Viega North America announces the latest additions to its product portfolio, adding globe, wafer check and butterfly valves to its MegaPress® and ProPress® portfolio. Viega press technology works across a wide range of materials, applications and configurations. These new products integrate seamlessly into Viega’s extensive product portfolio. Using Viega, customers can press everything from PEX Read more

ProPress

Viega North America announces the latest additions to its product portfolio, adding globe, wafer check and butterfly valves to its MegaPress® and ProPress® portfolio.

Viega press technology works across a wide range of materials, applications and configurations. These new products integrate seamlessly into Viega’s extensive product portfolio. Using Viega, customers can press everything from PEX in residential systems to copper and carbon steel in commercial situations and stainless steel in industrial piping systems with one tool. Viega MegaPress, ProPress and PureFlow® systems are all approved for over 2,500 applications, ensuring a solution for nearly every plumbing need four inches and under.

“With Viega, customers have an entire ecosystem designed to work together seamlessly. Viega products help streamline the installation process, boosting both speed and productivity. Pressing these valves and fittings with one tool saves valuable time and labor costs, all while ensuring that plumbing systems are secure and reliable,” said John Browning, Director, Product Management.

The new products launched are:

- MegaPress 316 Globe Valves

- ProPress and MegaPress Butterfly Valves

- ProPress and MegaPress Wafer Check Valves

The MegaPress 316 Globe Valve is the first globe valve on the market with IPS press ends and features EPDM or FKM sealing elements. Available ½″ – 2″, this globe valve provides precise flow regulation where throttling fluids is essential. Model 5185.1 with the EPDM sealing element features NSF-61 approval for potable water systems. Looking to use this in more challenging environments? Model 5985.1 with FKM sealing elements, 316 stainless steel body and components provide excellent corrosion resistance, enhancing the valve’s durability.

The ProPress and MegaPress Butterfly Valves, available in sizes 2 ½-4″, complete your system with dependable Viega press technology. These butterfly valves provide reliable flow isolation and control and are NSF-61-rated. Model 2979.8ZL is crafted with a ductile iron body and durable epoxy coating, proving more cost-effective than carbon steel while offering higher pressure and temperature ratings than cast iron. Model 5179.8 features a 316 stainless steel body, providing superior corrosion resistance against even the harshest medium. Both versions are equipped with an EPDM seal. These butterfly valves are optimized for use with ProPress and MegaPress flange adapters.

The ProPress and MegaPress Wafer Check Valves are used to prevent reverse flow. Available in sizes 2 ½″ – 4″, these valves feature a dual-disk design to create a more streamlined flow path, reducing pressure drops and increasing energy efficiency. Models 2974.3XL and 5174XL include an NSF-61 rating, making them the ideal choice for installing potable water systems with ease. Model 5974XL has FKM sealing elements for more demanding applications. This compact wafer check valve is optimized for use with ProPress and MegaPress flange adapters.

To learn more about the full line of Viega ProPress, MegaPress and PureFlow valves, visit Viega | viega.us

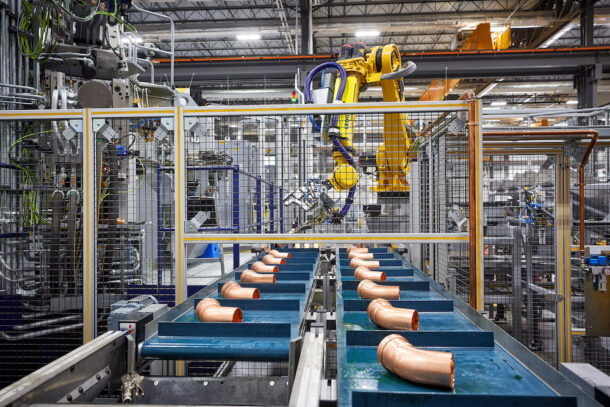

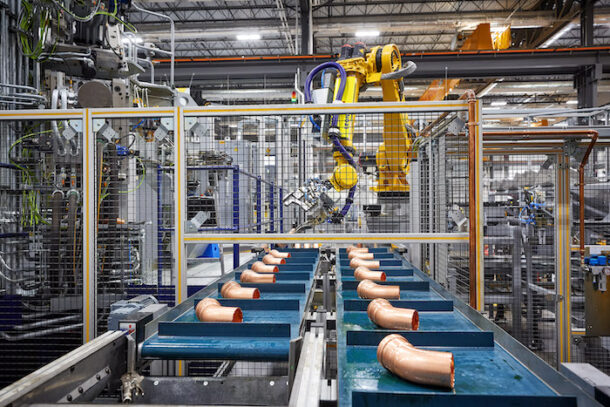

The 180,000-sq.-ft. plant in Shalersville, Ohio, will break ground in November 2023 and is expected to be operational in early 2025. Broomfield, Colo. — Viega recently announced that it will build a new manufacturing facility for its ProPress® and MegaPress® products in Shalersville, Ohio, about 40 miles southeast of Cleveland. Viega LLC President and CEO Read more

The 180,000-sq.-ft. plant in Shalersville, Ohio, will break ground in November 2023 and is expected to be operational in early 2025.

Broomfield, Colo. — Viega recently announced that it will build a new manufacturing facility for its ProPress® and MegaPress® products in Shalersville, Ohio, about 40 miles southeast of Cleveland. Viega LLC President and CEO Markus Brettschneider made the announcement.

“This is an exciting time at Viega, as our growth continues to prompt the expansion of our North American footprint,” said Markus Brettschneider, CEO and President of Viega LLC. “This new facility in Ohio, along with recent investments in our existing Kansas facility, further supports our growing demand and is part of Viega’s plan to increase North American production. We look forward to expanding our presence in this part of the country to further support our customers.”

The 80-acre parcel in Shalersville and the construction of the new plant represent an investment of approximately $200 million in Ohio. Viega’s business continues to grow in the U.S., and the additional plant will help support the increased demand for Viega products. It also aligns with the company’s sustainability goals, which include reducing the carbon emissions associated with importing products by manufacturing more items in the U.S. The new facility will be completely carbon neutral from the start, supporting the company’s long-term goal of achieving net-zero carbon emissions for all their plants by 2035.

“The expansion of our operations into Ohio shows our commitment to creating highly skilled jobs in the U.S.,” said Marki Huston, Head of Manufacturing for Viega LLC. “Our goal is to build more sustainable manufacturing processes and continue developing tomorrow’s workforce. With production scheduled to begin in early 2025, we expect to start hiring for positions as soon as January 2024, bringing more than 68 new jobs to the area over the next few years.”

Viega recently announced investments in new equipment for its McPherson, Kansas, manufacturing and distribution facility. In addition, Viega supports its customers and partners through distribution centers in Reno, Nev. and Carlisle, Penn., with more North American expansion planned for 2024 and 2025.

Viega worked with local, regional, and state organizations, including Team NEO, JobsOhio, Portage Development Board and the Shalersville-Streetsboro Joint Economic Development District on tax credit assistance and to select the 80-acre site. “We have a great manufacturing legacy, dedicated talent pool, and future-oriented industry resources to support Viega’s new operations,” said Team NEO Chief Executive Bill Koehler. “Along with JobsOhio and our local partners, we welcome Viega to the Northeast Ohio Region. We are confident they will thrive here.”

Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers. Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million Read more

Viega plans to invest over $70 million in the next two years as part of its long-term strategy to expand U.S. manufacturing and support the needs of its North American customers.

Broomfield, Colo. — Viega announced plans to expand its production capacity in McPherson, Kansas. The first wave of these investments is approximately $14 million and will increase the U.S. production of its industry-leading ProPress® products.

“As we continue to grow the business, we are bringing more production to the United States,” said Markus Brettschneider, CEO and President of Viega LLC. “These investments in our U.S. footprint will further support demand and leverage the talented U.S. manufacturing workforce, starting with the expansion of production capacity in Kansas.”

The McPherson manufacturing and distribution center is currently around 1 million sq. ft, with the facility more than doubling its footprint and workforce since opening in 2008. The new ProPress equipment is expected to be in production by the end of Q3 2023, with additional investments to come.

“We are proud to produce our fittings right here in Kansas. As we increase our U.S.-made products, we remain committed to creating highly skilled jobs in America, building out more sustainable manufacturing processes, and developing tomorrow’s workforce,” said Marki Huston, Head of Manufacturing for Viega LLC.

In addition to its McPherson, Kansas facility, Viega supports its customers and partners through distribution centers in Reno, Nev. and Carlisle, Penn., with further North American expansion planned for 2024 and 2025.

RIDGID offers full line of standard and compact press tool options RIDGID®, the leader in pressing tool technology, is bringing game-changing innovation to the skilled trades with the RP 351, its first in-line standard press tool. Engineered from the ground up to deliver reliability and efficiency, this tool operates with an advanced brushless motor requiring Read more

RIDGID offers full line of standard and compact press tool options

RIDGID®, the leader in pressing tool technology, is bringing game-changing innovation to the skilled trades with the RP 351, its first in-line standard press tool. Engineered from the ground up to deliver reliability and efficiency, this tool operates with an advanced brushless motor requiring no scheduled maintenance.

The RP 351 with SlimGrip™ handle for enhanced balance and control weighs only about eight pounds with battery. It joins the RIDGID RP 350 Press Tool, a drill grip standard press tool introduced to help professionals get more done on every job with less fatigue and no timeouts. Together, the advanced, long-running press tools are built for the most demanding situations and give professionals maximum standard press tool versatility on the job site. Both tools are ideal for making connections on carbon steel, copper, PEX and stainless-steel pipe on residential, commercial and industrial jobs.

The RP 350 and RP 351 feature an advanced brushless motor, known for maximizing tool longevity, efficiency and durability. Their 360-degree swivel is an industry-first and comes paired with brightest-in-class LED lights to let users not only access tight spaces but see them more clearly in low and no-light applications. And no scheduled maintenance means less downtime.

Both tools are also compatible with the full line of RIDGID standard series jaws and rings, including: ½ – 4-inch ProPress® for copper and stainless steel, ½ – 2-inch PureFlow® for PEX, and ½ – 2-inch MegaPress® for carbon steel. They also offer maximum versatility, pairing with the RIDGID Press Booster for 2 ½ -inch, 3-inch, and 4-inch carbon steel, StrutSlayr™ Strut Shear Head and the Press Snap™ Soil Pipe Cutter. Each tool’s 18V battery platform includes chargers for on-the-go battery charging including a 12V car charger cord that is compatible with vehicles; the unit also pairs with the RIDGID Link app to track tool usage, service needs, battery life and last known location.

All RIDGID press tools come with the RIDGID Full Lifetime Warranty.

Viega LLC will reduce paper waste by 32 tons a year by eliminating printed instructions in favor of QR codes Beginning in October, the printed instructions inside the packages of most ProPress, MegaPress and PureFlow products made in the United States will be removed in favor of a QR code printed on the product label. A Read more

Viega LLC will reduce paper waste by 32 tons a year by eliminating printed instructions in favor of QR codes

Beginning in October, the printed instructions inside the packages of most ProPress, MegaPress and PureFlow products made in the United States will be removed in favor of a QR code printed on the product label. A scan of the code will send the user to the product instruction page on viega.us. It’s estimated that this will eliminate more than 6 million pieces of paper a year, paper which often wound up littering jobsites.

Having the instructions in digital format means any updates are immediately and automatically reflected, another benefit.

“Viega LLC is committed to reducing its environmental impact in ways big and small,” said Adam Botts, Portfolio Manager for piping systems. “This is an example of a simple measure that, in total, will save an enormous amount of paper without inconveniencing customers. This absolves them of having to recycle or dispose of the instruction sheets properly. We look forward to rolling out additional initiatives, both seen and unseen, that will have positive impacts on our company footprint.”

Earlier this year, Viega Holding GmbH & Co., parent company of Viega LLC, was named one of the 50 Sustainability & Climate Leaders by TBD Media Group.