When approached by Greenlee to test a new product late last year, we knew it was the perfect opportunity to work with a couple of our favorite electrical contractors, Adam Sperry and Jon Block. Jon and Adam have been friends of The Hub for several years and bring a ton of electrical experience and knowledge Read more

Product Review

When approached by Greenlee to test a new product late last year, we knew it was the perfect opportunity to work with a couple of our favorite electrical contractors, Adam Sperry and Jon Block.

Jon and Adam have been friends of The Hub for several years and bring a ton of electrical experience and knowledge to our sites. We connected them with Greenlee and after a few projects over a couple months, they share their experience with the Greenlee GSB Series Step Bits.

Jon Block reviews Greenlee GSB Series Step Bits

First off, the step bits are ideal for advanced hole making solution and feature an improved split-point tip for even faster penetration and a patented split-step design to optimize chip load for a faster and smooth cutting experience while achieving more holes per charge.

“These are perfect for making holes in conduit and steel junction boxes as well as enclosures for conduit knockouts or enlarging holes to accommodate larger conduit openings,” said Jon Block, LH Block Electric.

“There’s no reservations in using these bits, Greenlee has a long history in the trade of high-quality products. I’m sure Jon and I both look for a product that is priced appropriate to the results attained and Greenlee is a brand I trust and believe in due to their quality products,” Sperry shared.

Both agreed that the progressive cutting edges on the bits provided balanced aggression to maximize torque efficiency and minimize stalling when using a cordless drill.

Additionally, an improved double flute design provides enhanced chip evacuation, while also increasing cutting speed and bit life. Laser markings on the bits allow for easy part and size identification.

The GSB Series Step Bits for mild steel are offered in two sets, available in 10 Imperial-sized step bits ranging from 1/8-inch to 1-3/8-inch, and three Metric-sized step bits ranging from 4mm to 32.5mm.

Adam’s Final Assessment:

- “These bits are the fastest, smoothest, most durable bits I have used and have performed beyond expectations even when subjected to less-than-ideal conditions.”

- “Personally, I see step bits as a “consumable” item, which I feel is contrary to popular opinion. Most people feel as though the price associated with quality step bits somehow means they should last forever. I disagree. There are a lot of situations where the drilling is less than ideal, or the driller is less than adequately trained which can lead to more wear and tear on a bit. I also prefer the bits to NOT have the quick connect shaft or be impact rated.”

https://www.instagram.com/p/CI1l-qLDl5-/

Jon’s Final Assessment:

- ” I love the double flute design and the marked with common conduit knockout sizes and long-life durability.”

- “The split step and the longer step for the common conduit hole sizes makes this a great tool for quick knockouts instead of grabbing a hydraulic knockout set. Greenlee tools are the best in the electrical contracting business.”

- Facebook Product Video

Professionals interested in the GSB Step Bits can visit Greenlee.com/StepBits to learn more information. To request a hands-on tool demonstration from a Greenlee Pro Tool Specialist, visit Greenlee.com/requestdemonstration. For more information on Greenlee, visit Greenlee.com.

ProStaff Reviewers:

Adam got his start in the electrical industry 20+ years ago from his father who was an electrical distributor general manager. Adam has always been keen on working with his hands and takes an extreme satisfaction in watching a project come together from start to finish. One of the keys he brings to our ProStaff is his ability to share whatever tools, insights, tips, tricks, and lessons that have helped him in his career. You can find him on social media at:

Adam got his start in the electrical industry 20+ years ago from his father who was an electrical distributor general manager. Adam has always been keen on working with his hands and takes an extreme satisfaction in watching a project come together from start to finish. One of the keys he brings to our ProStaff is his ability to share whatever tools, insights, tips, tricks, and lessons that have helped him in his career. You can find him on social media at:

- Instagram – completelycordless

- YouTube – Completelycordless

Jon, after serving his apprenticeship and acquiring his Chicago Supervising Electrician License, Jon joined his family at LH Block Electric in 1998. Jon brings a unique and extreme work ethic and his many new innovative ideas to the company and currently serves as the job superintendent and chief estimator. He is also a certified electrical inspector and loves teaching the trade in the classroom and in the field. Jon can be found on Facebook at:

Jon, after serving his apprenticeship and acquiring his Chicago Supervising Electrician License, Jon joined his family at LH Block Electric in 1998. Jon brings a unique and extreme work ethic and his many new innovative ideas to the company and currently serves as the job superintendent and chief estimator. He is also a certified electrical inspector and loves teaching the trade in the classroom and in the field. Jon can be found on Facebook at:

- Facebook – LH Block Electric

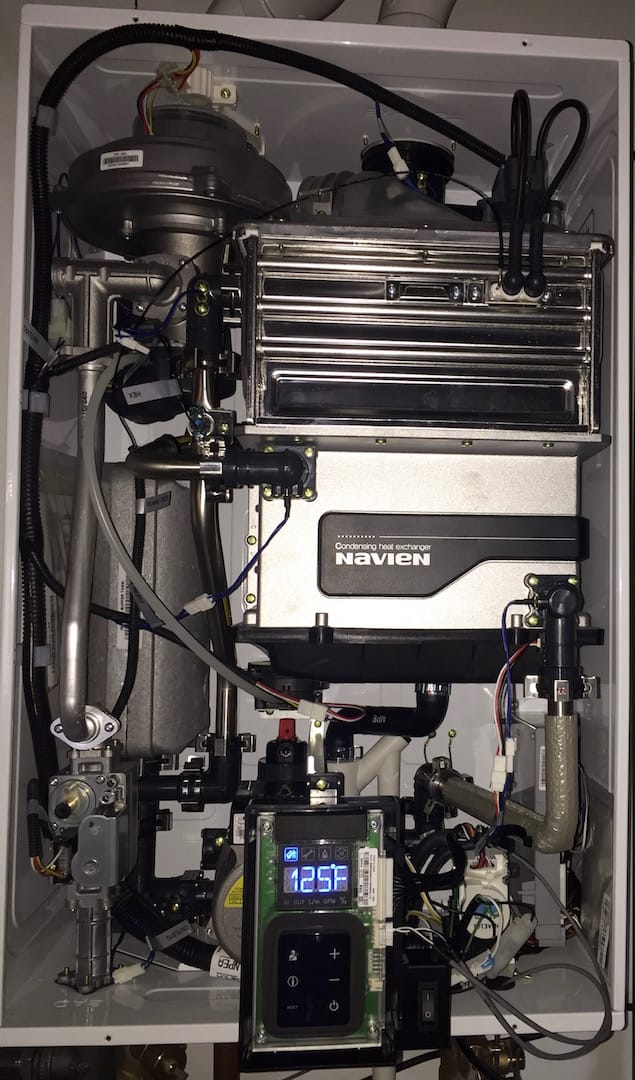

Navien tankless water heaters have been in the US market for quite some time, I recently installed the latest model in my own home. I live in central Minnesota, in a rural area where until this summer I had not had access to Natural Gas. Two Navien NPE-240A condensing tankless water heaters have now replaced Read more

Navien tankless water heaters have been in the US market for quite some time, I recently installed the latest model in my own home. I live in central Minnesota, in a rural area where until this summer I had not had access to Natural Gas. Two Navien NPE-240A condensing tankless water heaters have now replaced existing, 13 year old, tank water heaters. Here’s my take on the build, installation and overall performance.

First off, as with all tankless water heaters careful consideration must be taken to calculate needed performance values such as total flow rate needed, gas supply available, venting options, recirculation requirements and water temperature delta-t.

The Navien NPE-240A has a minimum input of 19,900 Btu/h with its maximum topping off at 199K. The negative pressure gas valve and fan with dual venturi operation allows for better adaptability to low gas pressure applications. Operating gas pressures of 3.5” w.c. – 10.5” w.c. are required. The dual stainless steel heat exchangers are an industry exclusive [at time of posting this review].

2” & 3” 2 in or 3 in PVC, CPVC, Polypropylene & Special Gas Vent Type BH (Class II, A/B/C) are listed as optional venting sizes and materials for both the intake and exhaust.

The NPE-A models features the “Comfort Flow” built-in recirculation system that monitor use patterns and closely match the hot water needs of the home or commercial building in an effort to eliminate the “cold water sandwich” that plagued the early tankless installs for so long. A built-in buffer tank and recirc pump are included.

The NPE-240A model has ¾” water, recirculation and gas connections. The unit comes equipped with a standard 120V appliance cord [installed] and operates between 200 and 300 watts (max 3 A with external pump connected).

The typical safety devices included are a flame rod sensor, ignition operation detector, water temp high limit switch, power surge fuse and an exhaust temp high limit sensor.

I have to point out that the overall size of the NPE-240 is rather large when compared to other top brands on the market. To be honest, this is a positive in my opinion. The larger cabinet affords more room inside. Where other tankless models are ultra cramped, this one is slightly less cramped. A little larger cabinet and heat exchanger adds to the total weight, the NPE-240A (w/ hot water circ pump & buffer tank) tips the scale at 82lbs. The cabinet measurements are as follows: 29” tall, 17” wide, 13” deep.

I have been installing and servicing tankless water heaters for a little over fifteen years. In that time dozens of models have came and went, none of them had the built-in features that the NPE has. The ability to operate under such low gas supply pressure, link up to 16 units in one group easily with a simple cable and control configuration. Common venting is a breeze too, though standard individual venting in 2” PVC/CPVC/PP can go as long as 60’. The 0.01 minimum flow rate for the “A” model is outrageously low when compared to the units we were installing as recent as 5 years ago.

In summary:

My family hasn’t noticed any changes since I made the switch to tankless. The installation was extremely simple, more so than other models I have installed in the past. I’m impressed by the easy to read and access front control and just how quiet the NPE model is; it’s nearly silent.

I’ll update this review if any issues arise over the next year. Thanks for your time, I hope you found this useful.

Eric Aune

Aune Plumbing, LLC