduce the transfer of heat through the pipe wall.

According to the SPFA, Spray Polyurethane Foam, or SPF, is a high-performance insulation material commonly used in homes and buildings of all types, and has been used as insulation for decades.

“The spray polyurethane foam curing reaction is exothermic,” explained Richard Duncan, Ph.D., P.E., executive director of SPFA, “which means that heat is generated during the foam reaction. The heat of reaction is highly dependent on the SPF formulation and is also based upon the overall intended application or lift (i.e., layer) thickness installed. Peak temperature within the layer of foam typically occurs within 5 to 15 minutes of application, followed by gradual cooling.”

According to SPFA documents, the chemical reaction that takes place during the application and curing of SPF will generate exothermic temperatures above the 120°F – 130°F setpoint temperatures of the proportioner and hoses. Peak temperatures at the mid-thickness of a pass can exceed 200°F for several minutes and reach peak temperatures 250°F – 275°F for a minute or two, especially for closed-cell SPF, when applied at the maximum pass thickness.

“Plastic pipes and fittings in both residential and commercial plumbing, residential fire protection, and most hydronic applications are typically required to have pressure ratings at 180°F (82°C) operating temperature,” explained Lance MacNevin, P. Eng., director of engineering for PPI’s Building & Construction Division.

MacNevin continued, “The plastic pipes and fittings referenced in PPI TN-69 will withstand short-term exposure to temperatures above 180°F. However, exposure to temperatures above the rated operating temperature of each material, which may occur if pipes are encased in a thick pass of closed-cell SPF, are likely to have negative effects on these materials, potentially leading to premature failure. It is important that SPF insulation is installed correctly to prevent overheating of pipes and fittings.”

Access the full content of PPI TN-69 at https://plasticpipe.org/common/Uploaded%20files/Technical/TN-69/PPI%20TN-69.pdf or by scanning:

Additional information and data about pressure pipe materials used for plumbing and mechanical systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

Additional information and data about pressure pipe materials used for plumbing and mechanical systems are available from the PPI Building & Construction Division at www.plasticpipe.org/buildingconstruction

Apple Valley, Minn. — Uponor North America (Uponor), a pioneer and leading provider of PEX (crosslinked polyethylene) piping products, launched its new Complete Polymer Solution for commercial-piping applications in the U.S. The innovative platform for this important announcement is a special, 90-minute, virtual event for customers, specifiers, installers, and other buying influencers in the commercial Read more

Apple Valley, Minn. — Uponor North America (Uponor), a pioneer and leading provider of PEX (crosslinked polyethylene) piping products, launched its new Complete Polymer Solution for commercial-piping applications in the U.S. The innovative platform for this important announcement is a special, 90-minute, virtual event for customers, specifiers, installers, and other buying influencers in the commercial plumbing and mechanical field.

The online unveiling included the official launch of two important initiatives: Uponor’s new PP-RCT mechanical piping system for commercial HVAC projects; and the new Uponor Construction Services, offering enhanced, professional estimation, design, and building information modeling (BIM) services to support the design and installation of plumbing and mechanical piping systems.

“Our new PP-RCT and Construction Services offerings, combined with our traditional PEX piping solutions, deliver a complete polymer solution for a wide range of commercial plumbing and mechanical projects,” says Bill Gray, president of Uponor North America. “From half-inch diameter PEX to 12-inch diameter PP-RCT, our piping solutions meet the performance, durability, and safety needs of the entire commercial structure. In addition to these industry-leading piping products, Uponor Construction Services can provide the systems design and engineering expertise to ensure a project is fully supported from kickoff to post-construction.”

Empire Pass Condos, Park City, Utah, AquaPEX and PP-RCT install 2019, Thermal Engineering, PNA

PP-RCT piping system: Uponor PP-RCT (PolyPropylene, Random copolymer with modified Crystallinity and Temperature resistance) has higher temperature and pressure ratings than PP-R pipe, as well as lower levels of expansion and contraction.

Proven reliable for commercial hydronic heating, chilled-water cooling, and distribution piping for radiant heating and cooling applications — including snow melt, turf conditioning, and permafrost prevention — PP-RCT is 80 percent lighter than steel pipe. That makes it not only easier, but also safer, to install than metallic pipe systems. It also offers higher resistance to corrosion, rust, and scale buildup and quieter operation than metallic piping materials.

In addition, contractors will be able to bid projects with more certainty and confidence, as polymer piping offers stable pricing that doesn’t fluctuate with market changes unlike alternative piping materials.

In addition, contractors will be able to bid projects with more certainty and confidence, as polymer piping offers stable pricing that doesn’t fluctuate with market changes unlike alternative piping materials.

Uponor initially announced its entry into the North American PP-RCT market in September 2019 through a partnership agreement with Pestan North America. As a result, Uponor is now marketing approximately 270 pipe and fitting products in the U.S. in sizes up to 12 inches in diameter and with plans to expand up to 24 inches. All Uponor PP-RCT pipe and fittings come protected by a 10-year warranty.

“With this new piping system, we are also offering comprehensive training and expert technical support — both online and through our nationwide network of in-person sales professionals — to help contractors learn our PP-RCT system,” says Gray. “This includes making pipe connections with special heat-fusion equipment, via our partnership with McElroy Manufacturing, the leading manufacturer of fusion equipment.”

Gray went on to say that whether their customers select virtual or hands-on training, Uponor’s professional guidance helps installers master best practices for both PP-RCT and PEX, helping to keep their projects on schedule and within budget.

Construction Services: Continuing its 27-year history of offering PEX piping system design for both residential and commercial radiant heating, cooling, and plumbing, residential fire safety, and commercial hydronic piping, Uponor has expanded this offering to become Uponor Construction Services, featuring regionally based designers, as well as a team of BIM experts.

Using the latest design and estimating tools, the Uponor team of skilled and experienced designers and project managers offers a deep menu of design and construction services at no charge, including:

Using the latest design and estimating tools, the Uponor team of skilled and experienced designers and project managers offers a deep menu of design and construction services at no charge, including:

- Square-foot budget estimations

- Material take-offs

- Piping material cost comparisons

- Design development

- Radiant heating and cooling loop layouts

- Pipe sizing and load recommendations

In addition, Uponor Construction Services provides fee-based, system design services (plansets in PDF, Revit®, and fabrication models), quoted to meet the particular needs of individual projects, at prices below standard industry system-design rates.

Other fee-based services from the BIM Services team include:

- Record modeling

- Estimating

- As-built modeling

- On-site support

- Project controls

- Modular construction

- Kitting and prefabrication

- BIM content

All of these services integrate directly into the user’s software platform and workflows, providing an integrated partnership with an end goal to deliver a well-designed project that is properly coordinated and fully supported.

“Evolving our Construction Services offering was in response to customer feedback and their growing expectations related to project efficiency, accuracy, quality, and consistency to better meet schedules and budgets,” says Gray. “We saw an opportunity to become a more involved partner from the very start of a project through construction onto completion and beyond. With this project-spanning partnership, we are confident we can help improve customers’ productivity and profitability.”

Since the evolution of Uponor Construction Services and the PP-RCT partnership announcement with Pestan in 2019, Uponor has provided PP-RCT piping systems and design expertise for several commercial projects in the U.S. The largest and most notable of these is a recently completed hybrid snow-melt system, involving both 1,900 feet of Uponor PP-RCT and 36,000 feet of Wirsbo hePEX™ pipe, for a 305-foot pedestrian bridge on the Utah Valley University campus in Orem, the largest public university in the state.