Ron George, CPD Below is a recommended flushing procedure for building owners, property managers, water utilities, health officials, code officials, service contractors, engineers, insurance companies and Interested parties to perform on buildings before re-opening buildings for occupancy after a long shut-down. With the recent coronavirus events causing many stay-at-home orders and extended vacancy of offices Read more

stagnant building

Ron George, CPD

Below is a recommended flushing procedure for building owners, property managers, water utilities, health officials, code officials, service contractors, engineers, insurance companies and Interested parties to perform on buildings before re-opening buildings for occupancy after a long shut-down.

With the recent coronavirus events causing many stay-at-home orders and extended vacancy of offices and workplaces, there is a looming, serious issue associated with stagnant water or aging water in the plumbing tanks, fixtures and pipes of buildings that have not been occupied for long periods of time. Bacteria will grow and flourish in the biofilm of the plumbing tanks, fixtures and pipes that have been sitting stagnant with ambient temperature or warm water where the water treatment chemicals have dissipated to levels that will not control bacterial growth. Studies have shown water treatment chemicals dissipate over time and there are several factors that affect the rate of dissipation such as pipe material, temperature, and organic contaminants in the water.

After the chlorine dissipates, bacteria can grow to high numbers. When bacteria and microorganisms are aerosolized in water from showers and other fixtures that can aerosolize the water it can be inhaled into the lungs causing Legionellosis or Legionnaires’ disease. Therefore, it is important to flush these stagnant pipes of bacteria laden water before re-occupying the buildings that have been vacant for long periods of time. I have been involved in developing Legionella standards & guidelines with ASHRAE and ASSE and I have spent over 42 years designing plumbing systems to simultaneously prevent scalding and Legionnaires disease. There are standards for flushing and disinfecting large public water mains but, there is no consensus standard for flushing and disinfecting plumbing systems within buildings.

In early 2020, government officials issued stay at home orders, with guidance from health officials, which has caused many buildings to sit abandoned with little to no water usage for weeks or months. When a building has been empty or unoccupied for an extended period, bacteria like Legionella and various other bacteria, viruses or disease-causing organisms can be found in inadequately treated water or stagnant water after the water treatment chemicals dissipate.

Before re-occupying a building that has been unoccupied for an extended period, it is recommended to flush stagnant water from the piping system before opening the building to occupants. To minimize to chances of transmission of Legionella bacteria and other microorganisms to humans, flushing water from the plumbing fixtures is the easiest, quickest and cheapest way to prepare for occupants to return to the building.

I am encouraging government officials, health officials, water utilities, code officials and other non-profits to implement these simple and inexpensive flushing procedures into national, state and local ordinances or guidelines to help protect the occupants of buildings from bacteria laden water upon return to buildings that have been sitting idle for long periods of time. These entities should use the language in this document and create a local flushing and disinfection ordinance for documentation of flushing procedures before opening and occupying buildings that have been idle for long periods of time. The government entity can decide what length of shut-down justifies flushing based on chlorine or other water treatment dissipation rates in your area. If a building has been idle for more than four weeks, a Legionella test should be conducted on first draw water before flushing to determine if a chemical disinfection procedure is needed to be performed. Chemical disinfection should be performed on the hot water system before heating the water.

Domestic Water Systems Flushing Procedure:

Building Address: ________________________________________ Flushing Date: ______________

Name of Persons Conducting the flush 0peration:_______________________________________________________________________ _______________________________________________________________________

For documenting the flushing operations, follow the tasks outlined below. Building owners or maintenance staff should be advised to perform these flushing operations in all buildings that have been closed for an extended period. This will reduce the risk of illness and death following a building that has been unoccupied for a long period. The objective is to replace all stagnant water in the potable water system with new water containing a disinfectant residual from the municipal distribution system.

Flushing personnel should wear an “N-95 respirator mask” and Personal Protective Equipment during flushing operations. When performing a flushing operation, complete the following flushing procedure in the following sequence:

1. Collect a water sample of first draw water for testing the water treatment chemical residuals in the building service pipe. Collect the sample from a monitoring point in the service pipe at or near the meter and backflow preventer or where the service pipe enters the building.

Note the Water utilities water treatment chemical type. This pre-flush test should be serve as a baseline to compare pre-flush water quality with post flush water quality.

Locaton ______________________; Free Chlorine Residual: _____ppm; Test By: ______; Time: ______ am/pm

Location ______________________; Legionella Test1: _________ cfu/ml; Test By: ______; Time: ______ am/pm

(Note 1. – Conduct a Legionella test if the building has been significantly unoccupied for more than 14 days.)

If the pre-flush water quality test indicates any water discoloration, odor or other unusual characteristics note them below:

Notes:_________________________________________________________________________________________________

2. Collect a water sample from first draw water of at least five (5) remote locations within the building to determine the building water chemical residuals in the building. These locations should be documented for to serve as a baseline pre-flush to post flush to compare pre-flush water quality with post flush water quality.

Loc. #1 ______________________; Free Chlorine Residual: _____ppm; Test By: ______; Time: ______ am/pm

Loc. #1 ______________________; Legionella Test1: _________ cfu/ml; Test By: ______; Time: ______ am/pm

Loc. #2 ______________________; Free Chlorine Residual: _____ppm; Test By: ______; Time: ______ am/pm

Loc. #2 ______________________; Legionella Test1: _________ cfu/ml; Test By: ______; Time: ______ am/pm

Loc. #3 ______________________; Free Chlorine Residual: _____ppm; Test By: ______; Time: ______ am/pm

Loc. #3 ______________________; Legionella Test1: _________ cfu/ml; Test By: ______; Time: ______ am/pm

Loc. #4 ______________________; Free Chlorine Residual: _____ppm; Test By: ______; Time: ______ am/pm

Loc. #4 ______________________; Legionella Test1: _________ cfu/ml; Test By: ______; Time: ______ am/pm

Loc. #5 ______________________; Free Chlorine Residual: _____ppm; Test By: ______; Time: ______ am/pm

Loc. #5 ______________________; Legionella Test1: _________ cfu/ml; Test By: ______; Time: ______ am/pm

If the pre-flush water quality test indicates any water discoloration, odor or other unusual characteristics note them below:

Sampling Notes: __________________________________________________________________________________________________________________________________________________________________________________________________

(Note 1. – Conduct a Legionella test if the building has been significantly unoccupied for more than 14 days.)

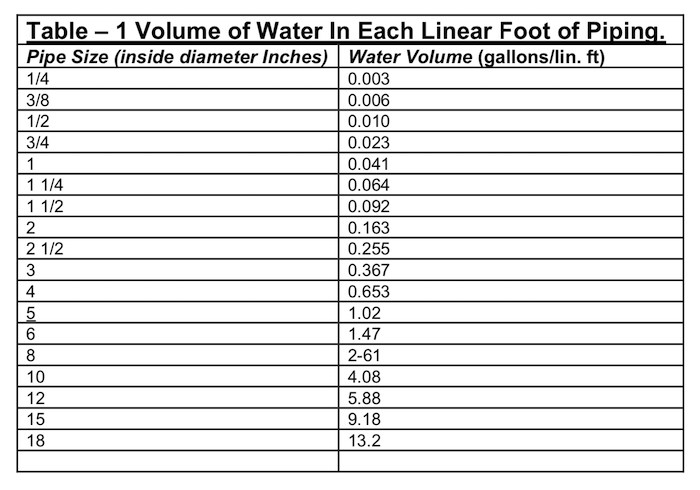

3. Determine the building service pipe size and length. Service pipe size: _________ , Volume gallons per Linear foot Service pipe length: _________

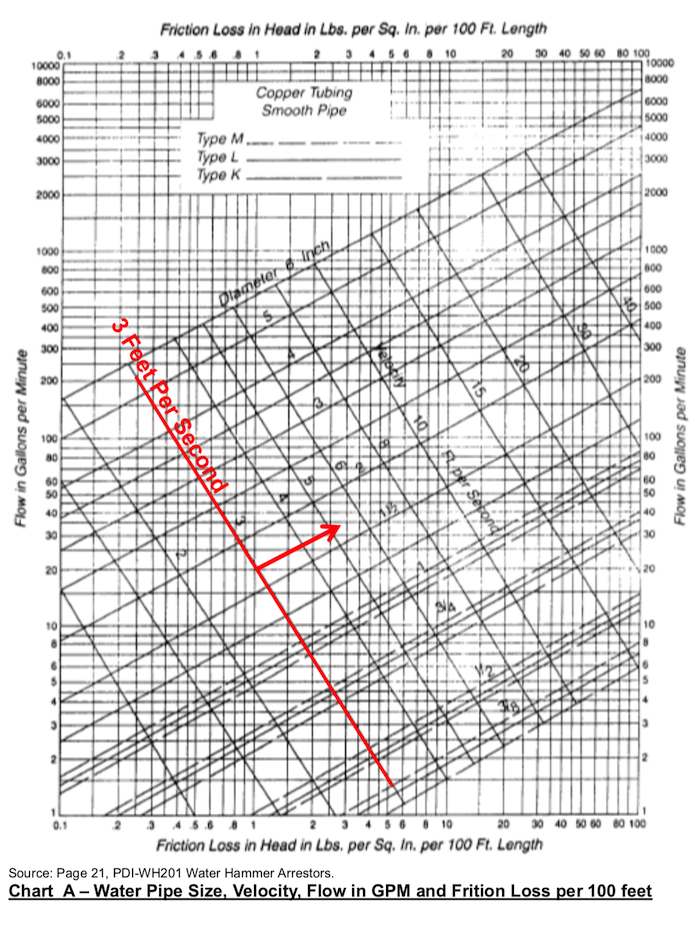

4. Determine the volume in the building service pipe based upon its size and length in Table 1 below and multiply the volume by 2 for the required volume to be flushed from the service piping.

Service pipe volume from Table 1: _________ (Linear feet of service pipe x volume per foot from #3 above)

Service pipe volume from Table 1 x 2 = _________ Note 2

Note 2 – Volume of water to be flushed through the service pipe at 3 feet per second velocity per Table 2.

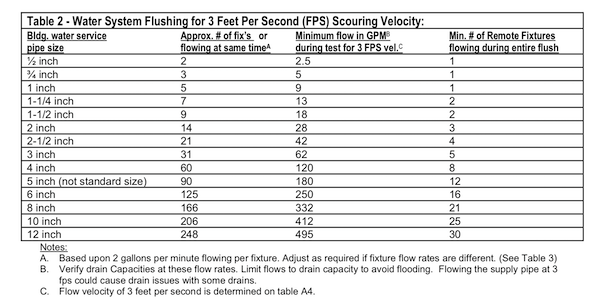

5. Determine and document the quantity and location of the fixtures required to be flowed simultaneously to have a velocity of 3 feet per second in the service pipe. (See table X) and hose valves will be flowing from the required number of flushing points in order to have a flushing velocity high enough to scour bio-film and sediment from the service pipe at a flow velocity in excess of 3 feet per second as determined in table 2.

6. Perform and document a pre-flush water quality test at the water service entrance and at 5 remote fixtures to determine water quality and water treatment residual, There should be a minimum 1 part per million (ppm) free chlorine at the building service entrance and 0.5ppm of free chlorine at the most remote fixture. For buildings with other water treatment chemicals in the utility water, consult with a professional for recommended minimum water treatment chemical levels or as directed by the facilities’ water management program team) entering the building. If the test shows the water quality is good, then no service pipe flushing is needed.

7. If the pre-flush water quality test indicates any water discoloration, odor or lack of sufficient free chlorine residual, perform and document a full velocity flush of 3 feet per second for the building water service pipe as follows:

a) Determining the proper number of fixtures to flow to flush the building service pipe at a minimum velocity of 3 feet per second, based on the size of the building service pipe size, (See table 2) b) The flow can be through a combination of fixtures can be flowed through a combination of hose bibbs, hydrants and fixtures near the water service entrance. and test the potable water service connection until a disinfectant residual is detected or a volume equivalent to double the water held in the service connection is cleared, whichever occurs first.

b) The flow can be through a combination of fixtures can be flowed through a combination of hose bibbs, hydrants and fixtures near the water service entrance. and test the potable water service connection until a disinfectant residual is detected or a volume equivalent to double the water held in the service connection is cleared, whichever occurs first.

8. If a disinfection residual is not detected, after 30 minutes of flushing the building service pipe, Stop flushing and do not continue with the potable water system flushing operation. Contact the water utility for direction and ask to have them or the fire department flush the water mains through nearby fire hydrants to bring chlorinated water close to the building. If the building is in a cluster of buildings or area with many unoccupied buildings ther may be a logical place to flush a hydrant near the end of the water main.

9. When a disinfectant residual is detected on the building service pipe, open some faucets that are the farthest away from the building water service and on the end of each major branch main of the water distribution piping and let the hot and cold water run continuously until a disinfectant concentration is detected close to or equal to that of the chlorine residuals in the building service connection. A branch main is defined as a main distribution pipe (typically greater than 3⁄4” diameter) which supplies other branch pipes and fixture branch pipes.

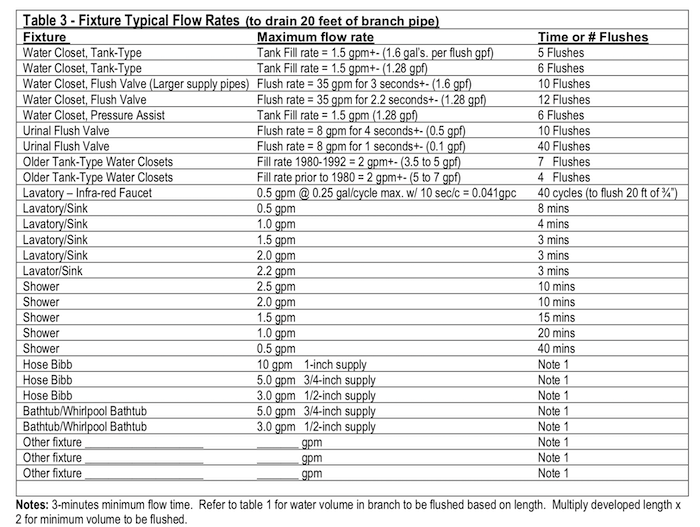

10. Flush all remaining fixtures, tanks, and appliances connected to the potable water system (including exterior outlets). Flow water from both the hot and cold water systems. The following flushing procedure should be used based on each fixture type:

- Toilets and urinals shall be flushed 5 times each for 1.6 gpf fixtures.

- All other fixtures shall be flushed for a minimum of 3 minutes each, both hot and cold water with flows of 2 gpm.

- Any water storage or hot water tanks should be flushed at a rate to flow at least 2 times the volume of the tank.

- Hydro-pneumatic and thermal expansion tanks should have the water pressure relieved from them so that they totally discharge all water within the tank.

Infra-red faucets shall be operated for a consecutive period of time equal to 20 cycles for every 10 feet of 3⁄4 inch branch piping. 11. The person performing the flushing operation should record the room number, the fixture type & ID, flow rate in gpm, start time and temperature, end time & temperature, chlorine residual near end of flushing operation, and notes or observations for each fixture like: ambient temperature of the room, when the water temperature starts to change indicating fresh water is arriving at fixture, chlorine residuals in the first draw and at completion. thereafter until a minimum chlorine residual of 0.5 ppm is achieved at each fixture. Take a water sample in the first draw and upon completion of the flushing and Note any water discoloration, odor, etc) for first draw and test the chlorine residual in the final draw at the completion of the flushing operation. If the measured chemical residual is insufficient to control bacteria growth, perform and record the flushing operation as shown on the following “Fixture Flushing Record Sheet.”

11. The person performing the flushing operation should record the room number, the fixture type & ID, flow rate in gpm, start time and temperature, end time & temperature, chlorine residual near end of flushing operation, and notes or observations for each fixture like: ambient temperature of the room, when the water temperature starts to change indicating fresh water is arriving at fixture, chlorine residuals in the first draw and at completion. thereafter until a minimum chlorine residual of 0.5 ppm is achieved at each fixture. Take a water sample in the first draw and upon completion of the flushing and Note any water discoloration, odor, etc) for first draw and test the chlorine residual in the final draw at the completion of the flushing operation. If the measured chemical residual is insufficient to control bacteria growth, perform and record the flushing operation as shown on the following “Fixture Flushing Record Sheet.”

12. The water utility has a duty to deliver safe drinking water to the building service meter according to the safe drinking water act. Note: the utilities are allowed fall below the level of quality in the safe drinking water act for three, consecutive 6-month reporting periods before they must notify the public. The responsibility for building water safety is the responsibility of the building owner. The drinking water provider has no responsibility for water quality on the building side of the water meter. A water utility should strive to deliver quality water, but we know that the water utilities cannot guarantee safe drinking water because there are often water main breaks, construction, fire events and other disruptions of water main flows that cause turbid water and high bacteria events. For this reason, the building owner has a duty and responsibility to monitor the water quality coming into their building and have a water management plan in place to address water quality issues. In this day of water conservation, water flows have been reduced to levels that are less than 20 percent of flows prior to 1992. The flow in water mains have been reduced to the point where water treatment chemical residuals dissipate to levels that will not control bacteria growth in the water mains. Building owners must monitor the incoming water and adjust the water quality if needed by using supplementary water treatment systems. When a building owner is considering a supplementary treatment system, they should consult with a professional to determine if they need licensing, certification and any filters.

13. When a building is unoccupied for more than 7 days or a period of time agreed to by the building’s water management Program team, flushing should be performed immediately prior to re-occupancy. When a building is unoccupied for more than four weeks (28 days), or a period of time agreed to by the building’s water management Program team, flushing and disinfection should be done immediately prior to the building being reoccupied.

Note: Flush all sinks first, then flush showers, then flush water closets & urinals. Fixtures with flush valves can become clogged with debris and not flush properly if they are flushed first. If flush valves do not perform properly and run-on, shut off water and remove diaphragm and clean the orifice. When done flushing, remove faucet strainers and shower heads and clean or replace them.

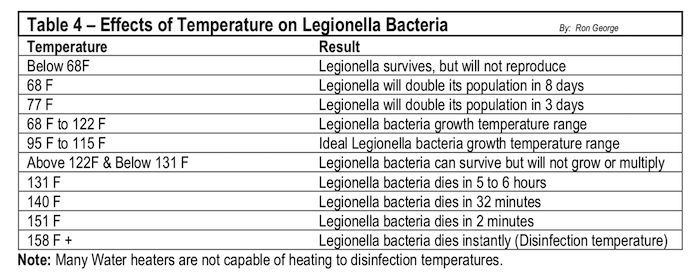

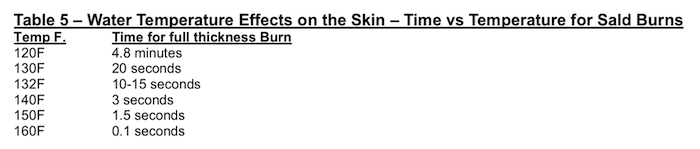

Storage Water heaters should be maintained at a minimum temperature of 140F or higher in the tank as needed to offset heat loss and maintain a minimum hot water temperature at the lowest temperature in the system a couple of degrees above the Legionella Growth temperature of 122 F. (124 F) on the hot water return pipe connection to the water heater. The hot water return pipe just before the cold water connection to the water heater is the lowest temperature point in the hot water system. See the “Temperature Effects on Legionella Bacteria Table” Below. To prevent Sclading, all shower valve maximum temperature limit-stops should be adjusted to a maximum temperature of 115 F at showers & bathtubs to prevent scalding. (Consider a maximum temperature limit stop setting for showers and tub/showers of 110 F at hospitals, nursing homes and similar facilities where there is additional risk of scalding.)

Hot water temperatures can be higher in the storage and distribution piping and should be reduced or limited at or near the fixtures by code compliant temperature limit-stops that are properly adjusted on tub/shower valves or by temperature limiting valves that are properly set to limit temperatures at the point of use.

Every fixture in the building should be flushed in accordance with these guidelines or until the water treatment chemical residuals reach an acceptable level. Following these procedures should prevent thousands of workers from getting sick and dying from Legionnaires disease and other types of waterborne illnesses associated with stagnant water.